A method for surface grinding of boride ceramic material

A ceramic material and boride technology, applied in the field of surface grinding of boride ceramic materials, can solve problems such as low grinding efficiency, achieve the effects of low grinding efficiency, improve grindability, and reduce material surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

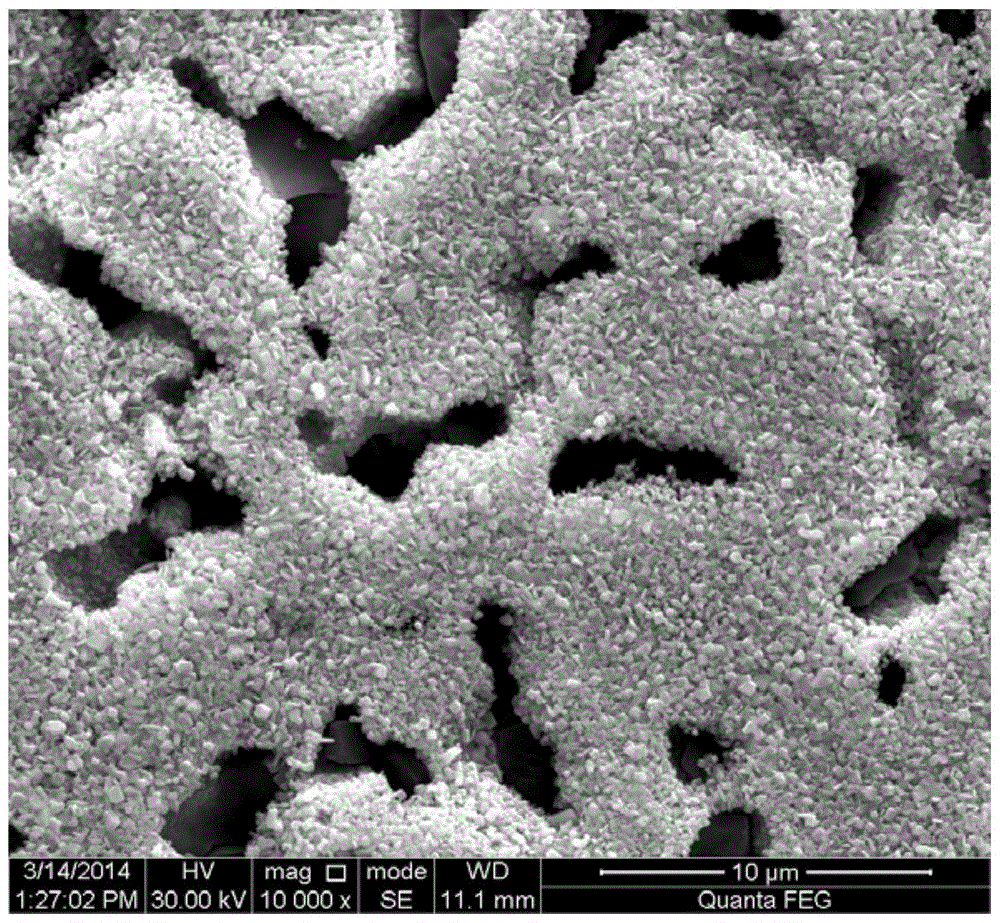

Image

Examples

specific Embodiment approach 1

[0012] Specific implementation mode one: this implementation mode is a method for surface grinding of boride ceramic materials, which is specifically completed according to the following steps:

[0013] 1. Ultrasonic cleaning: use absolute ethanol as a cleaning agent to ultrasonically clean boride ceramic materials for 5 minutes to 60 minutes to obtain boride ceramic materials after cleaning;

[0014] 2. Surface heating and oxidation: place the cleaned boride ceramic material in a muffle furnace, heat it from room temperature to 400-1500°C, heat and keep it at 400-1500°C for 1min-120min, and cool to room temperature to obtain surface oxidation post-boride ceramic materials;

[0015] 3. Grinding: The surface oxidized boride ceramic material is placed on a polishing machine, the abrasive is diamond particles or boron carbide particles, the grinding medium is water, and the polishing machine disc rotates at a speed of 100 rpm to 1000 rpm. Grinding treatment, that is, to achieve ...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the boride ceramic material is ultrasonically cleaned with absolute ethanol as a cleaning agent for 20 minutes to 40 minutes to obtain the cleaned boride ceramic material. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the cleaning agent in step 1 to the boride ceramic material is (4-10):1. Others are the same as those in Embodiment 1 or 2.

[0020] In this embodiment, the purpose of determining the volume ratio of the cleaning agent to the boride ceramic material is to ensure that the boride ceramic material is cleaned.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com