Paper feeding device

A paper feeding device and paper feeding technology, applied in printing devices, transportation and packaging, position/direction control, etc., can solve problems such as excessive noise, inability to control rotation and acceleration by itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

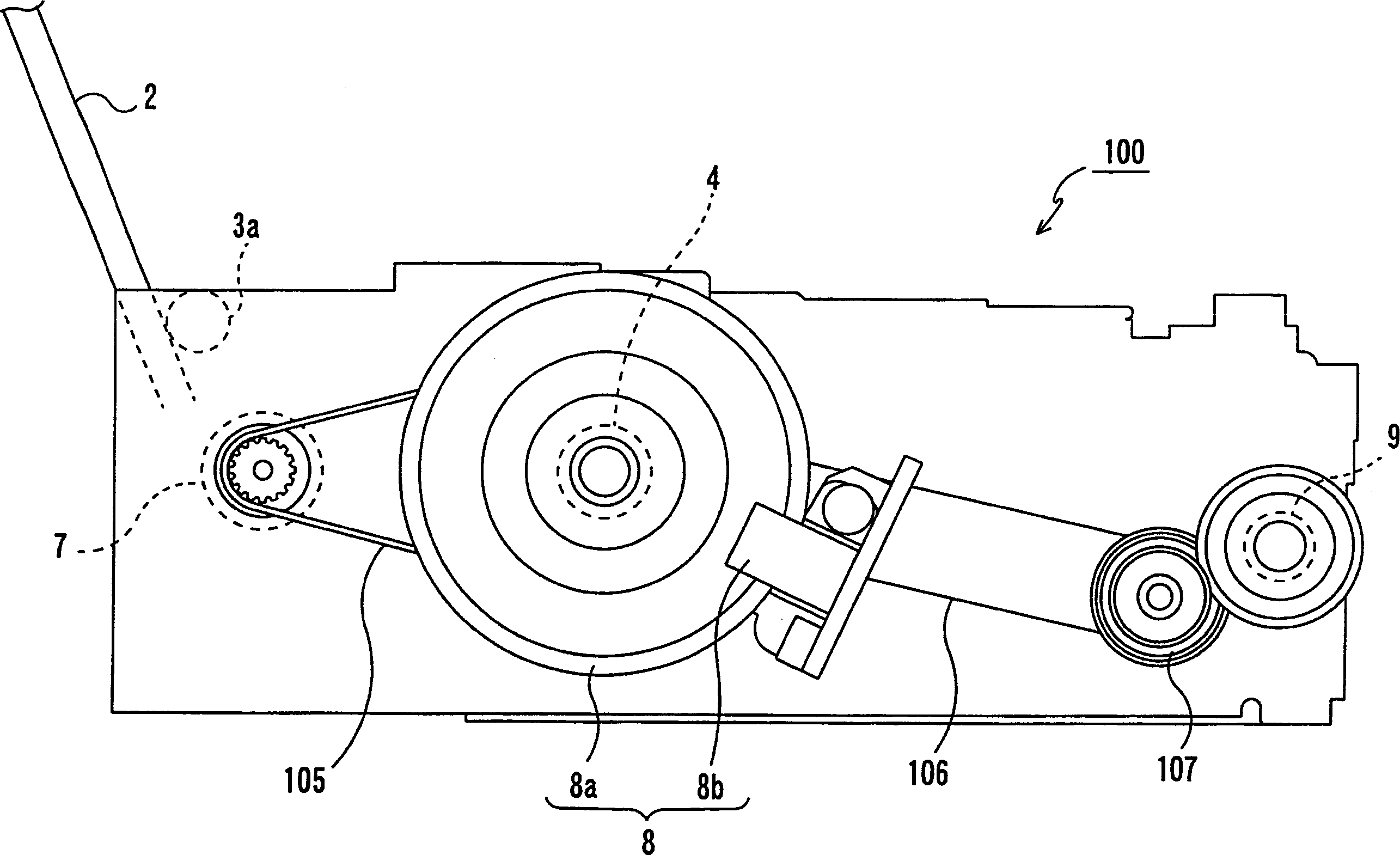

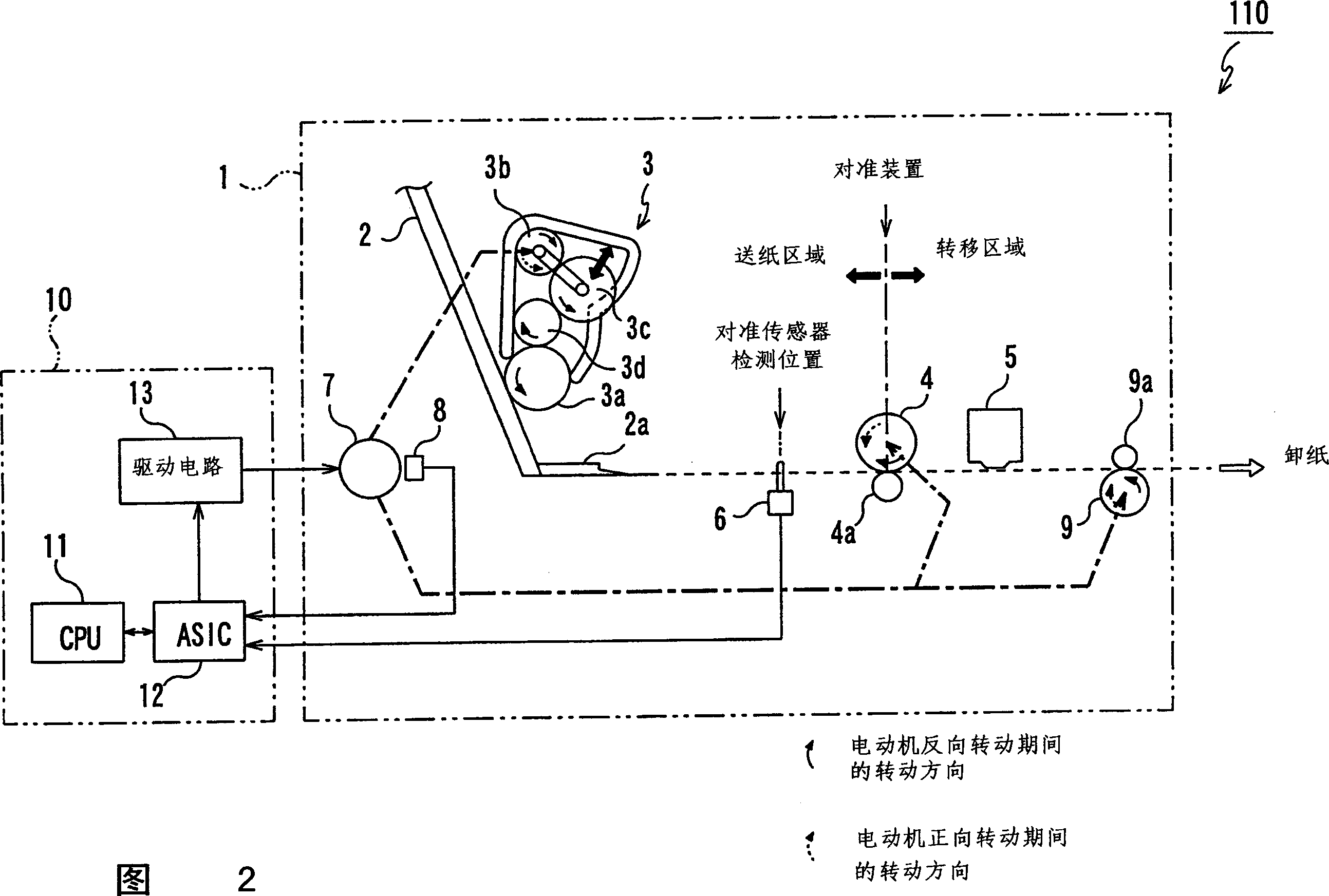

[0069] First, the figure 1 and 2 describe the schematic constitution of the printer according to this embodiment. figure 1 is a side view of the printer 100 to which the present invention is applied, and FIG. 2 is an explanatory view showing a schematic configuration of the paper feeding device 110 mounted on the printer 100 of the present embodiment.

[0070] Such as figure 1 As shown, the printer 100 of this embodiment mainly includes: a paper storage board 2, which is a paper storage unit for stacking and storing printing paper; 2; the transfer roller 4, which transfers the paper fed by the feed roller 3a during the printing operation; the unloading roller 9, which assists the transfer roller to transfer the paper during the printing operation and is unloaded after the printing operation paper; a line-feed (LF) motor 7, which is a rotation / drive source of the feed roller 3a, transfer roller 4, and discharge roller 9; and a rotary encoder (hereinafter simply referred to as...

no. 2 example

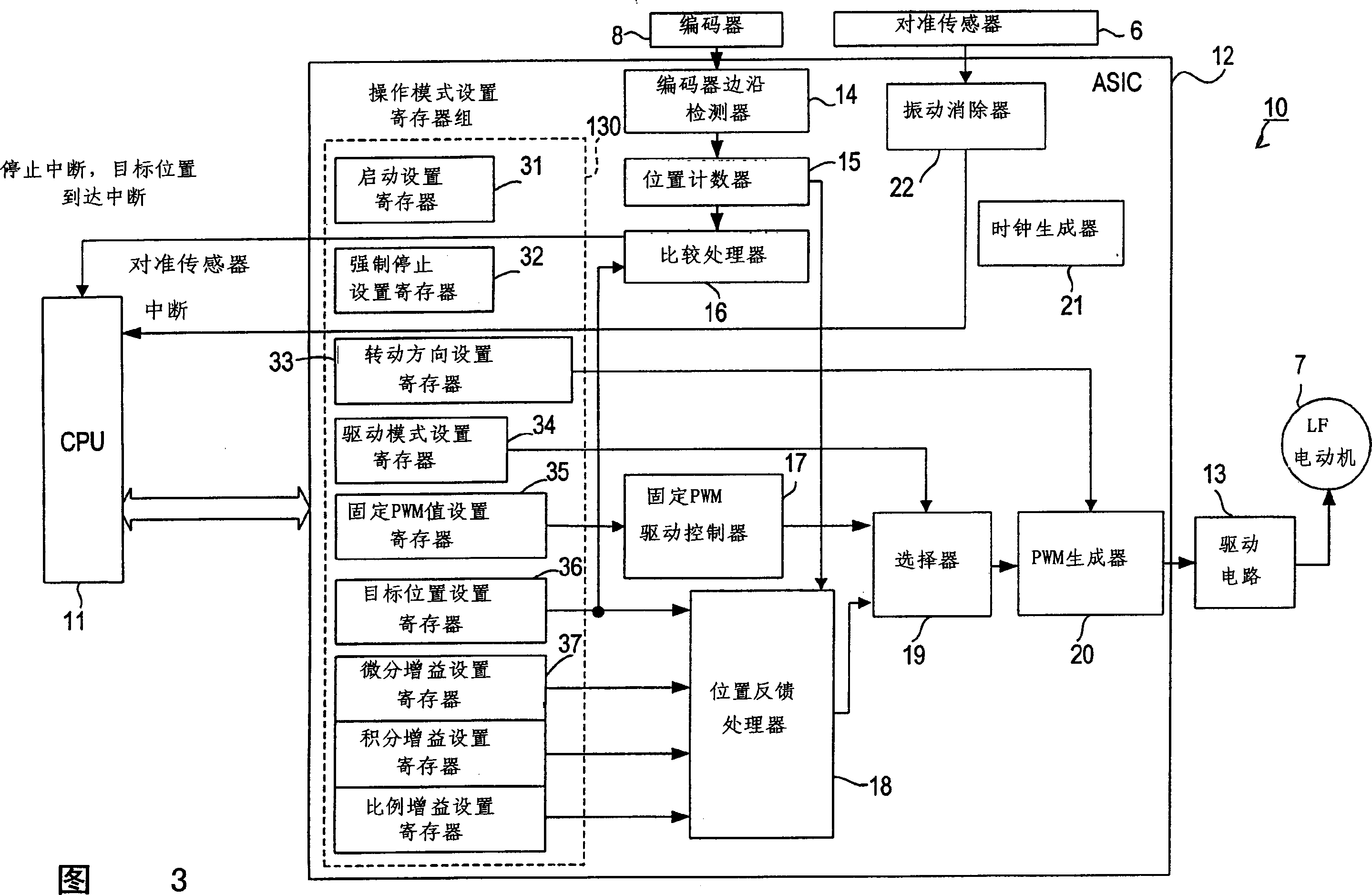

[0114] Fig. 7 shows a schematic configuration of a paper feed control device according to a second embodiment. As shown in FIG. 7, the ASIC 55 in the paper feed control device of this embodiment is different from the ASIC 12 of the first embodiment shown in FIG. speed feedback processor 47 , target speed setting register 41 , and gain setting register 42 . In addition, a cycle counter 45 and a speed converter 46 are arranged so as to acquire the rotation speed of the LF motor 7 (ie, the moving speed of paper) based on the pulse signal from the encoder 8 .

[0115] Another relationship is similar to that of the ASIC 12 of the first embodiment shown in FIG. 3 . Therefore, the same constituent elements as in FIG. 3 are denoted by the same reference numerals, and their descriptions will not be repeated.

[0116] The target speed setting register 41 configured in the operation mode setting register group 40 sets the transfer speed of paper (hereinafter simply referred to as "targ...

no. 3 example

[0127] FIG. 9 shows a schematic configuration of a paper feed control device according to a third embodiment. As shown in FIG. 9, the ASIC 60 in the paper feeding control device of this embodiment is different from the ASIC 12 of the first embodiment shown in FIG. The PWM increase coefficient setting register 64 and the fixed PWM driving controller 65 output PWM values according to the setting values of the respective registers 63 , 64 and the fixed PWM value setting register 35 .

[0128] Another relationship is similar to that of the ASIC 12 of the first embodiment shown in FIG. 3 . Therefore, the same constituent elements as in FIG. 3 are denoted by the same reference numerals, and their descriptions will not be repeated.

[0129] The initial PWM value setting register 63 arranged in the operation mode setting register group 62 defines a first PWM duty value at the start time of sheet feeding (separation). The PWM increase factor setting register 64 defines a method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com