Laser-heating-assisted efficient grinding experiment table for hard and brittle material

A kind of hard and brittle material, test bench technology, applied in the direction of grinding frame, grinding bed, grinding slide plate, etc., to reduce chatter, reduce transmission error and transmission cumulative error, and get enough heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

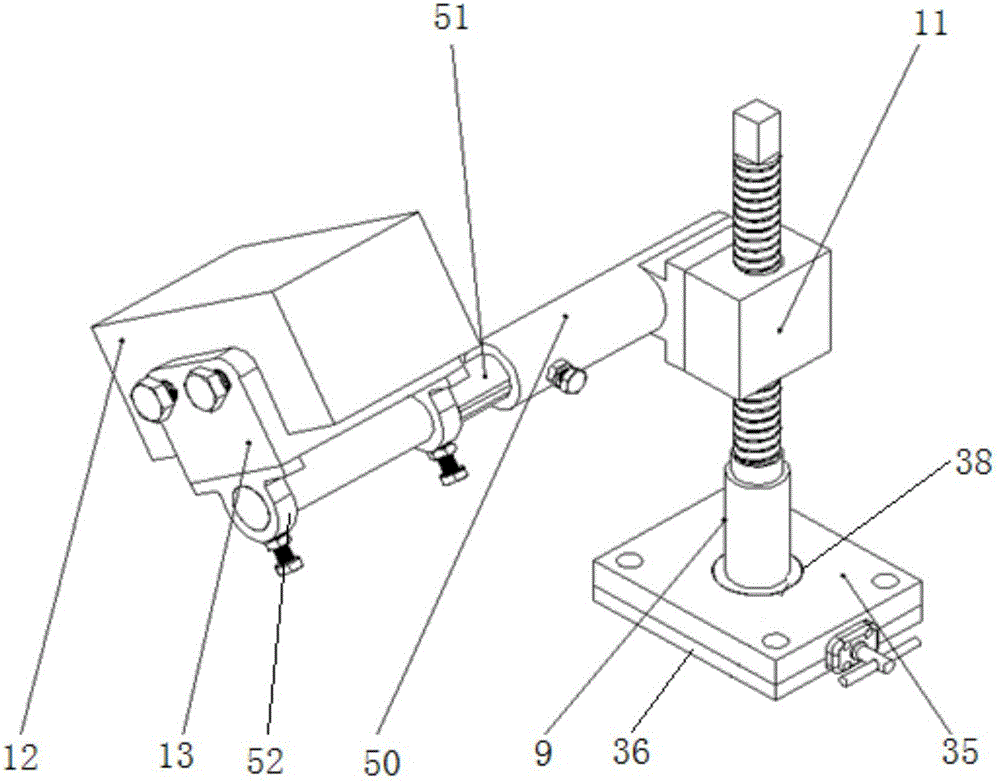

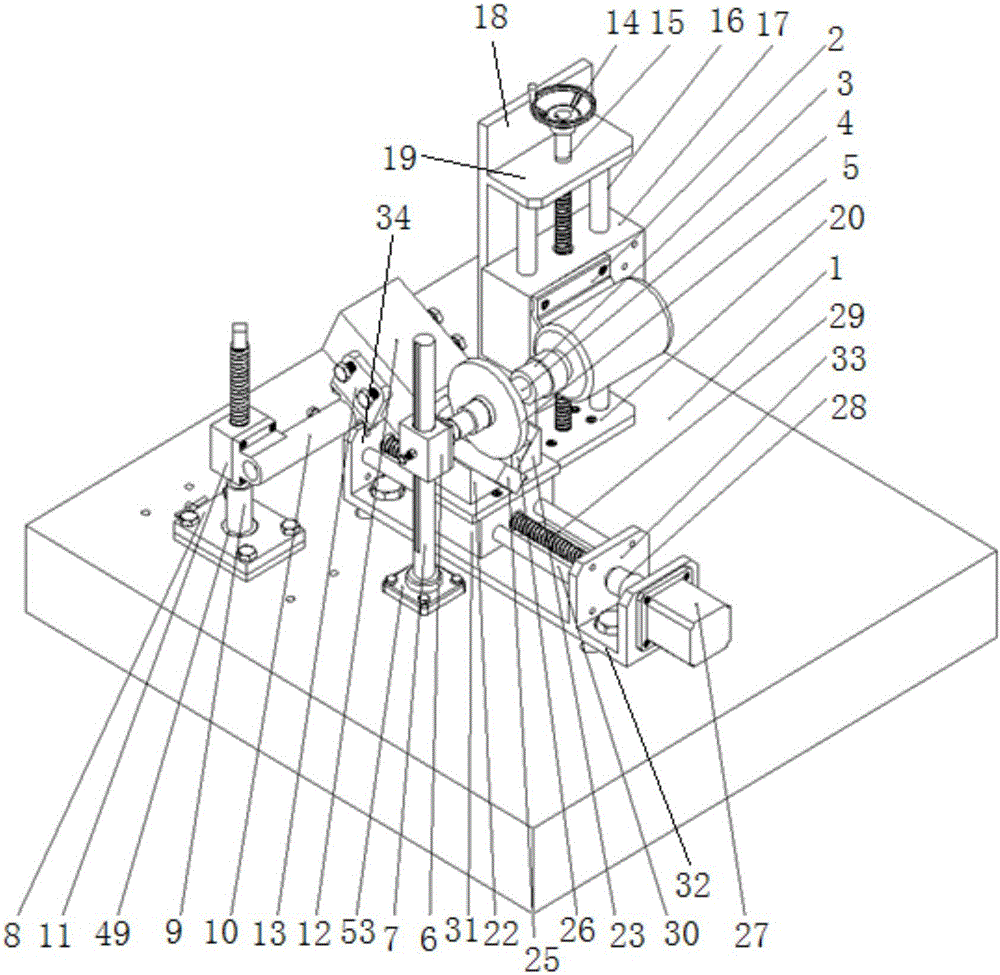

[0045] Such as Figure 1-Figure 6 As shown, a laser heat-assisted high-efficiency grinding test bench for hard and brittle materials includes a base 1, a grinding wheel support device, a jig support device and a laser heating device;

[0046] The grinding wheel support device includes a motor 2 and a vertical feed device that drives the motor 2 to move in the vertical direction. The output end of the motor 2 is connected to a horizontal shaft 4 through a coupling I3, and the horizontal shaft 4 A grinding wheel 5 is sleeved on it, and the other end of the horizontal shaft 4 is connected to the vertical rod 7 fixed on the base 1 through a shaft seat 6, and the shaft seat 6 can be along the axial direction of the vertical rod 7 Sliding, the vertical feeding device is fixedly connected with the base 1;

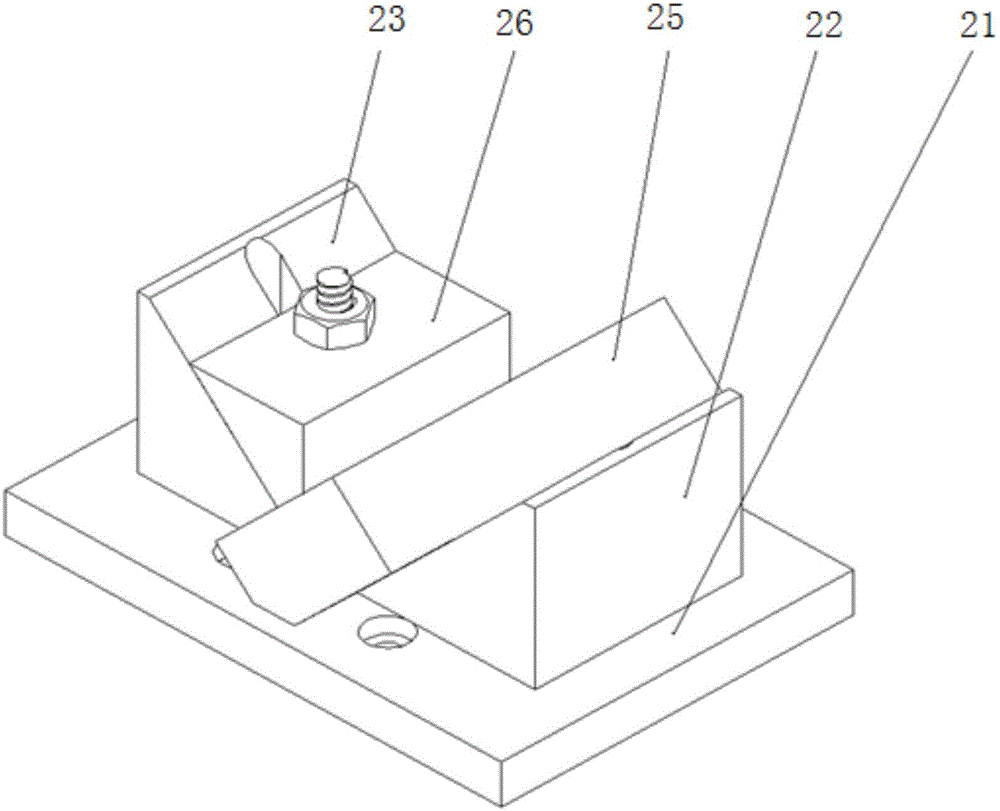

[0047] The fixture support device includes a fixture that fixes a cuboid workpiece 25 and makes its upper end long edge in the rotation plane of the grinding wheel 5, and a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com