Harmless treatment device for sludge

A technology of harmless treatment and sludge, applied in biological sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc. The effect of high mud utilization rate and convenient composting treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

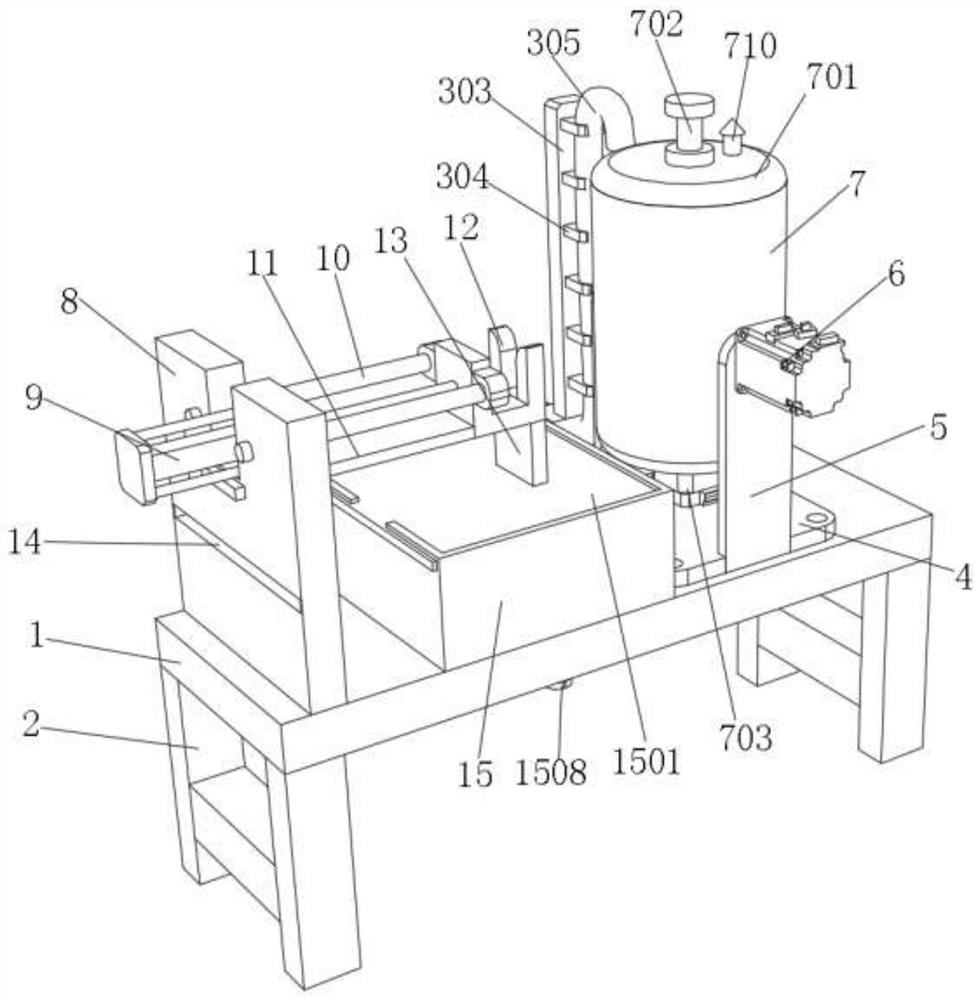

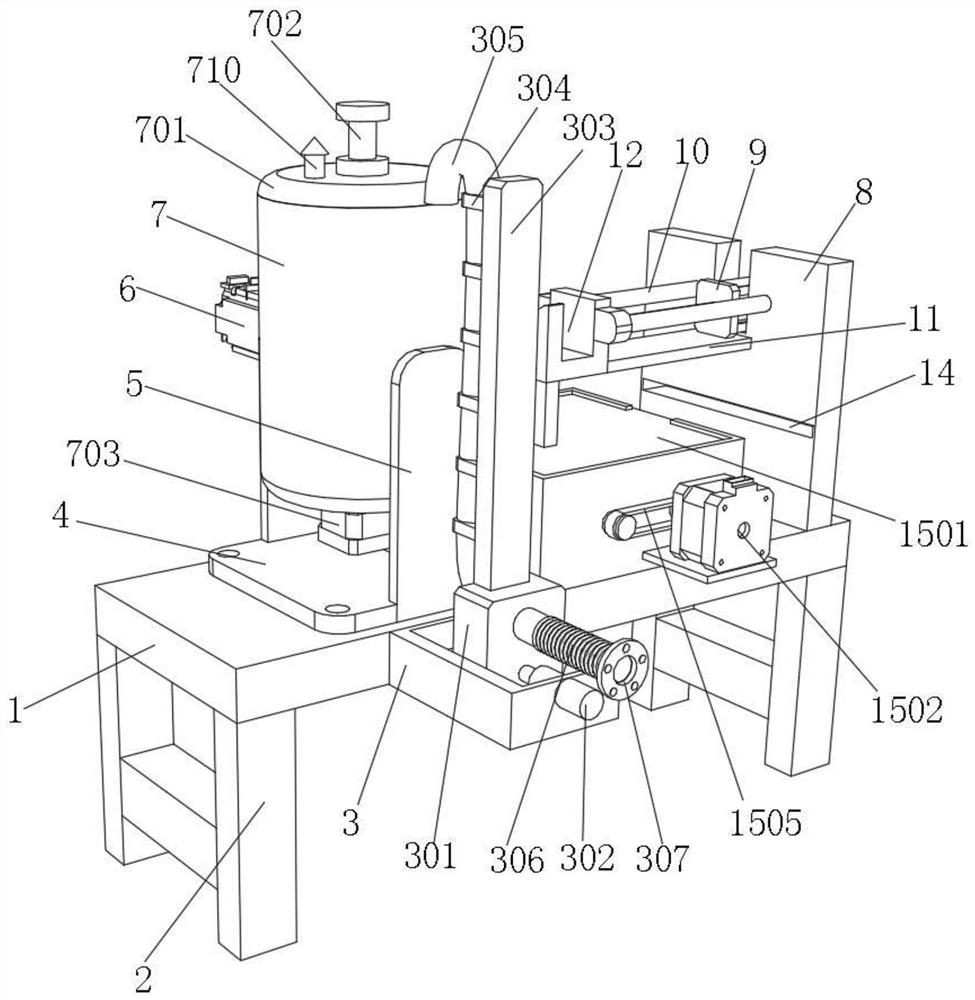

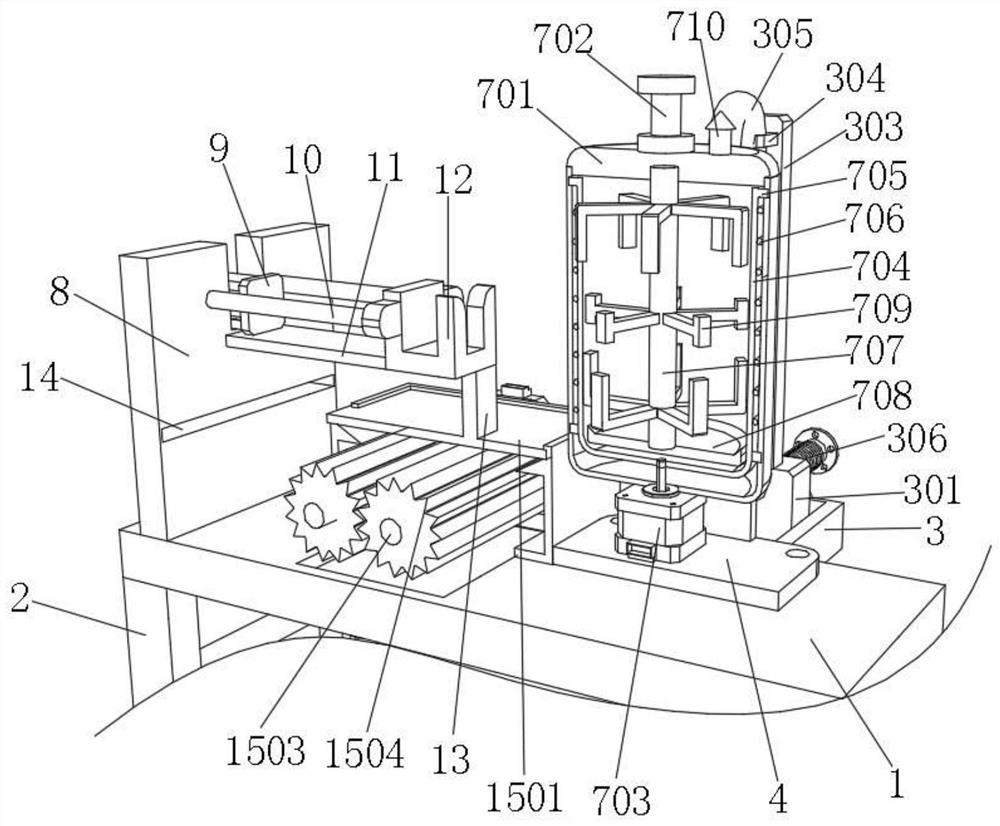

[0033] refer to Figure 1-Figure 5, a sludge harmless treatment device, comprising a bottom plate 1, a support frame 2 is fixed on the bottom of the bottom plate 1 by bolts, a feed adjustment mechanism is provided on one side of the bottom plate 1, and a fixed plate 4 is fixed on the upper surface of the bottom plate 1 by bolts , and the upper surface of the fixed plate 4 is fixed with two fixed frames 5 by bolts, and one side of the fixed frame 5 is fixed with a servo motor 6 by bolts, and a sludge treatment mechanism is connected between the two fixed frames 5, and the sludge treatment mechanism The setting can kill harmful substances and insect eggs in the sludge by heating at high temperature, and can also evaporate excess water in the sludge. The sludge treatment mechanism includes the outer cylinder 7 and the inner cylinder 704, and one side of the inner cylinder 704 is integrally formed There is a sliding ring 705, and the sliding ring 705 is slidingly connected with th...

Embodiment 2

[0037] refer to Figure 6-Figure 7 , a sludge harmless treatment device, one side of the support frame 2 is fixed with a second slideway 1602 by bolts, and one side of the second slideway 1602 is slidably connected with a slide rail 1601, and the slide rails 1601 are all fixed by bolts There is the same fermentation tank 16, and the fermentation tank 16 that can be pulled is set, which abandons the disadvantages of the traditional fermentation tank being inconvenient to move, and is more convenient for post-composting treatment. It has certain innovations and improves the efficiency of composting to a large extent. In order to improve the efficiency of sludge harmless treatment, one side of the fermentation tank 16 is fixed with a hinge by bolts, and the other side of the hinge is fixed with a discharge door 1603 by bolts.

[0038] The present invention also includes a method of fermenting sludge into fertilizer, the specific method is as follows:

[0039] S1: Adding bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com