Thin film conveying device

A conveying device and film technology, applied in the field of machinery, can solve the problems of large conveying deviation, intermittent conveying, and difficult to control conveying, and achieve the effect of ingenious and reasonable structure, flexible adjustment, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

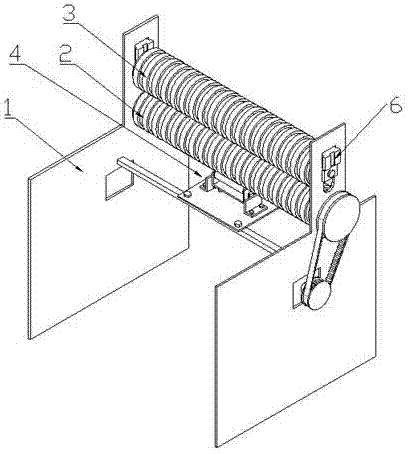

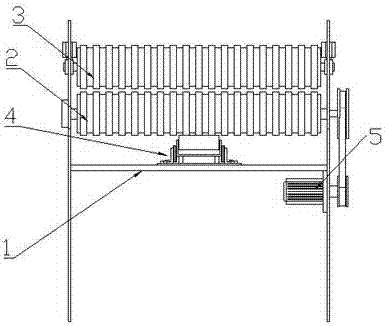

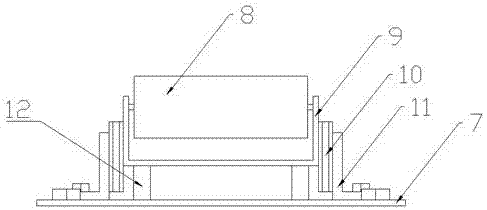

[0013] Such as Figure 1-3 As shown, a kind of film conveying device comprises frame 1, and described frame 1 is provided with drive roller 2, and described drive roller 2 is driven by motor 5, and described drive roller 2 top is provided with pressure roller 3, and described Both ends of the pressure roller 3 are provided with cylinders 6 to drive it to move up and down, and a support device 4 is provided below the driving roller 2, and the support device 4 includes a base 7 and a support roller 8, and the base 7 is installed on the On the frame 1, the supporting roller 8 is in contact with the driving roller 1, and the base 7 is provided with two fixed blocks 11, and the two fixed blocks 11 are provided with vertical guide rails 10, and the two vertical guide rails 10 is arranged oppositely, and the support roller 8 is installed on the support frame 9, and the support frame 9 is installed on the two vertical guide rails 10 by the sliders arranged at its two ends so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com