Pressing plate mechanism

A press plate and pressure technology, which is applied in the direction of thin material processing, sending objects, transportation and packaging, etc., can solve the problems of easy crushing and collapsing cardboard, and achieve the effect of adjustable pressure and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

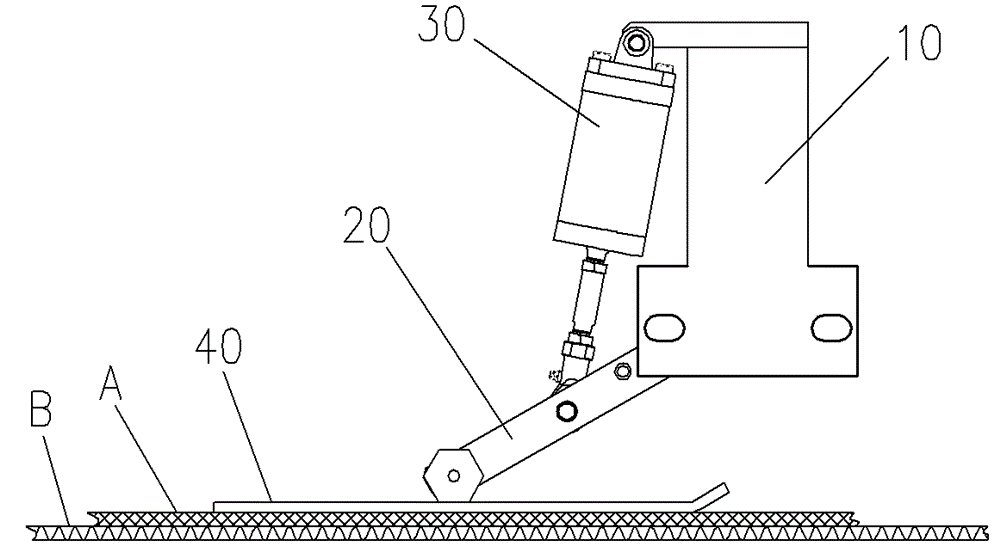

[0010] Such as figure 1 Shown is a preferred specific implementation example of the present invention, a pressing plate mechanism, including a mounting base 10, a rocker arm 20 movably connected to the mounting base 10, and used to drive the rocking arm 20 to swing The cylinder 30 and the pressure plate 40 arranged above the conveyor belt A, wherein, one end of the rocker arm 20 is movably connected to the mounting base 10, and the pressure plate 40 is connected to the other end of the rocker arm 20 At one end, the cylinder 30 is installed on the mounting seat 10, the piston rod 31 of the cylinder 30 is movably connected to the middle position of the rocker arm 20, and the rocker arm 20 is pulled by the expansion and contraction of the piston rod 31. Swing up and down, the pressure plate 40 is transmitted downward pressure by the cylinder 30 through the rocker arm 20, and the pressure plate 40 transmits the pressure to the cardboard B through the conveying belt A, so as to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com