Full-automatic safety cock for press

A technology of safety bolts and presses, which is applied in the field of presses, can solve the problems of easy toppling of safety bolts, low efficiency, poor operability, etc., and achieve the effects of high safety, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

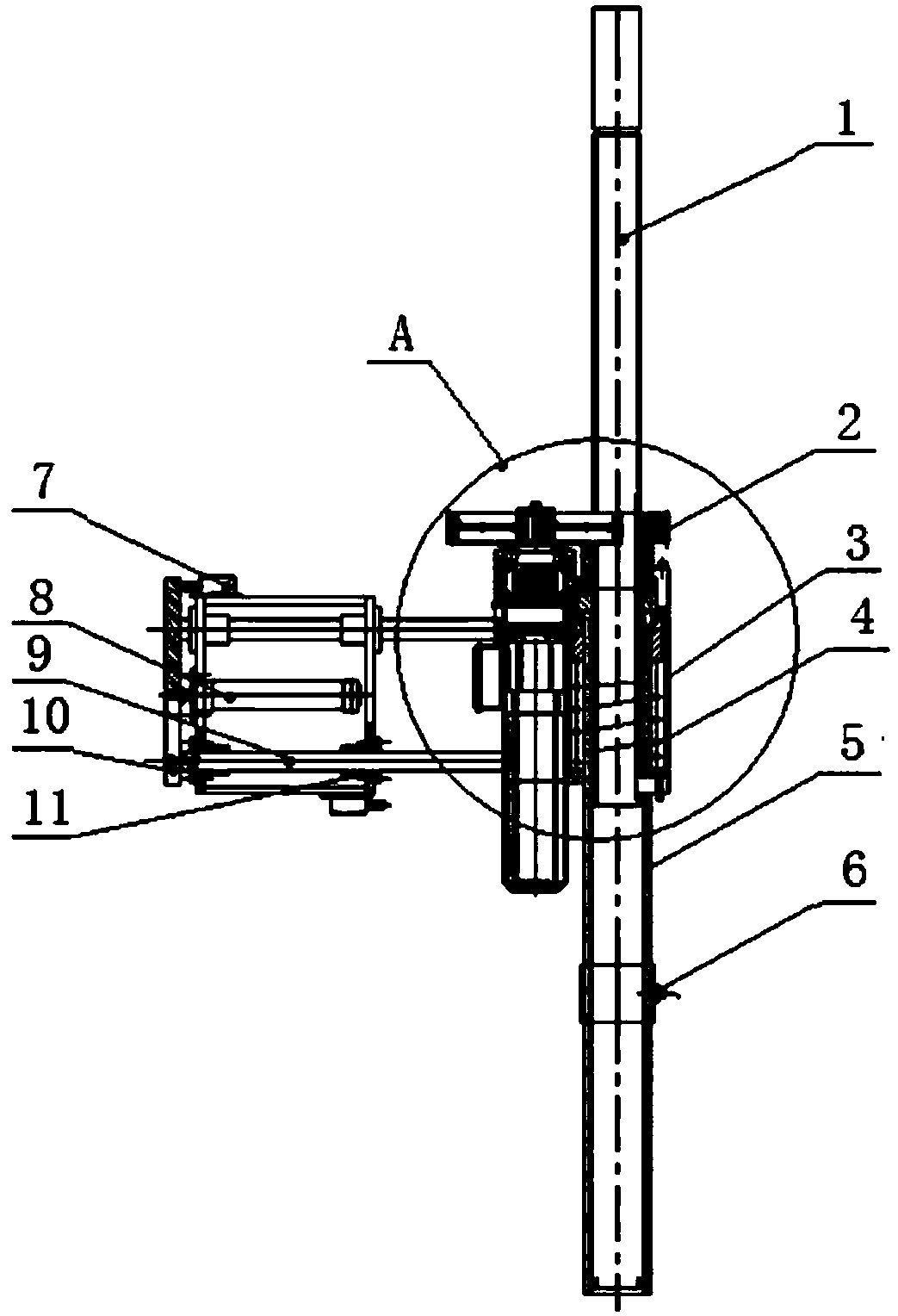

[0017] Figure 1a Shown is a schematic front view of the structure of the present invention.

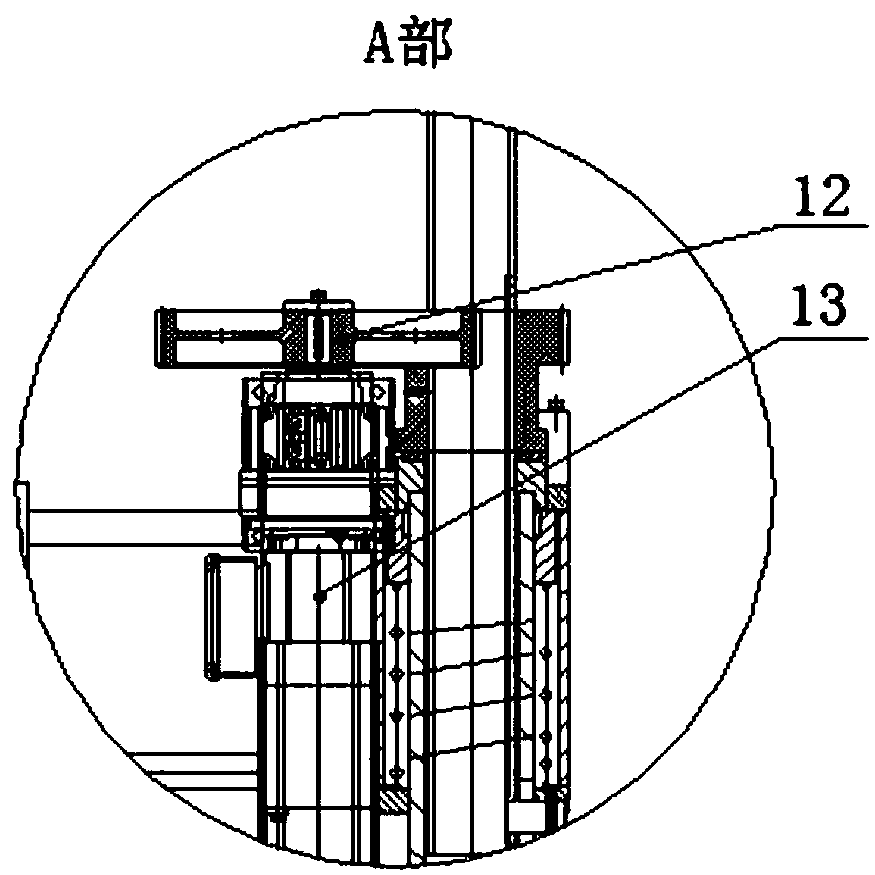

[0018] Figure 1b Shown is the invention Figure 1a The partially enlarged schematic diagram of part A.

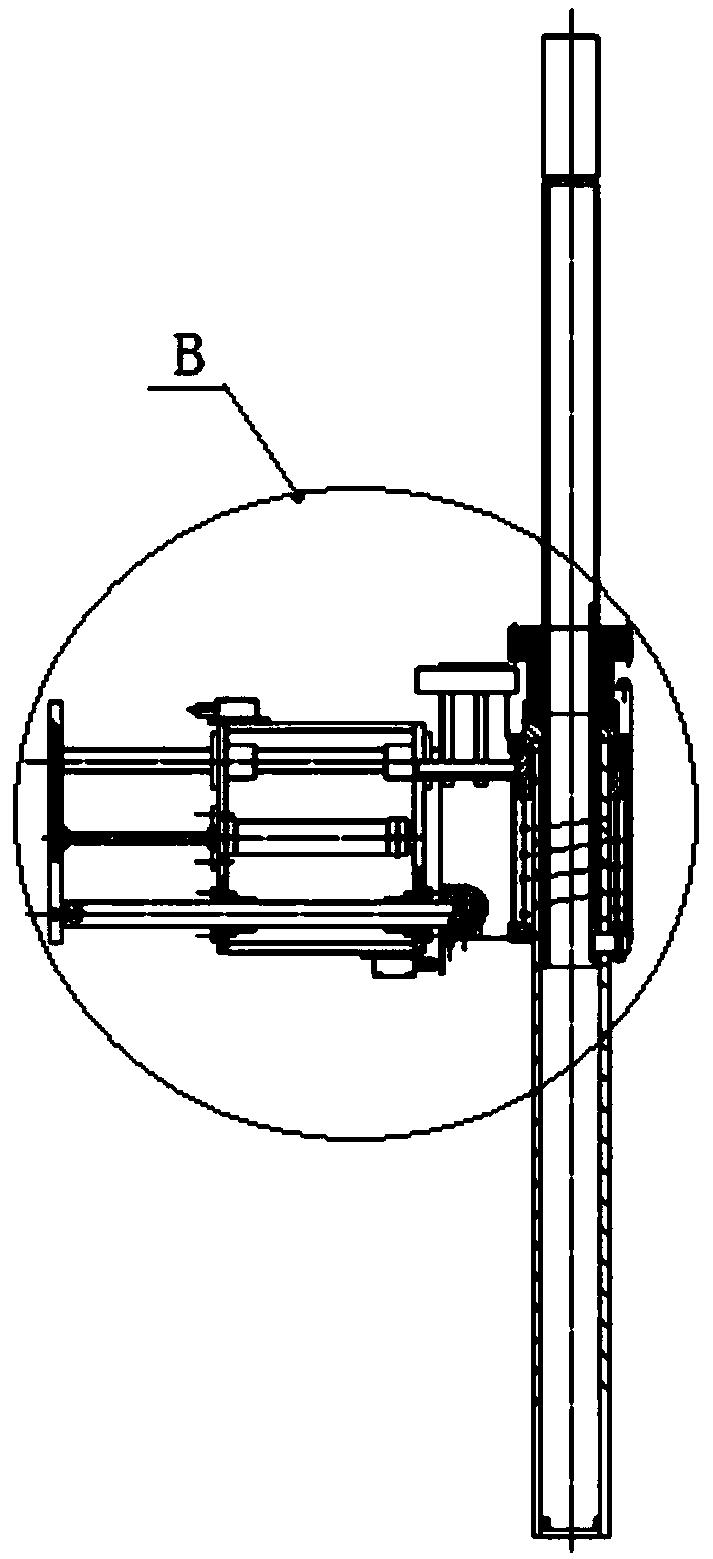

[0019] The invention provides a fully automatic safety bolt for a press, including an adjusting screw 1, a nut 2, a bracket 3, a spring 4, a support rod 5, a proximity switch 6, a limit switch 7, a cylinder 8, a connecting rod 9, and a connecting plate 10. Bearing 11, gear 12, motor 13, pressing block 14, cylinder 15 and support 16.

[0020] Described support 3 has semi-closed cavity, and spring 4, cylinder 15 are put into support 3 cavity, and support bar 5 passes support 3 cavity, and under spring 4 active force, supports support bar 5 by cylinder 15.

[0021] The adjusting screw 1 penetrates into the cavity of the supporting rod 5 and is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com