Omnidirectional conveying, sorting and transferring platform and transferring method thereof

A conveying platform and omni-directional technology, applied in the field of conveying and sorting equipment, can solve the problems of low production efficiency, inconvenient conveying of small-sized goods, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

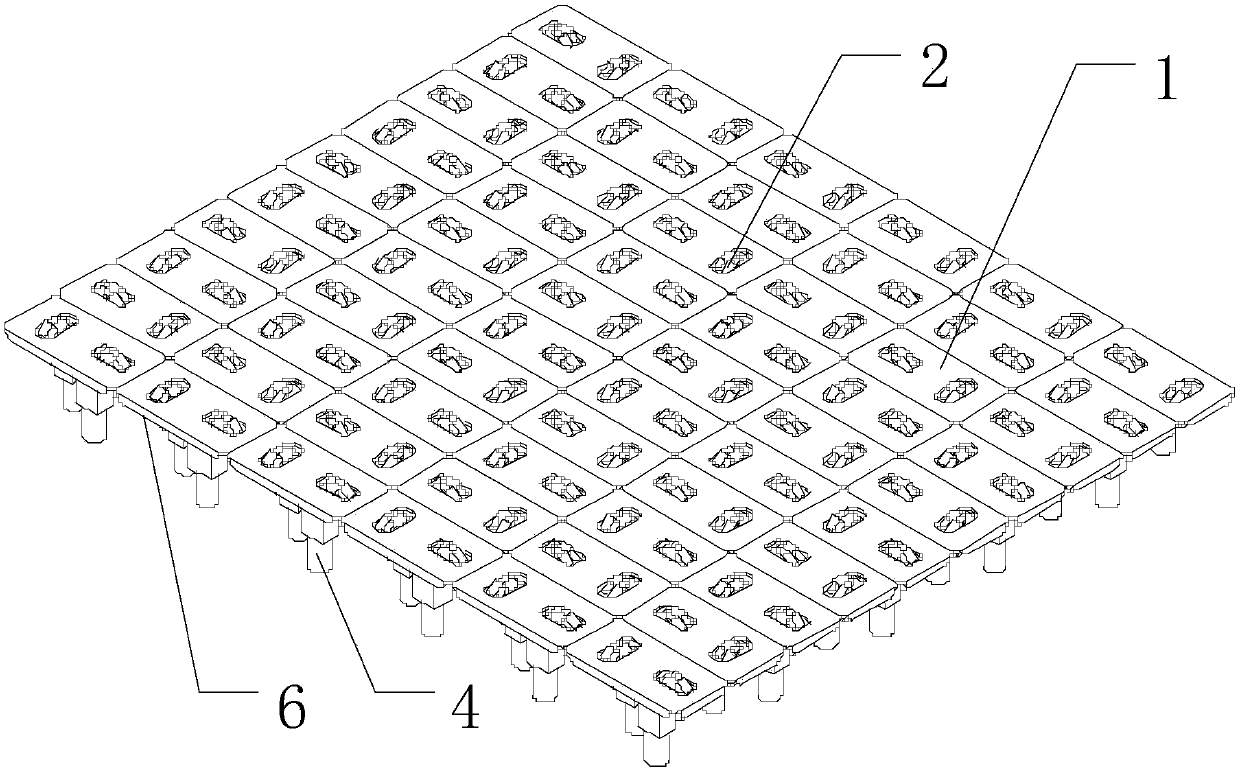

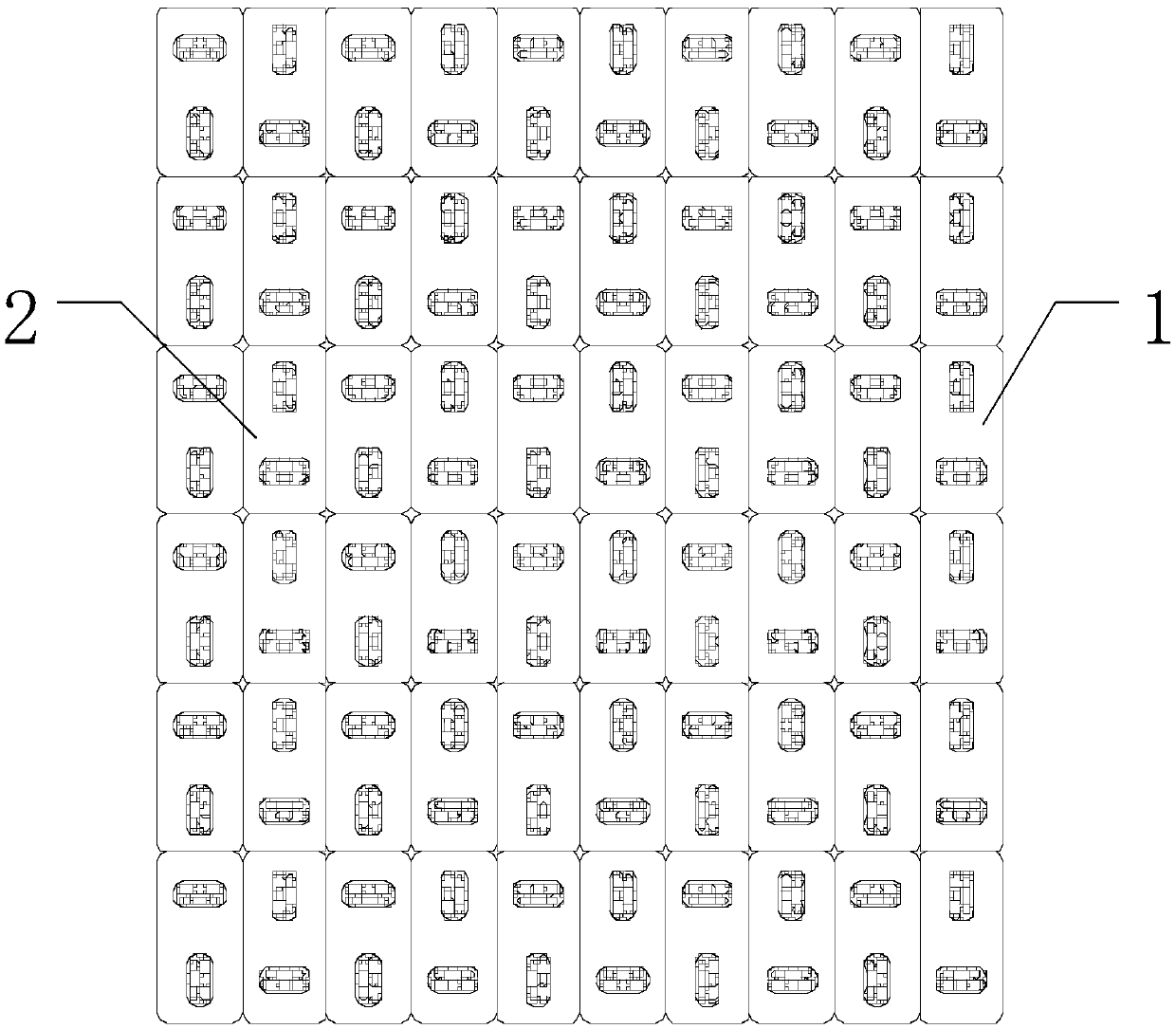

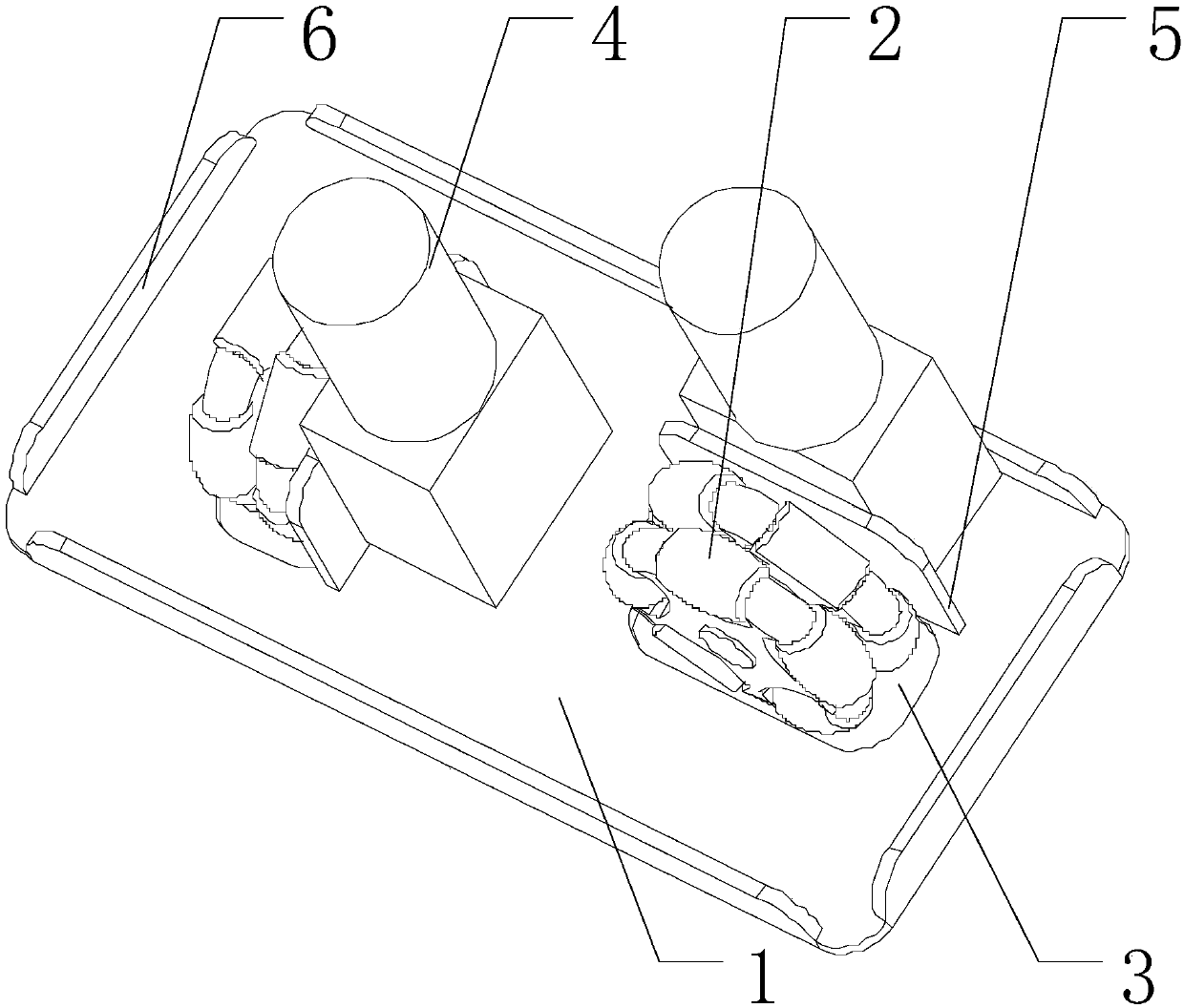

[0020] figure 1 It is a schematic diagram of an embodiment of the omnidirectional conveying, sorting and conveying platform of the present invention, figure 2 It is a top view of an embodiment of the omnidirectional conveying, sorting and conveying platform of the present invention, image 3 It is a schematic diagram of the conveying mechanism of the embodiment of the omnidirectional conveying sorting conveying platform of the present invention. As shown in the figure, the present invention provides an omnidirectional conveying sorting platform, including a support frame and several interconnected transmission mechanisms arranged on the support frame, and the transmission mechanism includes a transmission plate 1 and two Omnidirectional wheel 2, the angle between the central axes of the two omnidirectional wheels 2 is not equal to 0 degrees or 180 degrees, as a preference, the angle between the central axes of the two omnidirectional wheels 2 is 90 degrees, and the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com