Computerized electromagnet controller and control method thereof of low-voltage electromagnet keeping technology

A technology of microcomputer control and magnetic technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of large fluctuations in molten iron composition, affecting steel, molten iron quality, and lower molten iron quality, so as to ensure the feeding speed and smelting The effect of speed, prevention of rapid drop out of tolerance, and shortening of batching time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

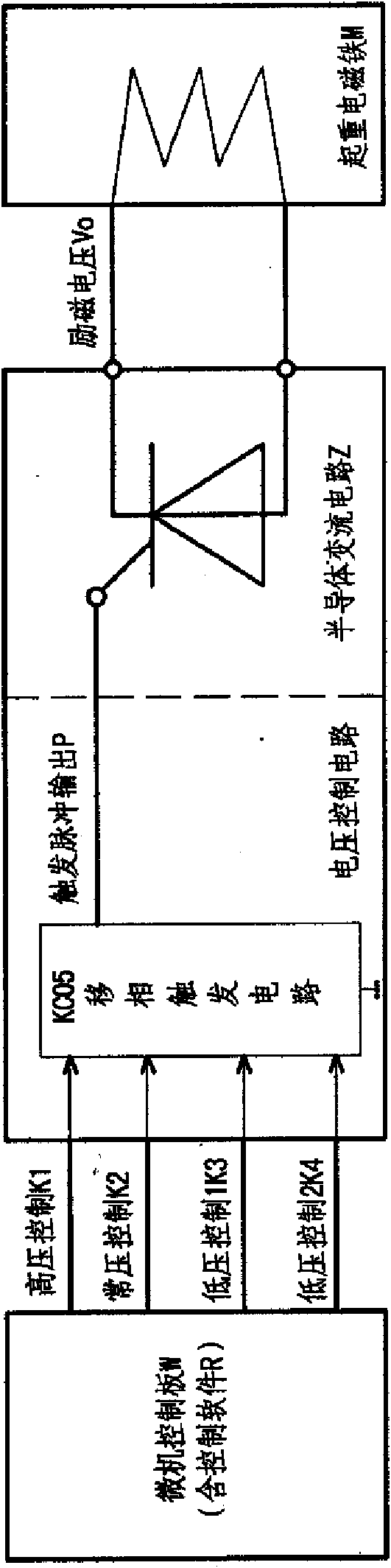

Method used

Image

Examples

Embodiment Construction

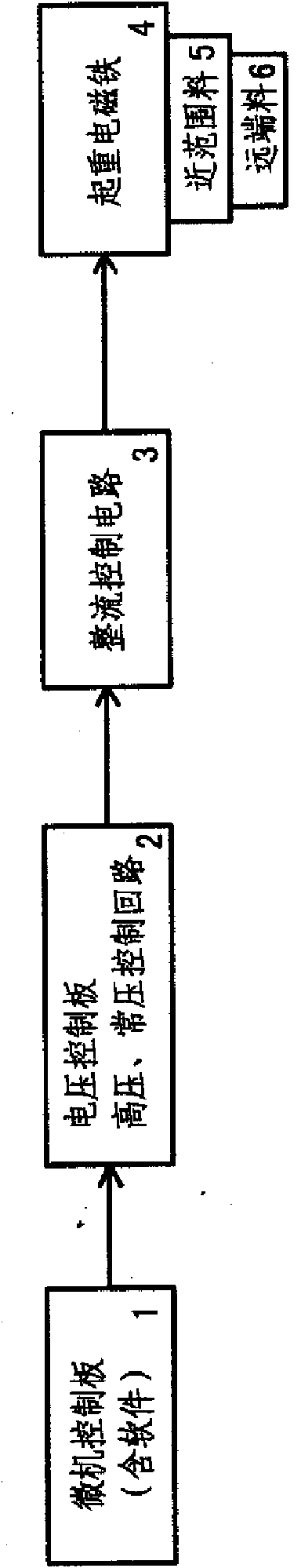

[0026] Such as figure 1 As shown, there is no low-voltage magnetic-preserving batching circuit and function, and only the pressure-loss residual magnetic batching is used. It is impossible to effectively control the near-range material 5 and the far-end material 6 when there is a lot of suction, and the batching failure rate is high, reaching more than 10%. , The average error of ingredients is greater than 3%.

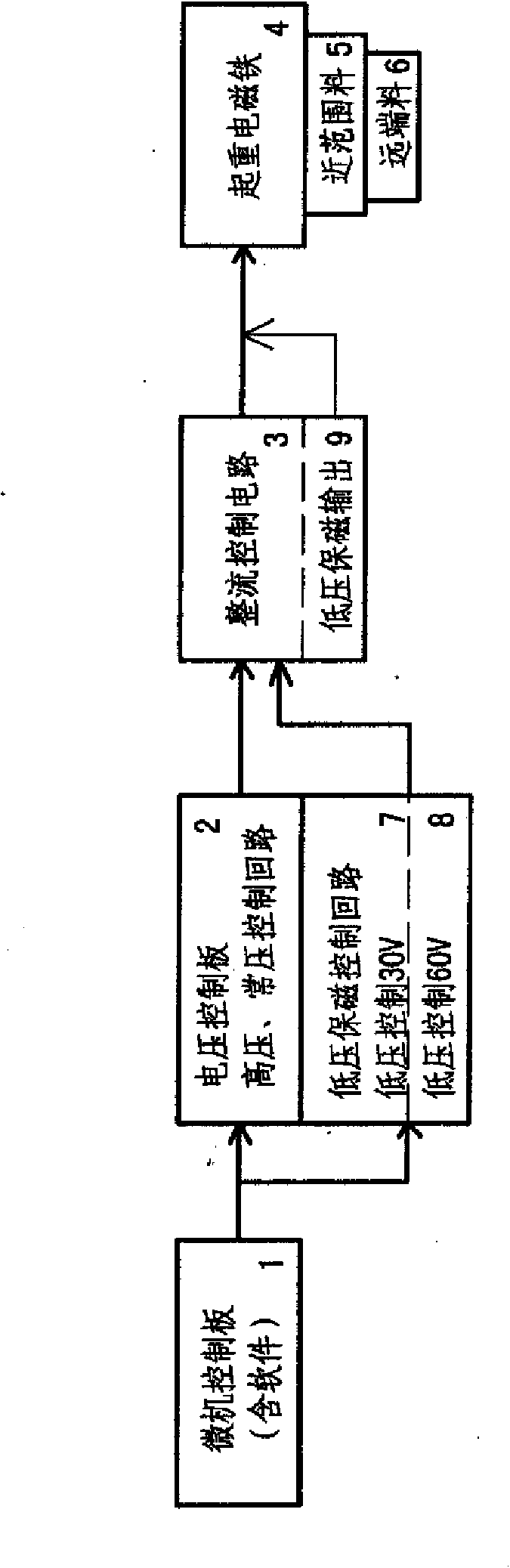

[0027] Such as figure 2 As shown, the present invention adds 7 and 8 low-voltage control loops on the basis of the original 2, and correspondingly has 9 low-voltage magnetic preservation outputs. When batching, the low-voltage excitation can strengthen the electromagnetic disk to effectively control the near-range material and prevent the far-end material from falling. It's not going to get completely out of hand either. The batching failure rate is greatly reduced, which can reach within 3%, and the batching accuracy can reach within 2%. Of course, the batching so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com