Near field probe range finding method and device based on laser reflection

A technology of laser reflection and ranging method, which is applied in the field of terahertz microscopic imaging, can solve the problem of accurately measuring the distance between the photoconductive microprobe and the sample that has not yet been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

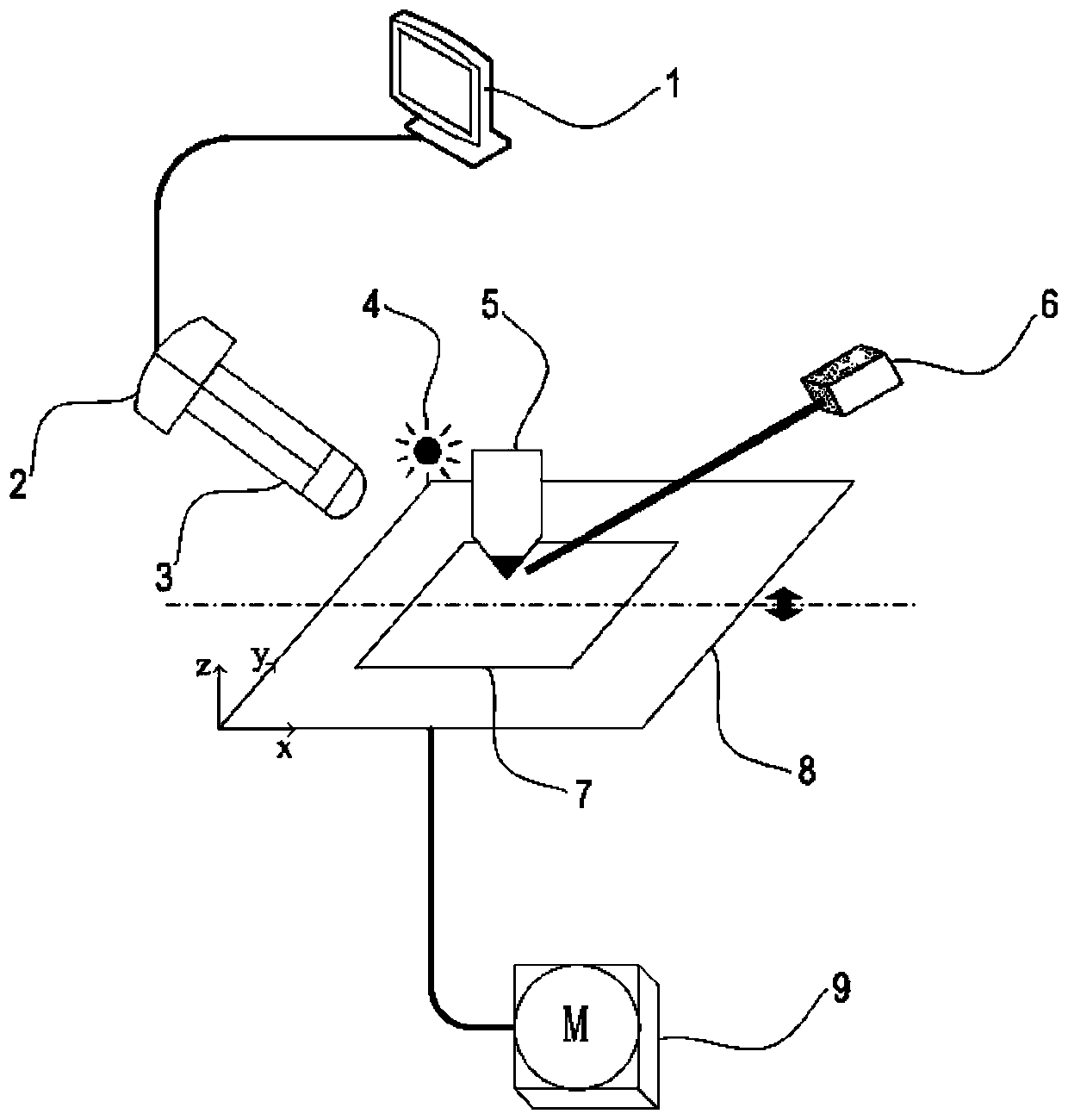

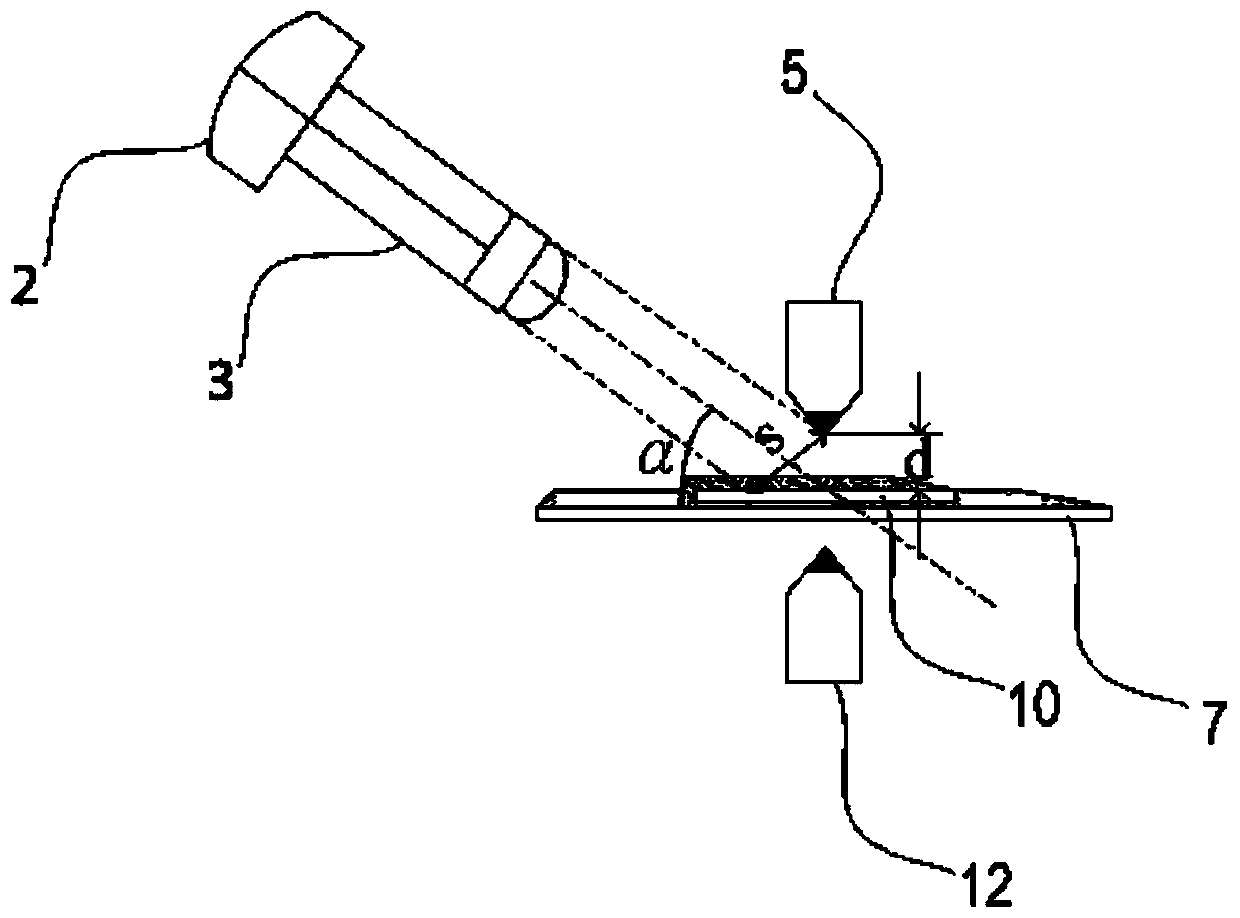

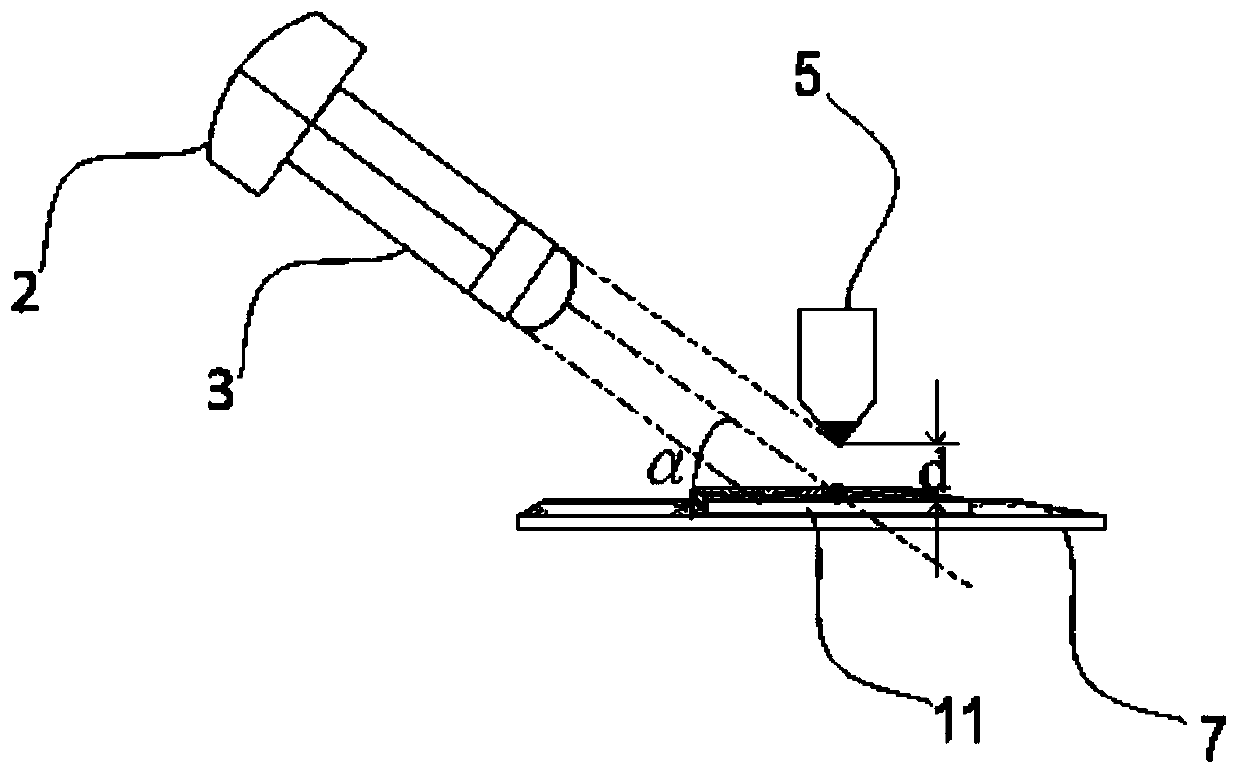

[0034] Embodiment 1: Measuring the distance between the photoconductive microprobe and the sample

[0035] Step 1: Image acquisition and processing

[0036] After adjusting the instrument and equipment, run the terahertz near-field scanning system to control the motor control box to move the sample toward the tip of the photoconductive microprobe (all sample movement operations in this system must be based on the fact that the sample does not touch the photoconductive microprobe. principle), after seeing the mirror image of the needle tip or the laser spot on the sample on the image fed back by the CCD, select a small amount of micron-level stepping movement, and then collect the color image transmitted by the CCD on the computer, and perform image processing and features on the collected image Extraction and other methods to obtain the photoconductive microprobe-sample spacing S on the image 1 .

[0037] Step 2: The measured image and the actual scale k

[0038] Control th...

Embodiment 2

[0041] Example 2: Automatically adjust and measure the distance between the photoconductive microprobe and the sample

[0042] Step 1: Image acquisition and scale determination

[0043] With step one, two in embodiment 1, measure scale k (wherein, for the sample with smooth surface, its image and actual scale are k 1 , for a sample with a rough surface, its image and actual scale bar is k 2 ).

[0044] Step 2: Automatically adjust the spacing system

[0045] Preset probe-sample spacing safety value d 0 , during the sample scanning test process, real-time extraction of the distance S on the image by computer, calculate the actual distance d according to the corresponding scale, and compare d with d 0 The size relationship is transmitted to the system control center, and then the movement of the sample in the Z direction is adjusted through the communication between the control center and the sample stage. Therefore, during the terahertz near-field scanning test, the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com