Fixed fluidized bed powder metering and distributing delivery device and method of realizing high stability transferring and distributing powder

A dispensing device and high stability technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., which can solve the problems of stable powder metering, difficulty in conveying and storage, inaccurate metering of small flow powder, and poor uniformity of distributed powder and other problems, to achieve the effect of reducing equipment investment and maintenance workload, high gas-solid ratio, and low flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

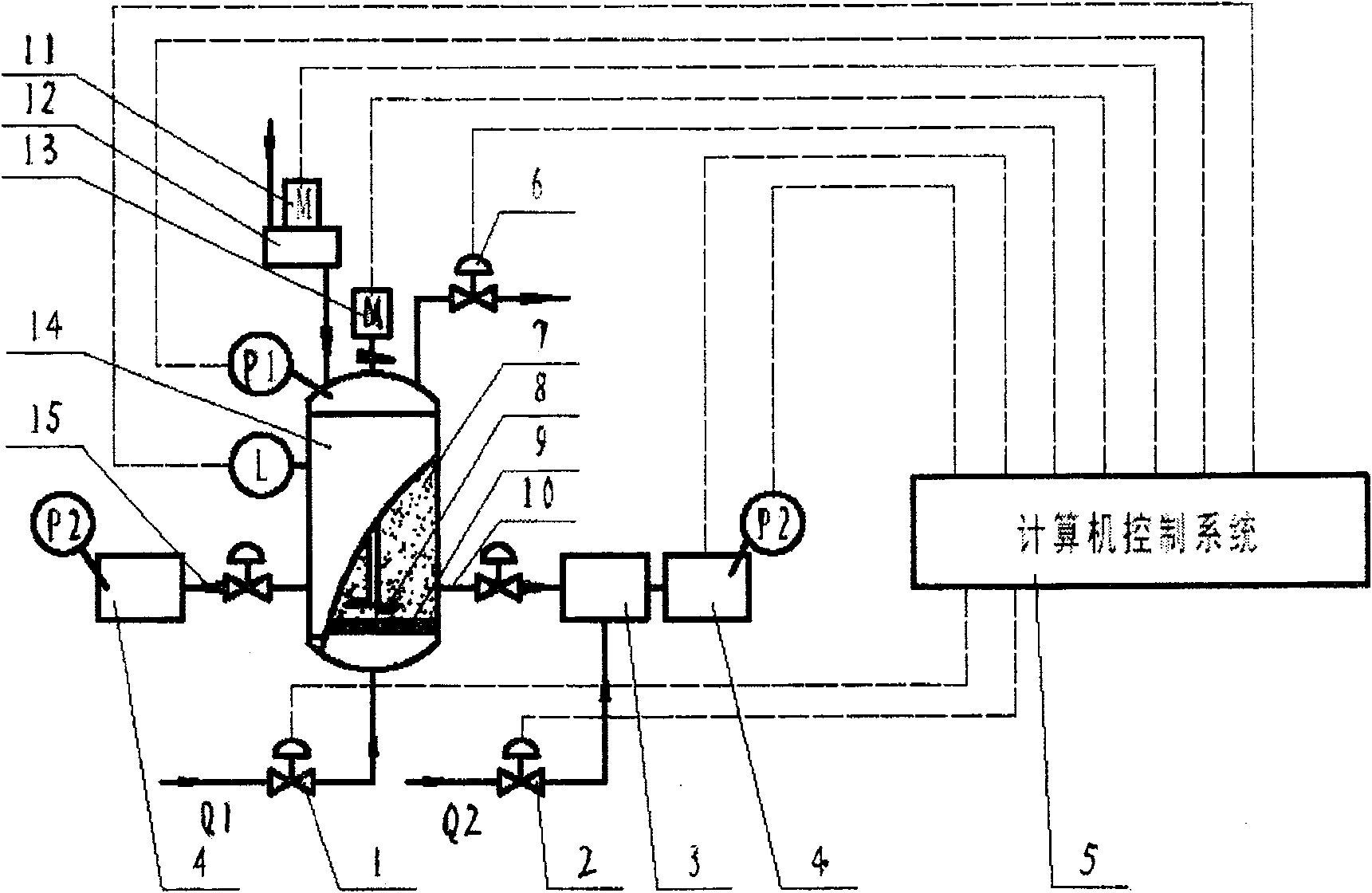

[0044] Application of thermal plasma pyrolysis coal direct production of acetylene powder feeding device

[0045] (1) Put the pulverized coal into a fluidized tank with a diameter of φ500mm, and the computer control system sets Q1=60NM 3 / h;

[0046] Q2=10NM 3 / h; Powder feeding amount = 2500kg / h; Stirring speed = 200 rpm; The speed of the feeder is automatically fed back to the material level of the fluidized tank. Fluidizing gas Q1 and accelerating gas Q2 are nitrogen

[0047] (2) The diameter of the powder feeding pipe is φ6mm, the length of the powder feeding pipe is 10m, and 4 powder feeding pipes supply powder to a plasma reactor at the same time.

[0048] (3), the computer control system sets the powder feeding amount = 2500kg / h;

[0049] (4) The pressure of the plasma reactor is 0.05-0.2Mpa, and the temperature is 1800-3000°C.

[0050] Results: The actual powder feeding volume is 2450kg / h, the speed of powder particles entering the plasma reactor is 28m / s, and the...

example 2

[0052] Application of powder feeding device in plastic processing industry

[0053] (1), 10 sets of plastic extrusion molding machines, the amount of plastic powder needed for each set is different, and the time for using plastic powder is different. The current process is that each plastic extrusion molding machine has a set of powder metering and conveying equipment.

[0054] (2) Adopt a powder fluidized feeding device with a diameter of φ1000mm, the fluidized gas Q1 is air, and the computer control system sets Q1=100NM 3 / h; stirring speed = 200 rpm; the speed of the feeder is automatically fed back to the material level of the fluidized tank. Connect 10 powder feeding pipelines with different diameters and lengths on the side of the fluidized tank (design according to the position of each plastic extruder and the amount of plastic powder required).

[0055] (3) The computer control system sets Q1; the stirring speed; the speed of the feeder is automatically fed back to t...

example 3

[0059] Adding nano-calcium carbonate powder during the reaction of polyvinyl chloride

[0060] (1) Adding nano-calcium carbonate powder in the PVC reaction process can enhance the strength of plastic products and reduce costs. The current process is to disperse the nano-calcium carbonate powder in the water phase, and then use a high-pressure water pump to drive it into a polymerization kettle with a pressure of 0.8Mpa. Since the nano-calcium carbonate powder is lipophilic particles, it is difficult to disperse in the water phase, so it is necessary to add surface activity. The agent and dispersing pump run for a long time, which has the following disadvantages:

[0061] a. Surfactants are likely to cause adverse side effects;

[0062] b. The dispersing pump runs for a long time, so that the nanoparticles grow up and lose the effect of increasing the strength of plastic products.

[0063] Using vinyl chloride gas as the dispersion medium can solve the above problems well.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com