Raymond mill crashing auto control method and equipment thereof

An automatic control device, Raymond mill technology, applied in the direction of adaptive control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of increased maintenance cost, low control accuracy, shutdown, etc., to reduce equipment failure rate, expand The scope of application and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

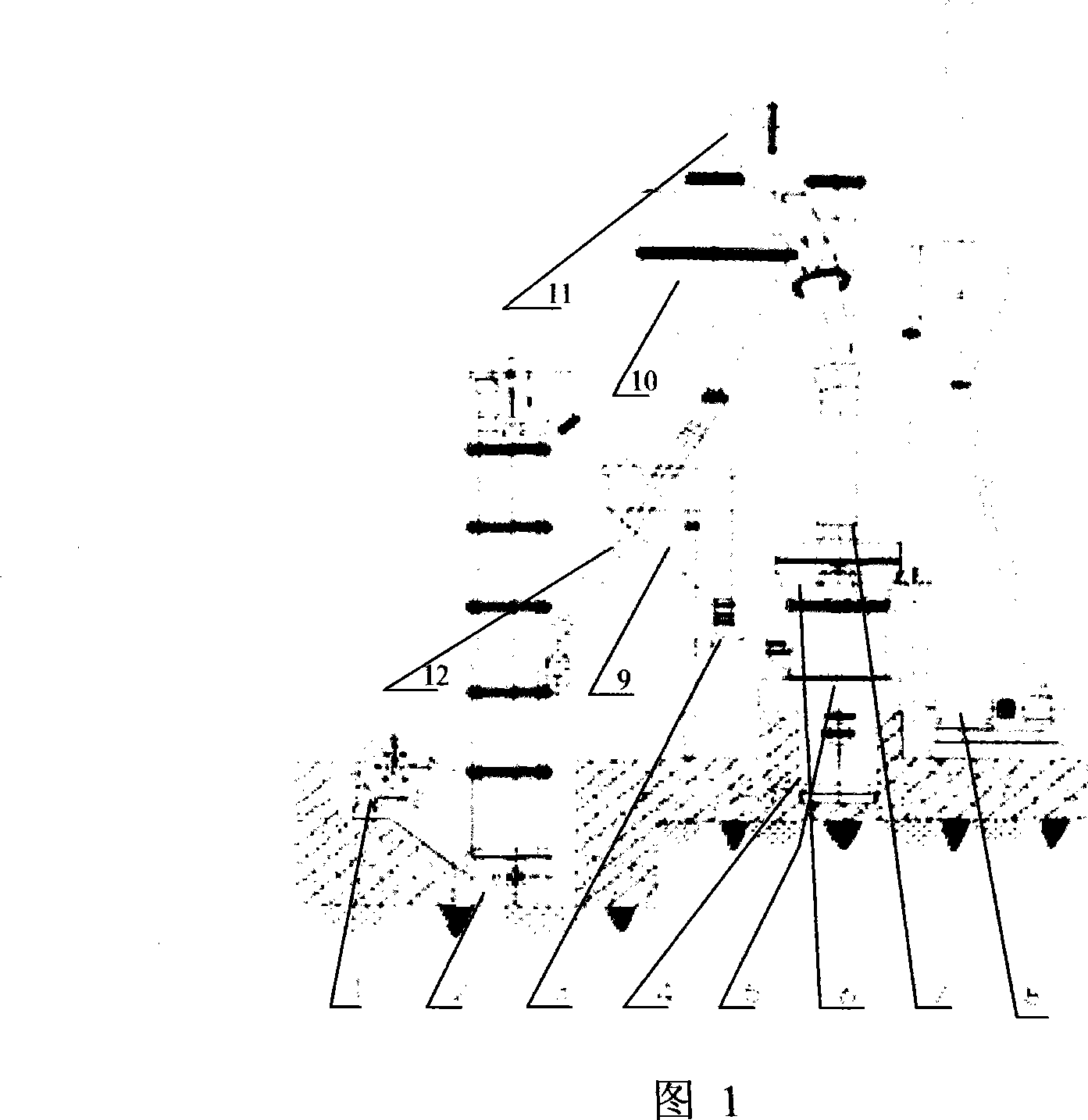

[0029] In Fig. 1, the block material crushed to a certain size by the jaw crusher 1 is shaped,

[0030] The particle size sand (diameter<20mm) obtained after water washing, drying, and magnetic separation and iron removal is vertically transported to the storage hopper 9 by the bucket elevator 2, and then the particle size sand is quantified, uniform, and It is continuously sent into the main machine 5 for grinding, and the ground powder is blown out by the blower 8, and then classified by the analysis machine 6 placed above the main machine 5. The powder whose fineness meets the specifications enters the large cyclone collector 10 with the wind flow, and after being collected, it is discharged through the powder outlet pipe 12 to become a finished product. The air flow is returned to the air blower 8 by the air return pipe 11 at the upper end of the large cyclone collector 10, and the entire air path system is in a closed cycle and flows under negative pressure.

[0031] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com