Integrated thin-layer chromatography plate paving instrument

A technology of plate laying instrument and thin layer chromatography, which is applied in the field of chromatographic analysis, can solve problems such as unqualified laying quality, and achieve the effect of solving uniformity and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

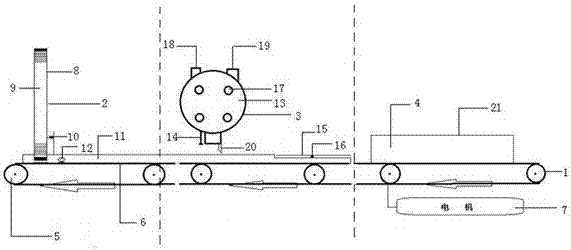

[0012] The invention will be further described according to the accompanying drawings and specific embodiments.

[0013] Such as figure 1 The integrated thin-layer chromatography plate laying instrument shown includes a conveying device 1, a chromatographic plate conveying area 2, a laying area 3, and a drying area 4. The conveying device includes a gear 5, a conveyor belt 6, and a motor 7, which are divided into three sections , which are respectively located under the chromatographic plate transfer area 2, the material laying area 3 and the drying area 4; Device A 10, one side movable baffle 11, movable baffle regulator 12, the chromatographic plate 9 to be used is placed close to one side of the metal baffle 8, and the screw regulator A 10 is fixed on the other side of the metal baffle 8, It is used to adjust the distance between the metal baffle 8 and the conveying device 1. The unilateral movable baffle 11 is located at the left and right ends of the conveyor belt 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com