Method for performing laser-assisted grinding on surface of superhard material grinding tool

A superhard material grinding tool and grinding processing technology, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of affecting the accuracy of grinding tools, large energy consumption, and low processing efficiency, so as to facilitate the realization of automation , wide range of applicable materials, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

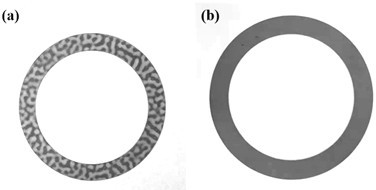

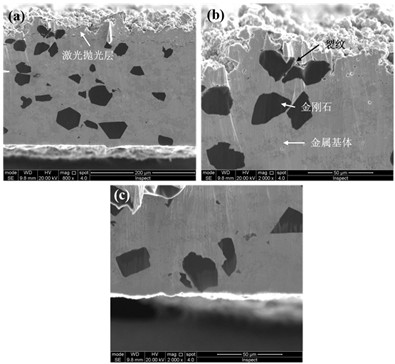

[0031] The invention provides a method for laser-assisted grinding on the surface of a superhard material grinding tool, such as figure 1 with figure 2 shown.

[0032] A method for performing laser-assisted grinding on the surface of a superhard material grinding tool, comprising the following steps:

[0033] 1. Laser polishing parameter design

[0034] According to the melting point, vaporization temperature, phase transition temperature, and decomposition temperature of superabrasive grains such as diamond, the appropriate laser power, wavelength, scanning rate and ambient atmosphere are selected.

[0035] The selection criteria of laser parameters are not limited to the decomposition of diamond abrasive grain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com