A wood powder conveying hopper and feeding system for wood-plastic composite board production

A board production, wood-plastic composite technology, applied in the field of feeding system, can solve the problems of clogging, easy sticking on the inner wall of the hopper, continuous accumulation, etc., to achieve the effect of reducing clogging, improving the quality of blanking, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

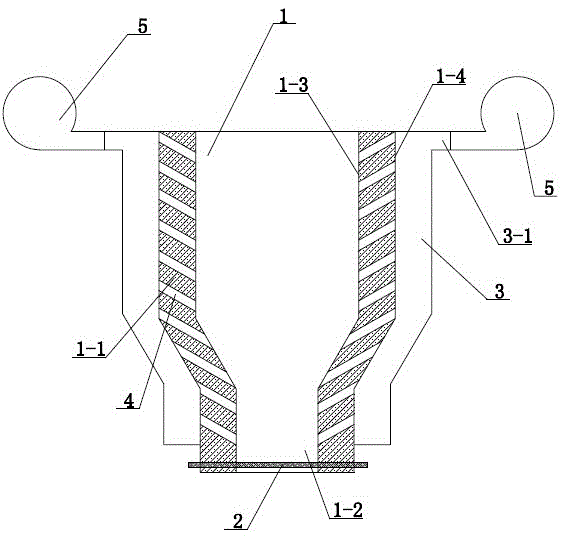

[0017] Such as figure 1 As shown, the wood powder conveying hopper for the production of wood-plastic composite boards provided by this embodiment includes a hopper body 1, and the bottom end of the hopper body 1 is provided with a discharge port 1-2 with a switch valve 2, The side wall 1-1 of the above-mentioned hopper body 1 is surrounded by a circle of sealed air duct 3, and a blower is connected to the position of the air inlet 3-1 of the sealed air duct 3. The side wall 1-1 of the above-mentioned hopper body 1 is closely arranged. There are ventilation holes 4 through the inner surface 1-3 and the outer surface 1-4 of the side wall 1-1, and the above-mentioned ventilation holes 4 are all obliquely facing the feeding port 1-2 at the bottom of the hopper body 1, and the hole diameter of the ventilation holes is to 1 cm.

[0018] Such as Figure 4 As shown, the present embodiment also provides a feeding system that adopts the wood powder conveying hopper for the production...

Embodiment 2

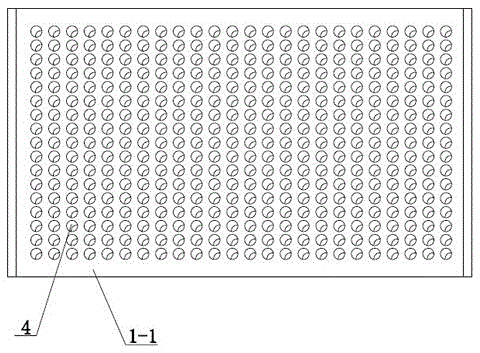

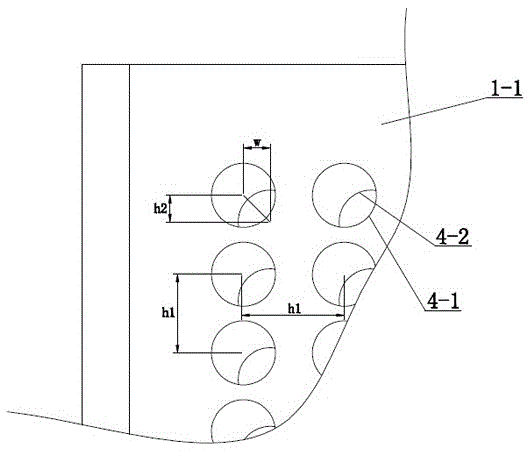

[0021] The wood powder conveying hopper provided by the present embodiment, its general structure domain embodiment 1 is consistent, as figure 2 and image 3 As shown, but the ventilation holes 4 in this embodiment are arranged in a rectangular array on the side wall 1-1 of the hopper body 1, wherein the outer surface openings of two adjacent ventilation holes 4 are between the center of the 4-1 center and the inner surface The vertical distance h between the center of mouth edge 4-2 1 Both are 4.5 centimeters, and each of the above-mentioned ventilation holes 4 faces the discharge port 1-2 at the bottom of the hopper body 1 at an oblique angle of 30°, and the outer surface opening of each ventilation hole 4 is along the center and inner surface opening of the 4-1 The horizontal spacing w and the longitudinal spacing h between the centers along 4-2 2 equal and both are 1.5 cm. In this embodiment, the wind generated by the wind source 5 passes through the ventilation hole 4...

Embodiment 3

[0023] The general structure of the wood flour conveying hopper provided in this embodiment is consistent with that of Embodiment 2, but the outer surface openings of the adjacent two ventilation holes 4 on the side wall 1-1 of the hopper body 1 in this embodiment are along the center of the 4-1 The vertical distance h between the center of the inner surface and the mouth along the 4-2 1 Both are 5.2 centimeters, the lateral spacing w and the longitudinal spacing h between the center of the outer surface mouth of each ventilation hole 4 along the center of 4-1 and the center of the inner surface mouth along 4-2 2 equal, and both are 1.8 cm, and each of the above-mentioned ventilation holes 4 faces the discharge port 1-2 at the bottom of the hopper body 1 at an oblique angle of 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com