Device and method for automatically controlling choke feed of conical crusher

A technology of cone crusher and automatic control device, applied in grain processing and other directions, can solve problems such as the influence of experience and responsibility, it is difficult to ensure the control target, and the operation intensity is high, so as to avoid manual manual operation, increase economic benefits, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

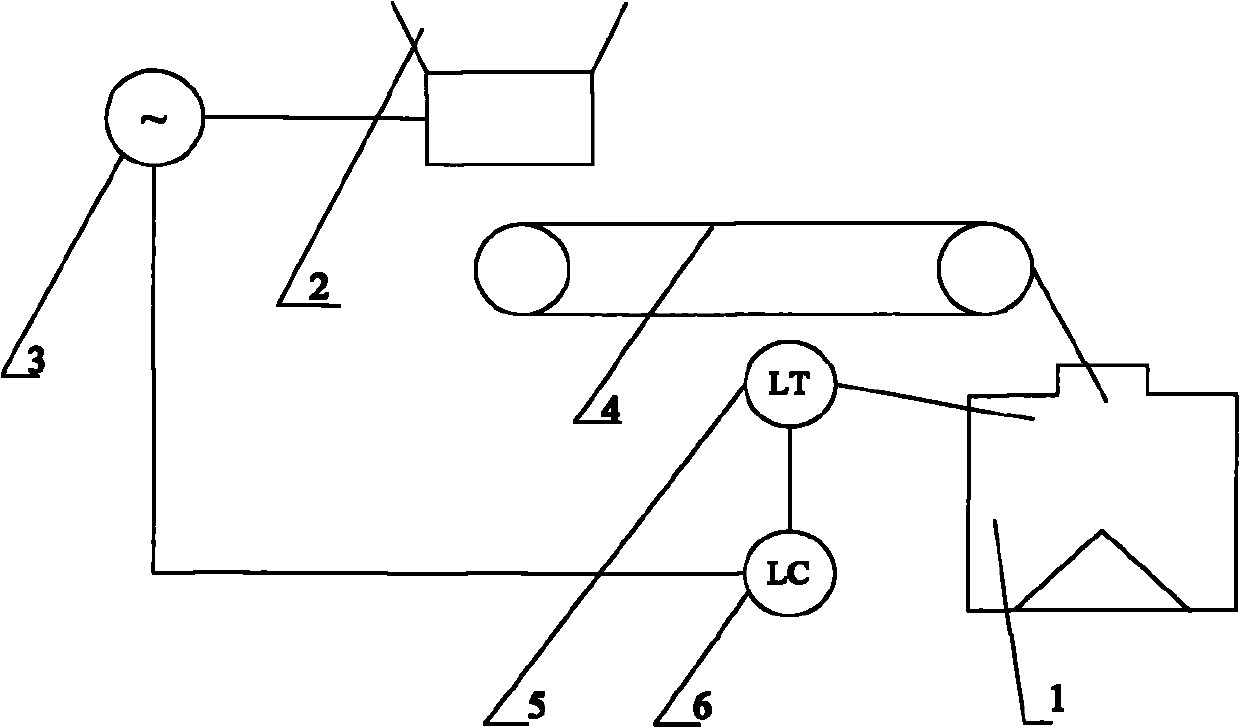

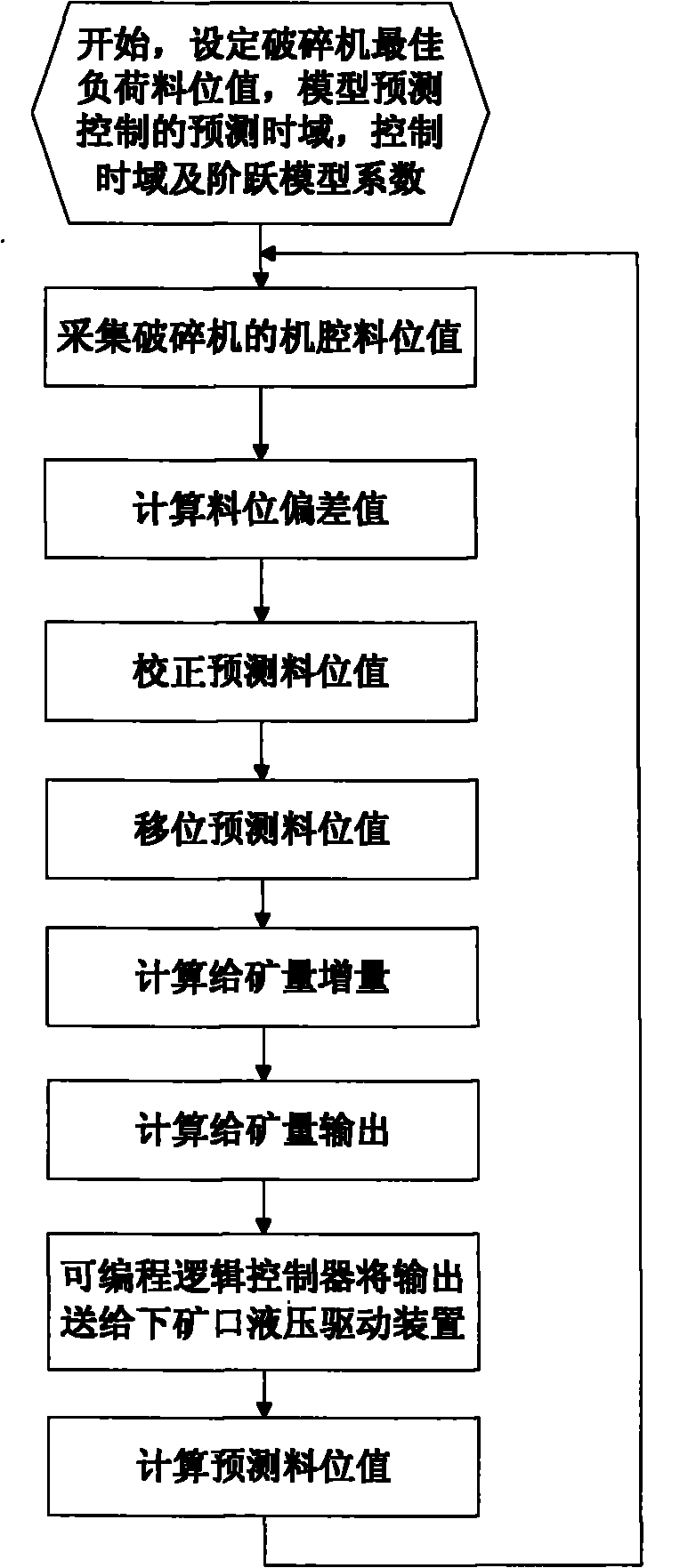

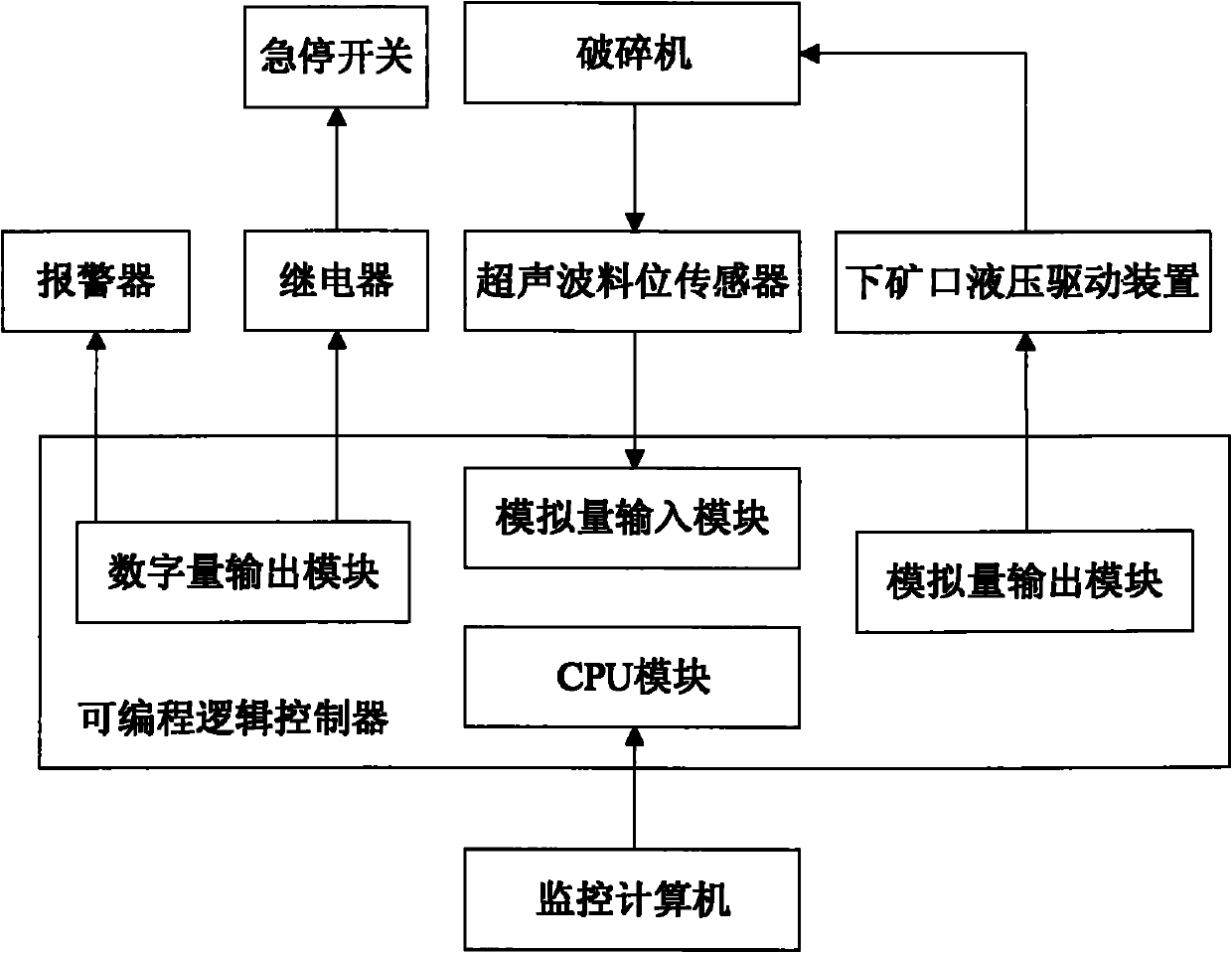

[0030] Such as figure 1 As shown, this embodiment includes a cone crusher 1, an ore bin 2, a hydraulic drive device 3 at the lower ore mouth, a feeding belt 4, an ultrasonic material level sensor 5 and a programmable logic controller 6 (ie, a material level controller), Among them: the ore in the ore bin 2 falls from the ore bin 2, and falls on the ore feeding belt 4 under the action of the hydraulic drive device 3 at the lower ore mouth, and the ore feeding belt 4 transports the ore to the cone crusher 1 for crushing; The level sensor 5 is set on the top of the machine cavity of the crusher 1 to detect the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com