Efficient aluminum profile extrusion method

An extrusion method and aluminum profile technology, applied in the field of aluminum profile extrusion, can solve the problems of reducing product output, affecting the efficiency of aluminum profile production, and not being able to replace molds, so as to achieve the effects of ensuring stability, convenient delivery, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

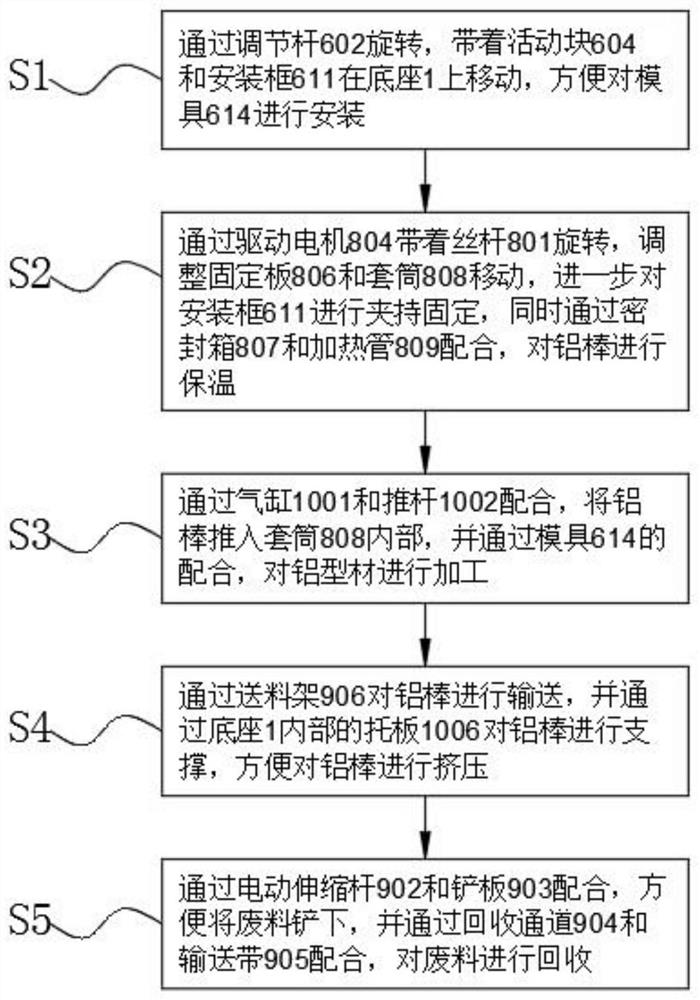

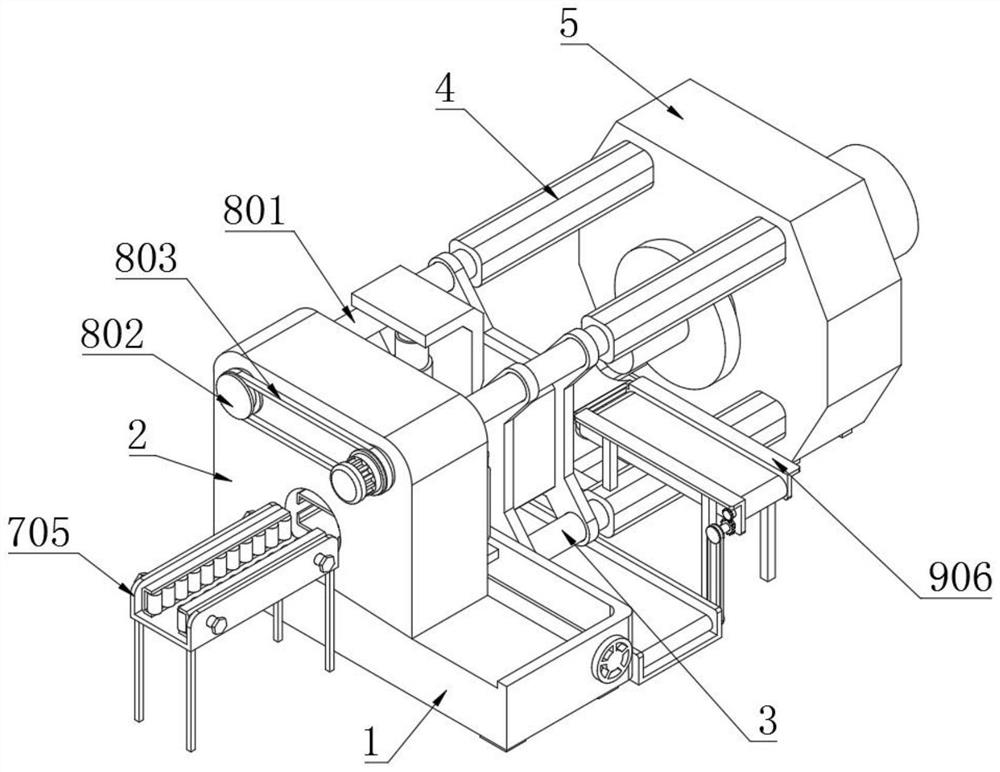

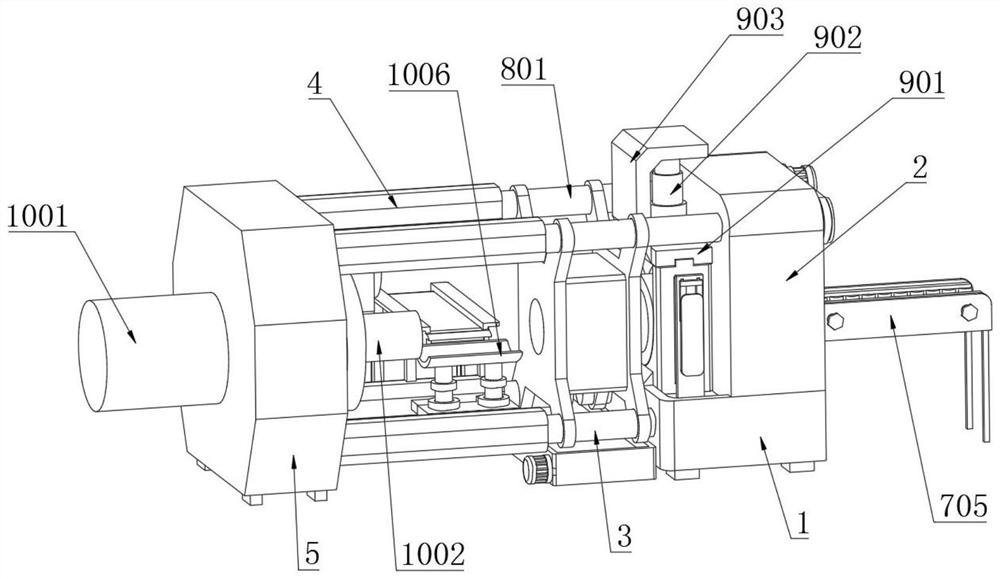

[0038] Example: such as figure 1 As shown, the present invention provides a technical solution, a high-efficiency aluminum profile extrusion method, comprising the following steps:

[0039] S1, through the rotation of the adjustment rod 602, move on the base 1 with the movable block 604 and the installation frame 611, so as to facilitate the installation of the mold 614;

[0040] S2, drive the motor 804 to rotate with the screw rod 801, adjust the movement of the fixing plate 806 and the sleeve 808, further clamp and fix the installation frame 611, and simultaneously cooperate with the sealing box 807 and the heating tube 809 to keep the aluminum rod warm;

[0041] S3, through the cooperation of the cylinder 1001 and the push rod 1002, push the aluminum rod into the inside of the sleeve 808, and process the aluminum profile through the cooperation of the mold 614;

[0042] S4. The aluminum rods are conveyed through the feeding frame 906, and the aluminum rods are supported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com