Adjustable furniture dust collecting and polishing machining platform

A processing table and adjustable technology, which is applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of large work table area, no dust removal structure, and difficulty in meeting the requirements, and achieve a high degree of automation, convenient adjustment, labor saving, and easy movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

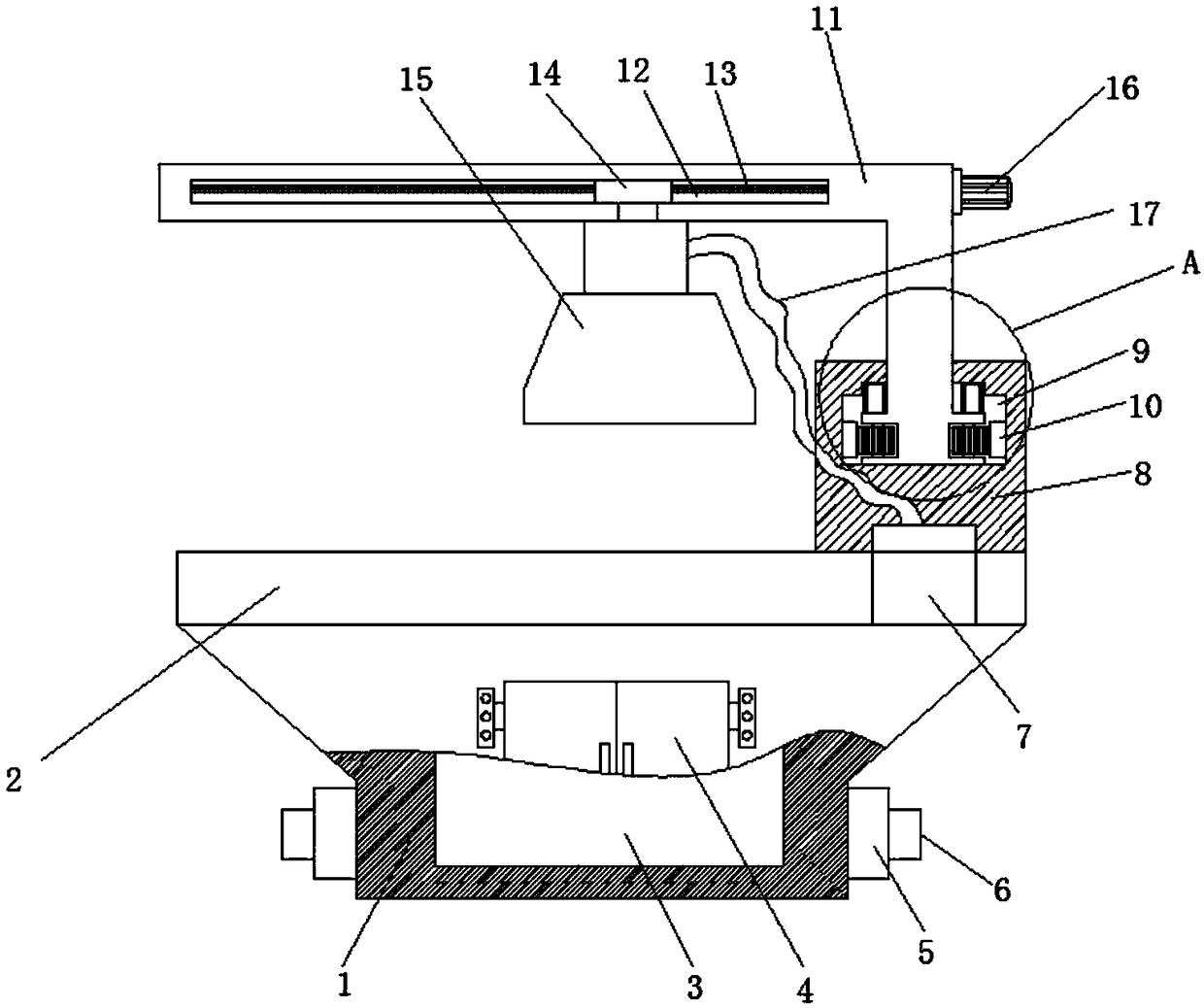

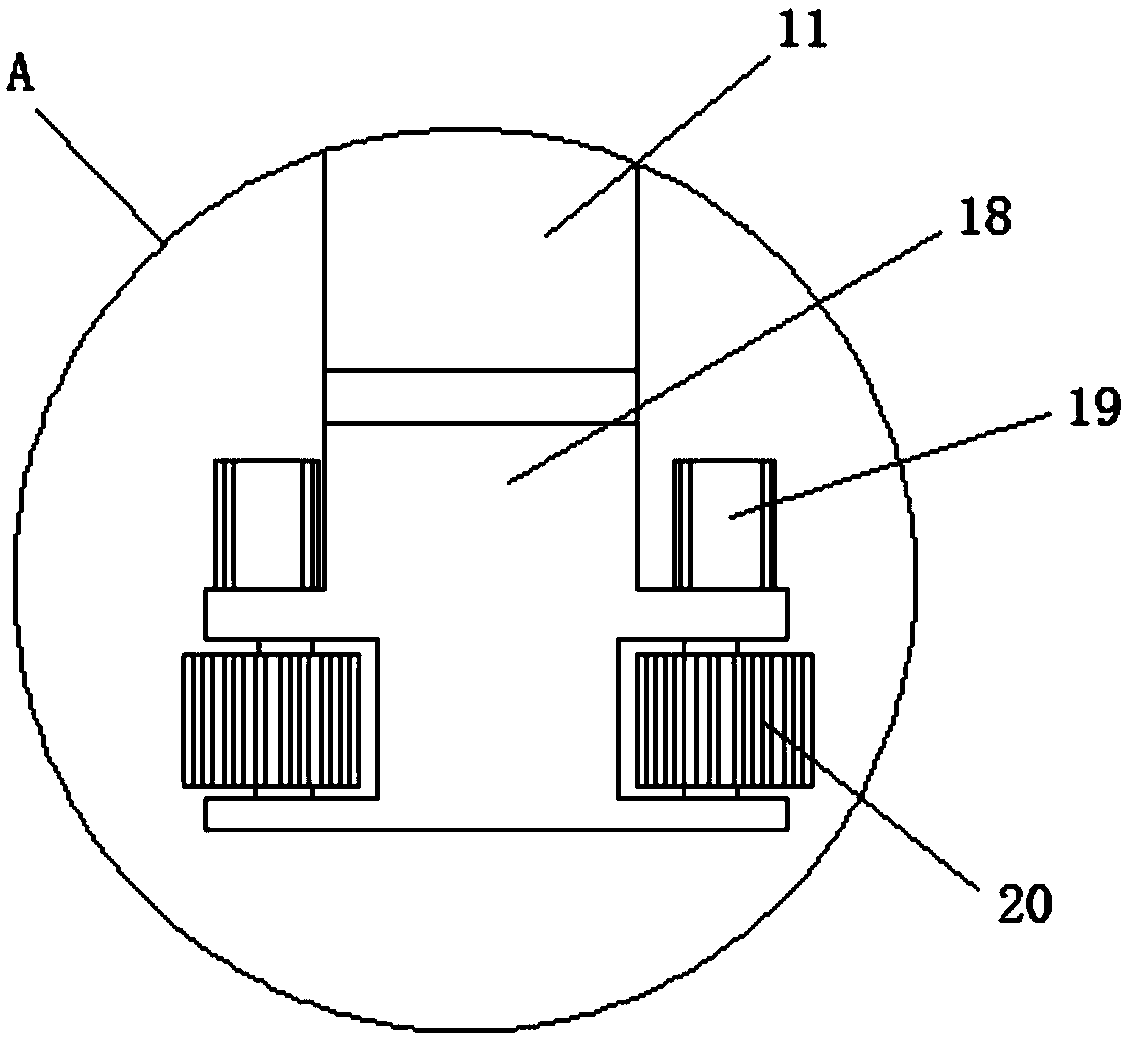

[0025] Embodiment one: refer to Figure 1-4 , an adjustable furniture vacuuming and polishing processing table, including a processing table 2, a base 1 is arranged at the bottom of the processing table 2, and a dust collection box 3 is embedded inside the base 1, and one side of the upper surface of the processing table 1 along the length direction A slide rail 8 is welded on the side, and the upper surface of the slide rail 8 is provided with a chute 9, and racks 10 are embedded on both sides of the inside of the chute 9, and the inside of the chute 9 is slidably connected with a sliding seat 18, and the sliding seat 18 An L-shaped fixed mount 11 is welded on the top, and the center of the horizontal arm of the L-shaped fixed mount 11 is provided with a first bar-shaped groove 12, and the inner rotation of the first bar-shaped groove 12 is connected with a lead screw 13, and a lead screw 13 is fixed on the lead screw 13. Nut 14, the bottom end of nut 14 is fixed with dust co...

Embodiment 2

[0026] Embodiment two: refer to figure 1 The cross section of the dust collection hood 15 is a conical structure, and the inside of the dust collection hood 15 is fixed with a suction fan, and the dust collection hood 15 is conductively connected with the dust collection box 3 through the first conduit 7 and the second conduit 17, wherein the first The conduit 7 is arranged on the processing table 2, and the first conduit 7 runs through the processing table 2 and is connected to the dust box 3, and the second conduit 17 is used to connect the first conduit 7 to the dust collection hood 15, and the suction fan generates suction The dust and waste chips produced by the furniture processing on the processing table 2 are sucked by the suction hood 15, and then discharged into the dust box 3 through the first conduit 7 and the second conduit 17 for collection.

Embodiment 3

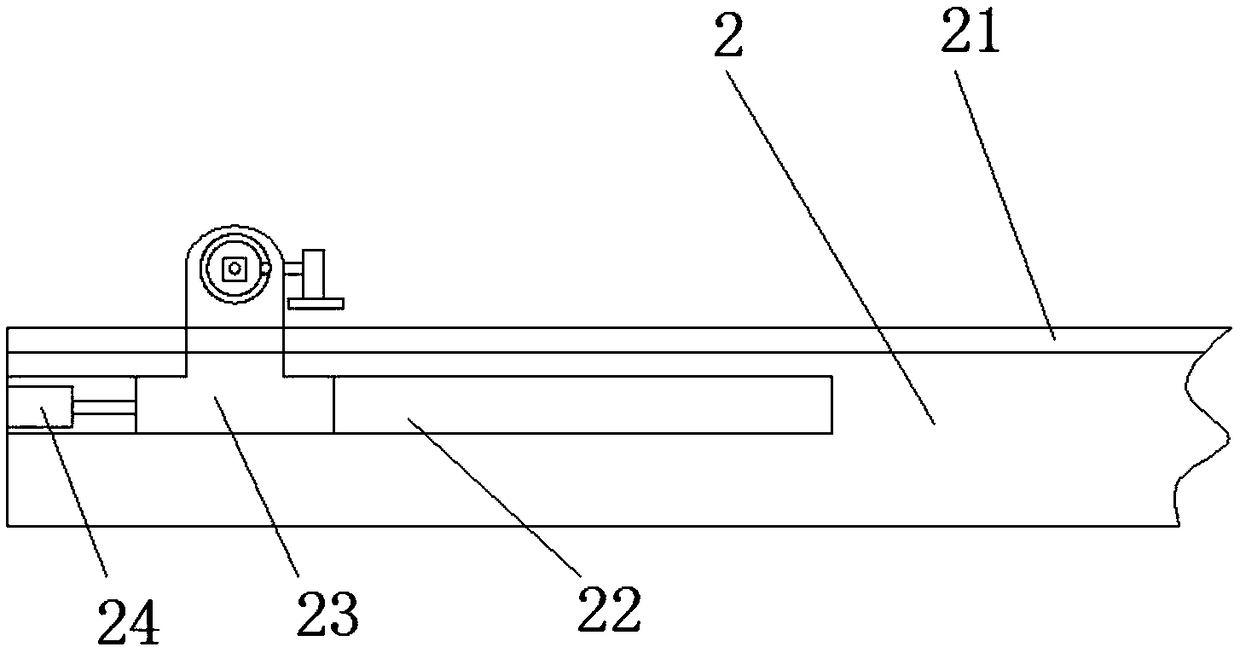

[0027] Embodiment three: refer to figure 1 and image 3 The surface wall on one side of the base 1 is connected with a sealed door 4 by hinge rotation, and the corner of the sealed door 4 is embedded with a gasket, and the surface wall on one side of the dust collection box 3 is connected with an exhaust pipe 6 that runs through the base 1. And the exhaust pipe 6 is fixed with a filter 5, and the sealing gasket is used to improve the sealing performance of the airtight door 4, and the airtight door 4 is arranged to facilitate the cleaning of the dust box 3 inside the base 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com