System and method for adjusting position and angle of optical fiber based on machine vision

An angle adjustment and machine vision technology, which is applied in the direction of instruments, use feedback control, image data processing, etc., can solve problems such as low production efficiency, uncontrollable position, and poor adjustment accuracy, so as to improve production efficiency and adjustment accuracy , to achieve the effect of fully automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

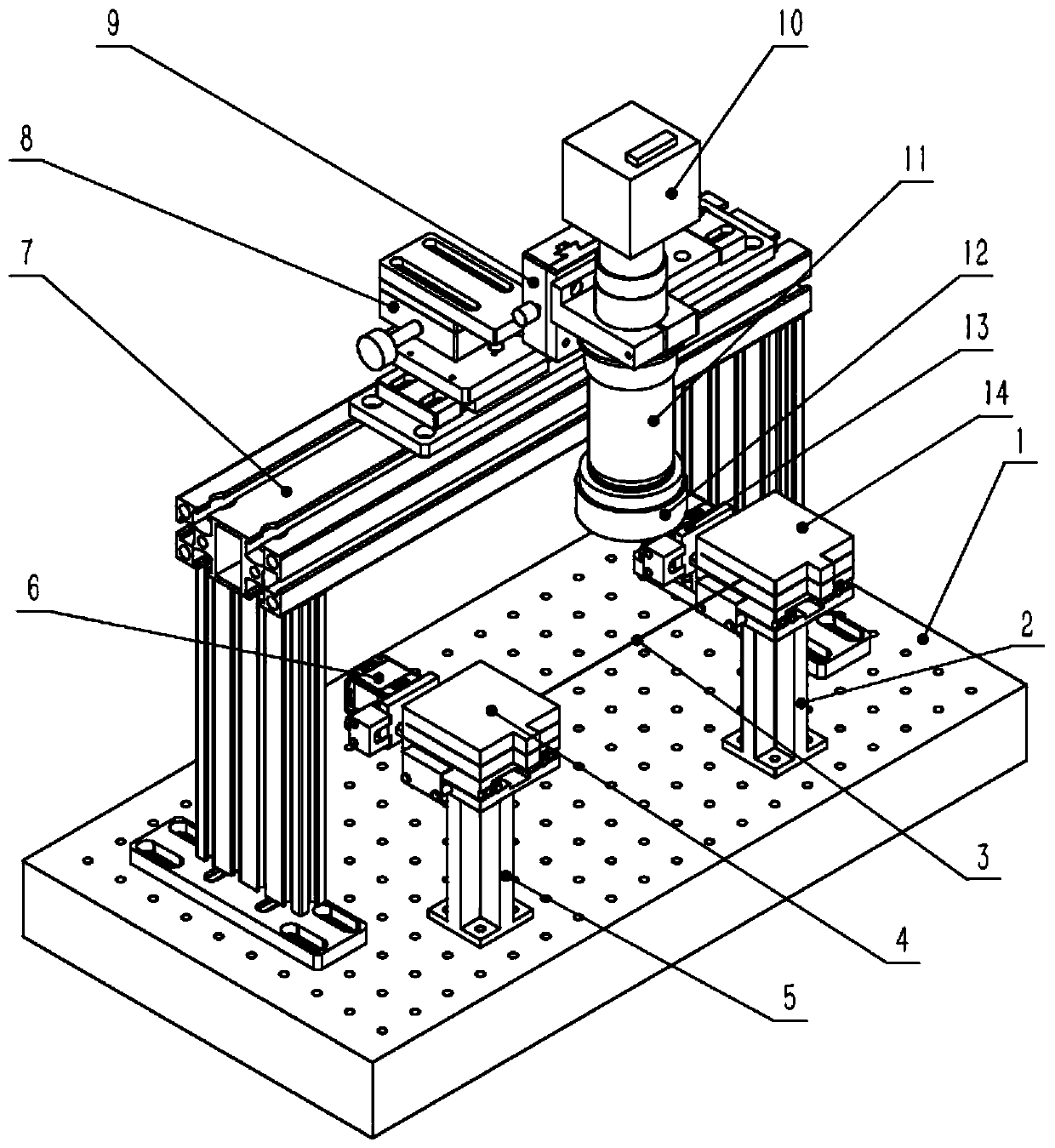

[0024] see figure 1 , this embodiment discloses a system for adjusting the position and angle of an optical fiber based on machine vision, including an industrial computer, an optical platform 1, and a CCD industrial camera 10 for taking images of optical fibers. The CCD industrial camera 10 is installed on the gantry 7 Above, the gantry 7 is installed on the optical platform 1, and the optical platform 1 is fixed with two supporting columns, which are respectively the left supporting column 5 and the right supporting column 2, and the left supporting column 5 is fixed with a left electric translation platform 6. The right electric translation platform 13 is fixed on the right support column 2, and the axis line of the electric shaft on the left electric translation platform 6 is parallel to the axis line of the electric shaft on the right electric translation platform 13 (on the left electric translation platform 6 The power output shaft axis line of the motor is parallel to ...

Embodiment 2

[0045] see Figure 1 to Figure 5 , this embodiment discloses a method for adjusting the position and angle of an optical fiber based on machine vision, including the following steps:

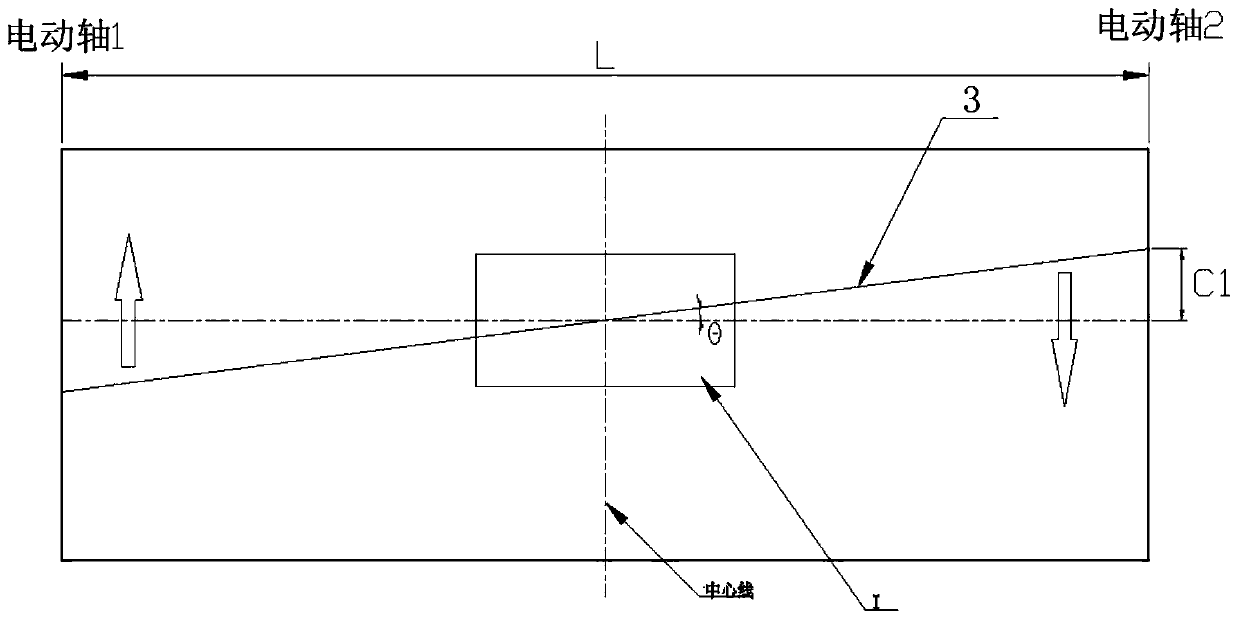

[0046] Obtain the fiber optic image currently captured by the CCD industrial camera, see figure 2 , the horizontal distance between the electric shafts at both ends of the optical fiber is L, the offset angle of the optical fiber center is θ, and the displacement to be adjusted for angle calibration is C1,

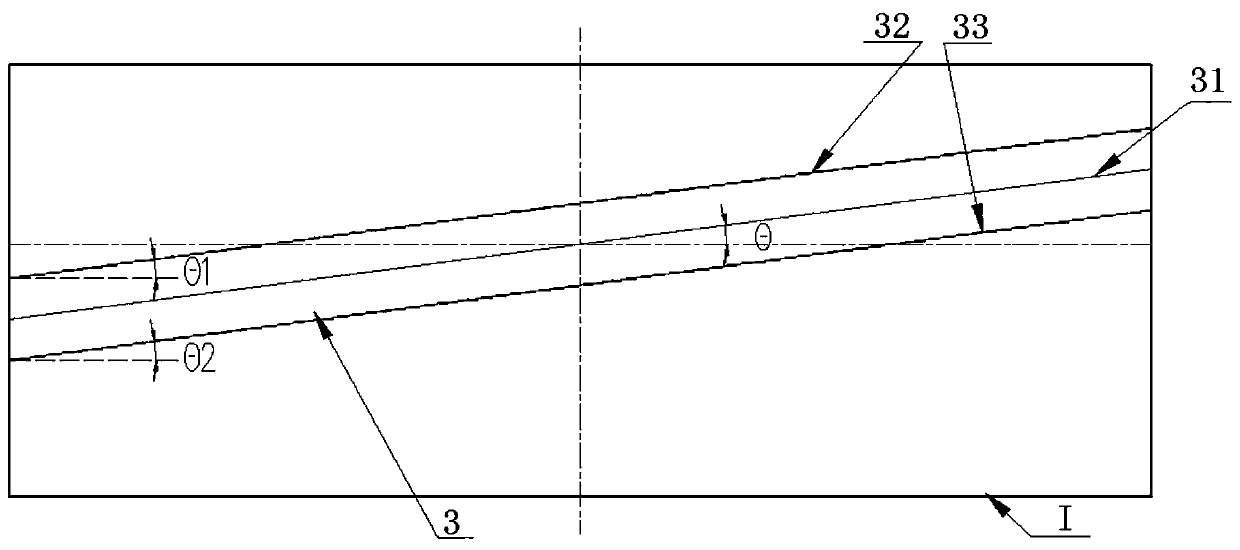

[0047] Adjust the angle so that the fiber angle is within the set target angle accuracy range, specifically including: obtaining the fiber image currently captured by the CCD industrial camera, performing edge detection calculations on the fiber image to obtain the upper and lower edges of the fiber in the camera coordinate system and the X-axis The included angles θ1 and θ2 are further calculated to obtain the current included angle θ between the centerline of the fiber and the X-axis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com