Automatic pressurizing line and processing technology thereof

A technology of automatic pressurization and processing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of shape change, high temperature resistance, low intelligence of elastomer processing production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

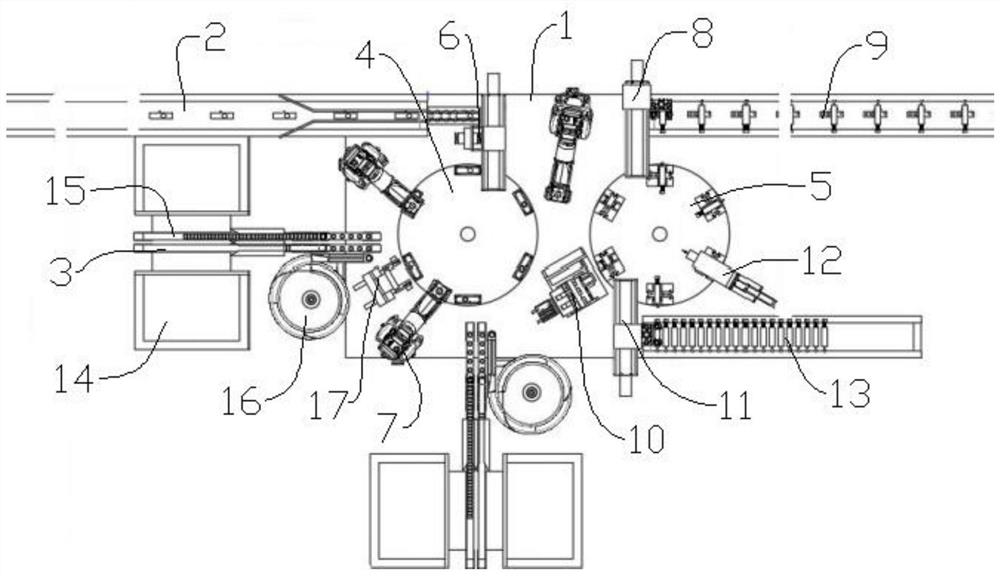

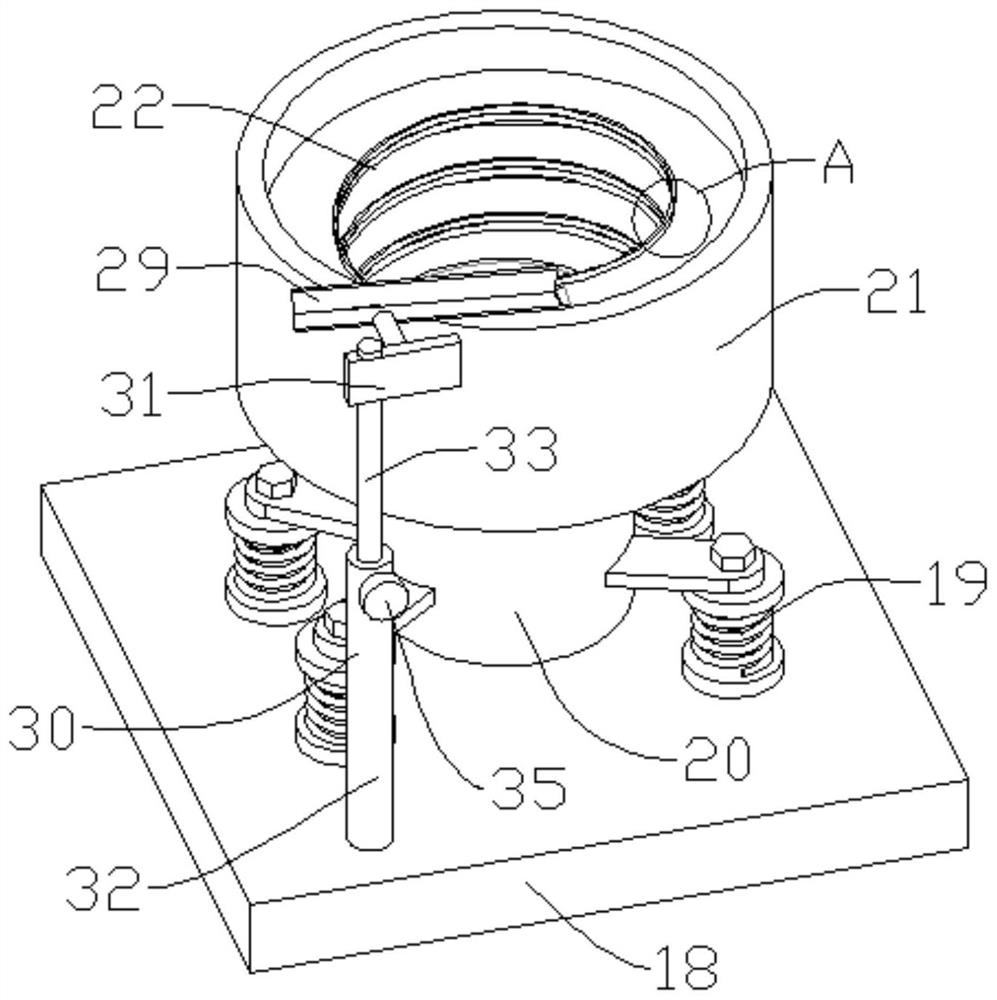

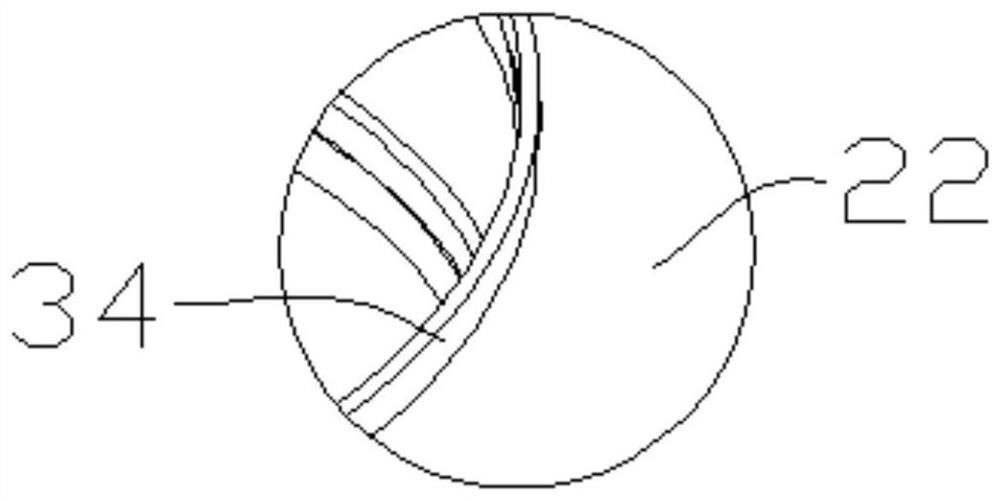

[0035] Such as figure 1 As shown, an automatic pressurizing line includes an operation table 1 and a buffer conveying line 2 that runs through the operation table 1 for elastic body transmission. The adjacent sides of the operation table 1 are respectively provided with an upper belt for conveying briquettes and silica gel plates. The material mechanism 3, the top of the operating table 1 is provided with a first indexing plate 4 and a second indexing plate 5 for driving the material to rotate, and between the buffer conveying line 2 and the first indexing plate 4 is provided for clamping the elastic body The elastic body feeding device 6, and three six-axis robots 7 for material transfer are arranged on the top of the operation table 1. The six-axis robots 7 include three-jaw grippers and suction cups for clamping the pressing block and the silicone plate. The operating table 1 is provided with a finished product unloading device 8 and a discharge buffer line 9 at the second ...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that an intelligent monitoring component for monitoring is arranged above the first indexing plate 4 and the second indexing plate 5 in this embodiment, when the six-axis robot 7, buffer When the conveyor line 2 and the discharge buffer line 9 fail, the intelligent monitoring component will send the dislocation information to the monitoring room, and notify the operator in real time to come and deal with it.

[0059] Principle of work of the present invention and use process:

[0060] When the automatic pressurizing line and its processing technology are in use, the present invention is applicable to the processing of 0.5-2.5tSQB elastic body, fully automatic production, and the present invention adopts three six-axis robots 7 and three feeding devices for loading and unloading, Improve production efficiency and production accuracy, the first indexing plate 4 and the second indexing plate 5 are both high-speed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com