Dosing system for inking up rollers in printing machine

A metering system and printing machine technology, applied in the field of metering systems, can solve problems such as uneven ink transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

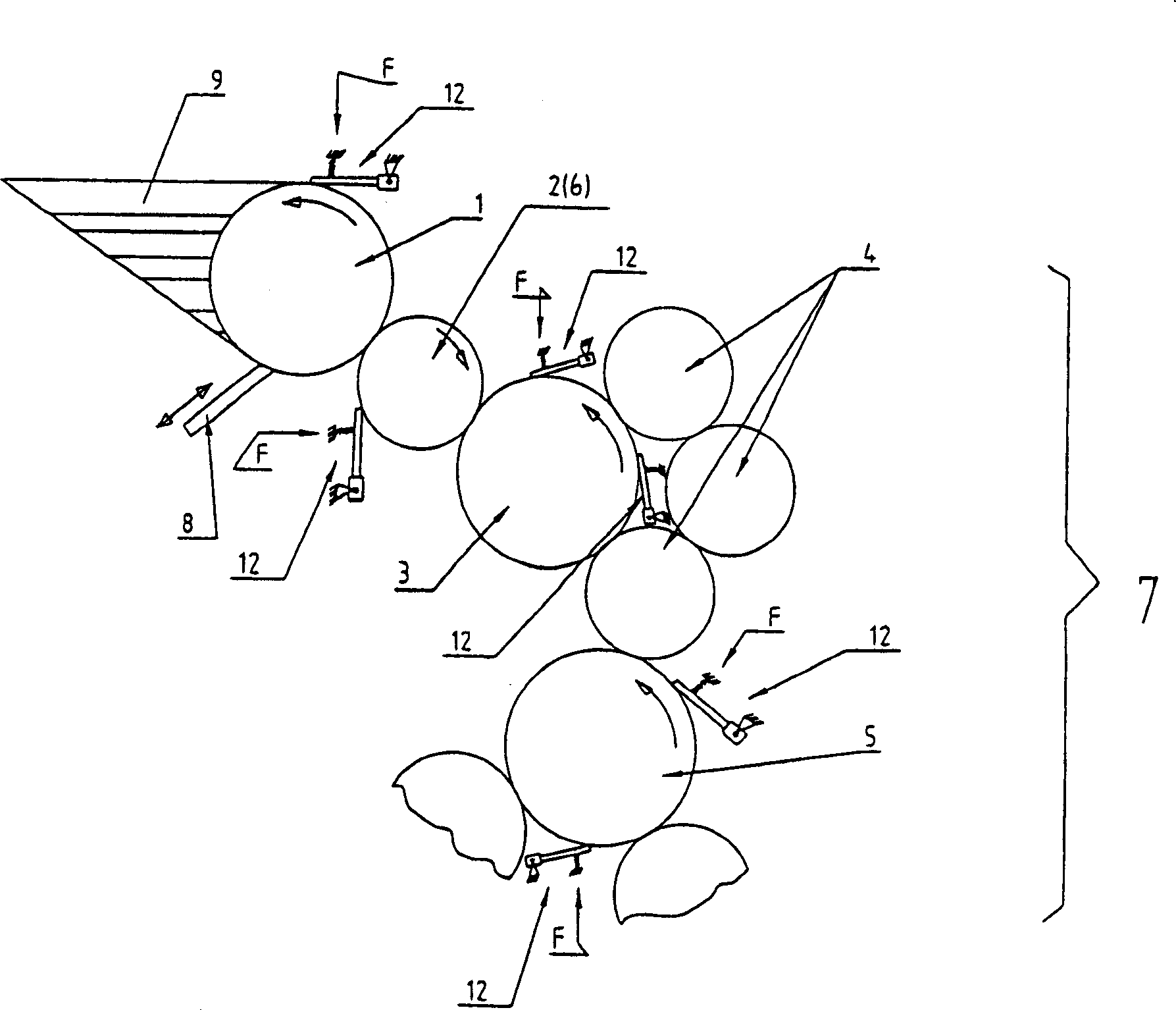

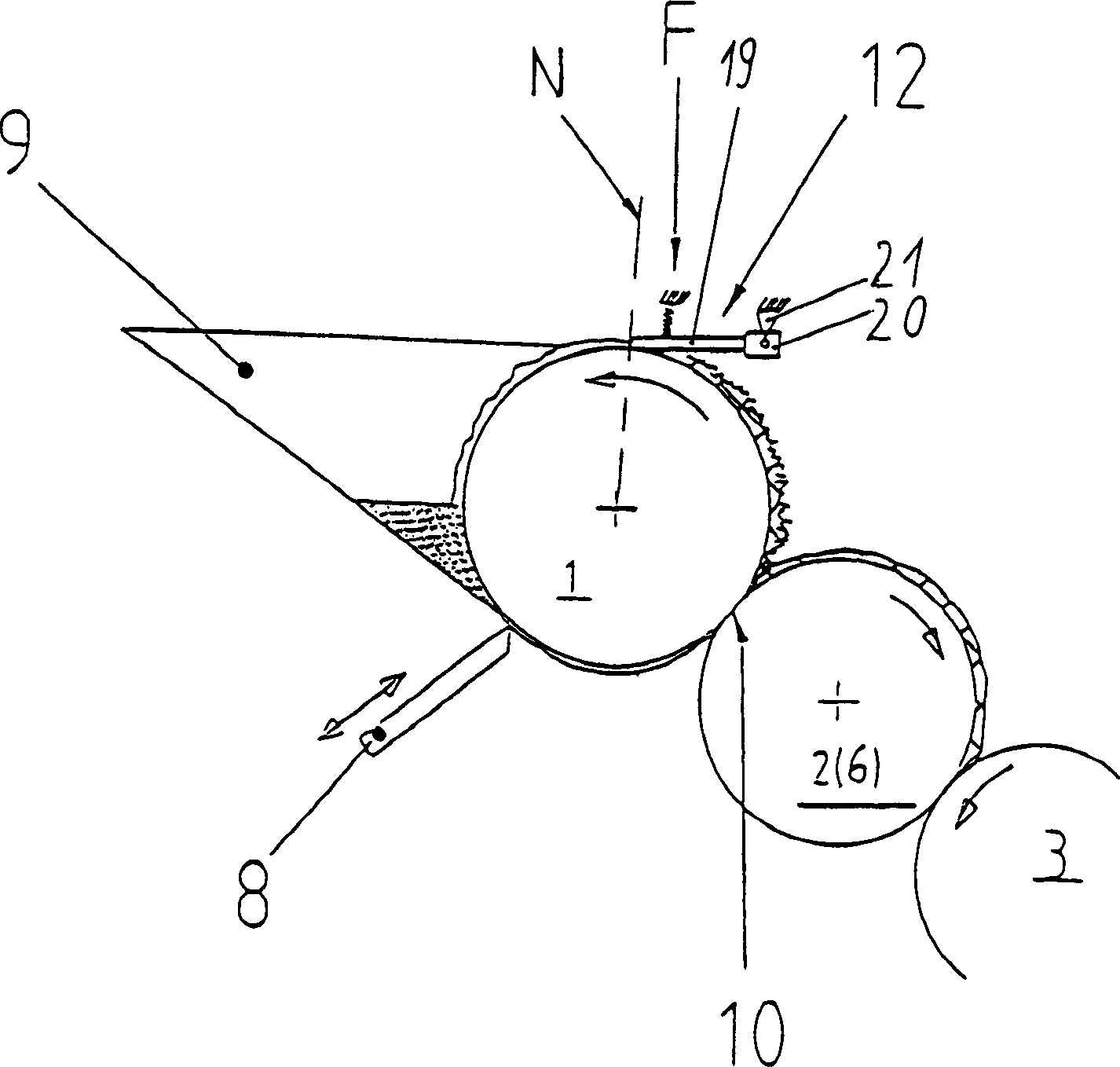

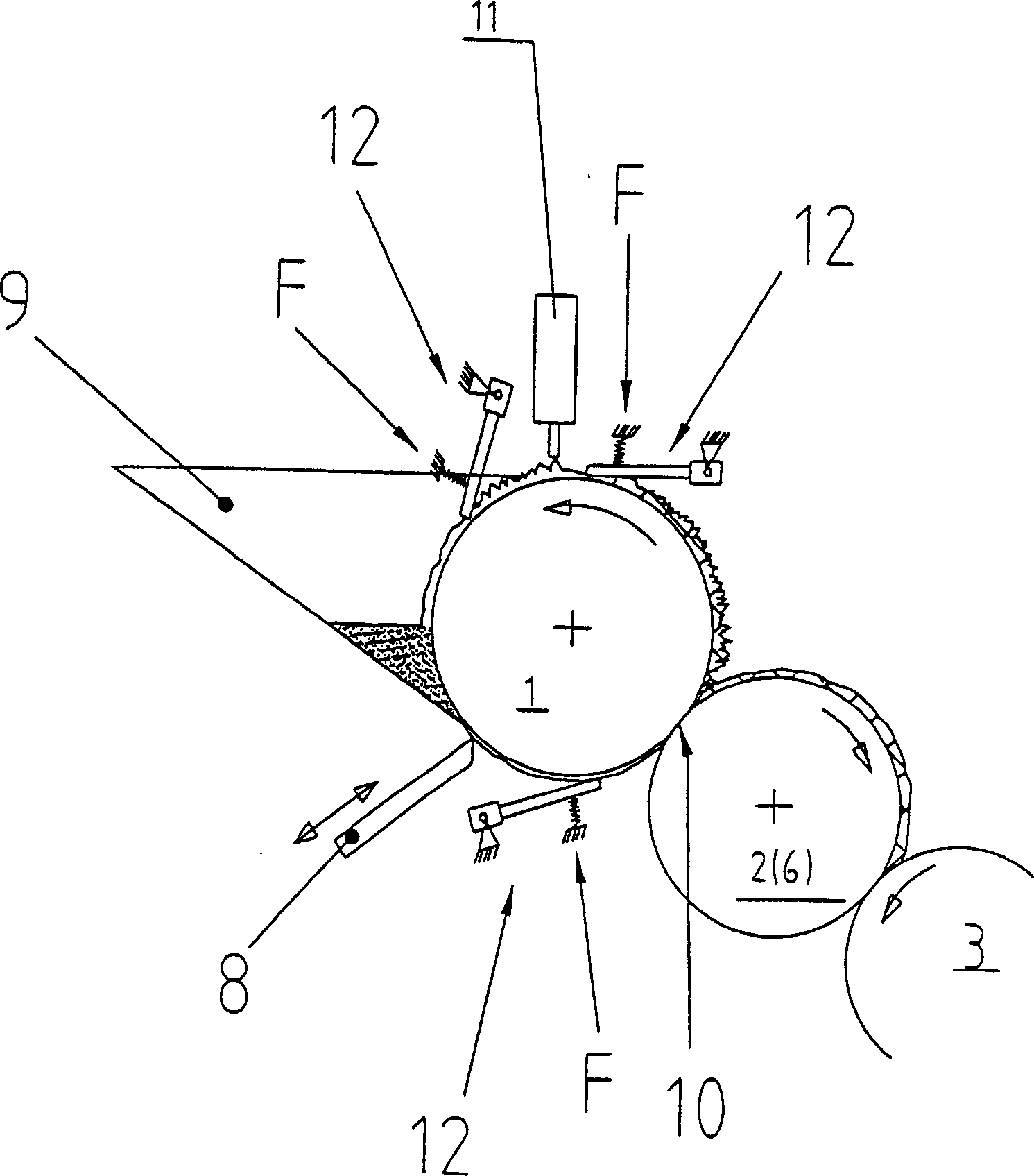

[0029] The offset printing unit of a sheet-fed rotary printing press essentially consists of an inking unit having an ink fountain roller 1 which is operatively connected to an ink fountain 9 which has an ink metering system 8 such as an ink slide valve. In addition, the inking unit has a siphon roller 2 or film roller 6 and an inking roller 3 of a downstream roller row 7 as a first series of inking rollers (rotatably driven and axially tracked). Roller train 7 leads to the plate cylinder and is known as a multiplicity of rollers, wherein for example the second series of inker rollers 5 (rotatably driven and axially tracked) is designed with inker rollers 4 in between.

[0030]At least one roller 1-6 of the inking unit is provided adjacently on its outer surface with a coating device 12 behind a contact zone 10 in which ink breaking or ink separation takes place, that it can be pressed against the roller 1-6 outer surface and preferably also separable therefrom. In this case,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com