Patents

Literature

40results about How to "Automatic spacing adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

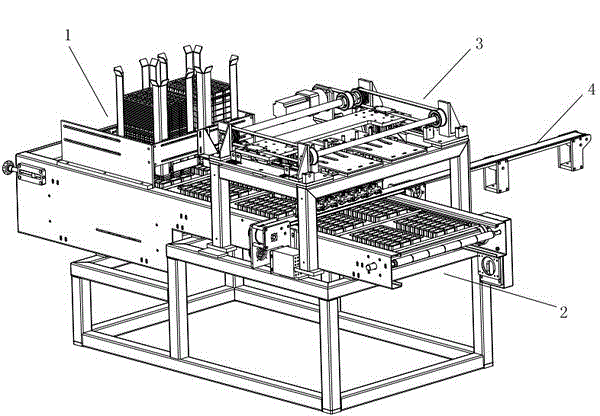

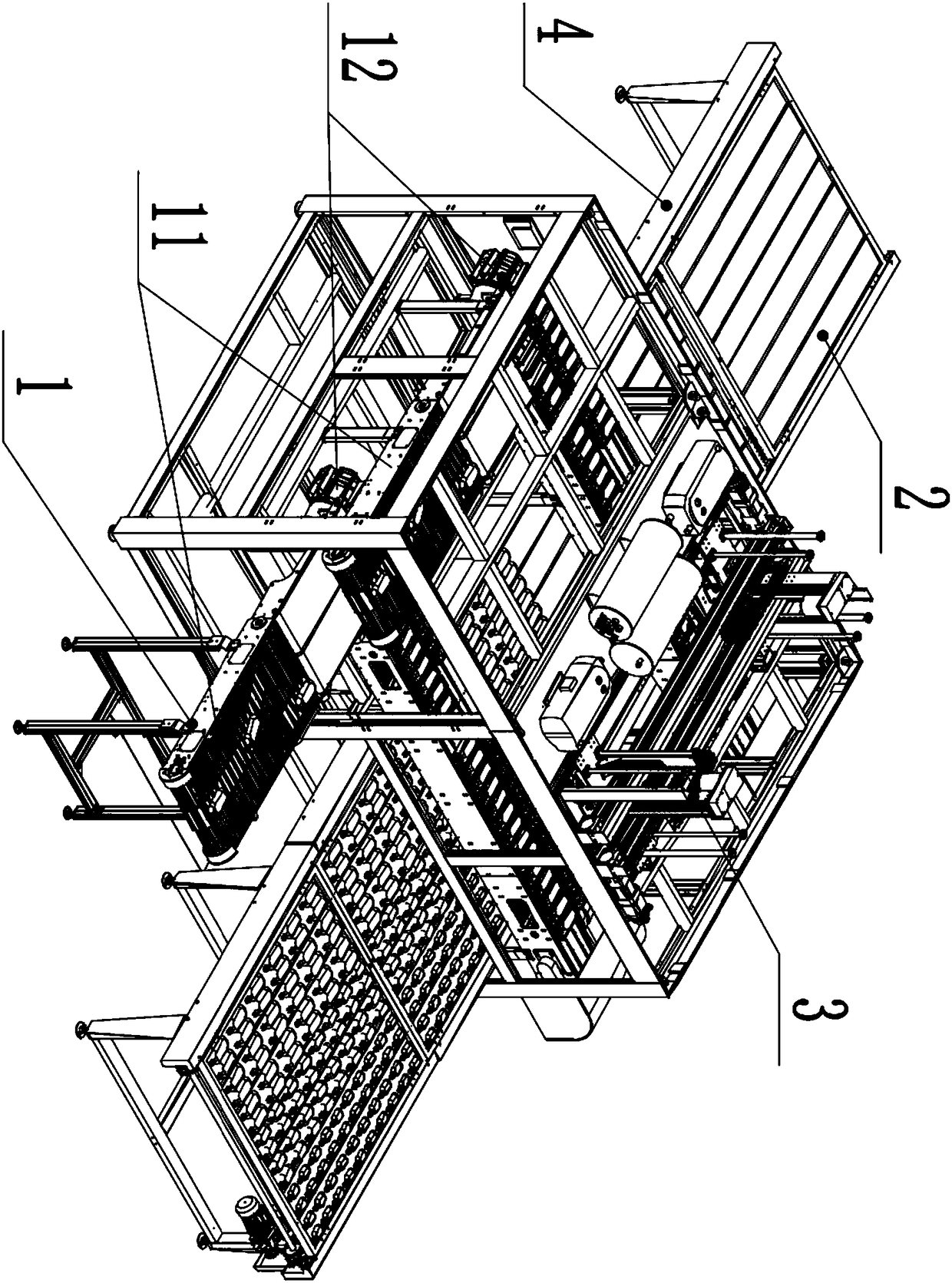

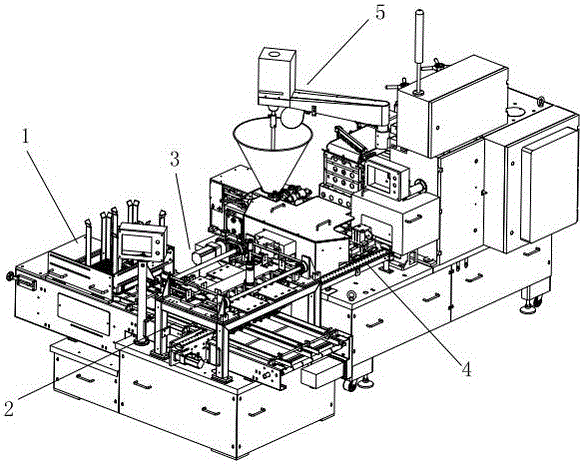

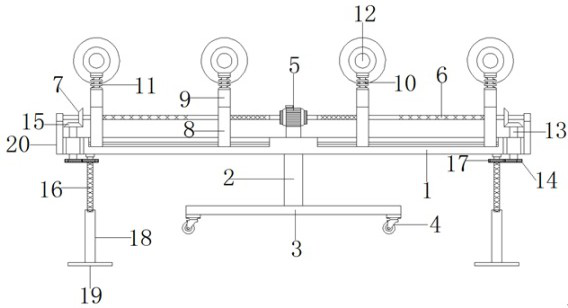

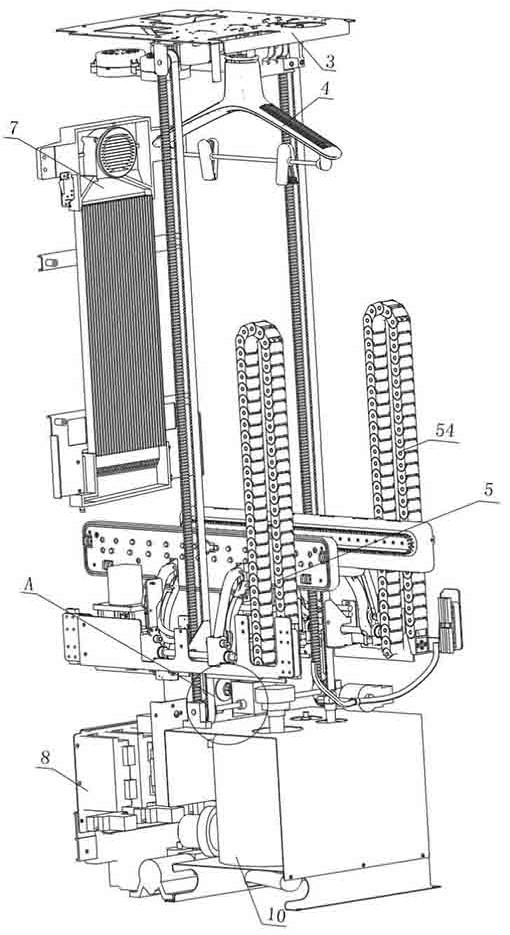

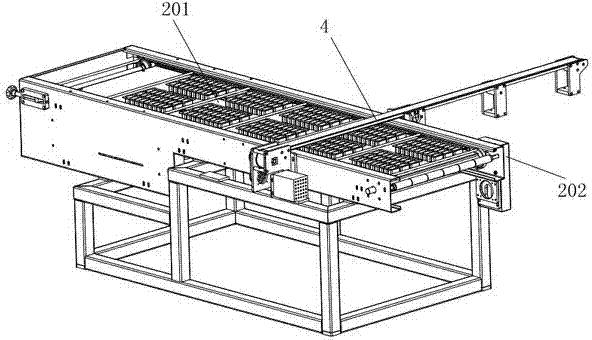

Food boxing machine

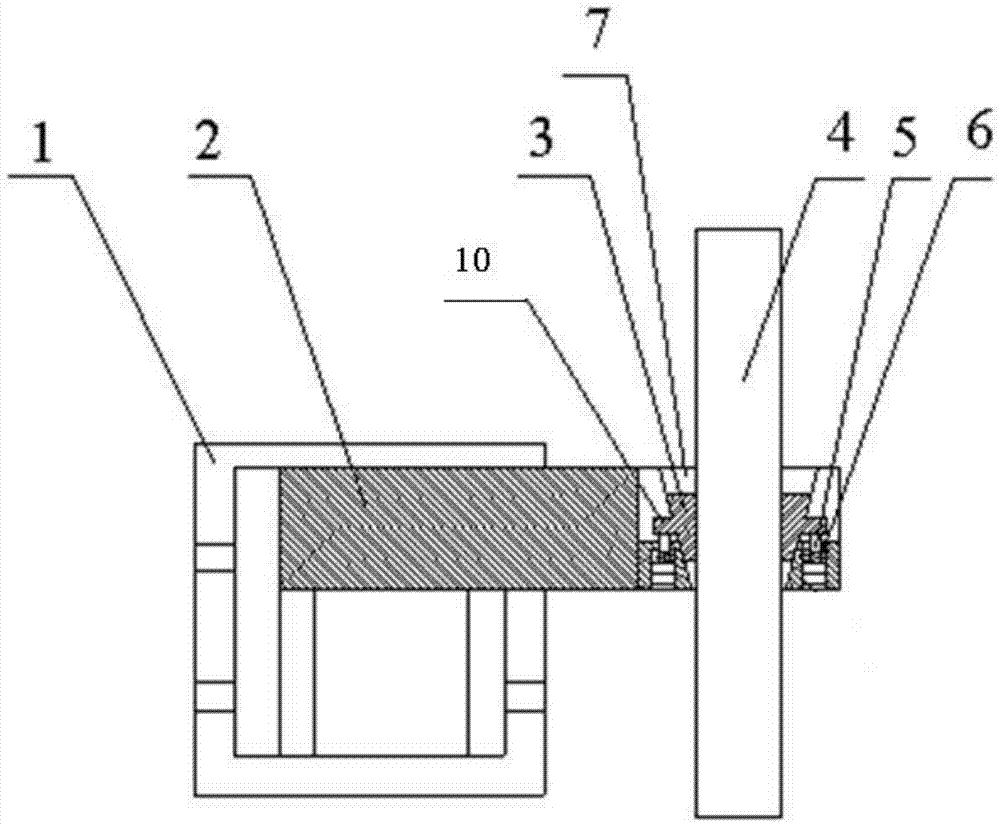

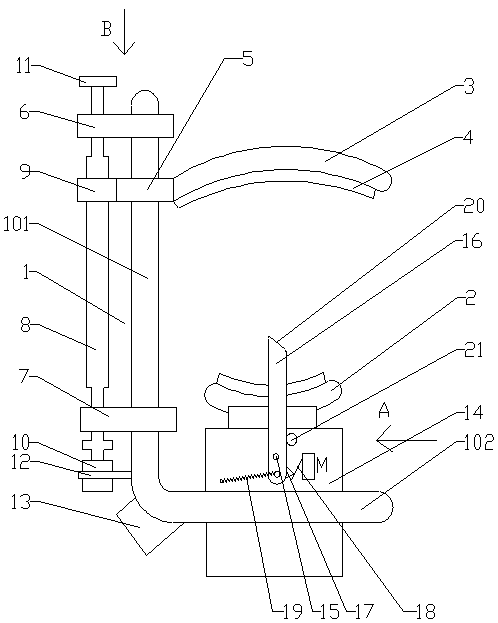

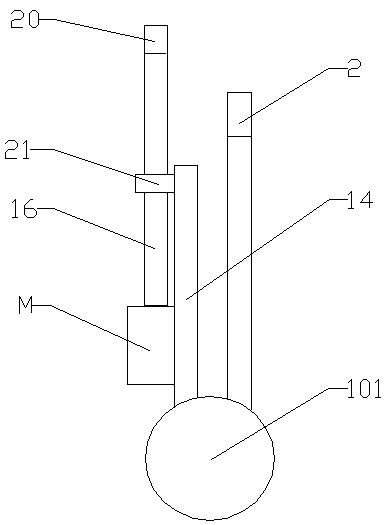

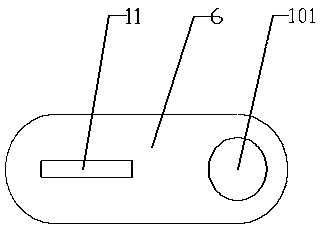

The invention relates to the field of a food processing machine, and particularly relates to a food boxing machine. The food boxing machine comprises a box feeding mechanism, a box arranging transport mechanism and a clamping mechanism, wherein the box feeding mechanism and the clamping mechanism are respectively arranged above the box arranging transport mechanism, the box feeding mechanism is arranged on one end of the clamping mechanism, and one side of the clamping mechanism is provided with a conveyor belt for transporting to-be-arranged food; the clamping mechanism comprises an installation framework, and the installation framework is provided with a plurality of mechanical claws. The movement of the mechanical claws in three directions are realized by utilizing a guide device, a horizontal drive mechanism and a vertical drive mechanism; moreover, the full-automatic adjustment can be realized, and the distance adjustment of the mechanical claws can be automatically realized under the situation that no manpower is needed; the food boxing machine can be suitable for various support boxes in various sizes only by replacing a track plate, the artificial anticipation is eliminated, the production efficiency is improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

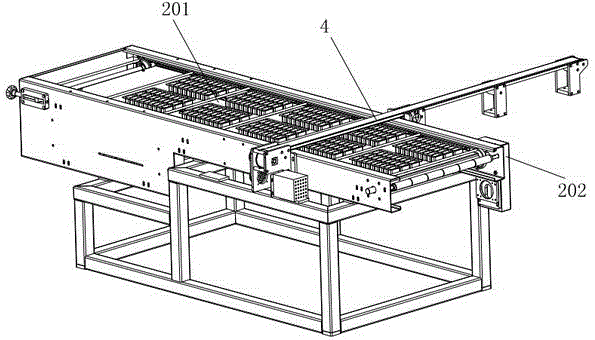

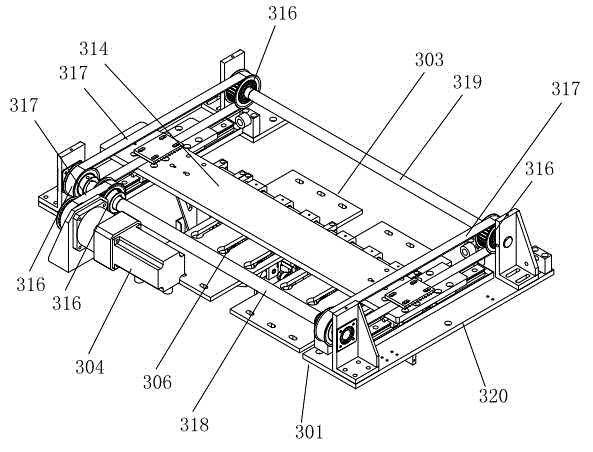

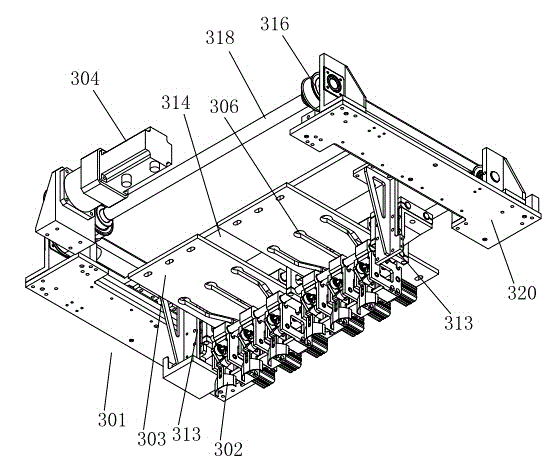

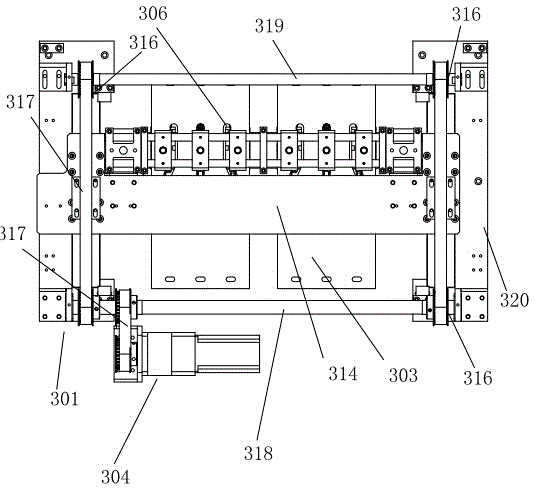

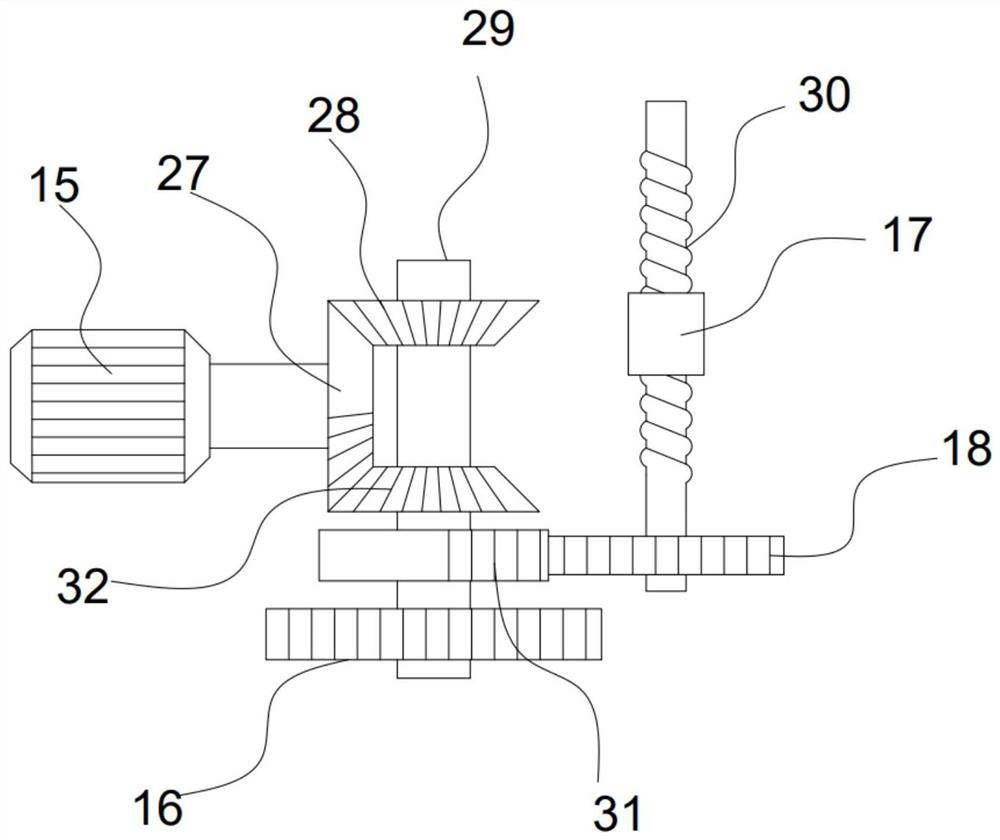

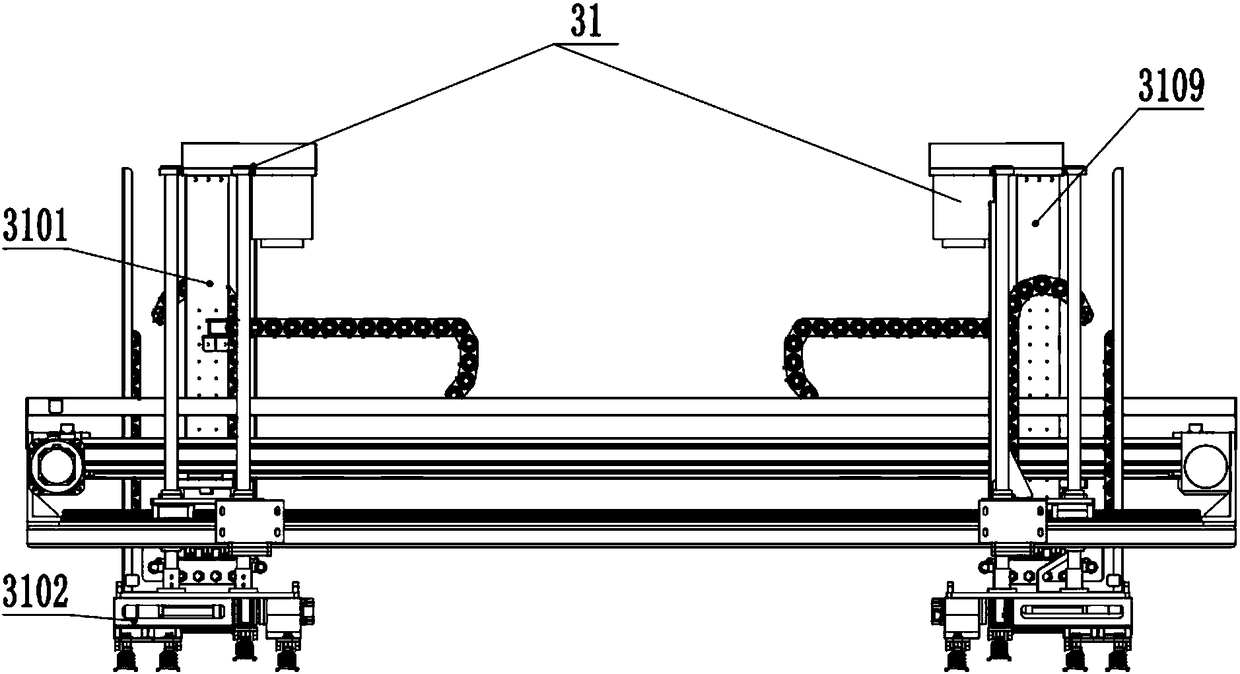

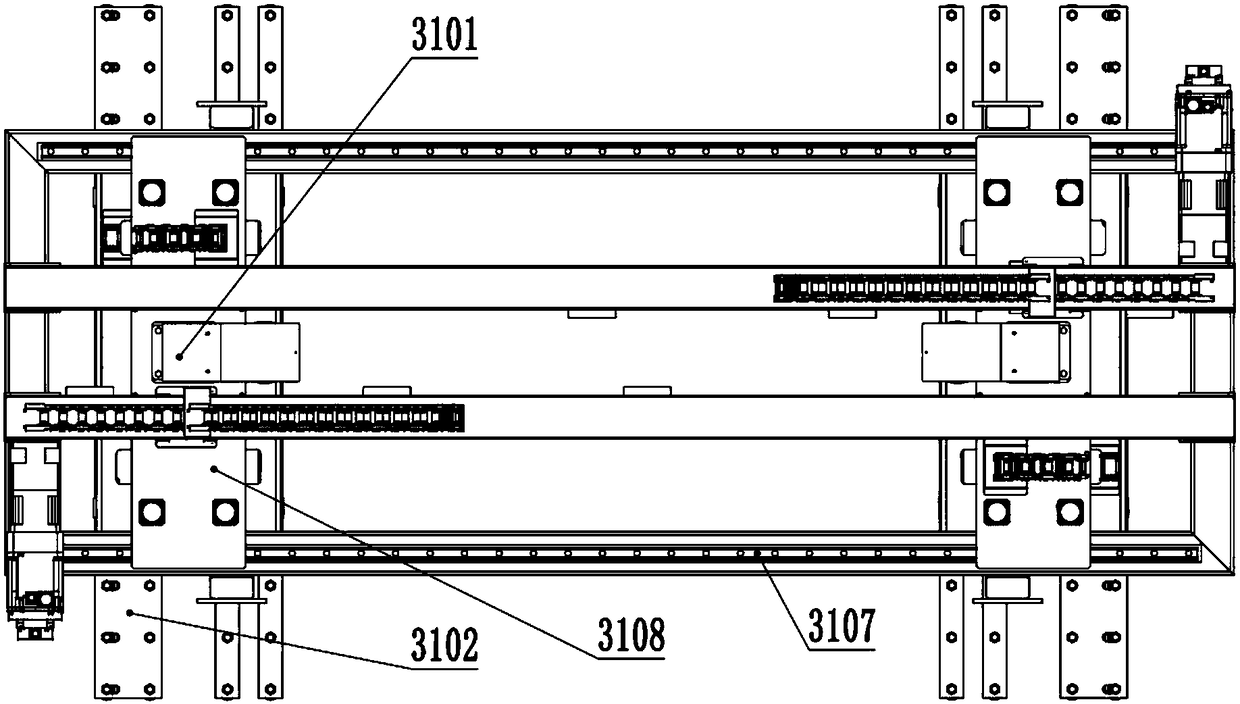

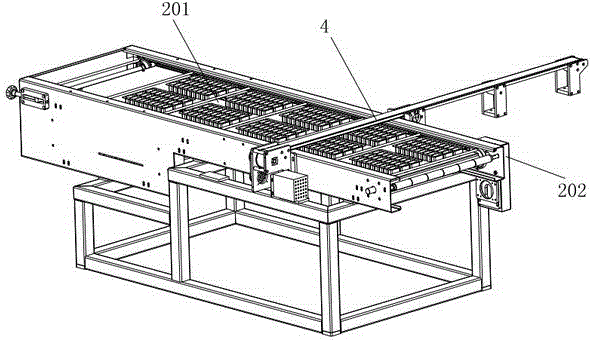

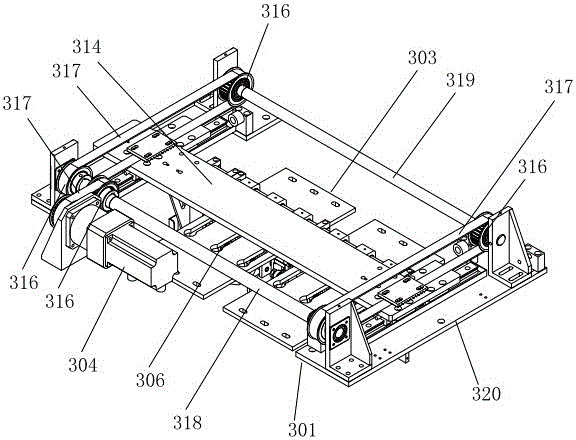

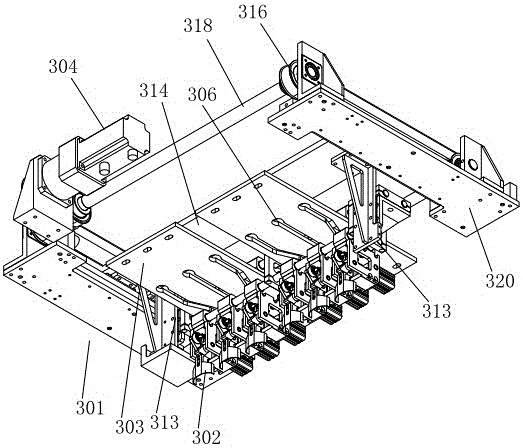

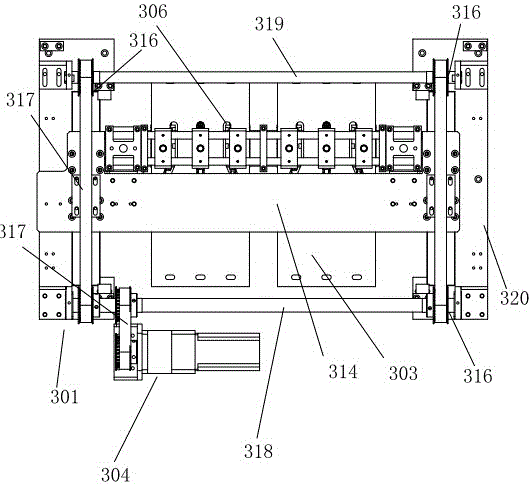

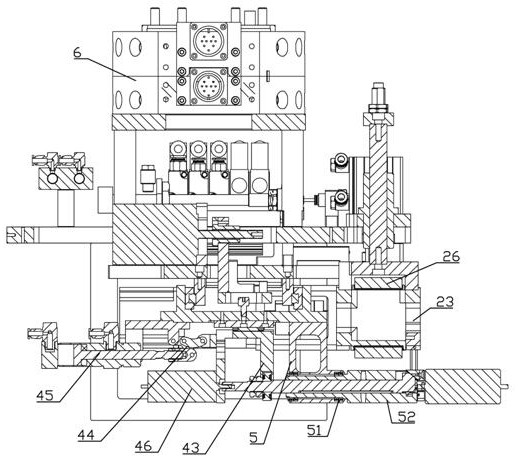

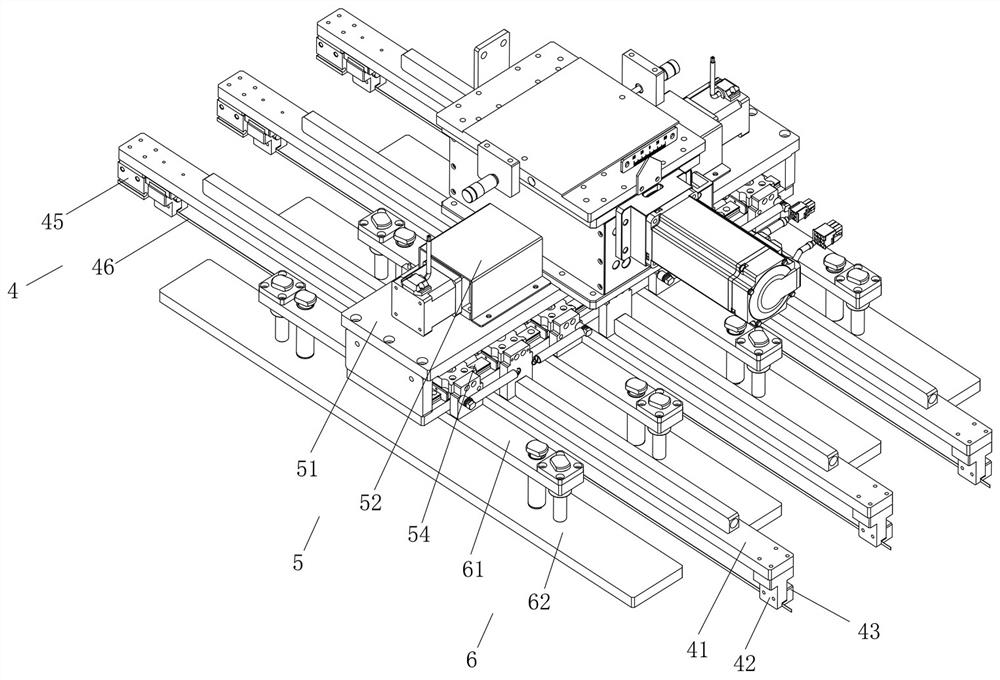

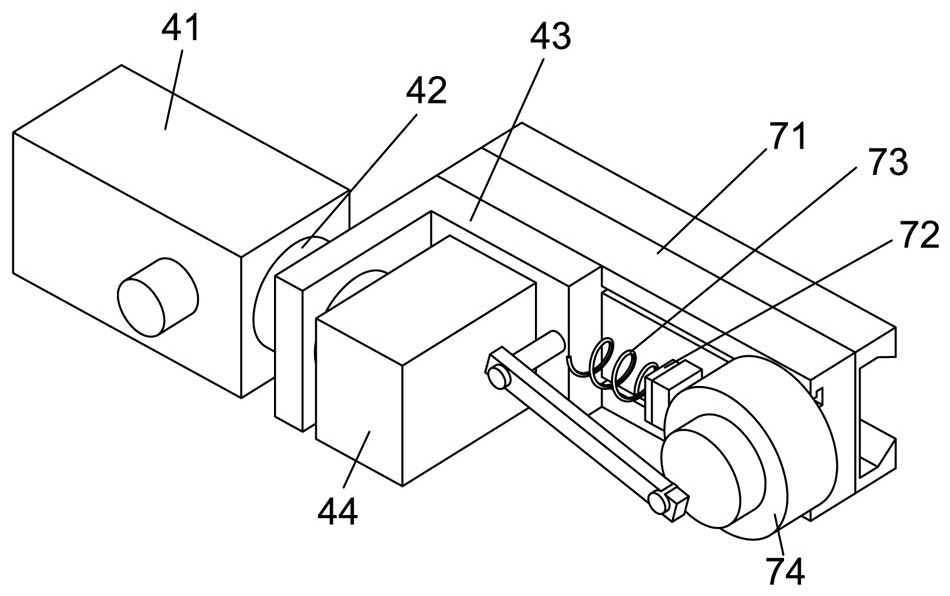

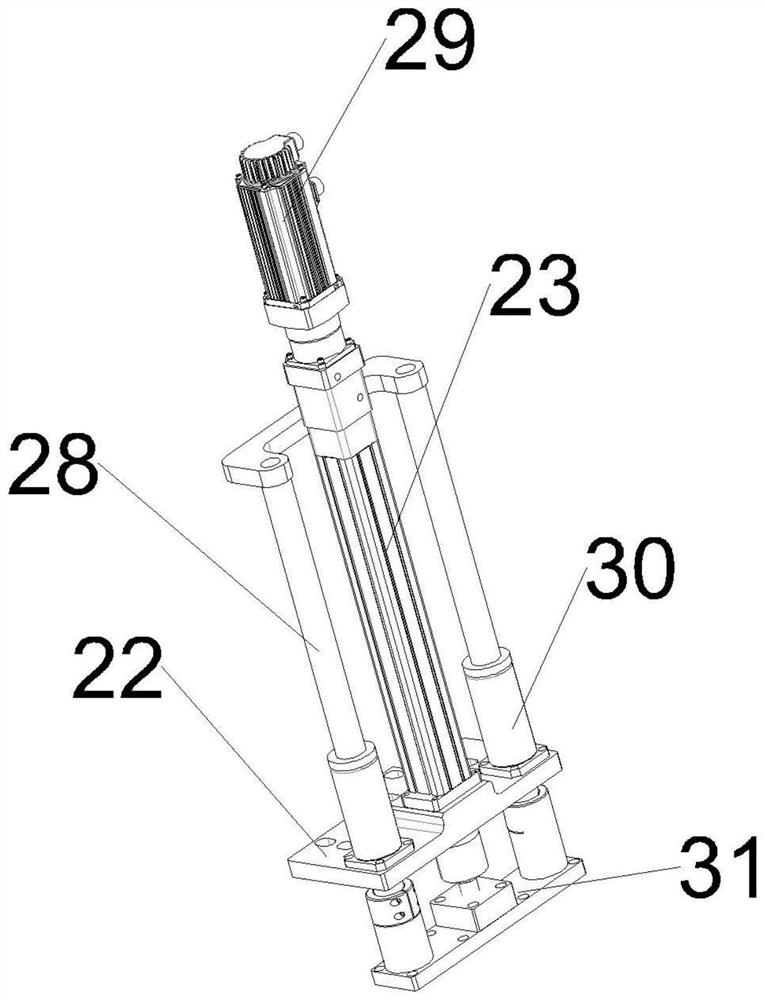

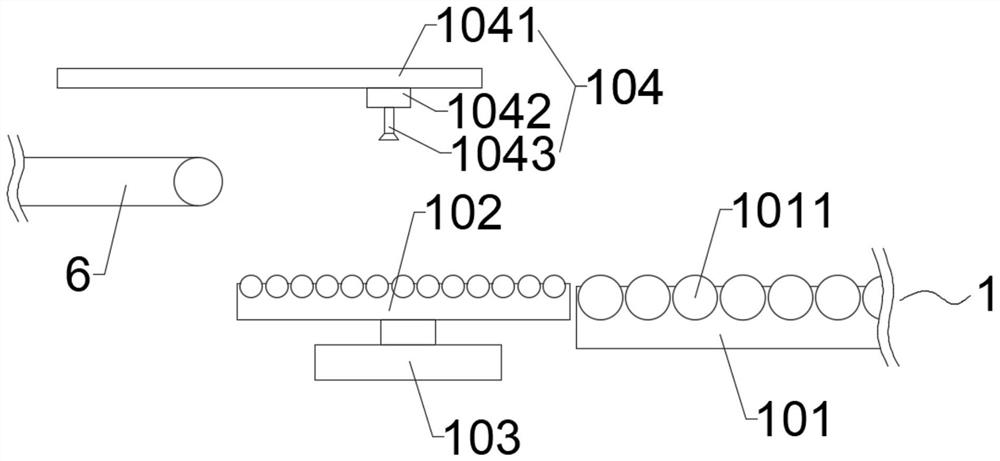

Push-in mechanism of food boxing machine

ActiveCN104803036AAutomatic spacing adjustmentFully automatic adjustmentPackagingEngineeringFood processing

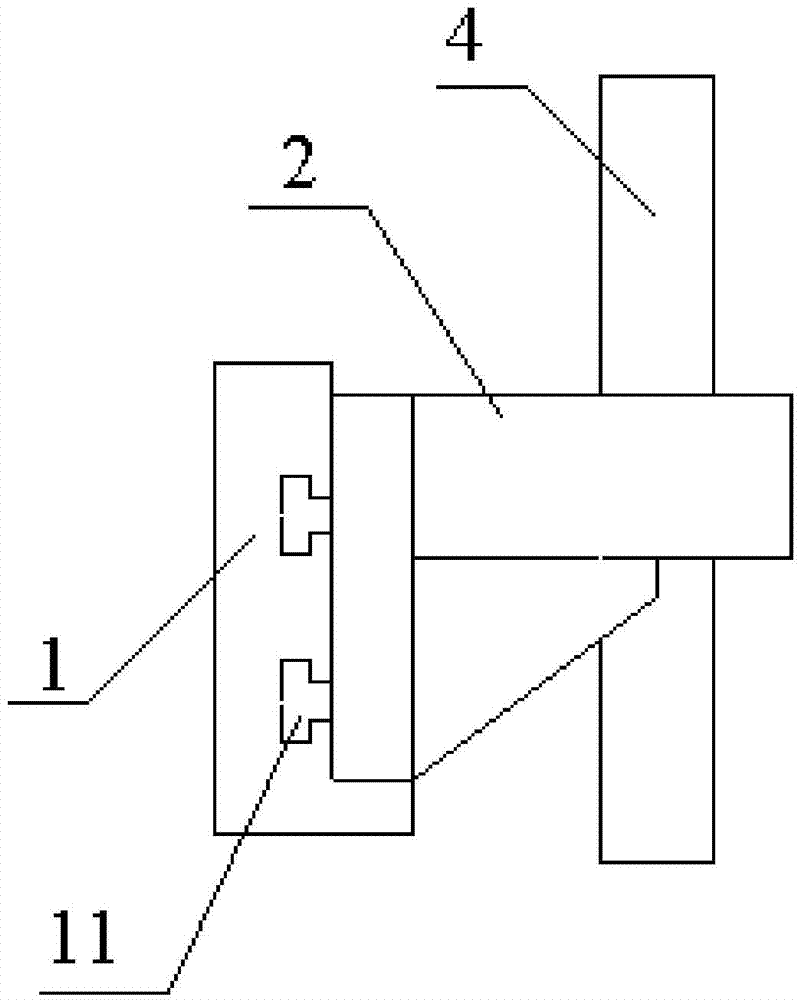

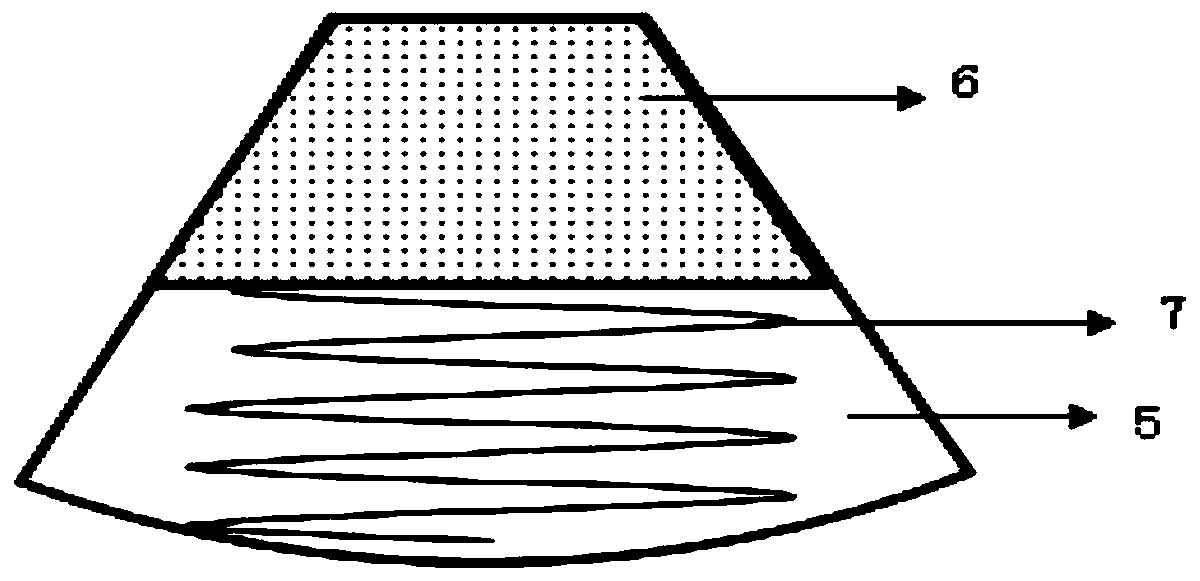

The invention relates to the field of a food processing machine, and particularly relates to a push-in mechanism of a food boxing machine. The push-in mechanism comprises an installation framework, wherein the installation framework comprises a fixed installation plate and a plurality of mechanical push plates which are arranged below the fixed installation plate, the mechanical push plate is provided with a guide device for adjusting the distance between two adjacent mechanical push plates, each mechanical push plate is connected with a horizontal drive mechanism for driving the mechanical push plate to move horizontally, and the fixed installation plate is fixedly provided with the horizontal drive mechanism. The movement of the mechanical push plates in two directions is realized by utilizing the guide device and the horizontal drive mechanism; moreover, the full-automatic adjustment can be realized, the distance adjustment can be automatically realized under the situation that the manpower is not need; the push-in mechanism can be applicable to various support boxes in various sizes only by replacing a track plate, the artificial participation is eliminated, the production efficiency can be improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

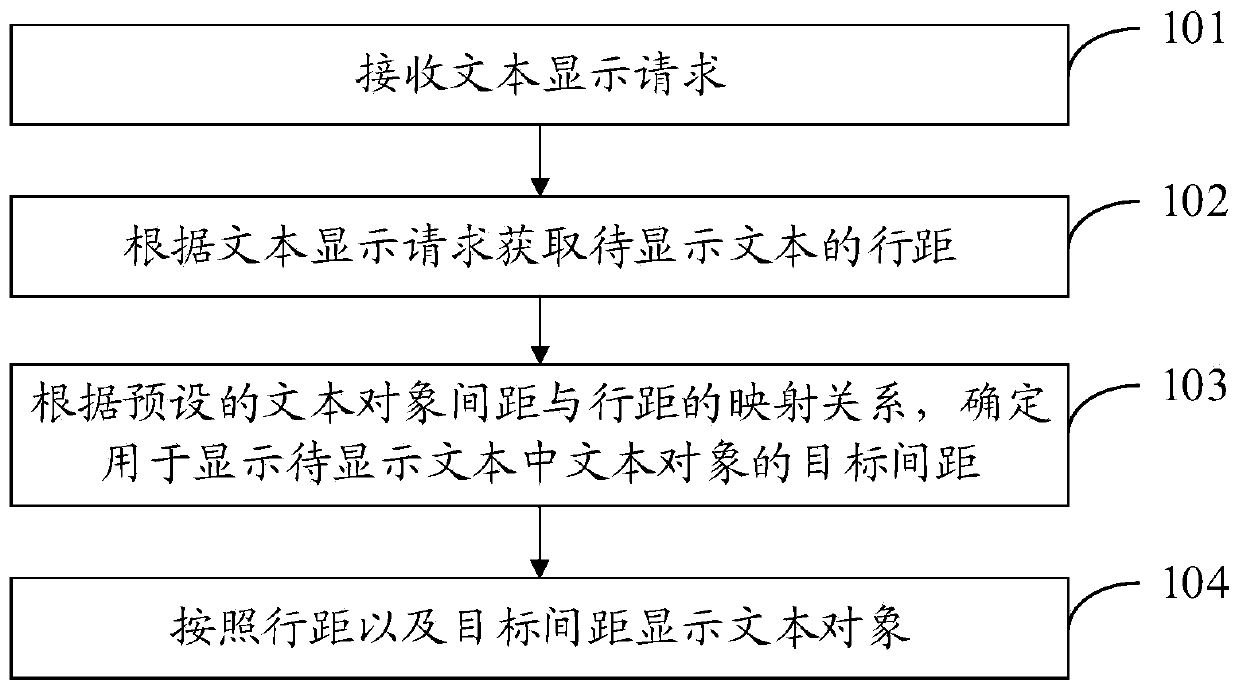

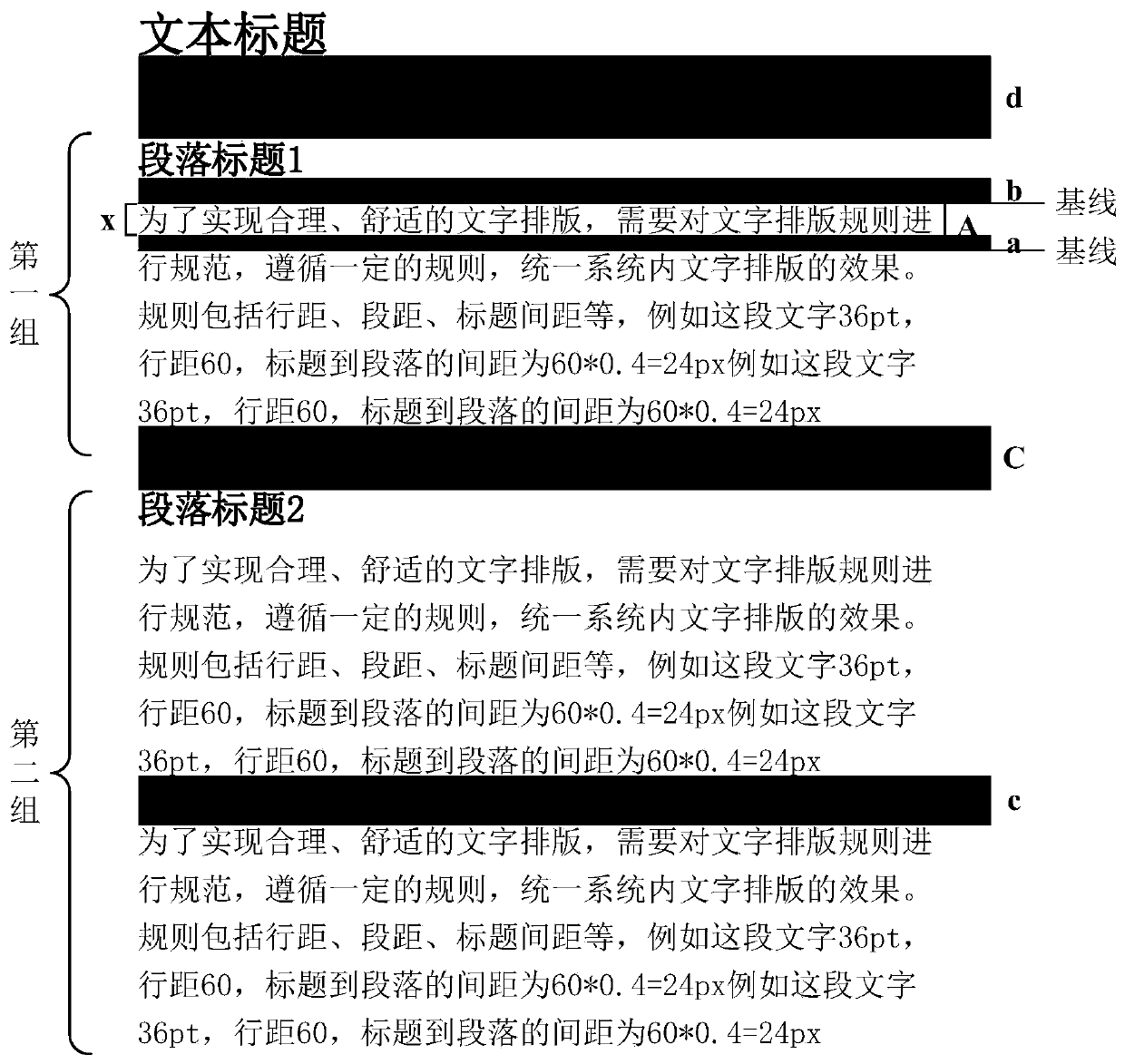

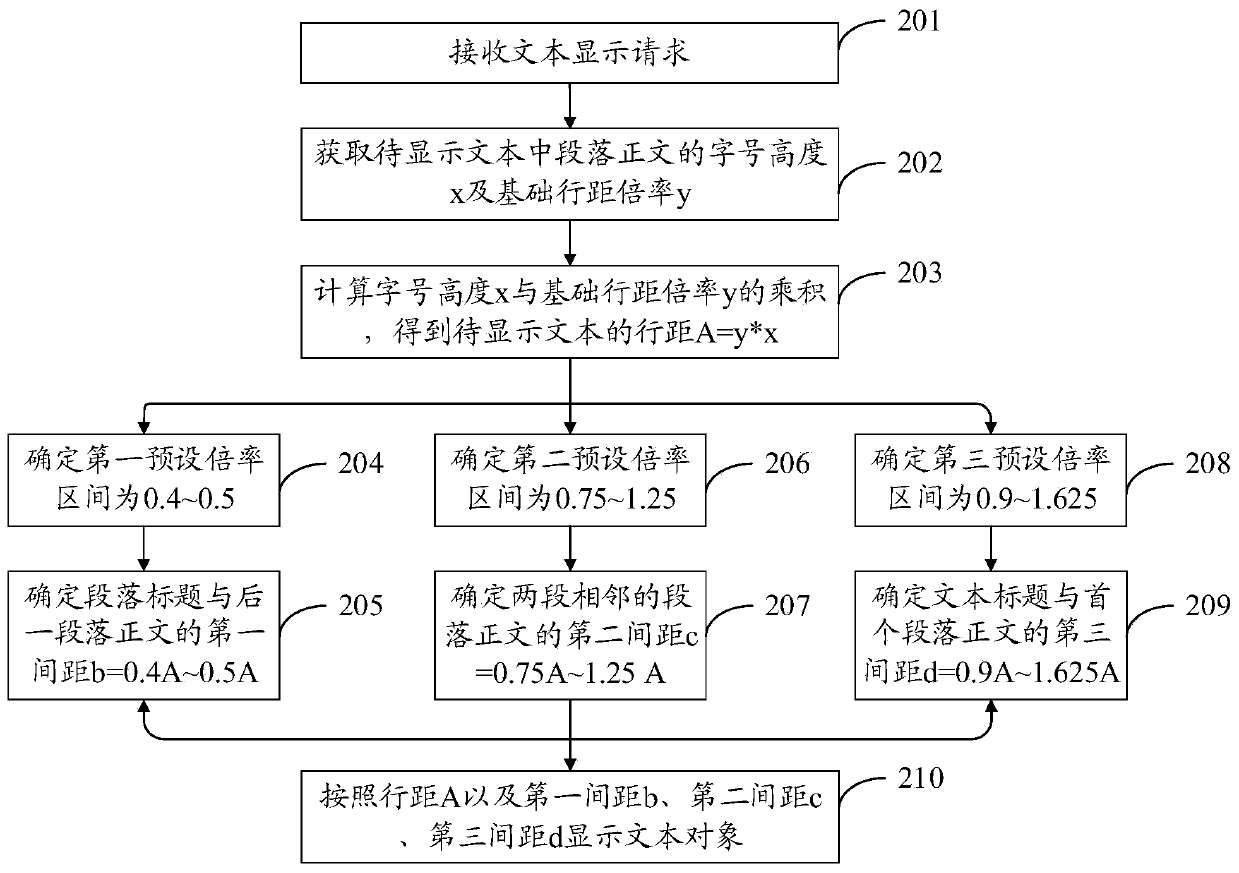

Text display method and device, computer readable storage medium and electronic equipment

ActiveCN110705208AAutomatic spacing adjustmentRealize linkage typesettingNatural language data processingText displayEngineering

The embodiment of the invention discloses a text display method and device, a storage medium and electronic equipment. The text display method comprises the steps of receiving a text display request;obtaining the line spacing of the to-be-displayed text according to the text display request; according to a preset mapping relationship between the text object spacing and the line spacing, determining a target spacing used for displaying the text object in the to-be-displayed text; and displaying the text object according to the line spacing and the target spacing. According to the embodiment ofthe invention, the spacing between the text objects is automatically adjusted according to the relationship between the text object spacing and the text line spacing, and linkage typesetting is realized, so that the text typesetting efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

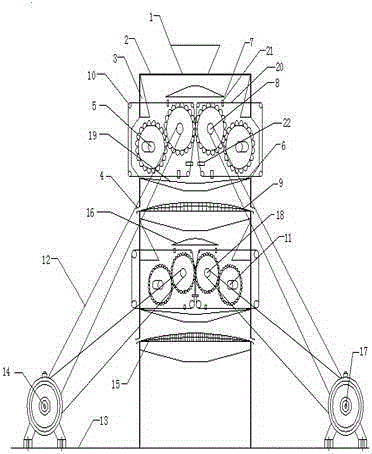

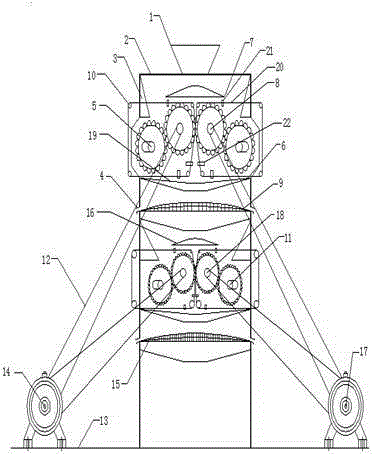

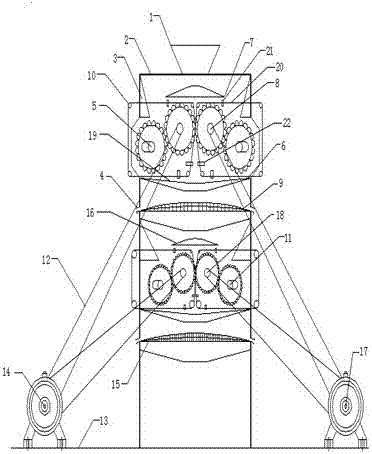

Automatic control method for eight-roller type crusher

ActiveCN105170301AHigh precisionImprove securityGrain treatmentsAutomatic controlControl engineering

The invention discloses an automatic control method for an eight-roller type crusher. A roller tooth detection module is used for detecting whether roller teeth are flat or not. A first input module, a second input module and a third input module are used for inputting relevant data. A main controller receives the relevant data and transmits execution signals to an alarm module, a roller adjusting module, a valve adjusting module and a pore diameter adjusting module after computational analysis. The alarm module, the roller adjusting module, the valve adjusting module and the pore diameter adjusting module receive the execution signals and further execute relevant instructions. According to the automatic control method for the eight-roller type crusher, the space between a first roller and a second roller or the space between a third roller and a fourth roller can be adjusted automatically according to the input space value; whether the rollers are deformed or not can be detected, and the size of a discharging outlet and the size of a screen can further be adjusted according to the input value.

Owner:乌海市千里山选煤有限责任公司

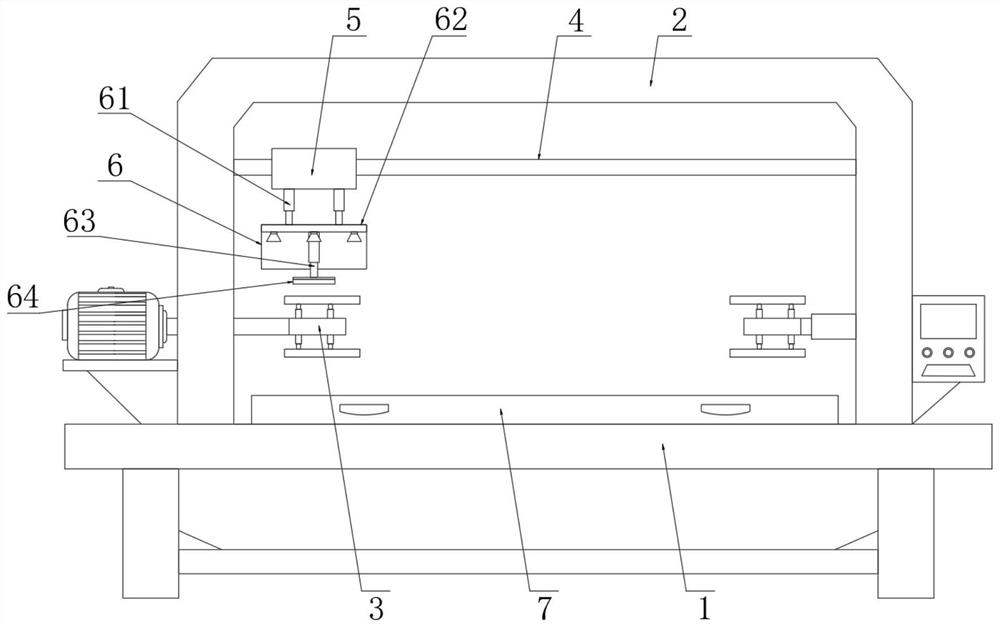

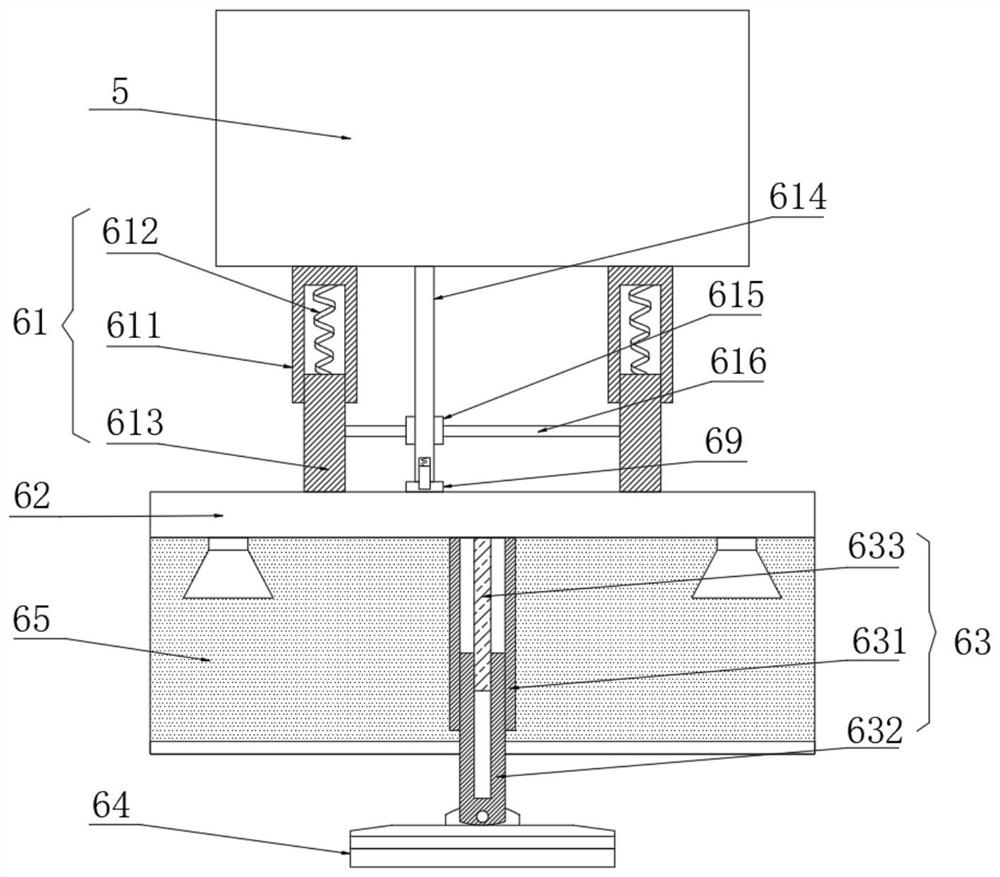

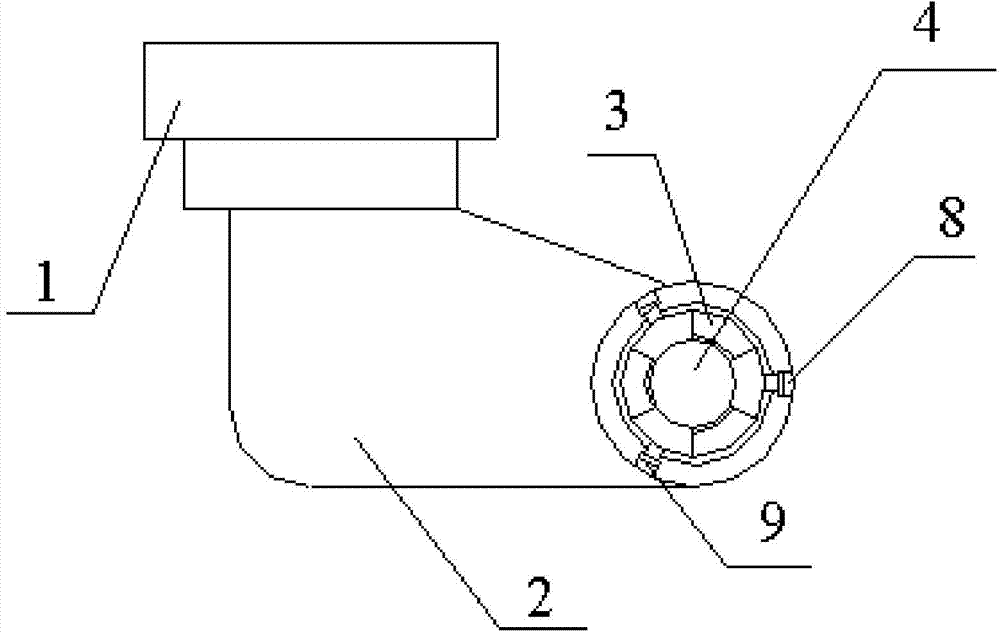

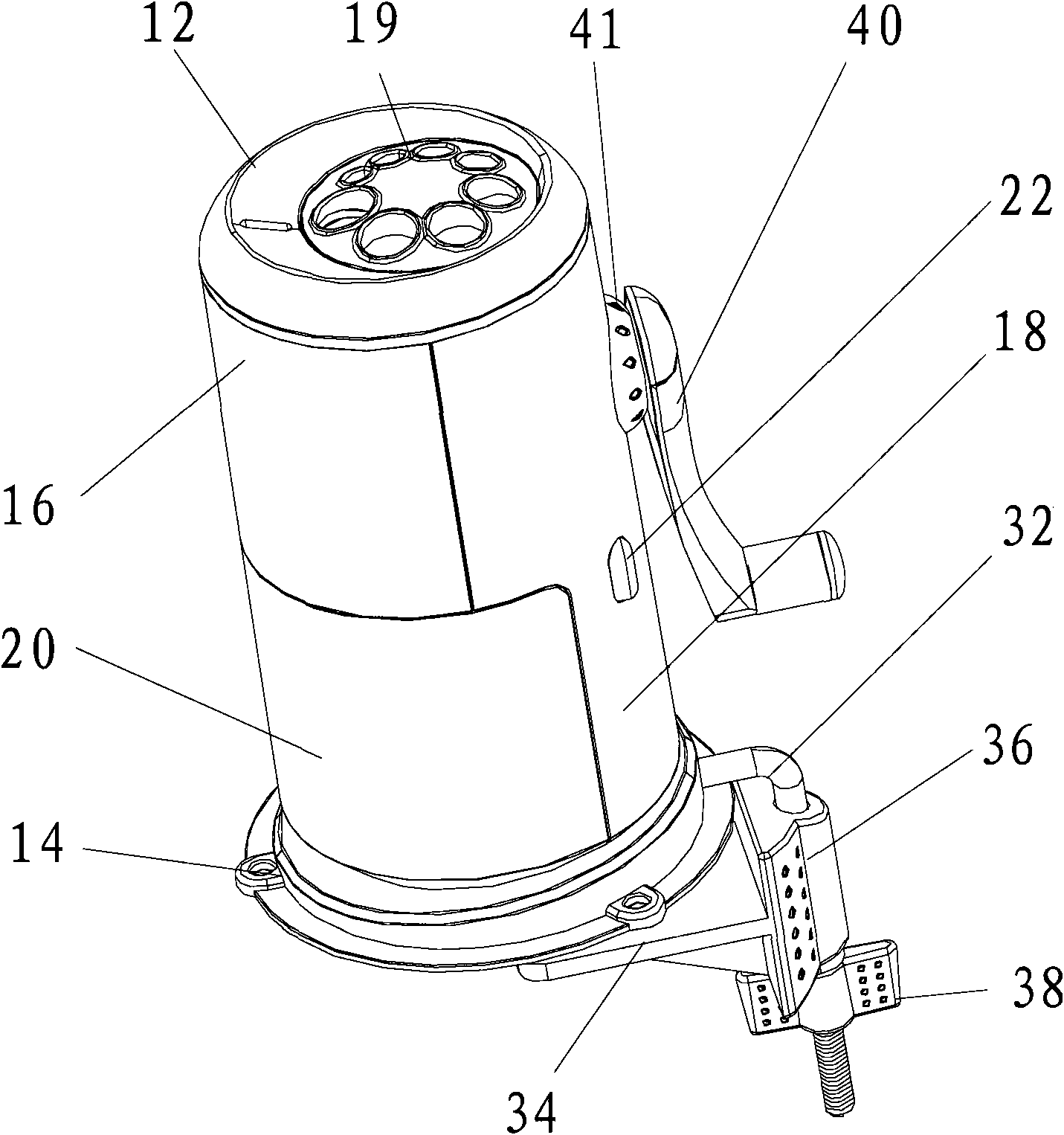

Circular hollow pipe outer side wall paint spraying equipment and working method thereof

ActiveCN112427180AAvoid uneven sprayingAutomatic spacing adjustmentSpraying apparatusElectric machineEngineering

The invention discloses circular hollow pipe outer side wall paint spraying equipment, and relates to the technical field of pipe paint spraying equipment. The circular hollow pipe outer side wall paint spraying equipment comprises a workbench and a rack, the rack is fixedly installed on the outer wall of the top of the workbench, clamps are arranged at the left end of an electric telescopic rod and an output shaft on the right side of a motor, a sliding rail is fixedly installed between the inner walls of the tops of the left side and the right side of the rack, the outer wall of the slidingrail is sleeved with a servo sliding table, a guide device is fixedly installed on the outer wall of the bottom of the servo sliding table, and a spray head is arranged on the outer wall of the bottomof the guide device. In the device, a trowelling block makes contact with the outer side wall of a circular hollow pipe, when the diameter of the circular hollow pipe is reduced, the trowelling blockcan move downwards under the action of a telescopic device, thus the guide device can automatically adjust the position of the spray head according to the diameter change of the circular hollow pipe,it is ensured that the distance between the spray head and the outer side wall of the circular hollow pipe cannot be changed, the situation that the circular hollow pipe is sprayed unevenly is avoided, and resources are saved.

Owner:山东金宝诚管业有限公司

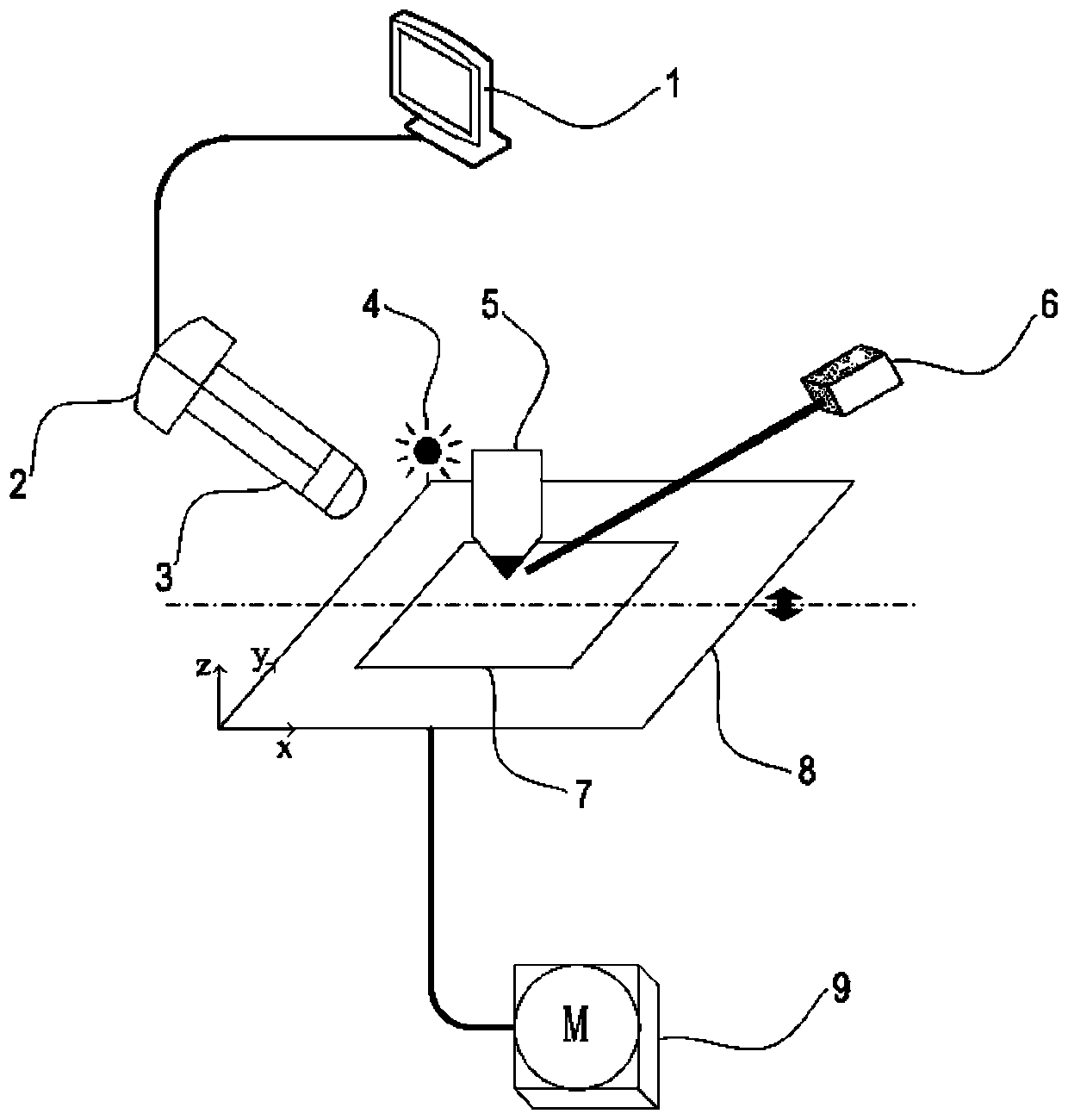

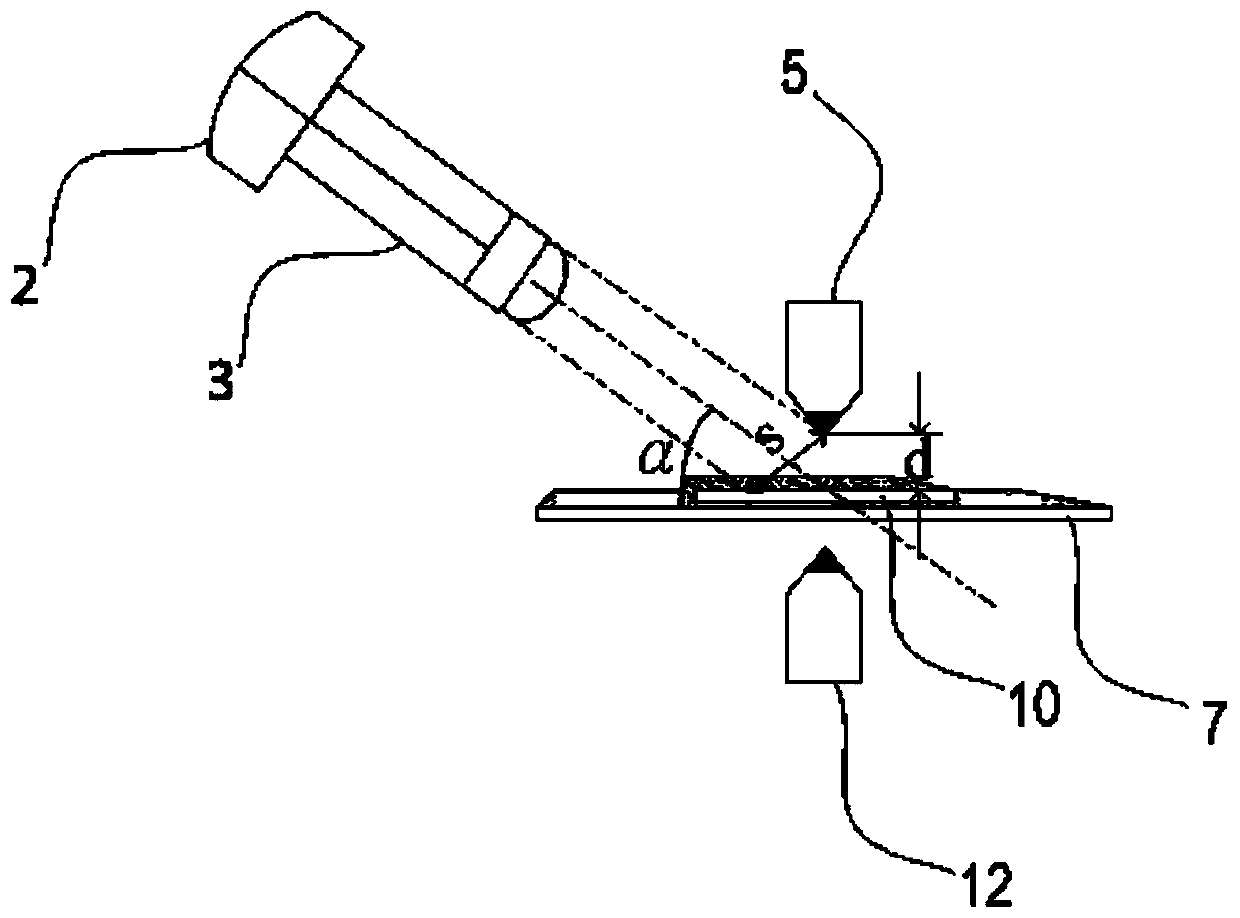

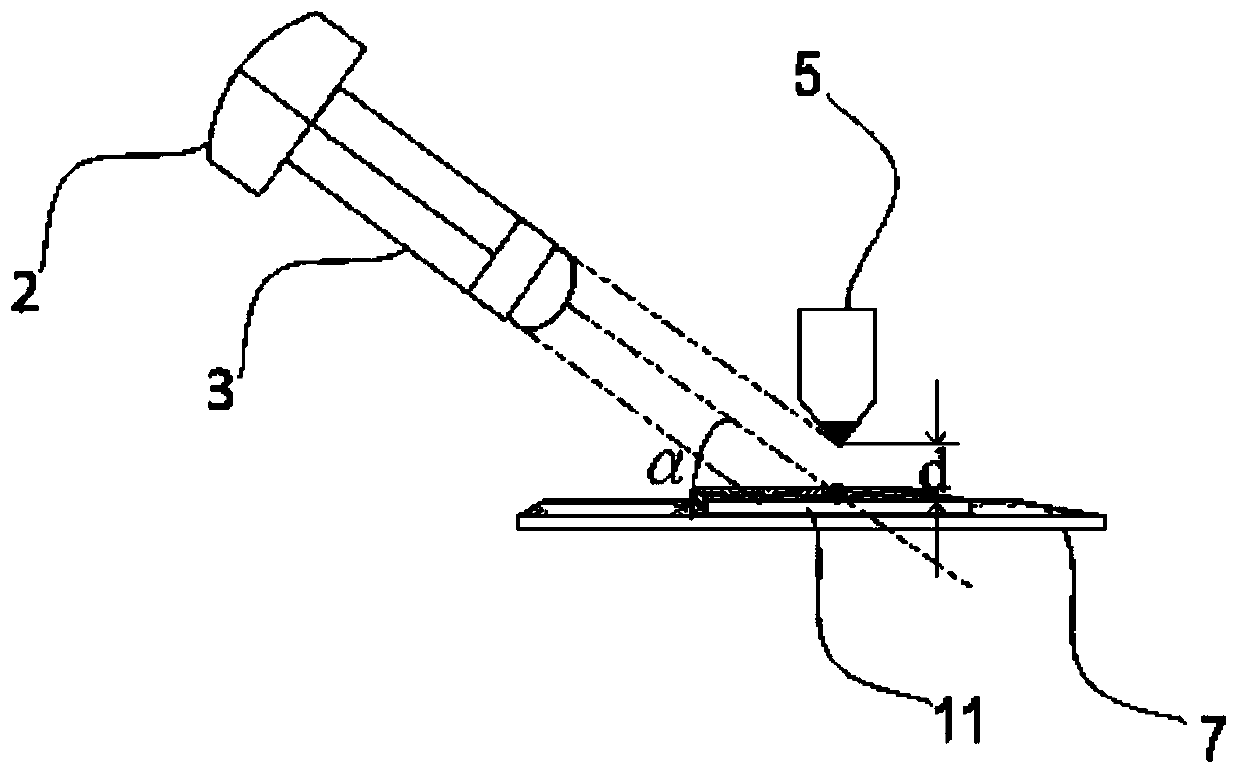

Near field probe range finding method and device based on laser reflection

InactiveCN109917407AAccurate measurementAutomatic spacing adjustmentElectromagnetic wave reradiationImage scalePhysics

The invention relates to a near field probe range finding method and device based on laser reflection and belongs to the terahertz microscopic imaging field. The method is realized based on the near field probe range finding device. The range finding device comprises a laser, a visible light source, a visible light microscope, a photoconductive microprobe, a sample, a sample displacement bench, amotor control box, and a computer. The method comprises the following steps of S1, placing the sample on the sample displacement bench; S2, irradiating visible light on a tip of the photoconductive microprobe, and acquiring a scene near the tip in real time through the visible light microscope and a CCD detector, and transmitting to the computer for image processing and characteristic extraction,and obtaining a spacing S of the photoconductive microprobe-sample on an image scale; and S3, calculating and acquiring an actual distance d of the photoconductive microprobe-sample through a relational expression between the spacing S on the image scale and an actual spacing. The method and the device are used for accurately measuring the spacing between the photoconductive microprobe and the sample and automatically adjusting the spacing.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

A hydraulic press slider locking device and the hydraulic press

ActiveCN103057157BImprove controlAutomatic spacing adjustmentPress ramPulp and paper industryHigh pressure

The invention discloses a hydraulic machine and a slider locking device thereof. The slider locking device of the hydraulic machine is used for locking and unlocking a slider of the hydraulic machine and comprises a connecting plate, a support, a wedged block, a sliding rod, pistons and springs. The sliding rod penetrates through a conical hole of the support without fitting. The support is connected with the connecting plate to form connection through a T-shaped slot. The connecting plate is fixed on a vertical column of the hydraulic machine. The sliding rod is fixed with the slider of the hydraulic machine. The sliding rod is locked by the aid of the wedged block and the conical hole of the support, so that the slider of the hydraulic machine is locked. During unlocking, high-pressure oil is fed into lower cavities of the pistons so as to drive the pistons to push the wedged block to move upwards to unlock the slider. The slider locking device of the hydraulic machine has the advantages that safety is high, locking at any positions can be realized, and performance of the hydraulic machine is improved. The invention further discloses the hydraulic machine with the slider locking device.

Owner:HEFEI METALFORMING MACHINE TOOL

Automatic control system and method of eight-roller type crusher

The invention discloses an automatic control system and method of an eight-roller type crusher. The automatic control system comprises a roller tooth detection module, a first input module, a second input module, a third input module, a roller adjustment module, a valve adjustment module, a main controller, a hole diameter adjustment module and an alarming module, wherein the roller tooth detection module is used for detecting whether roller teeth are flat or not; the first input module, the second input module and the third input module are used for inputting relevant data; the main controller receives relevant data and transmits execution signals to the alarming module, the roller adjustment module, the valve adjustment module and the hole diameter adjustment module after calculation and analysis; the alarming module, the roller adjustment module, the valve adjustment module and the hole diameter adjustment module receives the execution signals and then execute relevant instructions. The interval between a first roller and a second roller or the interval between a third roller and a fourth roller can be adjusted automatically according to an input interval value, whether the rollers deform or not can be detected, and the size of a discharging outlet and a sieve can be adjusted according to the input value.

Owner:江西翔麟矿业有限责任公司

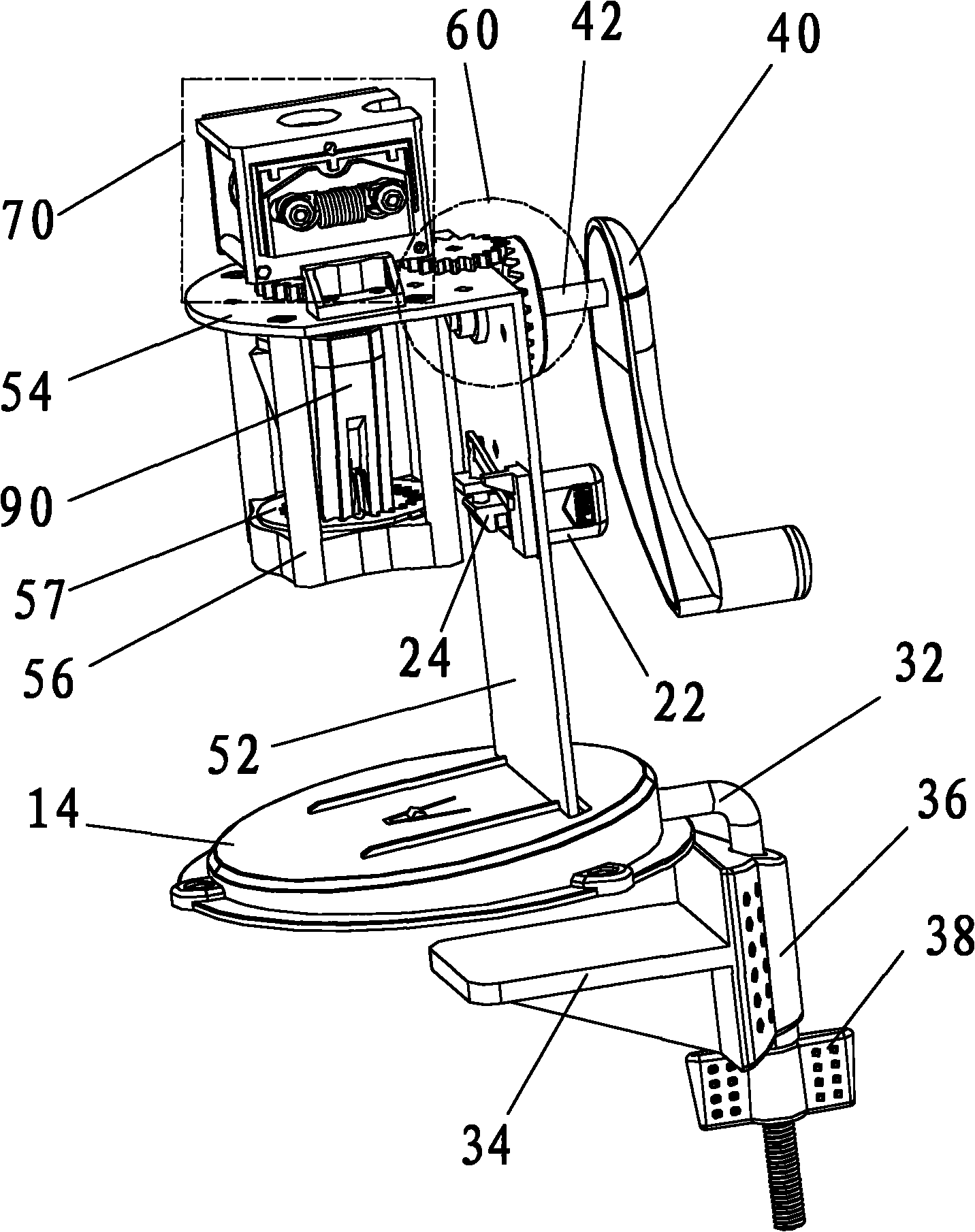

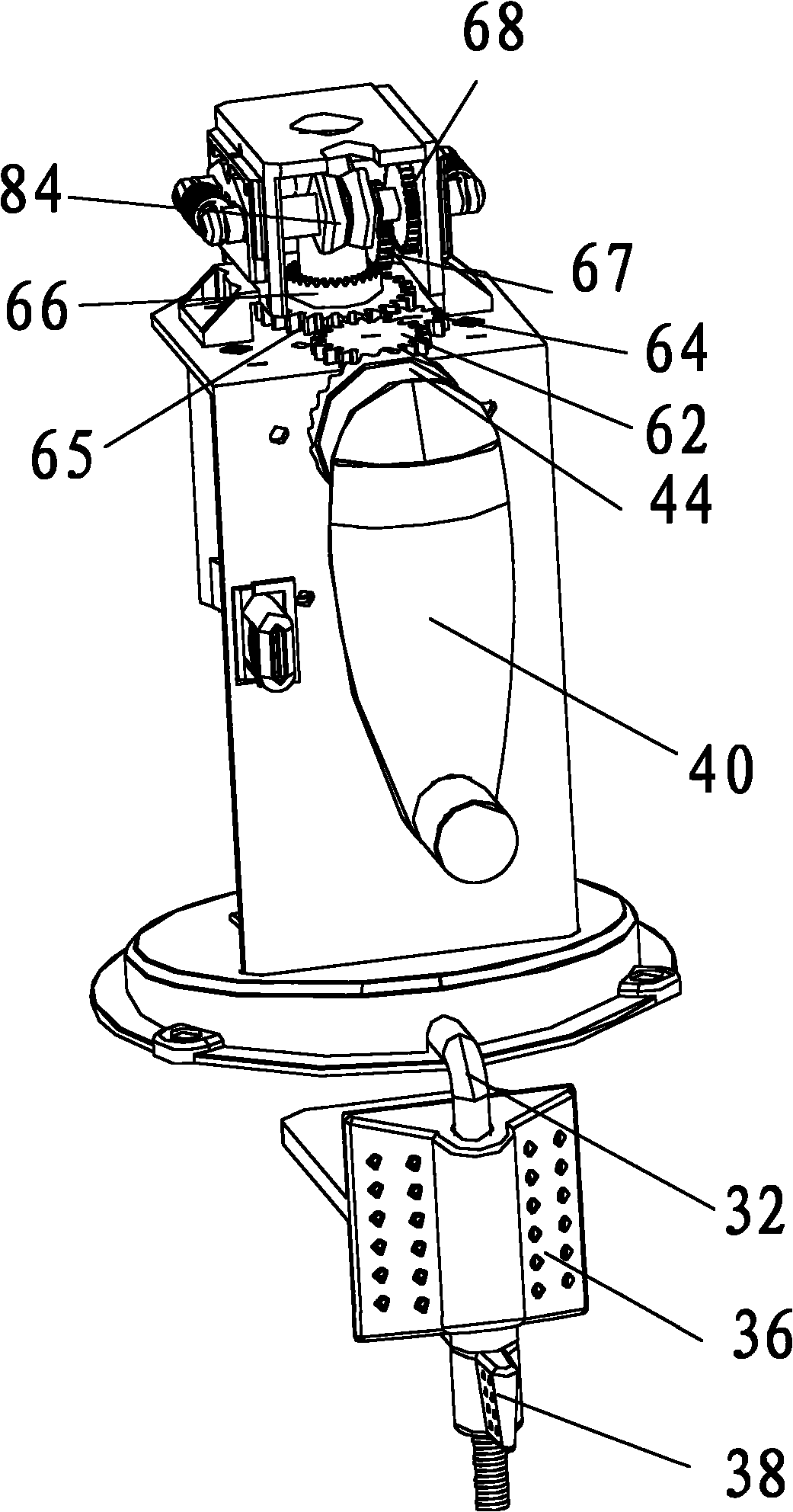

Pole climbing iron shoes realizing automatic telescopic adjusting

The invention relates to the field of electrician maintenance operation facilities of power supply systems, and particularly discloses pole climbing iron shoes realizing automatic telescopic adjusting. Each shoe comprises a sliding rod, a lower baffle plate and an upper baffle plate, wherein the upper baffle plate can slide up and down on the sliding rod under the driving of a motor and a lead screw, so that the distance between the upper baffle plate and the lower baffle plate is automatically adjusted; and the sliding rod is provided with a control circuit, a movable touch rod and a return spring, so that the forward and backward rotation of the motor can be controlled. The forward and backward rotation of the motor is controlled through a 555 time base timing circuit, the forward and backward rotation of the motor also adjusts the distance between the upper baffle plate and the lower baffle plate, so that the requirements of different electric pole sections are adapted, and meanwhile, during the process of climbing up and down, the distance between the upper baffle plate and the lower baffle plate can be automatically adjusted along with the change of the diameter of the electric pole. The pole climbing iron shoes are simple in structure and convenient to use, the actual use requirements of electricians during the pole climbing operation are better conformed, the physical strength of the pole climbing personnel can be effectively alleviated, and thus the safety is guaranteed.

Owner:CHENGWU POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO LTD

Hand-operated pencil planing

InactiveCN101844475AReduced impact on gouging qualityQuality improvementSharpenersEngineeringElectrical and Electronics engineering

The invention relate to a hand-operated pencil planing, comprising a case, a transmission device arranged in the case and a planing device, wherein, the transmission device is connected with a manual rocking handle and transmits the rotation of the rocking handle on the planing device; a pencil is placed into the planning device along a vertical pencil delivering path for planing. The hand-operated pencil sharpener also comprises a pencil delivering device arranged on the pencil delivering path; the transmission device also comprises a transmission branch used for driving the pencil delivering device; the positive rotation or reverse rotation of the handle leads the inserted pencil to automatically feed in or quit through the linkage of the transmission branch and the pencil delivering device. In the hand-operated pencil sharpener of the invention, the pencil is delivered into the planing device along the pencil delivering path for planing under the action of the pencil delivering device; when the hand-operated pencil sharpener is used, the pencil is inserted into the corresponding opening, thus reducing the influence of manual pencil delivering on the pencil planing quality, greatly improving the pencil manual planing quality and simplifying the structure of the pencil delivering device.

Owner:JUXING ELECTRONICS HUIZHOU

Livestock breeding forage swing type crushing device

InactiveCN112470722ARealize the effect of rotary cutting and crushingAchieve horizontal extrusion cutting effectCuttersAgricultural scienceCrop livestock

The invention discloses a livestock breeding forage swing type crushing device, and relates to the technical field of livestock breeding. The livestock breeding forage swing type crushing device comprises a fixed frame; an output shaft of a servo motor is in transmission connection with a translation mechanism used for driving a hanging bracket to move back and forth relative to a hanging plate; and the servo motor is in driving connection with an automatic adjusting mechanism used for driving a crushing mechanism to move transversely. According to the invention, a rotary sleeve pipe and a fixed sleeve pipe rotate to drive crushing blades on the rotary sleeve pipe and the fixed sleeve pipe to rotate to achieve the rotary cutting and crushing effect on forage grass; the arranged automatic adjusting mechanism can drive the rotary sleeve pipe to drive the crushing blades on the rotary sleeve pipe to transversely move leftwards and rightwards in a small range, so that automatic adjustmentof the distance between the crushing blades on the rotary sleeve pipe and the fixed sleeve pipe is achieved, the transverse extrusion cutting effect on the forage grass is achieved, and sufficient thinning of the forage grass is promoted; and the arranged translation mechanism can drive the crushing mechanism to reciprocate back and forth in a stepping mode, so that the crushing range is greatly widened, and the forage grass cutting and thinning degree is remarkably improved.

Owner:顾胜洪

Product transfer control device and method

ActiveCN103381957BAutomatic spacing adjustmentControl devices for conveyorsControl signalEngineering

A product transmission control device is used for automatically adjusting intervals of products in a transmission line, and comprises a sensing device, a control device and a blocking device, wherein the sensing device is used for sending transmission information of the products in the transmission line, and sending a sensing signal to the control device when a first produce passes the blocking device; the control device presets a blocking time according to the received sending signal and sends a first control signal to the blocking device; the blocking device blocks a second product in the transmission line to pass the blocking device; when blocking time of the blocking device reaches the preset blocking time, the control device sends a second control signal to the blocking device, and the blocking device releases the blocking of the second product to enable the second product to be continuously transported on the transmission line according to the second control signal. The invention further provides a product transmission control method.

Owner:海南金红叶纸业有限公司 +1

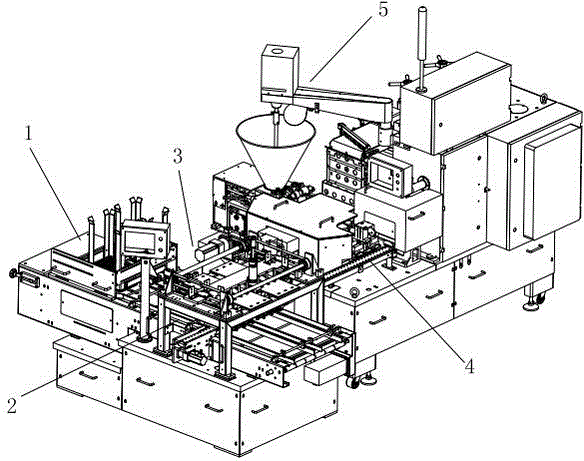

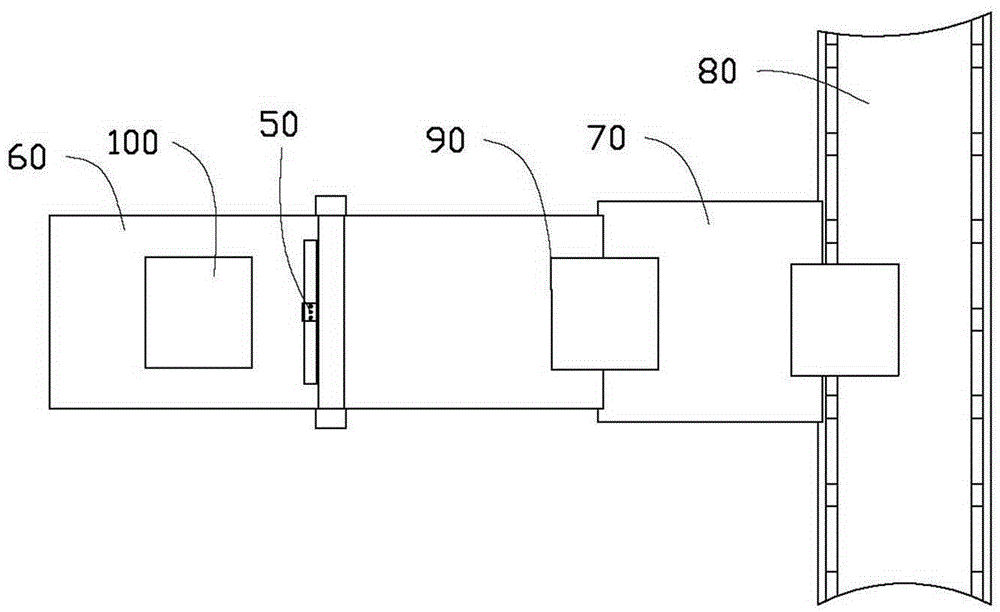

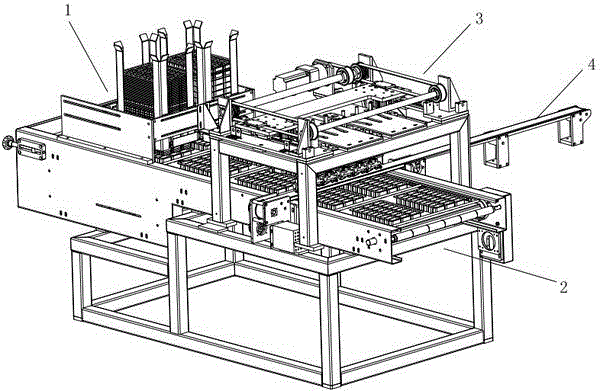

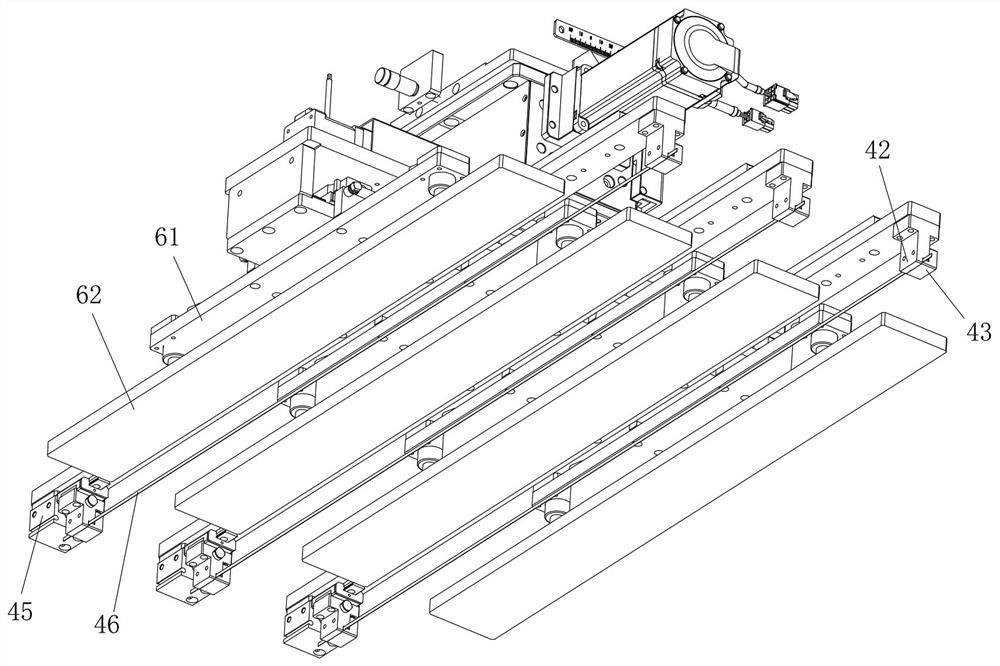

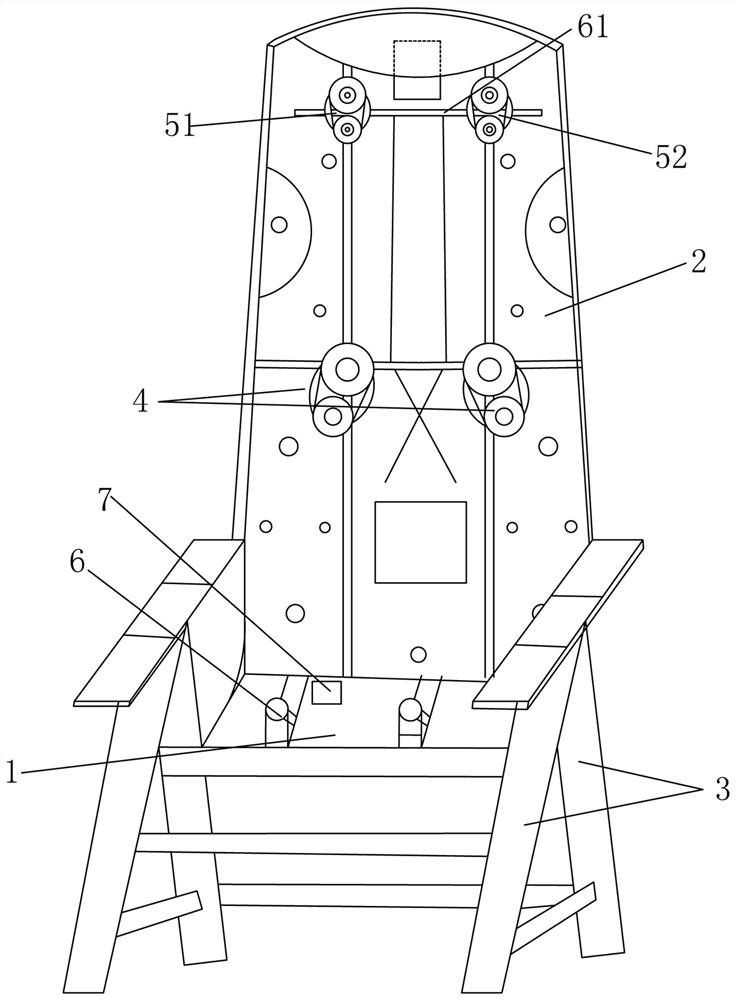

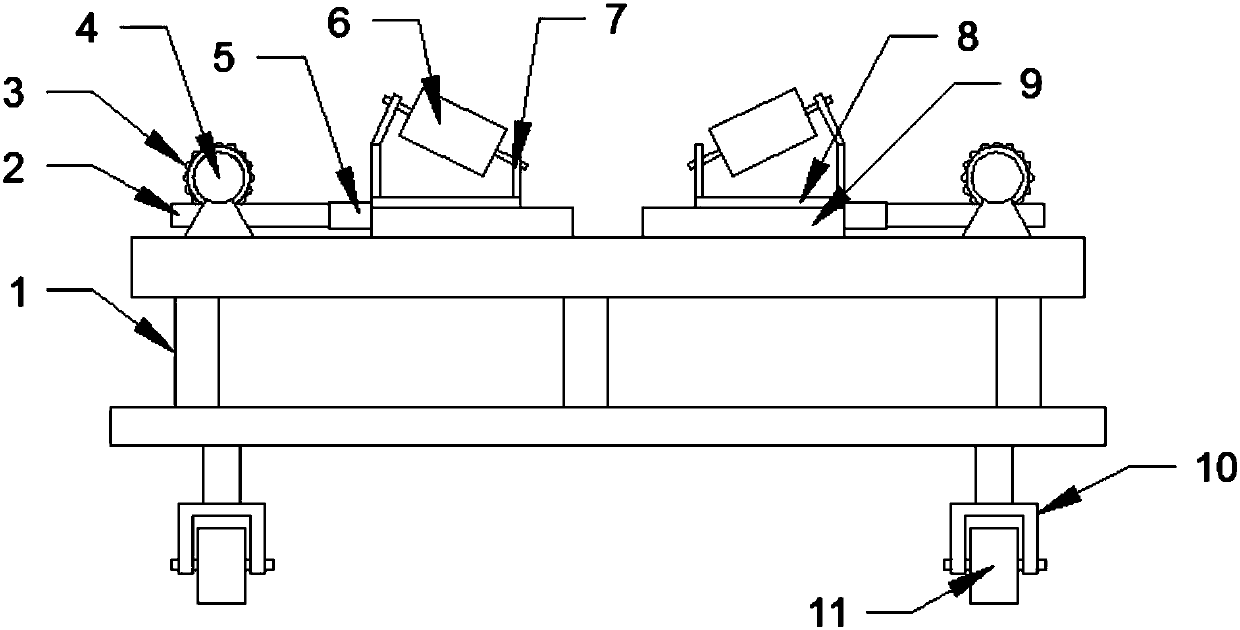

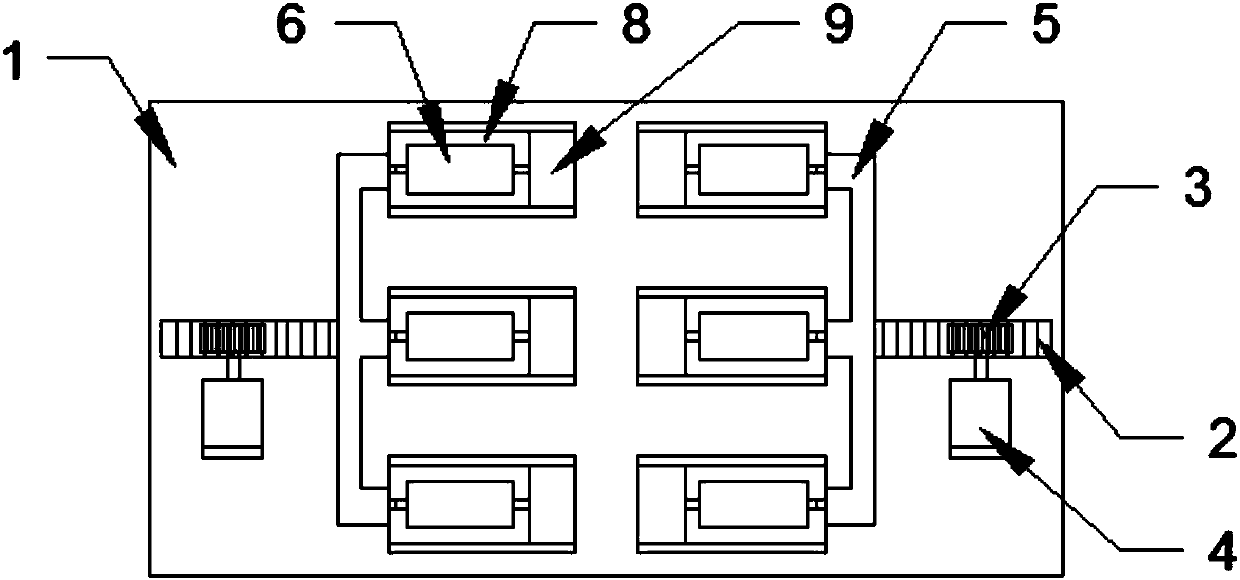

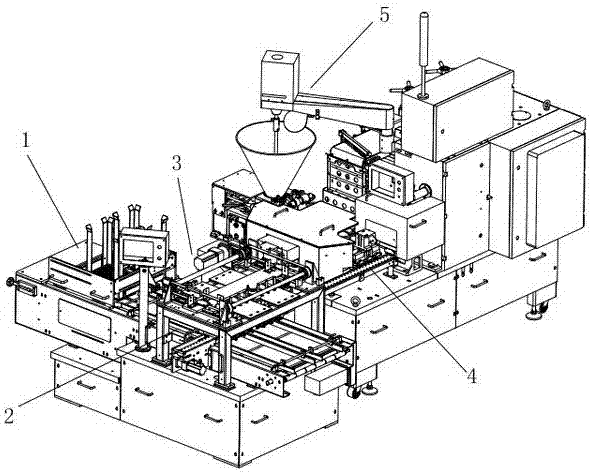

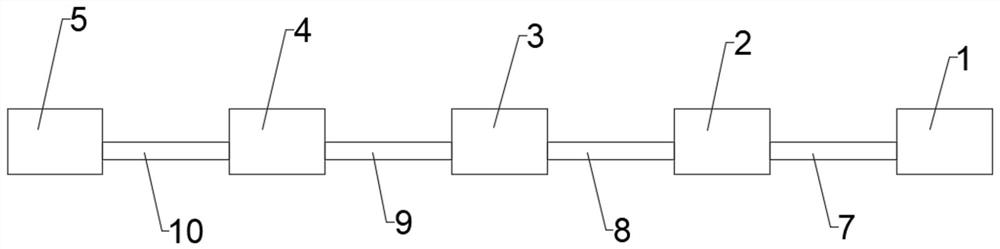

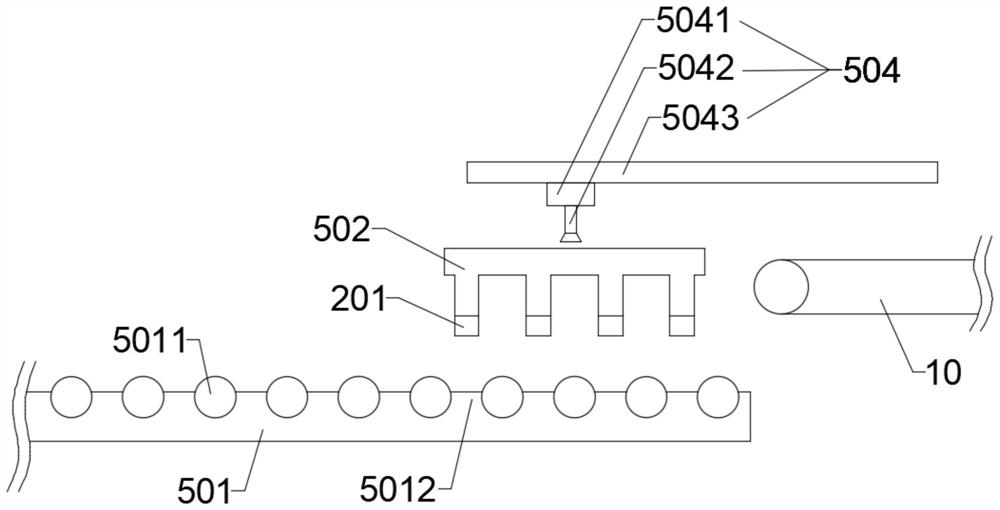

An automatic bagging production line for infusion bags

ActiveCN105819208BAutomatic spacing adjustmentImprove feeding efficiencyConveyorsConveyor partsProduction lineEngineering

The invention discloses an automatic infusion bag feeding production line which comprises a feeding production line body, an infusion bag tray and a feeding manipulator. The multi-way feeding production line body comprises distribution devices distributing one-way infusion bags into multiple branch ways and conveying lines for respectively conveying the infusion bags of each branch way distributed by the distribution devices to the infusion bag tray, wherein the conveying lines are equal to the branch ways distributed by the distribution devices in number. The feeding manipulator comprises an infusion bag taking unit. The automatic infusion bag feeding production line adopts the structures of an infusion bag distribution mechanism and the multi-shaft feeding manipulator, can perform multi-way distributed feeding of infusion bags, improves the feeding efficiency and is good in applicability, a jig is replaceable, the separation distances of multiple groups of sucking discs on the feeding manipulator can be automatically adjusted, and feeding operation of large, medium and small specifications of infusion bags can be performed.

Owner:WUXI LION MEDICAL AUTOMATION TECH

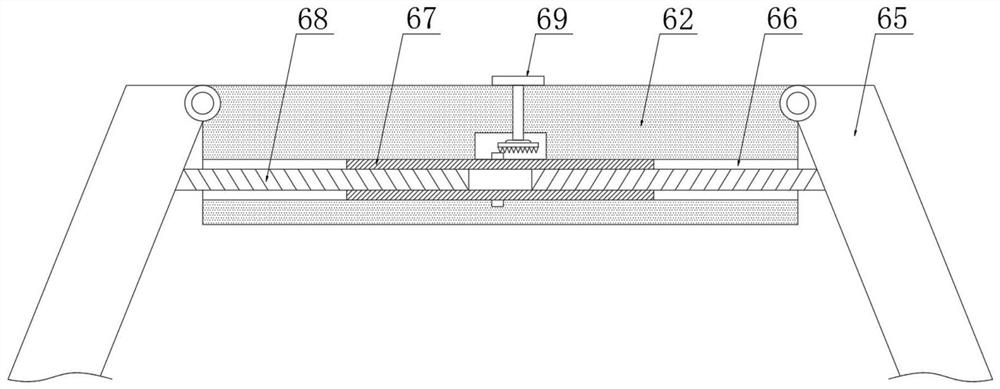

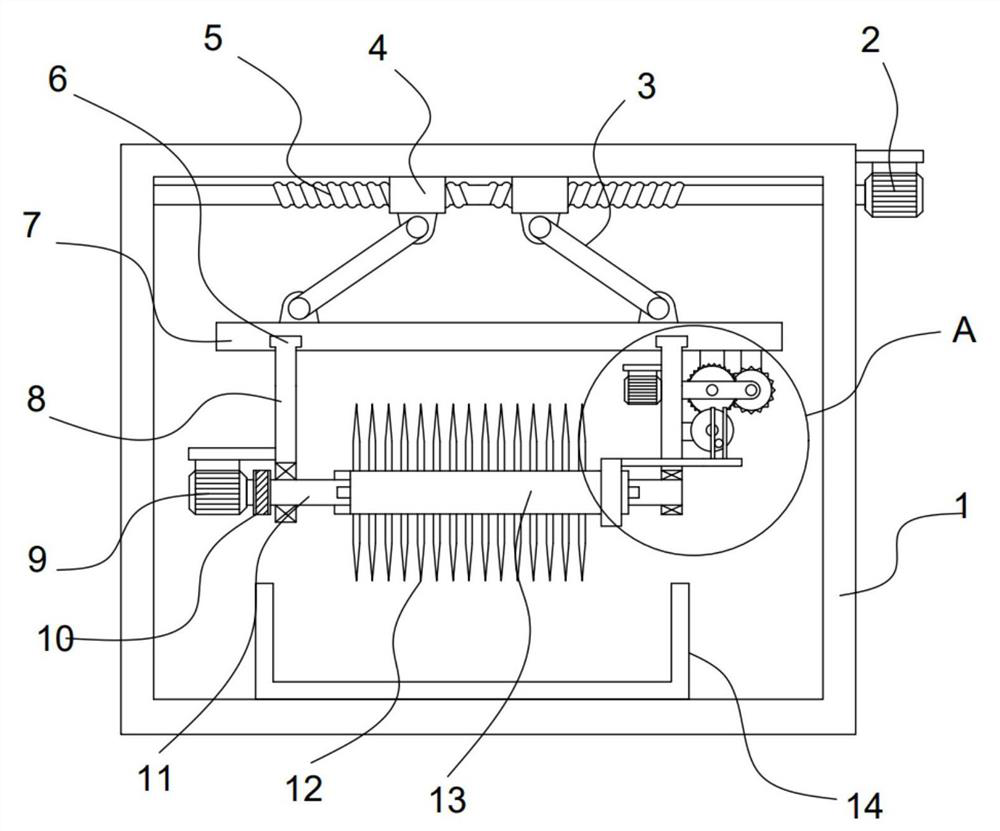

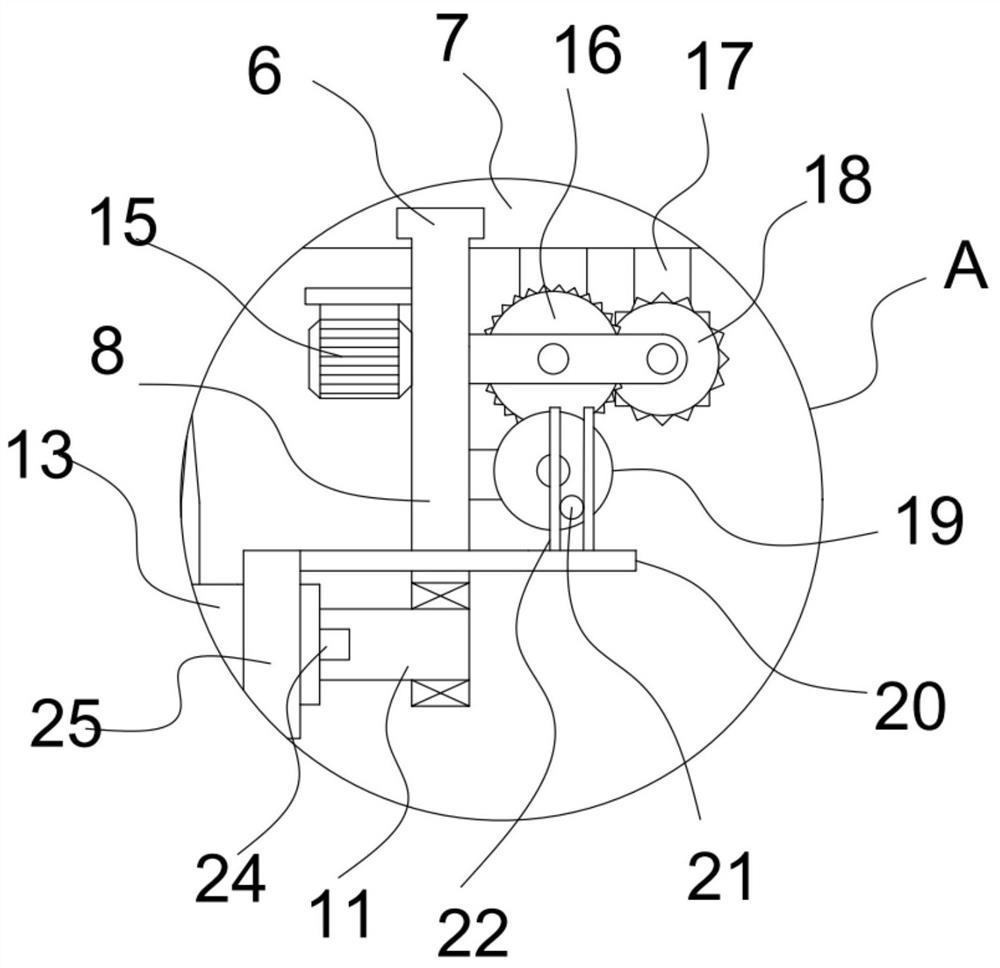

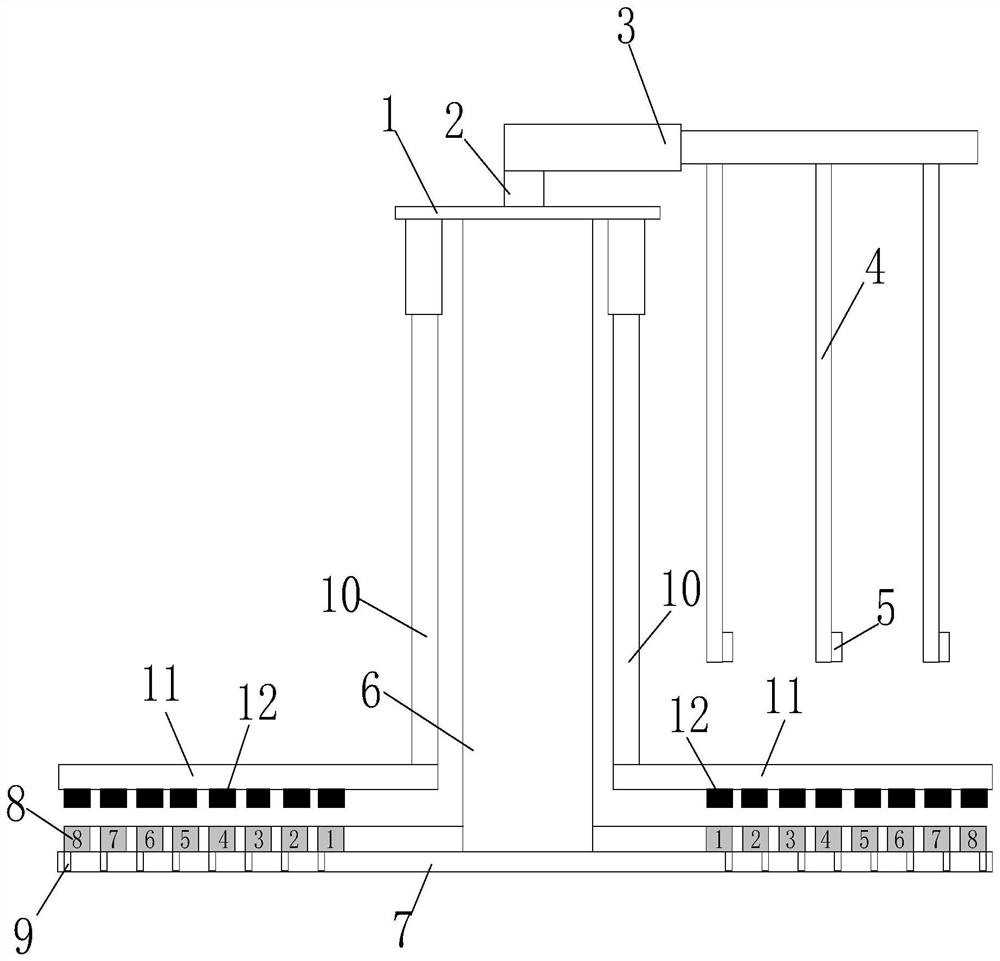

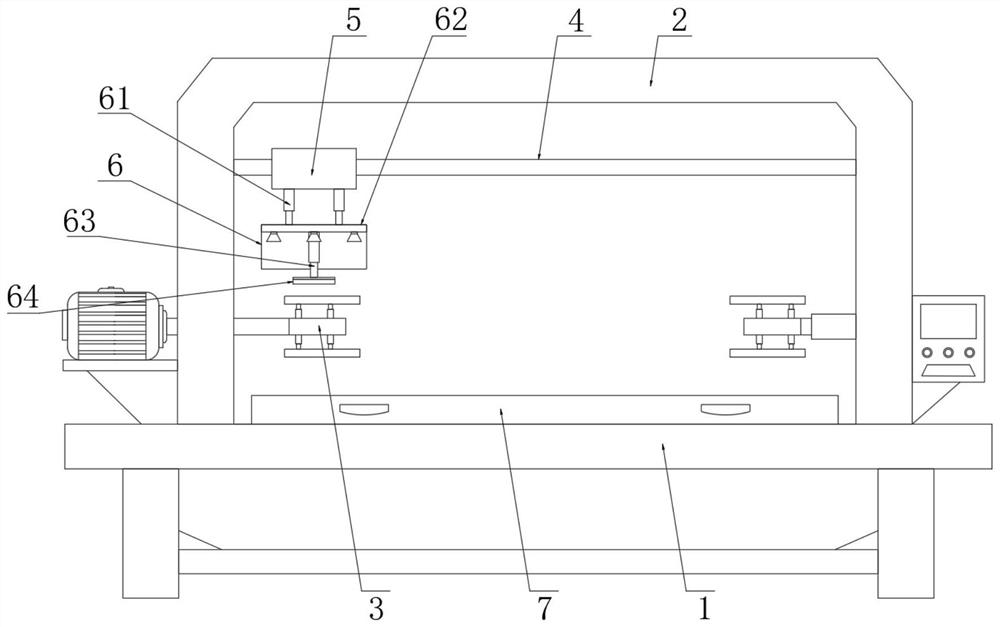

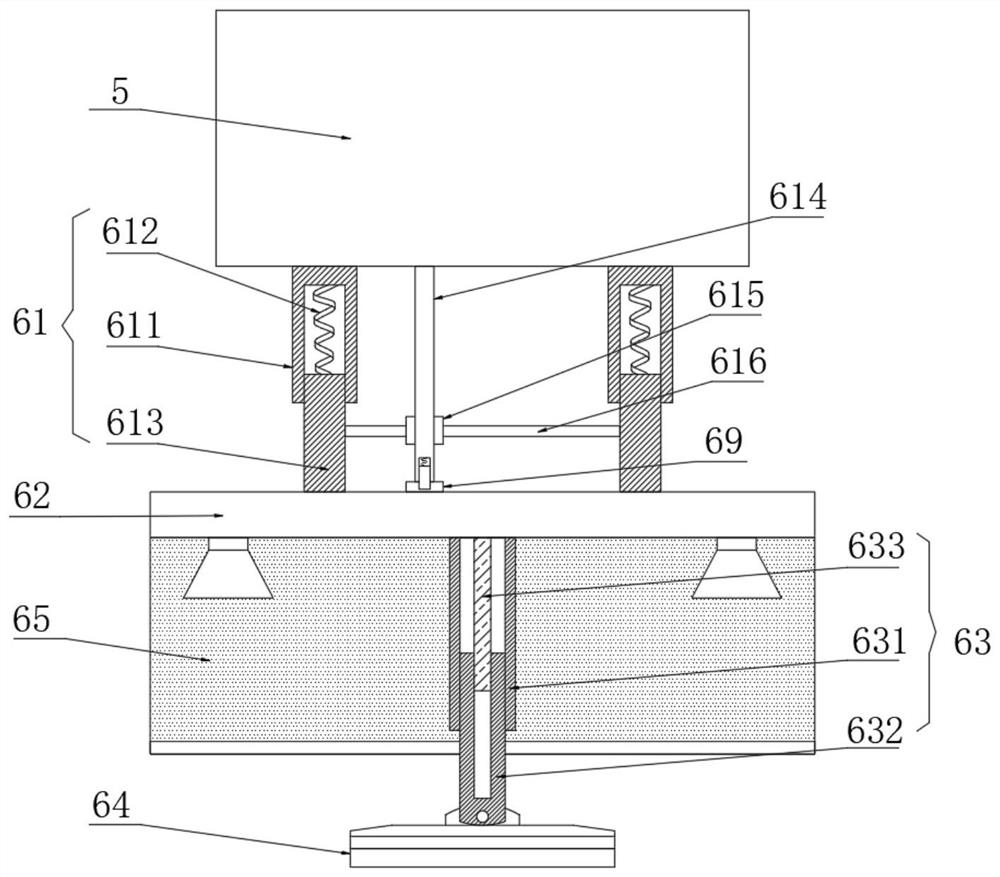

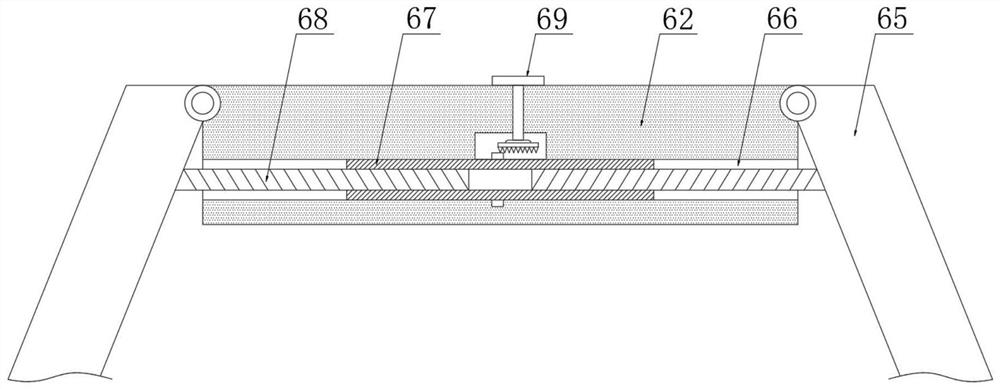

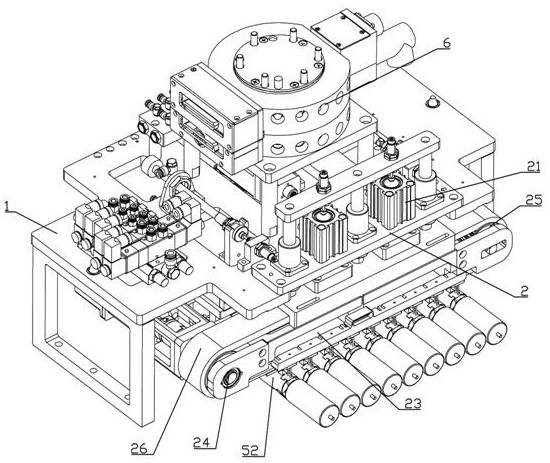

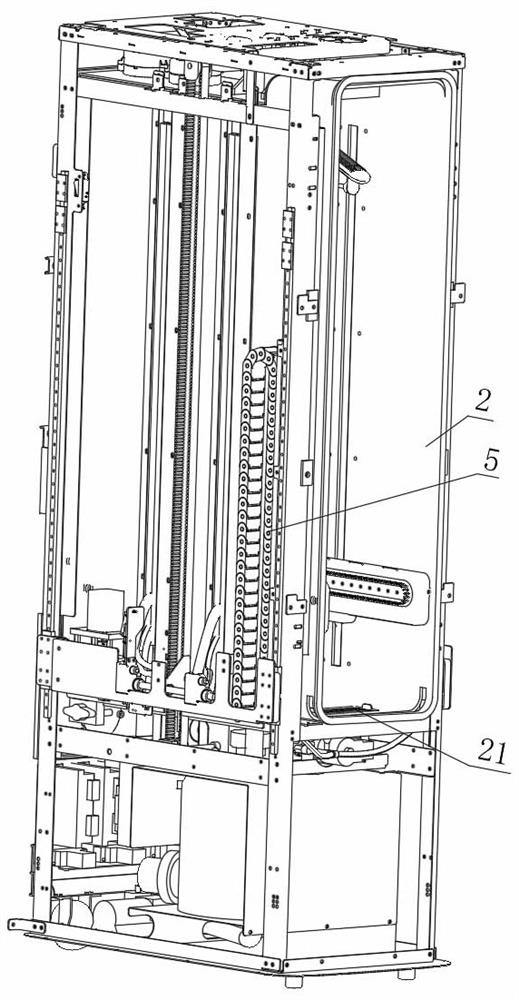

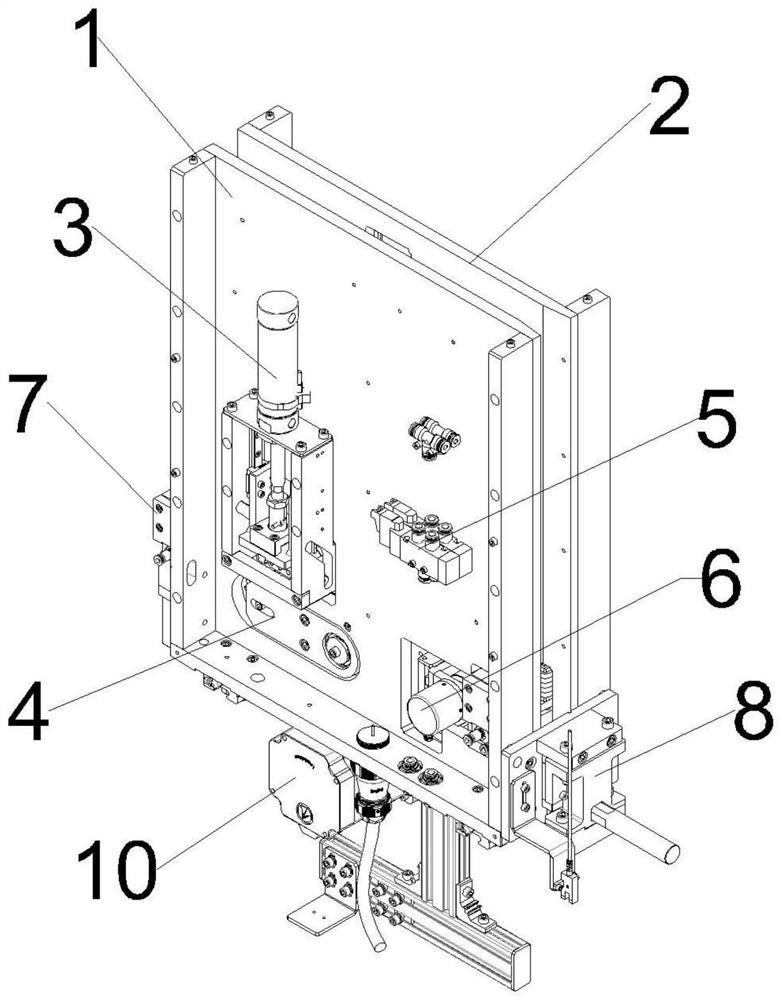

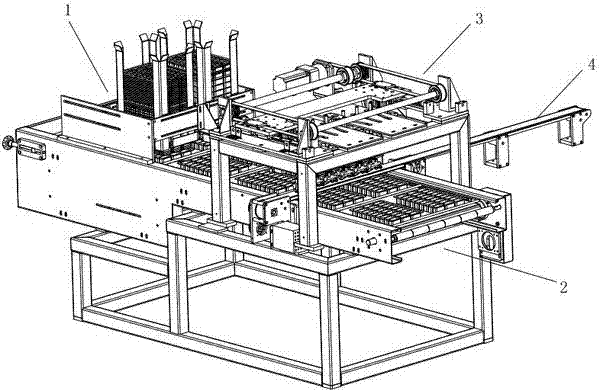

Food cartoning machine

ActiveCN104803034BFully automatic adjustmentAutomatic spacing adjustmentPackagingConveyor beltFood processing

The invention relates to the field of a food processing machine, and particularly relates to a food boxing machine. The food boxing machine comprises a box feeding mechanism, a box arranging transport mechanism and a clamping mechanism, wherein the box feeding mechanism and the clamping mechanism are respectively arranged above the box arranging transport mechanism, the box feeding mechanism is arranged on one end of the clamping mechanism, and one side of the clamping mechanism is provided with a conveyor belt for transporting to-be-arranged food; the clamping mechanism comprises an installation framework, and the installation framework is provided with a plurality of mechanical claws. The movement of the mechanical claws in three directions are realized by utilizing a guide device, a horizontal drive mechanism and a vertical drive mechanism; moreover, the full-automatic adjustment can be realized, and the distance adjustment of the mechanical claws can be automatically realized under the situation that no manpower is needed; the food boxing machine can be suitable for various support boxes in various sizes only by replacing a track plate, the artificial anticipation is eliminated, the production efficiency is improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Carrier roller with automatic adjusting function

Owner:安徽独库机械设备有限公司

Push mechanism of food cartoning machine

ActiveCN104803036BAutomatic spacing adjustmentFully automatic adjustmentPackagingEngineeringFood processing

The invention relates to the field of a food processing machine, and particularly relates to a push-in mechanism of a food boxing machine. The push-in mechanism comprises an installation framework, wherein the installation framework comprises a fixed installation plate and a plurality of mechanical push plates which are arranged below the fixed installation plate, the mechanical push plate is provided with a guide device for adjusting the distance between two adjacent mechanical push plates, each mechanical push plate is connected with a horizontal drive mechanism for driving the mechanical push plate to move horizontally, and the fixed installation plate is fixedly provided with the horizontal drive mechanism. The movement of the mechanical push plates in two directions is realized by utilizing the guide device and the horizontal drive mechanism; moreover, the full-automatic adjustment can be realized, the distance adjustment can be automatically realized under the situation that the manpower is not need; the push-in mechanism can be applicable to various support boxes in various sizes only by replacing a track plate, the artificial participation is eliminated, the production efficiency can be improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

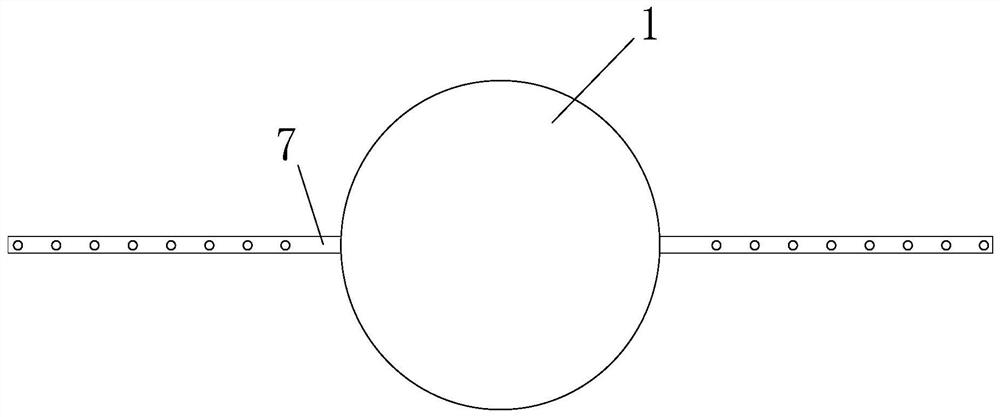

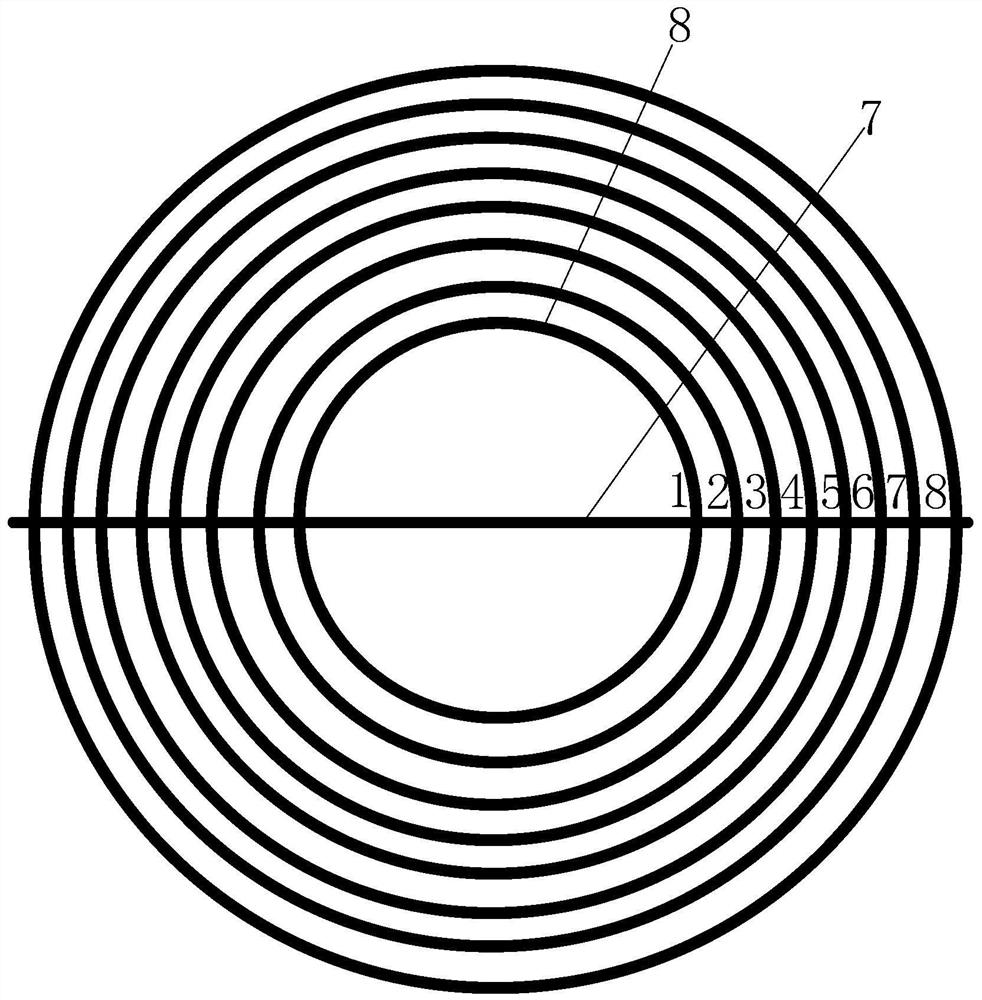

Agricultural intelligent detection system with adjustable measurement precision

ActiveCN111610311AAutomatic distance adjustmentAutomatic spacing adjustmentEarth material testingAgricultural engineeringElectric machinery

The invention provides an agricultural intelligent detection system with adjustable measurement precision. The detection system comprises a controller and a circular plate; a first motor is arranged in the center of the upper surface of the circular plate; the first motor drives a first electric telescopic rod capable of stretching out and drawing back leftwards and rightwards to rotate around a central vertical shaft of the circular plate; a plurality of first vertical rods are arranged on the lower side of an inner rod of the first electric telescopic rod; each first vertical rod can slide left and right along a sliding groove in the lower side of the inner rod; and a sensor is arranged at the bottom end of each first vertical rod. A cylinder is arranged in the center of the lower surface of the circular plate, the lower bottom of the cylinder is connected with a transverse fixing plate in an aligned mode; and for each of the multiple circular rings, a transverse fixing plate is usedfor fixing a position relation between the circular rings from the lower portion; two second electric telescopic rods capable of stretching out and drawing back up and down are further fixed to the lower surface of the circular plate; a first transverse rod is fixed to the bottom end of an inner rod of each second electric telescopic rod, and electromagnets corresponding to the circular rings respectively are arranged on the lower surface of the first transverse rod.

Owner:中明邦发展集团有限公司

Wrench for mounting oxygen flow meter

The invention relates to a wrench for mounting an oxygen flow meter. The wrench for mounting the oxygen flow meter comprises a magnetic handle and a magnetic wrench body, wherein the outer side of thewrench body is of a C-shaped structure; the inner side of the wrench body is of a polygonal structure; the wrench body is composed of a plurality of clamping teeth; and the handle is connected with the wrench body. The wrench for mounting the oxygen flow meter is safe and practical, and is high in flexibility and excellent in user experience.

Owner:GUANGDONG GENERAL HOSPITAL

A kind of equipment for spraying paint on the outer wall of a circular hollow pipe and its working method

ActiveCN112427180BAvoid uneven sprayingAutomatic spacing adjustmentSpraying apparatusStructural engineeringIndustrial engineering

The invention discloses a painting equipment for the outer wall of a circular hollow pipe in the technical field of pipe painting equipment. It includes a workbench and a frame. The side output shafts are all provided with fixtures, slide rails are fixedly installed between the top inner walls on the left and right sides of the frame, the outer walls of the slide rails are sleeved with servo slides, and the outer walls of the bottom of the servo slides are fixed with guide devices. And the outer wall of the bottom of the guide device is provided with a nozzle, and the device contacts the outer wall of the circular hollow tube through a smoothing block. When the diameter of the circular hollow tube decreases, the smoothing block will move downward under the action of the telescopic device, so that the guide The device can automatically adjust the position of the nozzle according to the diameter change of the circular hollow tube to ensure that the distance between the nozzle and the outer wall of the circular hollow tube will not change, avoiding uneven spraying of the circular hollow tube and saving resources .

Owner:山东金宝诚管业有限公司

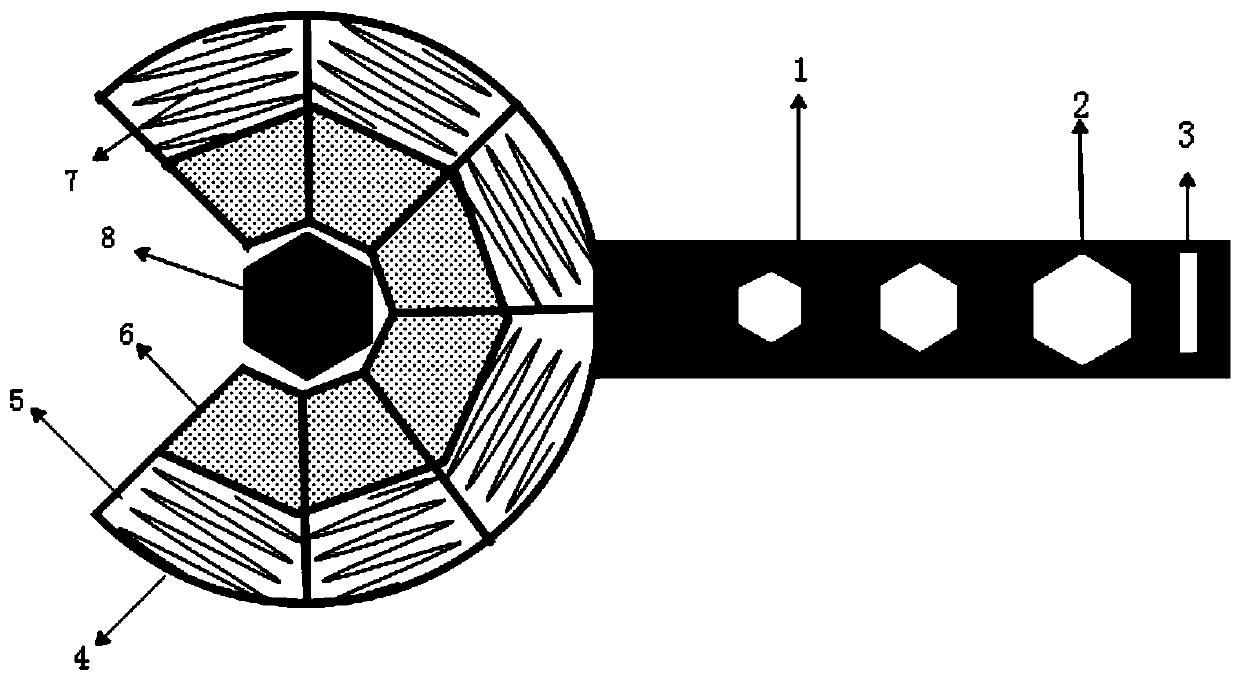

Full-automatic multifunctional battery cell disassembling mechanism

ActiveCN112388272ARealize automatic disassemblyFlexible layout quantityWaste accumulators reclaimingMetal working apparatusDrive wheelElectric machinery

The invention belongs to the technical field of battery cell disassembling, and particularly relates to a full-automatic multifunctional battery cell disassembling mechanism. The full-automatic multifunctional battery cell disassembling mechanism comprises a supporting frame, an air cylinder supporting plate is installed on the supporting frame, an air cylinder is installed on the air cylinder supporting plate, a connecting frame is connected with the power output end of the air cylinder, a belt supporting frame is installed on the connecting frame, and a driving wheel, a driven wheel and a belt are installed on the belt supporting frame; the supporting frame is connected with a motor supporting plate, the motor supporting plate is provided with a motor, the power output end of the motor is connected with a lead screw, the lead screw is connected with a lead screw nut, the lead screw nut is connected with a lead screw nut fixing base, the lead screw nut fixing base is connected with aguide plate, the guide plate is provided with a center guide groove set, the center guide groove set is provided with a bearing, and the bearing is connected with a guide seat mounting plate; and a guide seat is installed on the guide seat mounting plate, a second bearing is installed in the guide seat, the second bearing is fixedly connected with a lock nozzle, a guide shaft is installed in the lock nozzle in a sliding mode, the guide shaft is provided with a plurality of claw clamp guide blocks, and a claw clamp block is installed on a claw clamp block mounting seat.

Owner:深圳市金凯博自动化测试有限公司

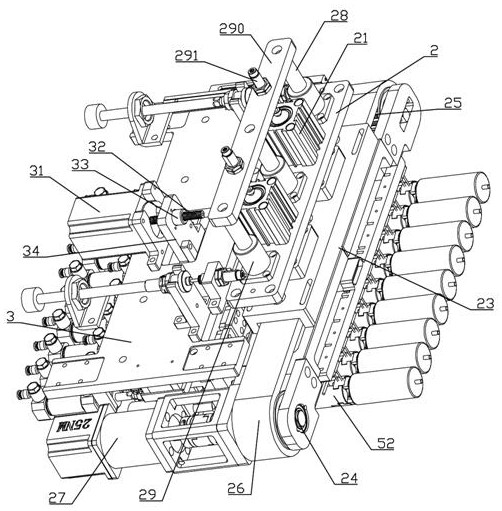

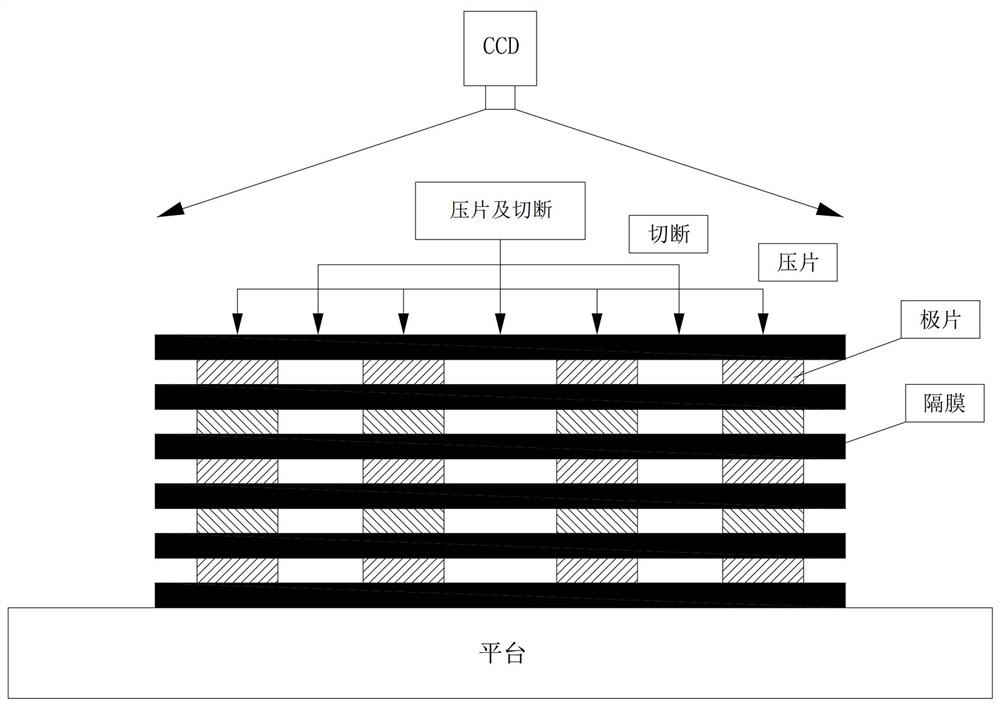

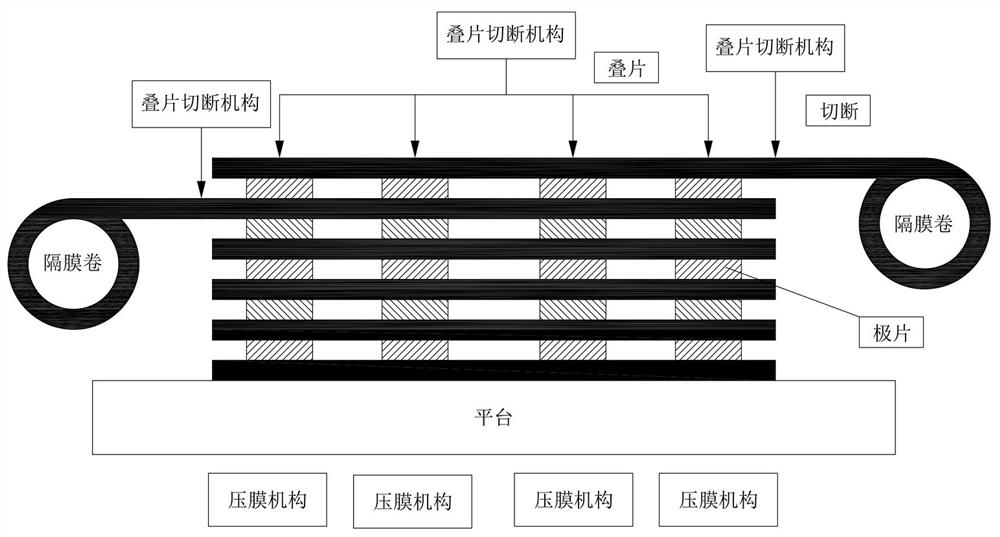

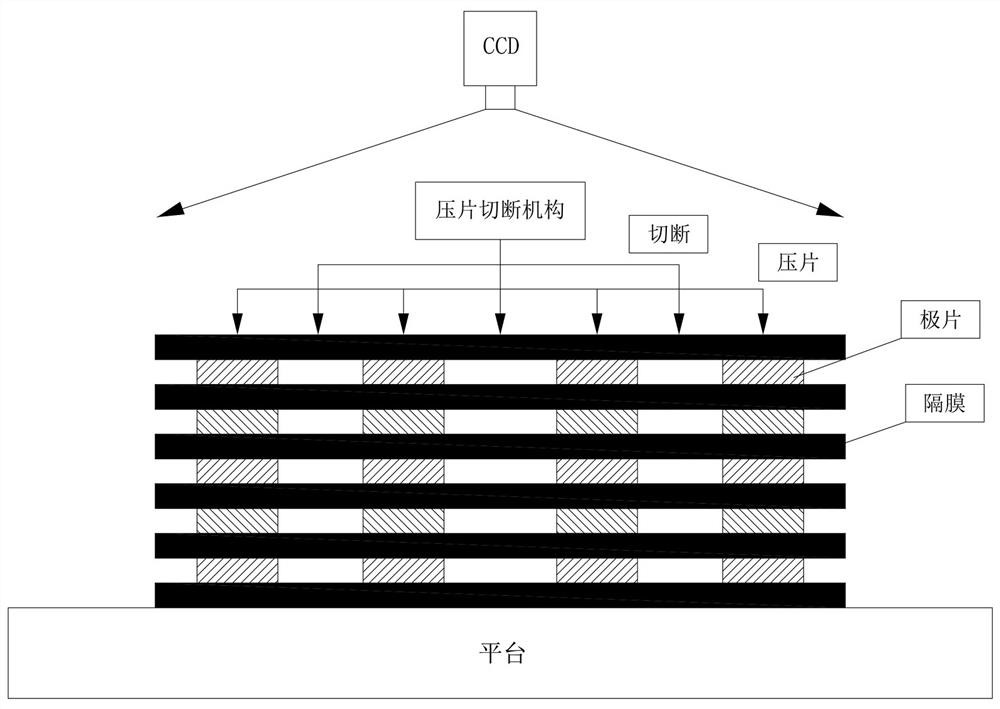

A multi-electrode sheet group linkage tablet pressing and cutting device with width adjustment function

ActiveCN114069056BWith width adjustment functionImprove cutting efficiencyElectrode rolling/calenderingFinal product manufactureStructural engineeringTableting

The invention discloses a multi-pole sheet group linked tablet pressing and cutting device with a width adjustment function, comprising a support adjustment assembly, a cutting assembly and a tablet pressing assembly, the support adjustment assembly includes a support component, a driving component and an adjustment component; the support component is arranged horizontally , the driving parts include two groups, which are respectively arranged on both sides of the supporting part; the adjusting parts include at least two groups, and the adjusting parts are movably arranged on the supporting parts, wherein the two groups of adjusting parts are connected with the output ends of the two groups of driving parts; The assembly includes at least two groups, the cut-off assembly is arranged horizontally below the support adjustment assembly, and is respectively connected with the adjustment parts; the pressing assembly includes at least two groups, and the pressing assembly is arranged horizontally below the support adjustment assembly, and is respectively connected with the adjustment parts . The invention is applicable to the multi-electrode sheet lamination process, has the tablet pressing and cutting linkage function, and has the width linkage adjustment function while ensuring the cutting accuracy and improving the cutting efficiency.

Owner:江苏兴禾自动化有限公司

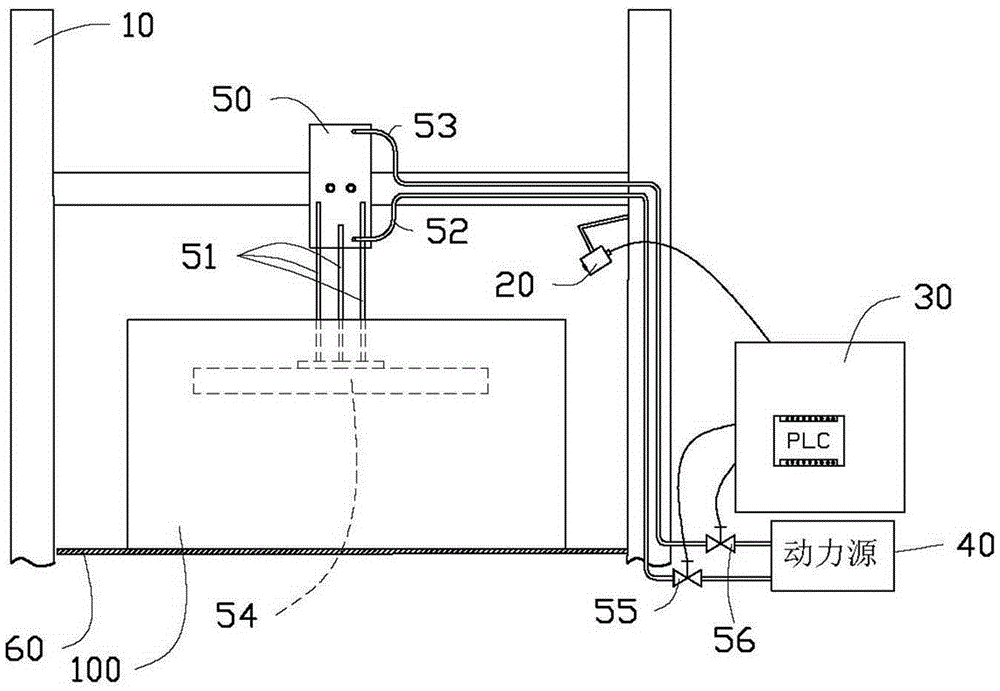

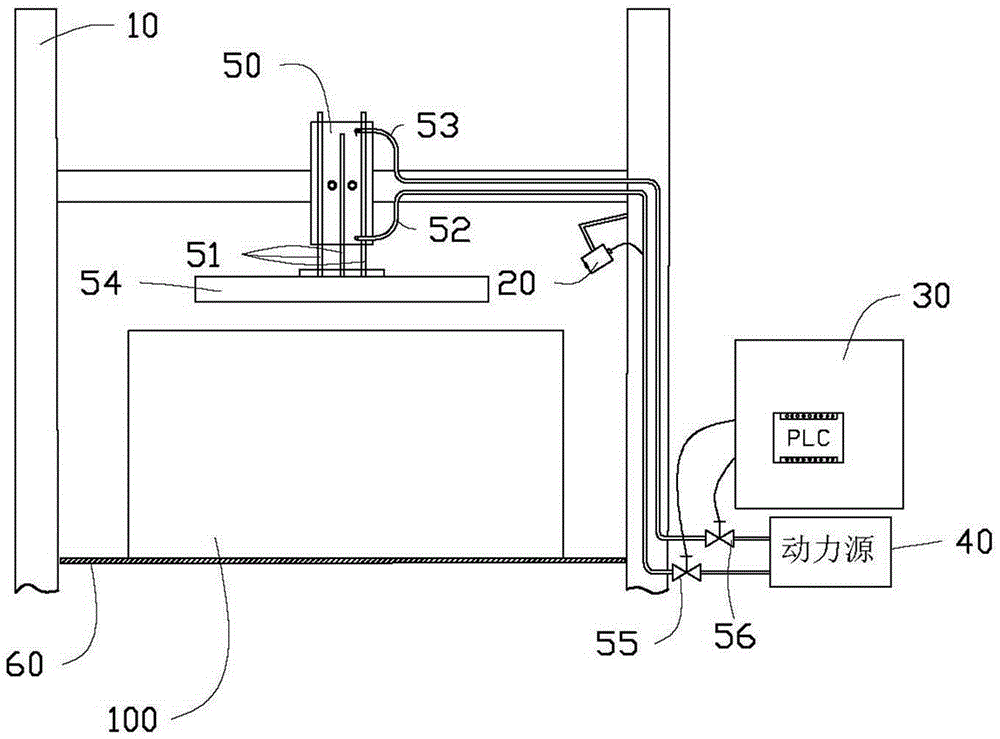

Household intelligent ironing robot

InactiveCN114672977AGentle handlingNot easy to damageIroning apparatusTextiles and paperHome useControl system

The invention discloses a household intelligent ironing robot, relates to the technical field of clothes ironing, and aims to solve the problems that a large amount of traditional clothes ironing products depend on manual operation, the ironing function effect of nursing machine products is weak, and the daily ironing flatness requirement cannot be met. The steam ironing module is connected with the up-down driving mechanism and used for providing close-range targeted steam to soften and iron the clothes; the air blowing and sucking module is used for being matched with the ironing process and controlling the inflatable clothes hanger to blow and suck air; the main control system is connected with the steam ironing module and the air blowing and sucking module respectively, judges the type of ironed clothes according to different input signals, controls the air blowing and sucking module and the steam ironing module to carry out corresponding ironing processes, simulates manual ironing elements in a mode of mutual cooperation of software and hardware, achieves the effect close to manual ironing, liberates manpower, and is small in whole machine structure and convenient to operate. The device is small in space limitation, very suitable for household use and easy to popularize.

Owner:杭州优地工业设计有限公司

An automatic control system and method for an eight-roller crusher

Owner:江西翔麟矿业有限责任公司

Smart Folding Massage Chair

ActiveCN109288647BAutomatic spacing adjustmentImprove comfortChiropractic devicesRoller massageInterior spacePhysical medicine and rehabilitation

An intelligent folding massage chair relates to the technical field of massage chairs. To solve the problem that existing massage chairs are not suitable for use as ordinary office or leisure seats, the left neck massage component, the right neck massage component and the waist massage component pass through the first telescopic driving structure, the second telescopic driving structure and the second telescopic driving structure respectively. The three-telescopic drive structure is mounted on the seat back support. Not only can it be used as a traditional massage chair, but the left neck massage component, right neck massage component and waist massage component can be retracted into the inner space of the backrest when no massage is needed, so that the back of the chair is flat, soft and comfortable, and can be used as an ordinary office or leisure seat When the chair is used, it is especially suitable for use in the family. In addition, the distance between the left neck massage unit and the right neck massage unit can be automatically adjusted through the automatic distance adjustment mechanism. For users with thin or thick necks, moderate massage strength can be used, and the comfort is good. User Experience Effects.

Owner:深圳市诺嘉智能养生发展有限公司

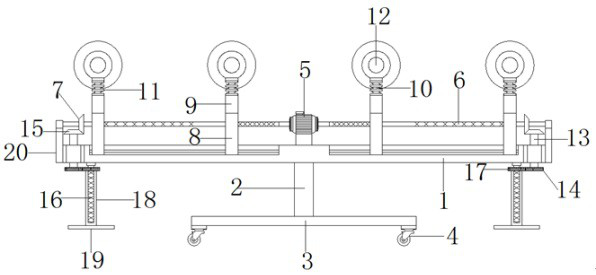

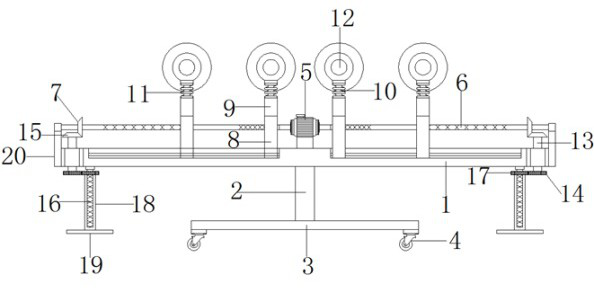

Conveying device

PendingCN107777212ASimple structureReasonable designConveyorsRoller-waysEngineeringMechanical engineering

The invention provides a conveying device. The conveying device comprises a support and is characterized in that a plurality of slide grooves are fixedly connected to the top of the support, the slidegrooves are distributed in two rows, the positions of the slide grooves are in one-to-one correspondence, a slider which can slide relative to each slide groove is arranged in the corresponding slidegroove, a roller support is fixedly connected to each slider, and a roller is fixedly mounted on each roller support. The conveying device has the advantages that the conveying device is simple in structure, reasonable in design, convenient to use, suitable for being used to convey thermal-insulation pipes of various sizes, high in operation stability and capable of being popularized and used ina large-scale manner in thermal-insulation-pipe production enterprises, and the interval between every two rollers can be adjusted.

Owner:TIANJIN JINCHENGTAI ENERGY SAVING BUILDING MATERIAL TECH

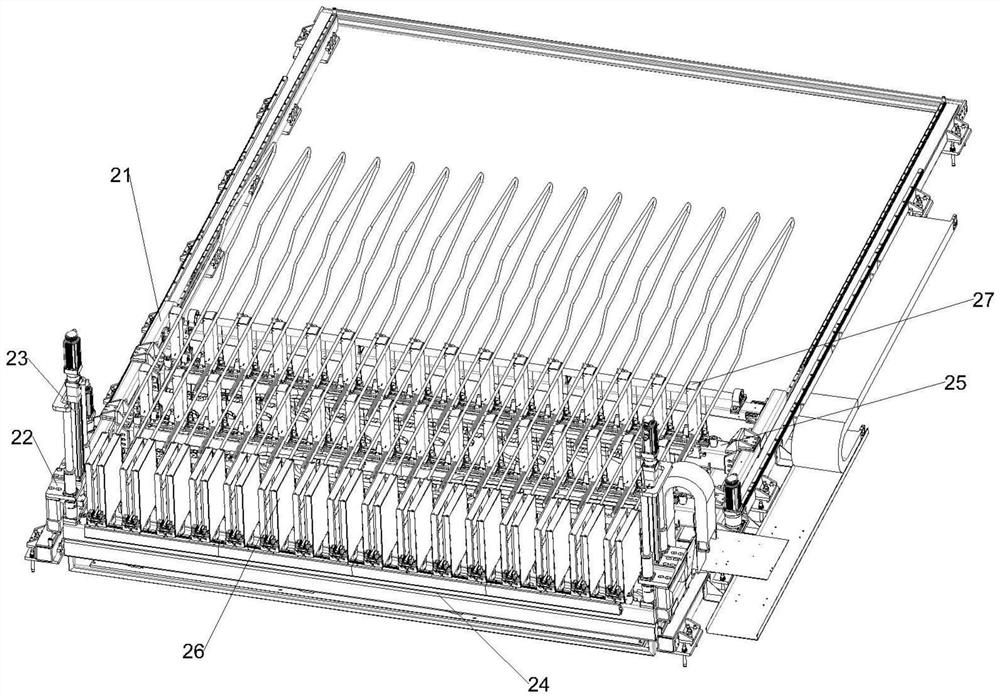

Machine for conveying multiple U-shaped steel bars

PendingCN114714131ARealize flexible torque conversionAutomatic spacing adjustmentMeasurement/indication equipmentsMetal working apparatusClassical mechanicsEngineering

The machine comprises a rack, base plates are fixedly arranged at the tops of the two sides of the rack, linear bearings and electric cylinders are arranged on the base plates, guide rod shafts are connected into the linear bearings in a sleeved mode, first servo motors are arranged at the tops of the electric cylinders, and the guide rod shafts and output shafts of the electric cylinders penetrate through the base plates to be connected with load mounting plates. The load mounting plate is arranged on a first support, a plurality of sliding feeding mechanisms are arranged on the first support, at least one second support parallel to the first support is further arranged between the racks, and a plurality of material supporting mechanisms are arranged on the second support. The feeding mechanisms drive the first enclasping devices to move through the first dial-up assemblies to achieve interval adjustment on the first support, and the supporting mechanisms drive the second enclasping devices to move through the second dial-up assemblies to achieve interval adjustment on the second support. Fixed-length conveying of a plurality of U-shaped steel bars is achieved, the U-shaped steel bars with openings of different widths are compatible, and flexible torque changing between the U-shaped steel bars can be achieved.

Owner:RBS PARTNERS S&T CO LTD

Food cartoning machine

ActiveCN104828287BAutomatic spacing adjustmentExclude human interventionIndividual articlesEngineeringMechanical equipment

The invention relates to the field of food processing mechanical equipment, and particularly discloses a novel food boxing machine, which comprises a lower box mechanism, an arranged box conveying mechanism and a pushing-in mechanism, wherein both the lower box mechanism and the pushing-in mechanism are placed above the arranged box conveying mechanism; the lower box mechanism is arranged at one end of the pushing-in mechanism; one side of the pushing-in mechanism is provided with a conveying belt used for conveying food for which a box is to be arranged; the novel food boxing machine also comprises a mounting framework; the mounting framework comprises a fixed mounting plate and a plurality of mechanical push plates which are located below the fixed mounting plate. According to the novel food boxing machine, the movements of the mechanical push plates in two directions are realized by utilizing a guiding device and a horizontal driving mechanism; moreover, the full-automatic adjustment can be realized; therefore, the mechanical push plates can be used for automatically realizing spacing adjustment in the condition of without the help of manpower; moreover, the novel food boxing machine can adapt to supporting boxes in multiple sizes by only replacing a track plate; the manpower participation is removed; the production efficiency is improved; the degree of automation is increased.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Iron sheet printing production line

ActiveCN112895699AHigh degree of automationExtended delivery pathConveyorsRotary pressesUV curingProcess engineering

The invention discloses an iron sheet printing production line. The iron sheet printing production line comprises a feeding device, a printing device, a UV curing device, a cooling device and a discharging device which are sequentially arranged, the feeding device is connected with the printing device through a first conveying belt, the printing device is connected with the UV curing device through a second conveying belt, the UV curing device is connected with the cooling device through a third conveying belt, and the cooling device is connected with the discharging device through a fourth conveying belt. According to the iron sheet printing production line, automatic feeding and discharging operation on iron sheets is achieved, automation of the iron sheet printing production line is improved, position detection can be carried out on the iron sheets in a continuous working state through a detection device, and therefore it is ensured that the situation that two iron sheets are overlapped cannot occur, and the production efficiency is improved.

Owner:广州市恒宇印铁制罐有限公司

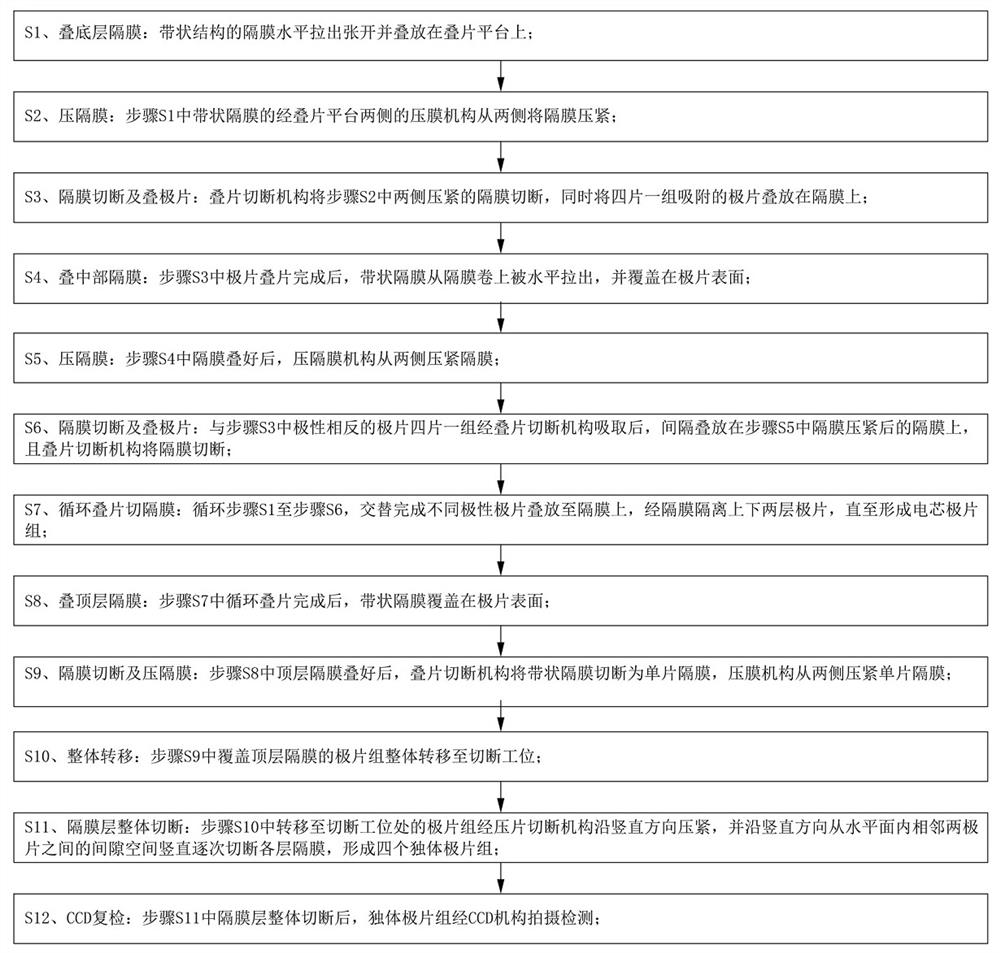

A multi-pole laminated diaphragm cutting process and device

ActiveCN114050323BGuaranteed lamination accuracyGuaranteed accuracyFinal product manufactureSecondary cellsStructural engineeringMechanical engineering

Owner:江苏兴禾自动化有限公司

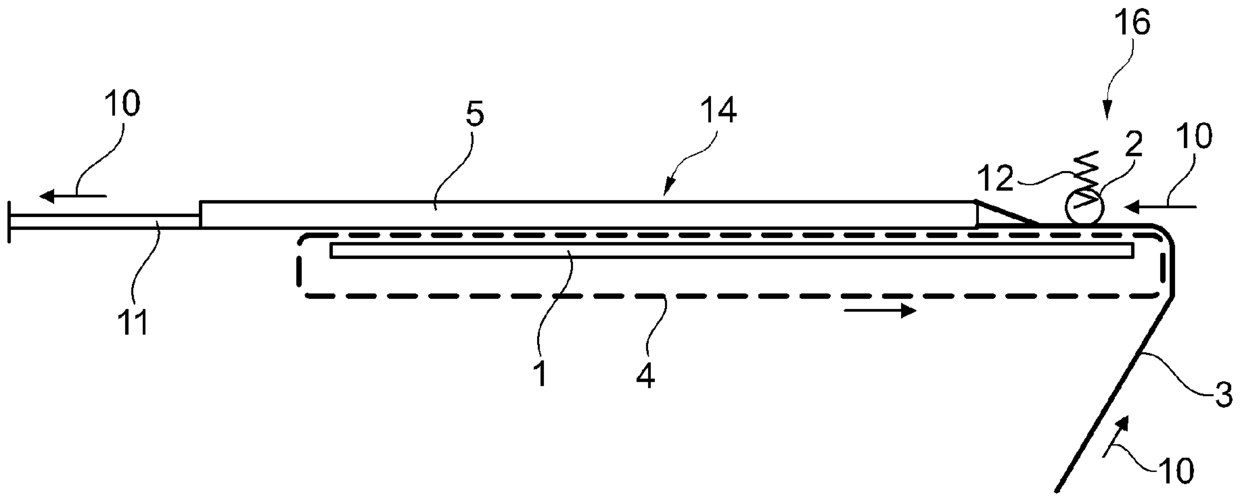

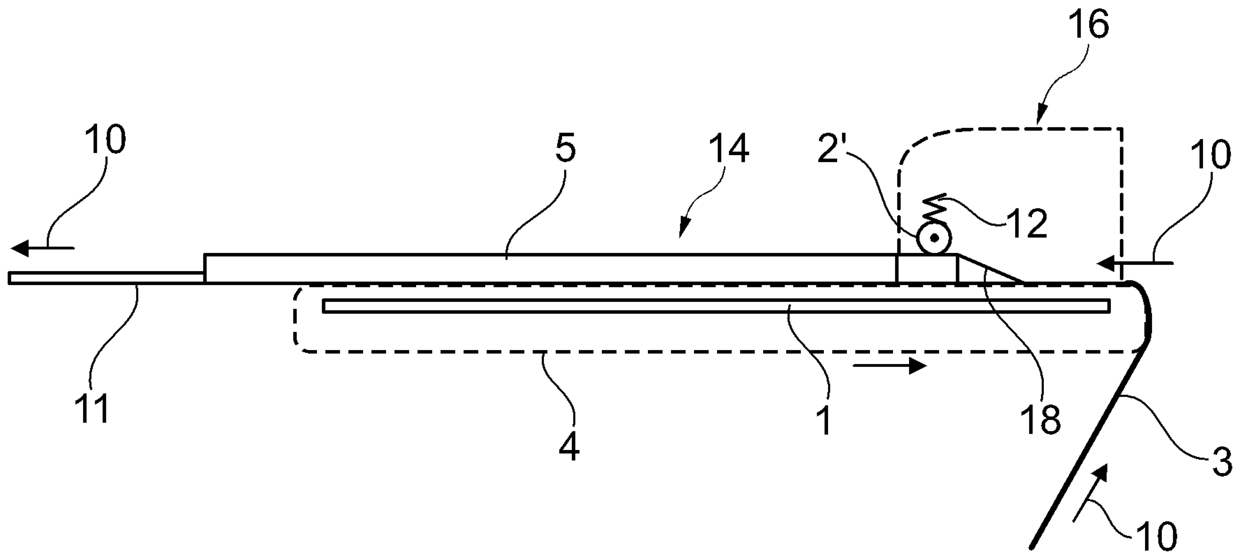

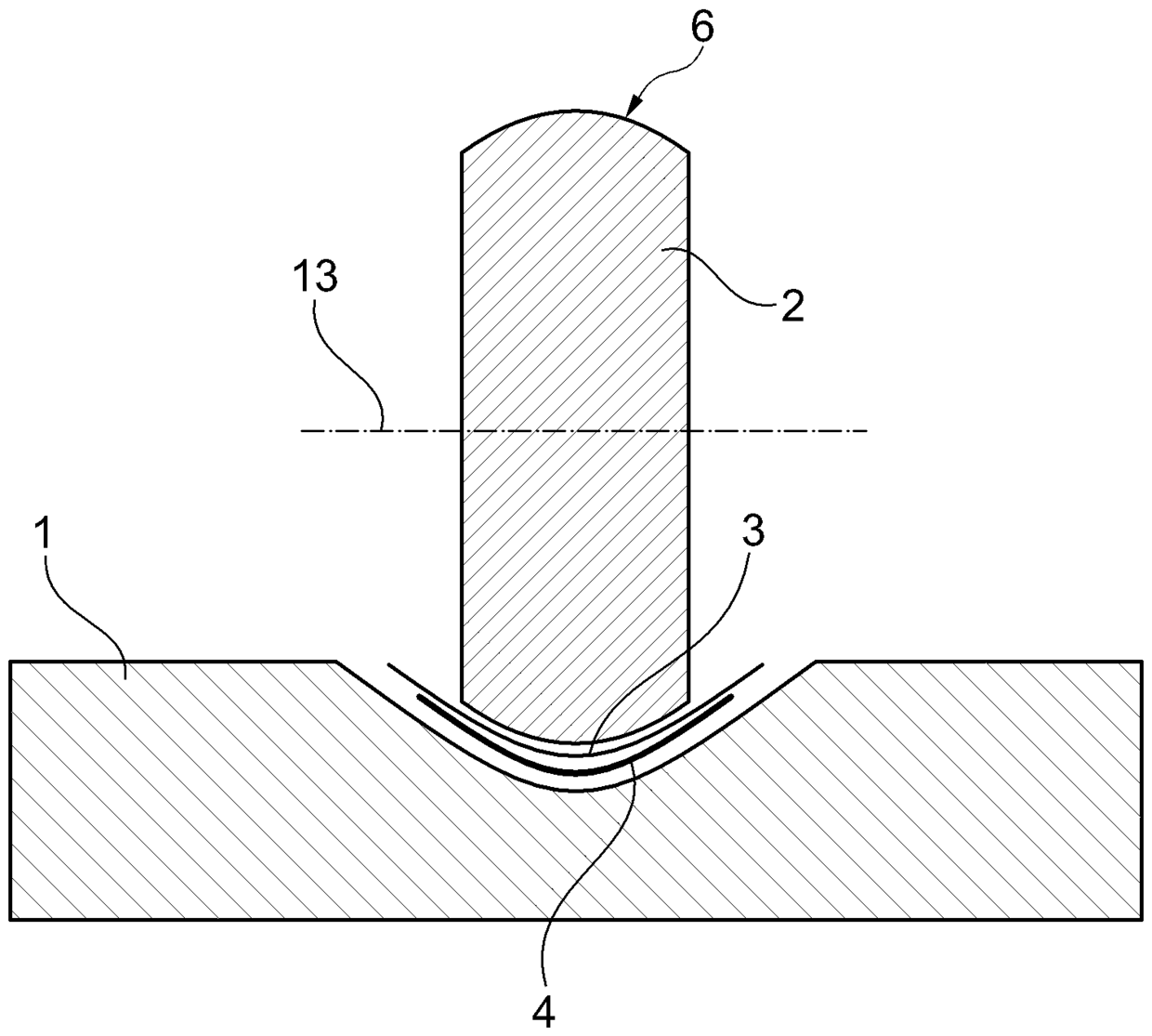

Hollow tube forming method in tobacco-processing industry and forming device

InactiveCN109198719ASafe to carryBig planeCigarette manufactureTobacco smoke filtersEngineeringTube forming

The invention relates to a method for producing a hollow tube (11) in the tobacco-processing industry, comprising steps of: conveying at least one flat material strip (3), which has longitudinal extent, in a longitudinal axial direction (10) to a forming device (14); applying the at least one material strip (3) to a forming strip (4) of the forming device (14), wherein the forming strip (4) is moved in the longitudinal axial direction (10) and arranged on a forming strip guide surface (15); preforming at least one material strip (3) in an inlet region (16) of the forming device (14) by means of a rotary device (2), the rotary device (2) exerting pressure on the at least one material strip (3) and the forming strip (4), wherein the preforming comprises pre-bending of the at least one material strip (3) in a direction transverse to the longitudinal extent of the at least one material strip (3); and forming the at least one material strip (3) into a hollow tube (11). Moreover, the invention relates to a forming device of the tobacco-processing industry.

Owner:HAUNI MASCHINENBAU AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com