A kind of pretreatment method of food waste

A food waste and pretreatment technology, applied in the direction of solid waste removal, etc., to achieve stable separation, long process chain, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

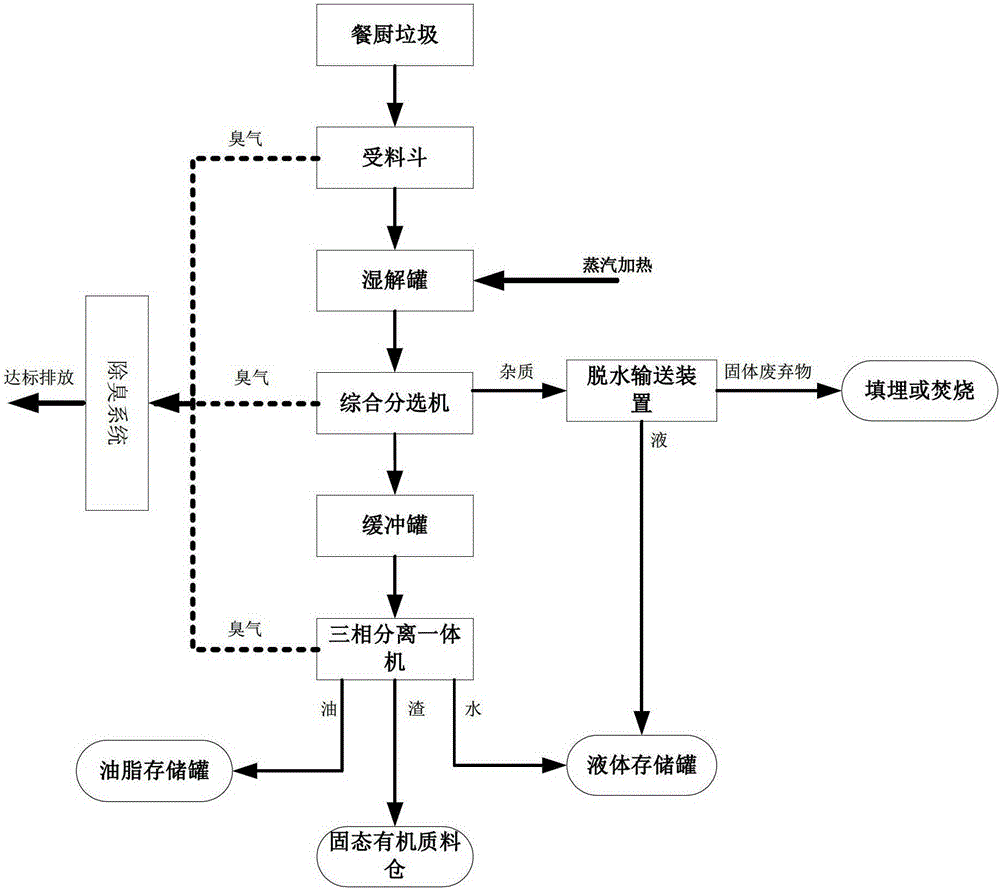

[0018] Such as figure 1 As shown in the figure, the food waste is sent to the treatment system by the special food waste collection and transportation vehicle, and then directly put into the hydrolysis tank through the receiving hopper;

[0019] The wet hydrolysis tank is a pressure vessel resistant to high temperature. Under certain pressure and temperature conditions (temperature 150°C, pressure 0.48Mpa), the food waste is subjected to wet heat hydrolysis. The heat source of the wet heat hydrolysis is steam; through the wet heat hydrolysis process, the food waste The animal and vegetable oils are fully separated out, so that the recovery rate of the oil is improved, and the organic materials are hydrolyzed and refined, and the viscosity and fluidity of the materials are improved;

[0020] The material after wet heat hydrolysis is discharged into the comprehensive separator, and the viscosity and fluidity of the material after wet heat hydrolysis treatment are improved, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com