Yogurt fermentation device and yogurt preparation method

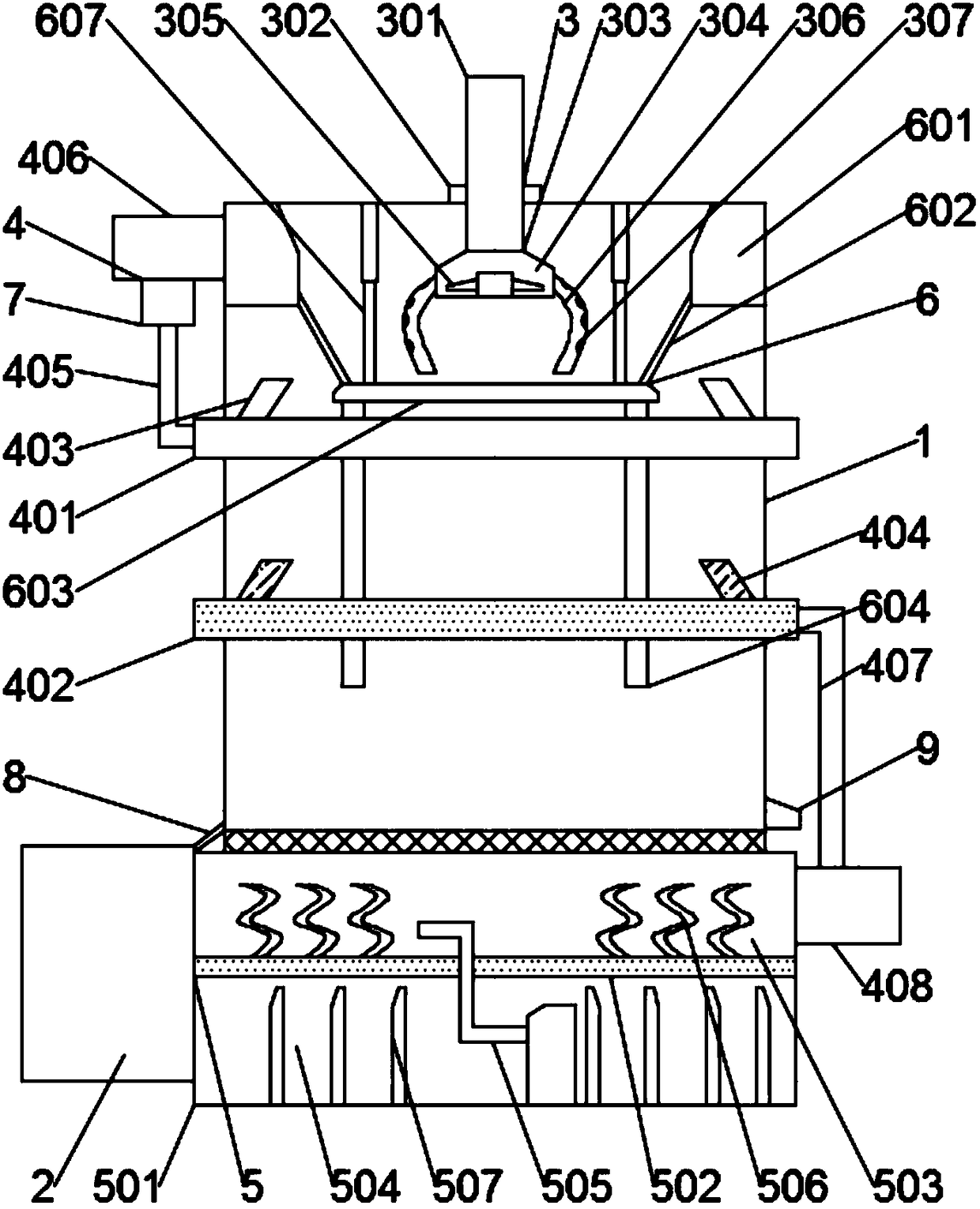

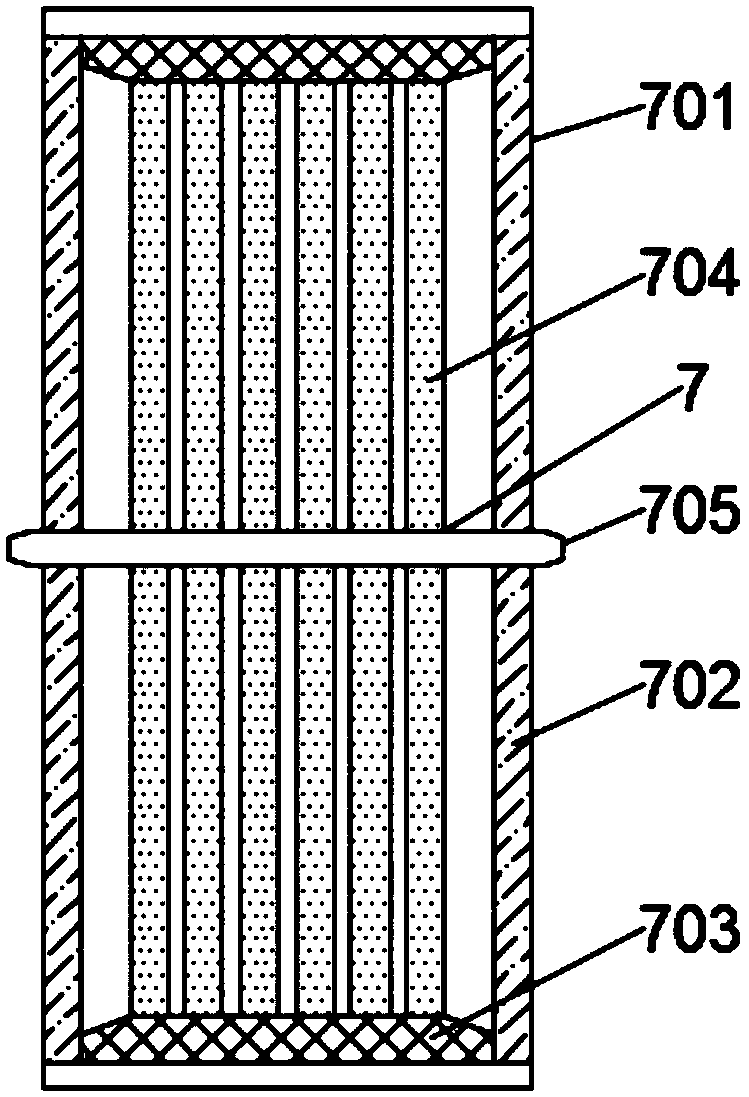

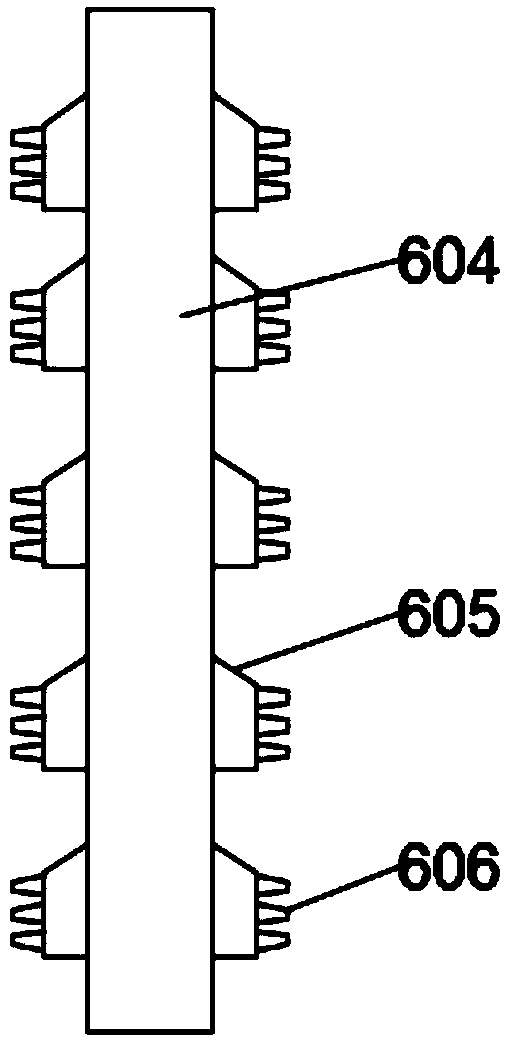

A fermenting device and yogurt technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as the inability to ensure the replacement of air quality, the impact on the hygiene of yogurt, and unfavorable temperature control, so as to prevent the growth of bacteria inside and reduce the splash of raw materials Accurate effect of injection and temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Such as Figure 4 Shown, the present invention also provides a kind of preparation method of yogurt, comprises the steps:

[0062] S100. Sterilization of raw materials. Pasteurization is used for raw milk at a temperature of 85-100°C. Impurities and bacteria in raw milk are removed by pasteurization to improve safety and health while retaining milk nutrients;

[0063] S200, primary homogenization, heat the raw materials after mixing and perform the first homogenization treatment, the homogenization pressure is 9-15MPa, mix fructose syrup, white sugar and sterilized raw milk according to the proportion, heat after mixing and perform the second homogenization treatment One-time homogenization treatment, the initial homogenization allows the added sugar to be fully mixed in raw milk, which is conducive to improving the taste and flavor of yogurt in the subsequent process;

[0064] S300. Mix and sterilize the auxiliary materials and homogenize for the second time. Add high...

Embodiment 1

[0074] The invention provides a kind of yogurt, which is composed of the following raw materials according to parts by weight:

[0075] 800-1500 parts of raw milk, 60 parts of fructose syrup, 55 parts of white sugar, 20 parts of high methoxyl pectin, 0.1 part of probiotics, 4 parts of mixed stabilizer, 0.5 parts of purple sweet potato syrup, 0.2 parts of mulberry syrup, bamboo shoots 0.1 part of stock solution, 0.2 part of camellia powder suspension, 0.4 part of schisandra pulp, 0.1 part of probiotics, 0.1 part of tartary buckwheat sprout pulp, 0.1 part of ground soft juice, 0.3 part of agaricus blazei fermented liquid.

Embodiment 2

[0077] The invention provides a kind of yogurt, which is composed of the following raw materials according to parts by weight:

[0078] 1200 parts of raw milk, 90 parts of fructose syrup, 80 parts of white sugar, 35 parts of high methoxy pectin, 0.5 parts of probiotics, 6 parts of mixed stabilizer, 0.8 parts of purple sweet potato pulp, 0.4 parts of mulberry pulp, 0.3 parts of bamboo shoot stock solution 0.3 parts of camellia powder suspension, 0.6 parts of schisandra fruit pulp, 0.2 parts of probiotics, 0.3 parts of tartary buckwheat sprout pulp, 0.2 parts of ground soft juice, and 0.5 parts of Agaricus blazei fermented liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com