Preparation method of graphene oxide-supported silver-palladium composite material

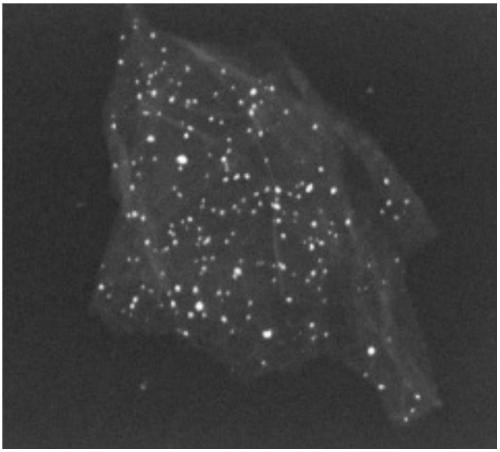

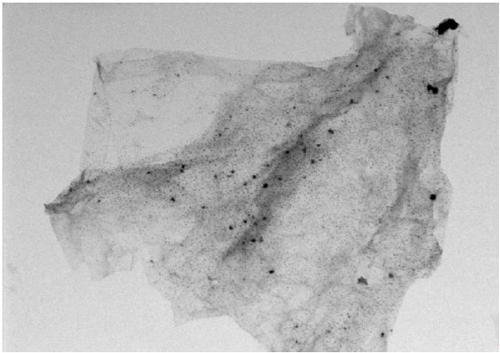

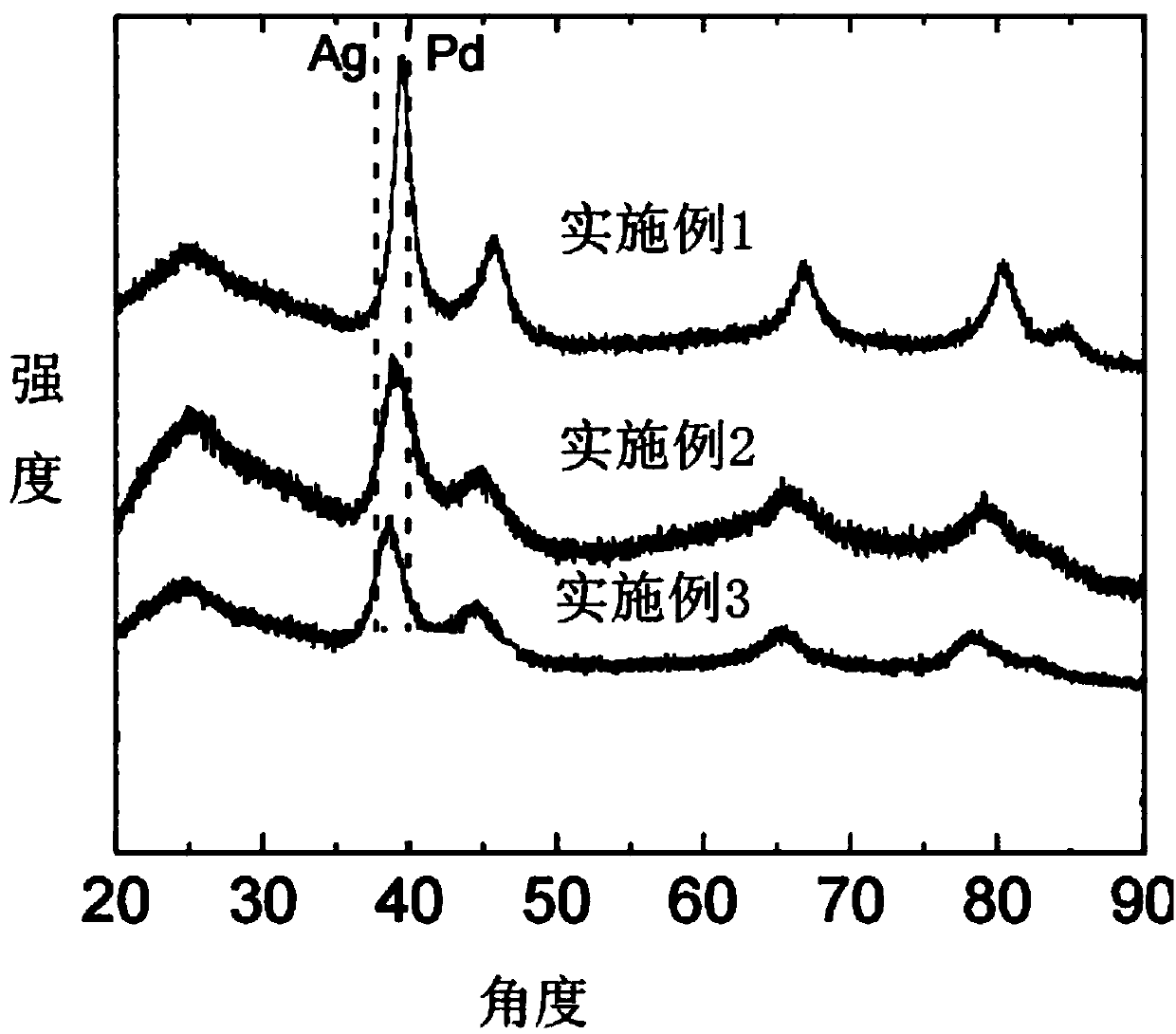

A composite material and graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation methods and high energy consumption, and achieve the effects of high phase purity, uniform dispersion and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, graphene oxide loaded silver-palladium composite material is realized according to the following steps:

[0032] (1) Weigh 1g of tetrachloroalloy acid, 1g of palladium nitrate and 1g of graphene oxide, dissolve them in 50ml of ethylene glycol in the order of tetrachloroalloy acid, palladium nitrate and graphene oxide, and then transfer the mixed solution to a special beaker placed in an ultrasonic instrument for ultrasonic treatment, with an ultrasonic power of 50 Hz and an ultrasonic time of 15 min, to obtain a mixed solution;

[0033] (2) Transfer the mixed solution obtained in step (1) to a sealed beaker, and then place the beaker in a water bath for water bath treatment. The temperature of the water bath treatment is 60 ° C, the reaction time is 3 hours, and magnetic stirring is maintained during the treatment process. , the magnetic stirring speed is 250rpm;

[0034] (3) The hydrothermal reaction product obtained in step (2) is subjected...

Embodiment 2

[0037] In this embodiment, the graphene oxide-loaded silver-palladium composite material is realized by the following steps:

[0038] (1) Weigh 1g palladium nitrate, 1.1g tetrachloroalloy acid and 1.2g graphene oxide, dissolve them in 45ml ethanol in the order of palladium nitrate, tetrachloroalloy acid and graphene oxide, then transfer the mixed solution to a special beaker placed in an ultrasonic instrument for ultrasonic treatment, the ultrasonic power is 50 Hz, and the ultrasonic time is 15 min, that is, the prepared mixed solution is dissolved in the solvent;

[0039] (2) Transfer the mixed solution obtained in step (1) to a sealed beaker, and then place the beaker in a water bath box for water bath treatment. The water bath treatment temperature is 70 ° C, the reaction time is 10 h, and magnetic stirring is maintained during the treatment process. , the magnetic stirring speed is 300rpm;

[0040] (3) The hydrothermal reaction product obtained in step (2) is centrifugall...

Embodiment 3

[0043] In this embodiment, the graphene oxide-loaded silver-palladium composite material is realized by the following steps:

[0044] (1) Take by weighing 1g palladium nitrate, 4g tetrachloroalloy acid and 8g graphene oxide, dissolve in the order of palladium nitrate, tetrachloroalloy acid and graphene oxide in 100ml ethanol, then transfer the mixed solution to a special beaker, Put it in an ultrasonic instrument for ultrasonic treatment, the ultrasonic power is 50Hz, and the ultrasonic time is 15min-25min, and the mixed solution is obtained;

[0045] (2) Transfer the mixed solution obtained in step (1) to a sealed beaker, and then place the beaker in a water bath for water bath treatment. The temperature of the water bath treatment is 80 ° C, and the reaction time is 14 hours. During the treatment, magnetic stirring is always maintained , the magnetic stirring speed is 400rpm;

[0046] (3) The hydrothermal reaction product obtained in step (2) is subjected to centrifugal cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com