Automatic metering structure and automatic feeding device

An automatic metering and feeding device technology, applied in the direction of transportation and packaging, conveyors, rotary conveyors, etc., can solve the problems affecting the measurement accuracy and the feeding speed, so as to ensure the measurement accuracy, ensure the feeding speed, The effect of improving quality and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

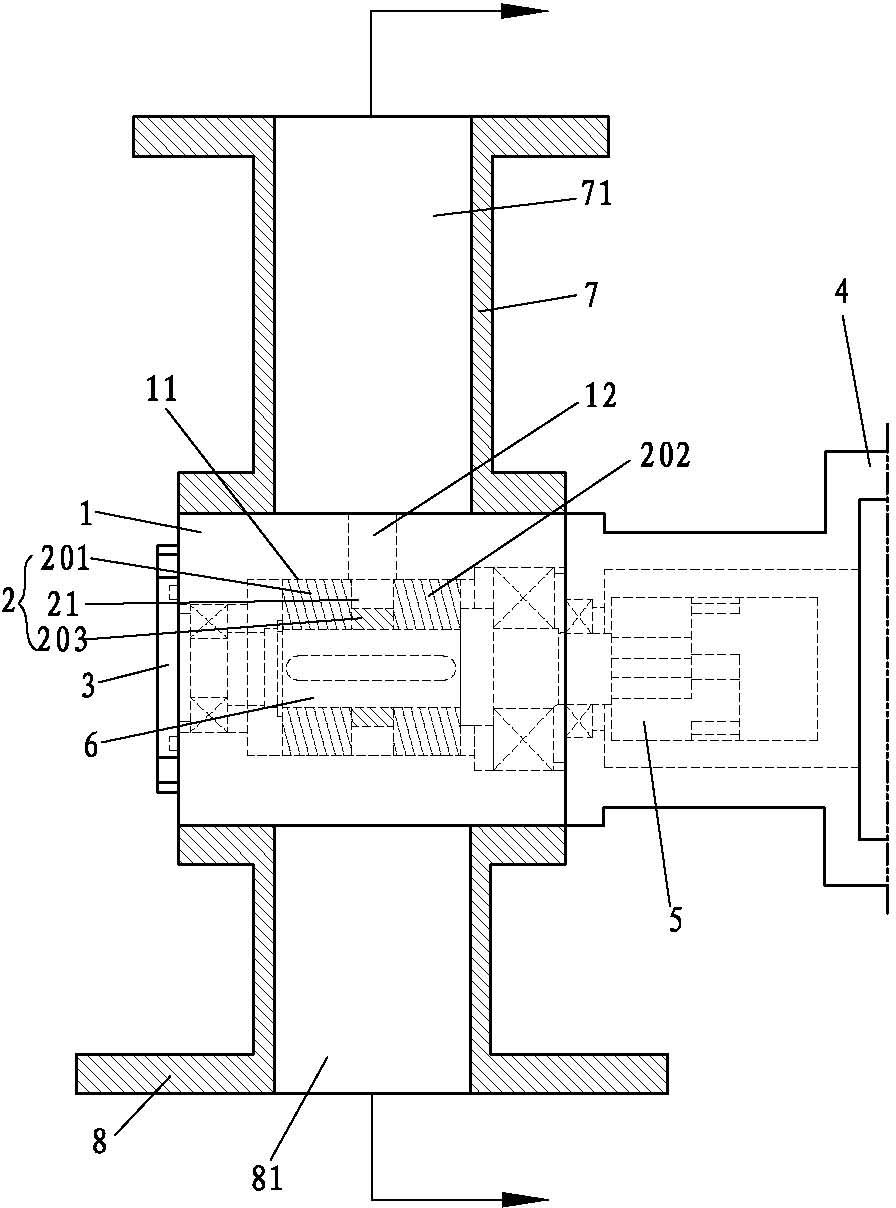

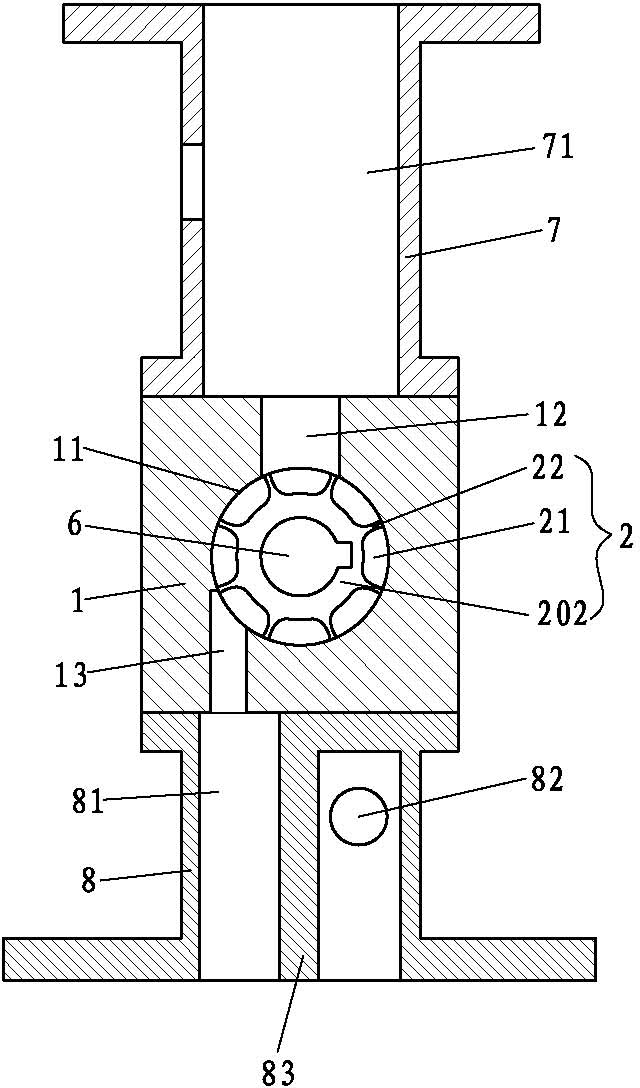

[0035] Such as figure 1 and figure 2 Shown is a preferred embodiment of the present invention.

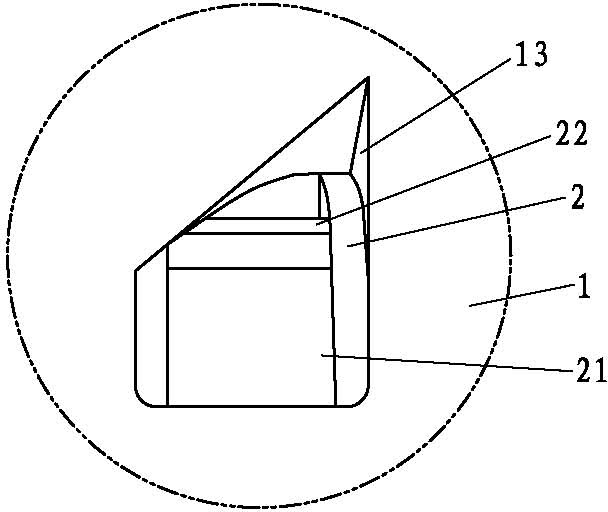

[0036] An automatic metering structure disclosed by the present invention includes a casing 1 and a rotor 2 . A drum 11 , a material inlet 12 and a material outlet 13 are formed on the housing 1 , and the feed inlet 12 and the material outlet 13 communicate with the drum 11 . The rotor 2 is inserted in the drum 11, and a tight fit is formed between the rotor 2 and the drum 11 to prevent fluid leakage; the outer wall of the rotor 2 corresponds to the feed port 12 and the discharge port 13 to form a ring of metering grooves 21 (metering The number of tanks 21 is not limited, and can be designed according to needs), this metering tank 21 is used to accurately measure fluid materials, and cooperate with the rotating speed of the rotor 2 to achieve the purpose of quantitative feeding, the volume of the metering tank 21 can be the smallest 0.5 cubic centimeter, there is a partition 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com