Food cartoning machine

A cartoning machine, food technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problem of not being able to put food in, achieve the effect of simple structure, simple replacement, and enhanced automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

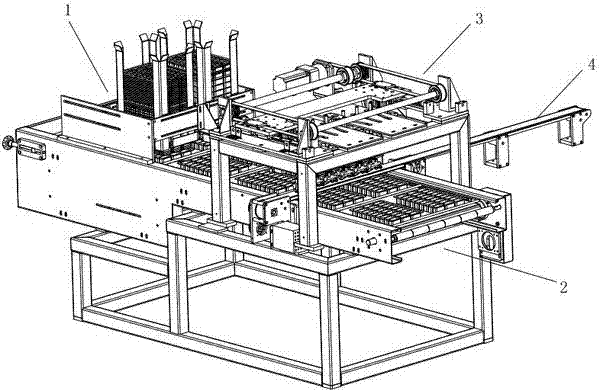

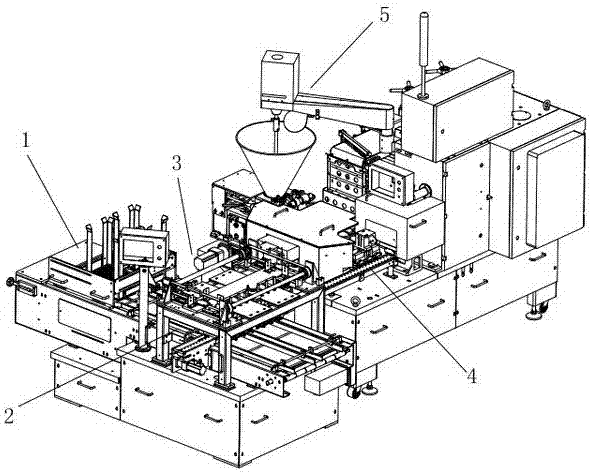

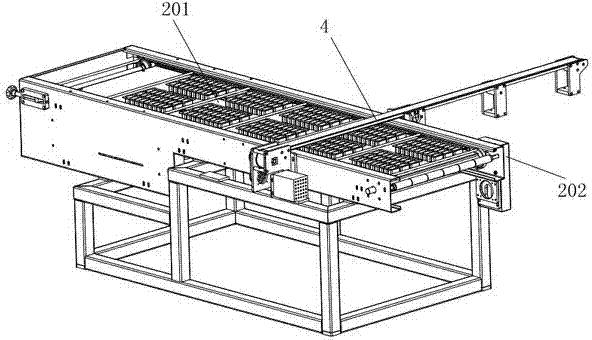

[0061] The food cartoning machine includes a lower box mechanism 1, a box discharge mechanism 2 and a push-in mechanism 3, and the lower box mechanism 1 and the push-in mechanism 3 are placed above the box discharge mechanism 2, and the lower box mechanism 1 is arranged on One end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and a fixed mounting plate 320 below. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, and the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, so The horizontal driving mechanism 304 is fixedly disposed on the fixed installation plate 320 .

[0062] The con...

Embodiment 2

[0065] The food cartoning machine includes a lower box mechanism 1, a box discharge mechanism 2 and a push-in mechanism 3, and the lower box mechanism 1 and the push-in mechanism 3 are placed above the box discharge mechanism 2, and the lower box mechanism 1 is arranged on One end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and a fixed mounting plate 320 below. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, and the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, so The horizontal driving mechanism 304 is fixedly disposed on the fixed installation plate 320 . One end of the c...

Embodiment 3

[0084] The food cartoning machine includes a lower box mechanism 1, a box discharge mechanism 2 and a push-in mechanism 3, and the lower box mechanism 1 and the push-in mechanism 3 are placed above the box discharge mechanism 2, and the lower box mechanism 1 is arranged on One end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and a fixed mounting plate 320 below. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, and the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, so The horizontal driving mechanism 304 is fixedly disposed on the fixed installation plate 320 . One end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com