Oil press

An oil press and press chamber technology, applied in presses, manufacturing tools, etc., can solve the problems of unstable use, insufficient manufacturing precision, unreasonable design, etc., and achieve the effect of stable changes in oil output conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

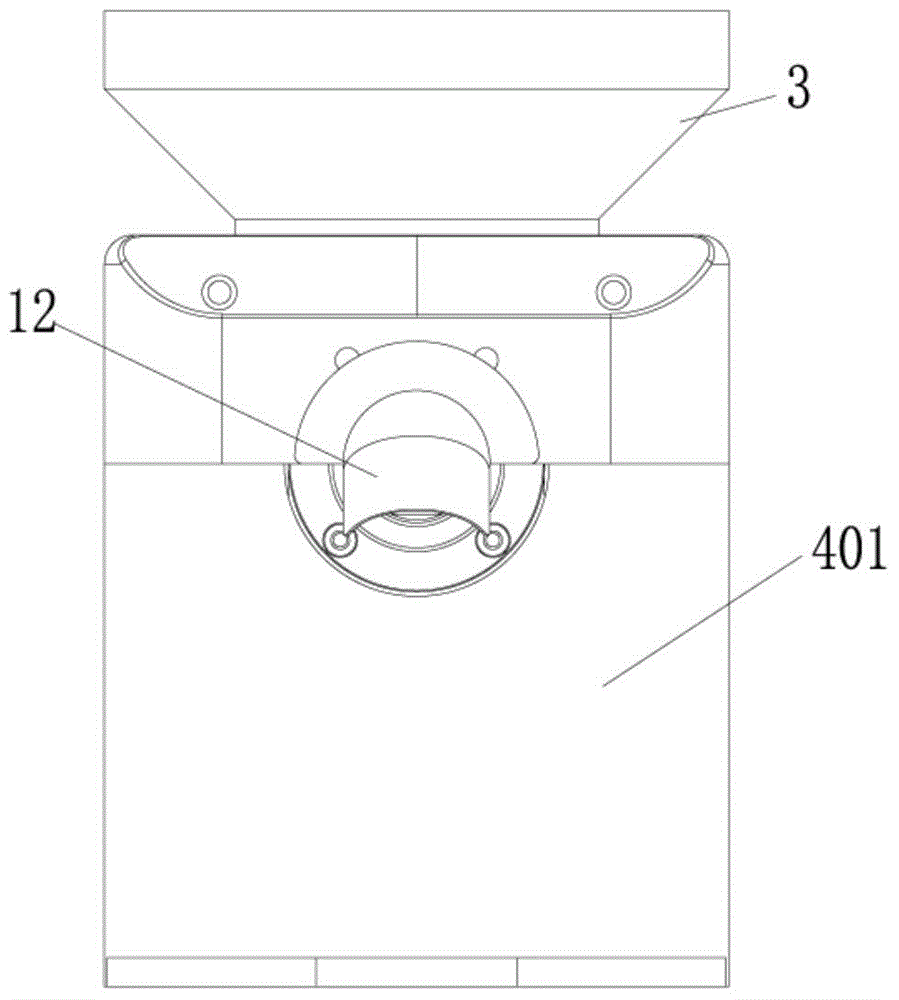

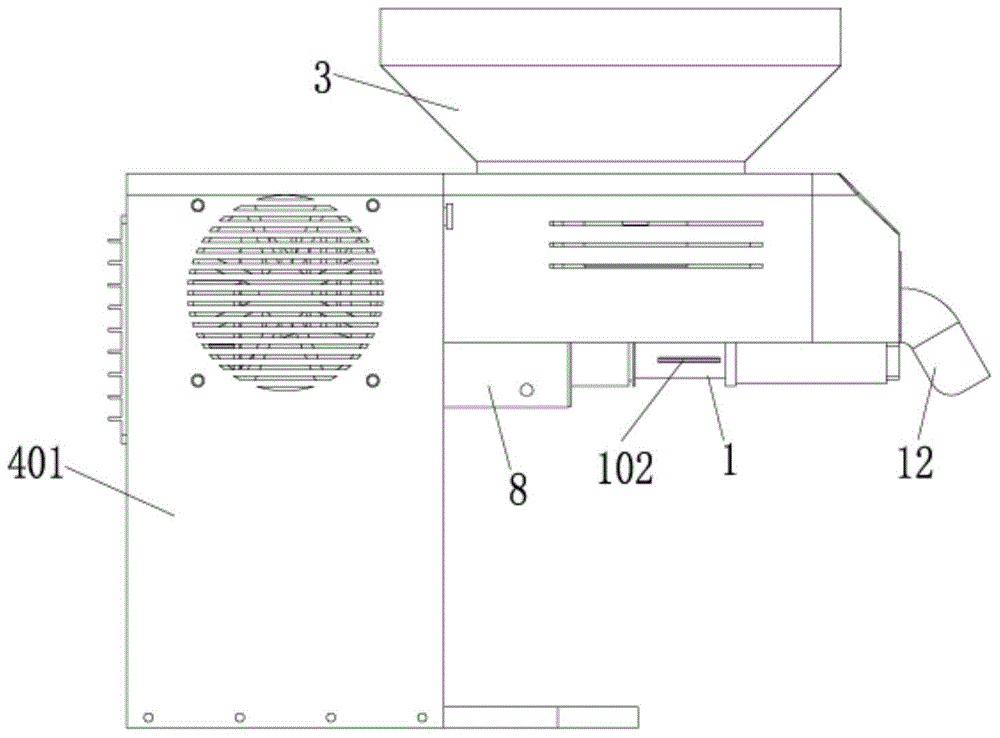

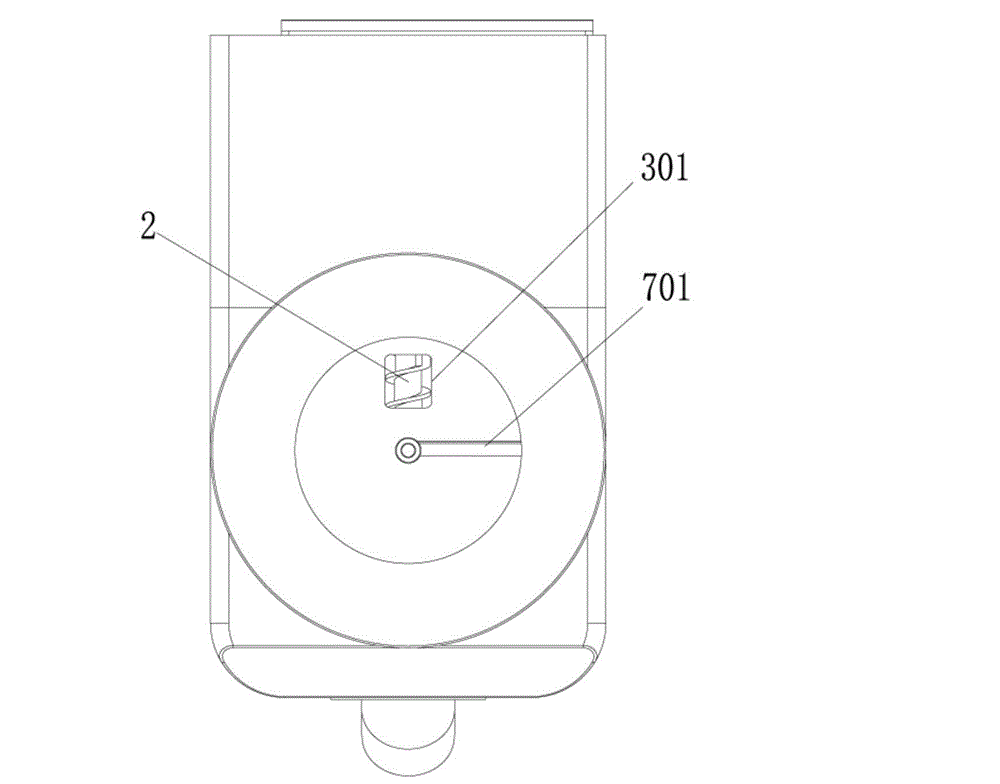

[0034] like Figure 1 to Figure 11As shown, the oil press described in this embodiment includes a pressing chamber 1, a pressing rod 2, a hopper 3, a main engine, a heating unit 5, and a non-directional feeding unit, wherein one end of the pressing chamber 1 is an inlet The material end, the other end of which is the slag discharge end, the top of the body of the feed end is provided with a material inlet 101, and the port of the slag discharge end is detachably connected with a hollow slag discharge head 6 and equipped with a The slag discharge stop cover 12 of the slag discharge head 6 has six elongated oil outlets 102 evenly distributed along its circumference on the body between its two ends, and its internal hollow cavity is a positive inner hexagonal straight hole. The press chamber 1 is horizontally installed on the main machine and fixed, and the press chamber 1 is connected with the main machine through the press chamber fixing sleeve 8, and is vertically inserted and...

Embodiment 2

[0040] The difference from Example 1 is that the squeeze rod 2 in this embodiment rotates counterclockwise, and the oil outlet is opened at 6.84° in the clockwise direction. This design principle is the same as that in Embodiment 1, except that the squeeze rod rotates in the opposite direction. , then the oil outlet can be opened in the opposite direction to achieve the same effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com