Spiral conveyer

A screw conveyor and main conveying technology, which is applied in the field of screw conveyors and feeding devices, can solve the problems of uneven distribution density of materials, affecting the effect of dry granulation, and the transportation accuracy cannot meet the requirements of use, so as to reduce the unevenness of thickness. one effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

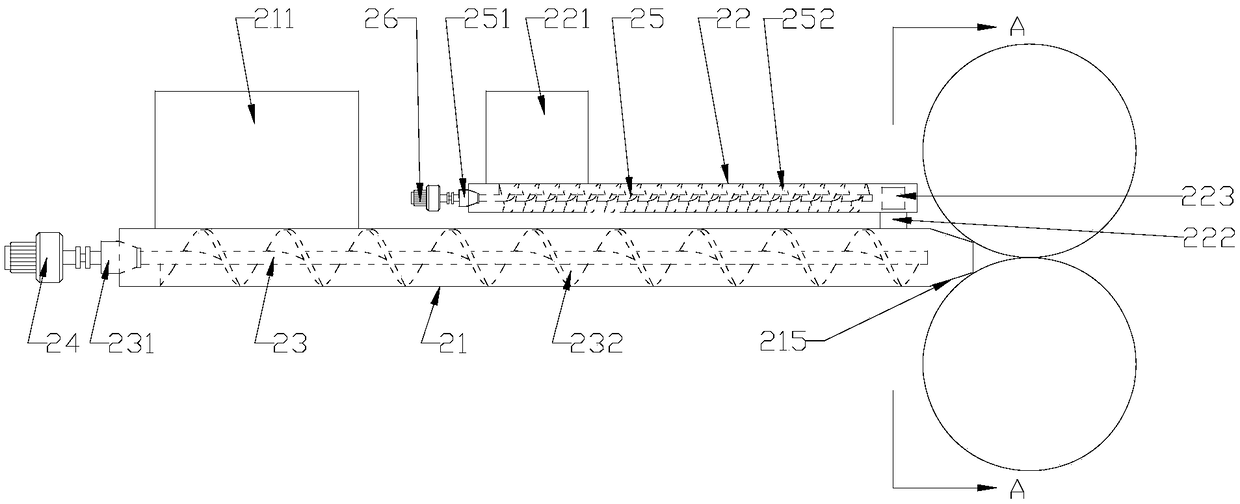

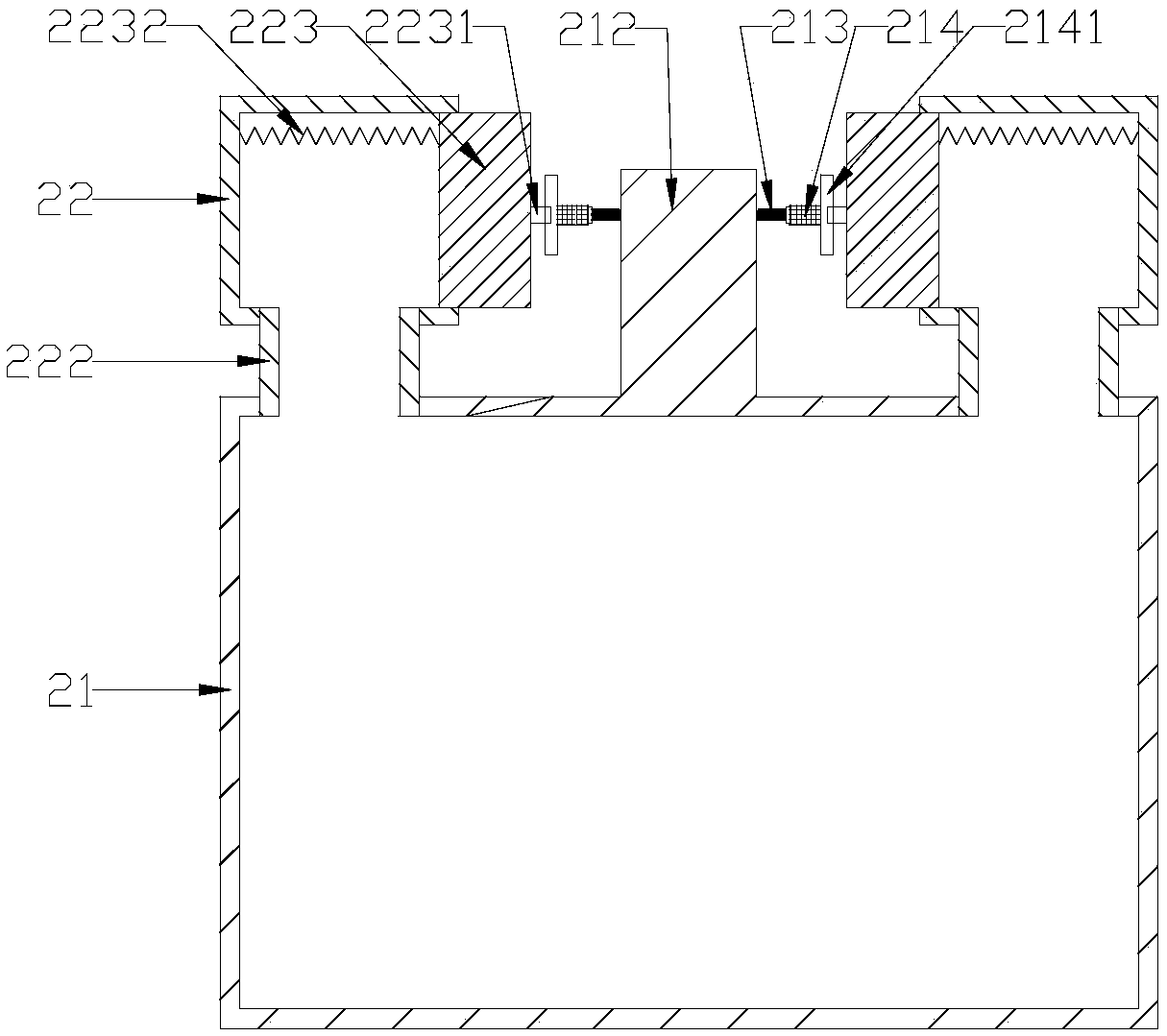

[0016] refer to figure 1 and figure 2 , a screw conveyor of the present invention includes a main conveying unit and an auxiliary conveying unit, the main conveying unit includes a first material conveying housing 21, a first rotating rod 23 and a first motor 24, and the auxiliary conveying unit includes two Set of the second material delivery housing 22, the second rotating rod 25 and the second motor 26, the auxiliary conveying unit is located on both sides of the upper end of the main conveying unit, and the first rotating rod 23 and the second rotating rod 25 respectively pass through The first bearing seat 231 and the second bearing seat 251 are fixed on the first material delivery housing 21 and the second material delivery housing 22, and the output shafts of the first motor 24 and the second motor 26 are respectively connected to the first motor 24 and the second motor 26 through a coupling. The first rotating rod 23 is connected with the second rotating rod 25, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com