Quick fertilizer applicator with quantitative control function

A quantitative control and fertilizer applicator technology, applied in fertilization devices, fertilizer distributors, applications, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

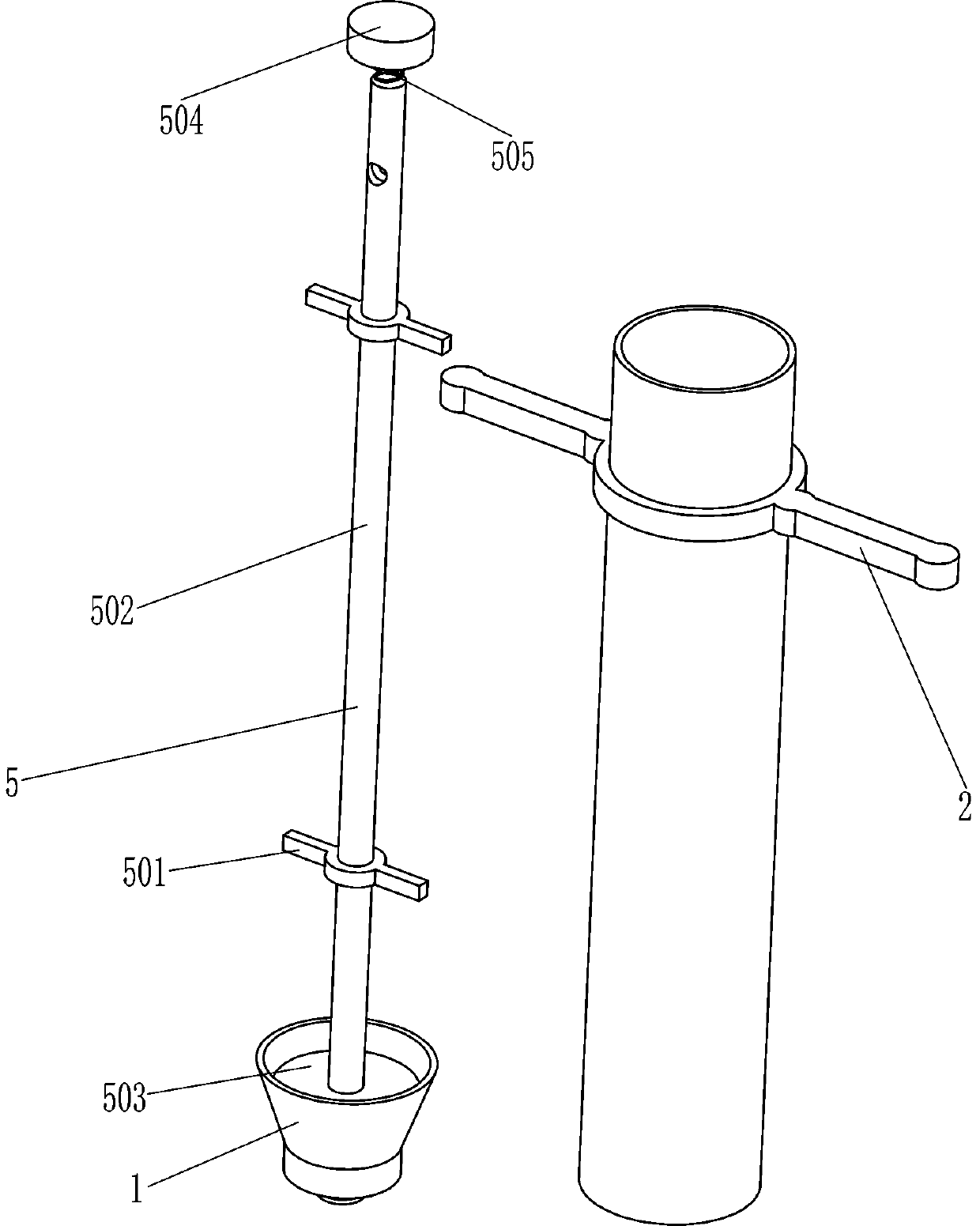

[0022] A rapid fertilizer applicator with quantitative control, such as figure 1 As shown, it includes a long barrel 1, a handle 2 and a discharge device 5, the top of the long barrel 1 is provided with a handle 2, and the long barrel 1 is provided with a discharge device 5.

[0023] When people need to apply fertilizer, first people place this equipment on the place where fertilization is needed. When the bottom of the discharge device 5 is in contact with the land, the discharge device 5 will move upwards. At this time, the fertilizer will fall out from the bottom of the long barrel 1. When the fertilizer is applied, people lift up the device. At this time, the bottom of the discharge device 5 is separated from the land, and the discharge device 5 will move downward. Tight contact occurs between the bottom of the discharge device 5 and the bottom of the long barrel 1, so that the fertilizer will not fall out, so that fertilization can be completed.

Embodiment 2

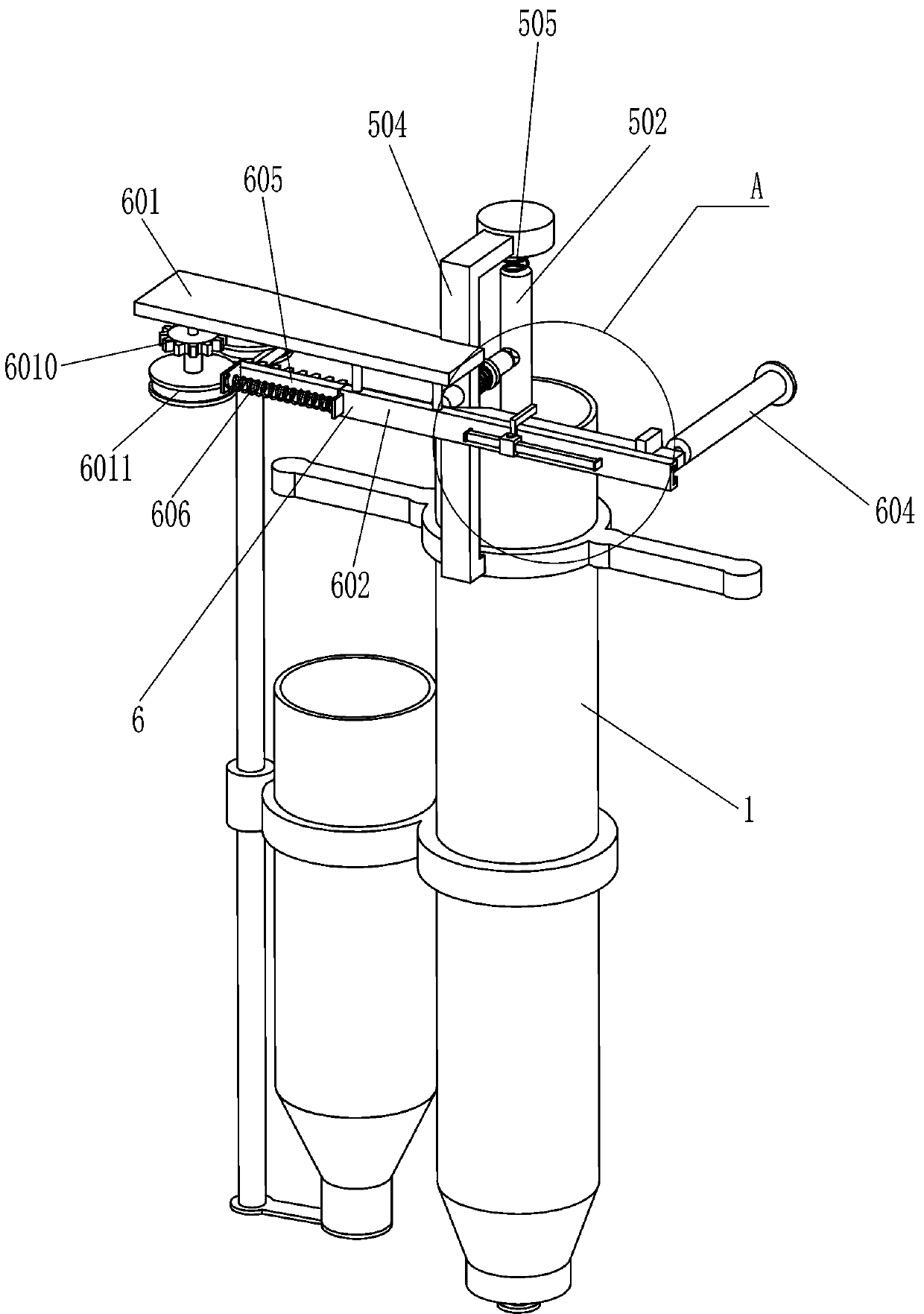

[0025] On the basis of Example 1, such as Figure 1-3 As shown, the discharge device 5 includes a guide sleeve 501, a guide rod 502, a circular baffle 503, a support frame 504 and a first compression spring 505, and the long barrel 1 is vertically provided with a guide sleeve 501, which slides in the guide sleeve 501. There is a guide rod 502 connected in the same way, the lower part of the guide rod 502 is provided with a circular baffle 503, the circular baffle 503 is attached to the inner wall of the lower part of the long barrel 1, and a support frame 504 is provided in the middle of the rear part of the handle 2, and the upper part of the support frame 504 is located on the guide Above the rod 502 , a first compression spring 505 is connected between the support frame 504 and the guide rod 502 .

[0026] When people need to fertilize, align the long barrel 1 with the place where fertilization is needed, then press it down with your hands, the bottom of the guide rod 502 c...

Embodiment 3

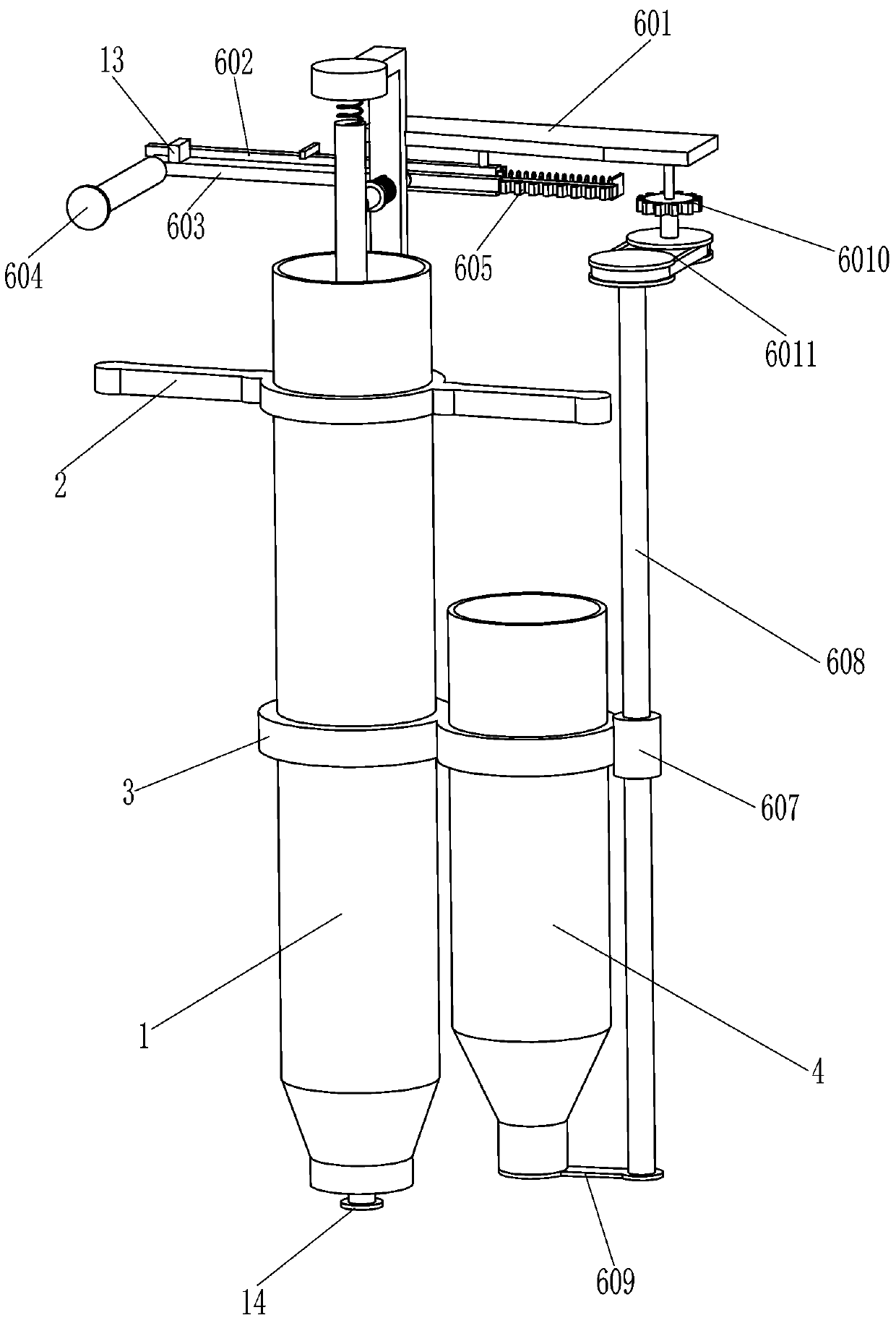

[0032] On the basis of Example 2, such as figure 2 and Figure 4 As shown, the discharge speed control device also includes a rack 605, a second compression spring 606, a driving gear 6010, and a belt transmission assembly 6011. The right end of the arc panel 603 is connected to the rack 605, and the right wall of the rear part of the rack 605 is connected to the slide rail. A second compression spring 606 is connected between 602, a drive gear 6010 is rotatably connected to the bottom right side of the mounting plate 601, and a belt transmission assembly 6011 is connected to the rotating shaft 608 and the drive gear 6010.

[0033]When people need to control the discharge, they can use the short barrel 4 to fertilize. People push the handle 604 to the right with their hands, and the movement of the handle 604 to the right drives the arc panel 603 to move to the right. When the arc panel 603 moves to the right When in contact with the clamping rod 7, the third compression spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com