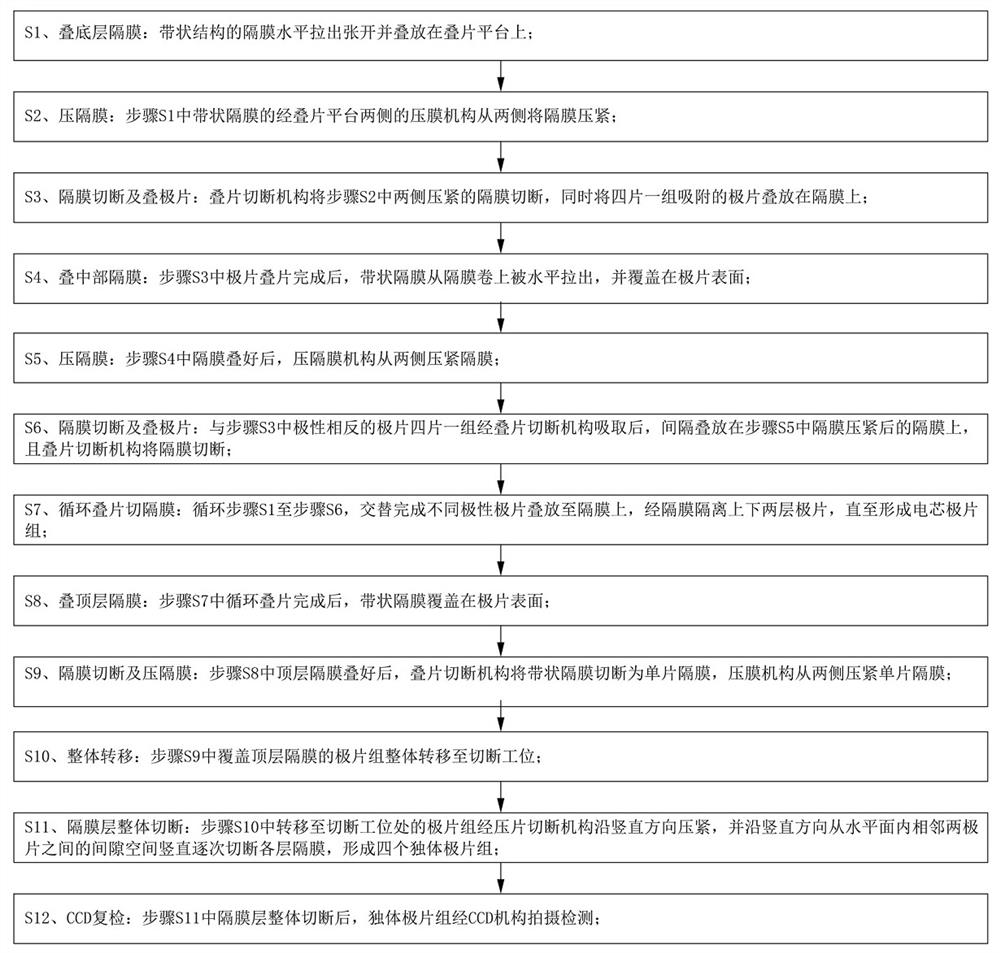

A multi-pole laminated diaphragm cutting process and device

A technology for cutting devices and diaphragms, which is applied in metal processing, sustainable manufacturing/processing, climate sustainability, etc., and can solve problems such as inability to guarantee lamination efficiency, inability to guarantee the accuracy of positive and negative electrodes, and lack of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

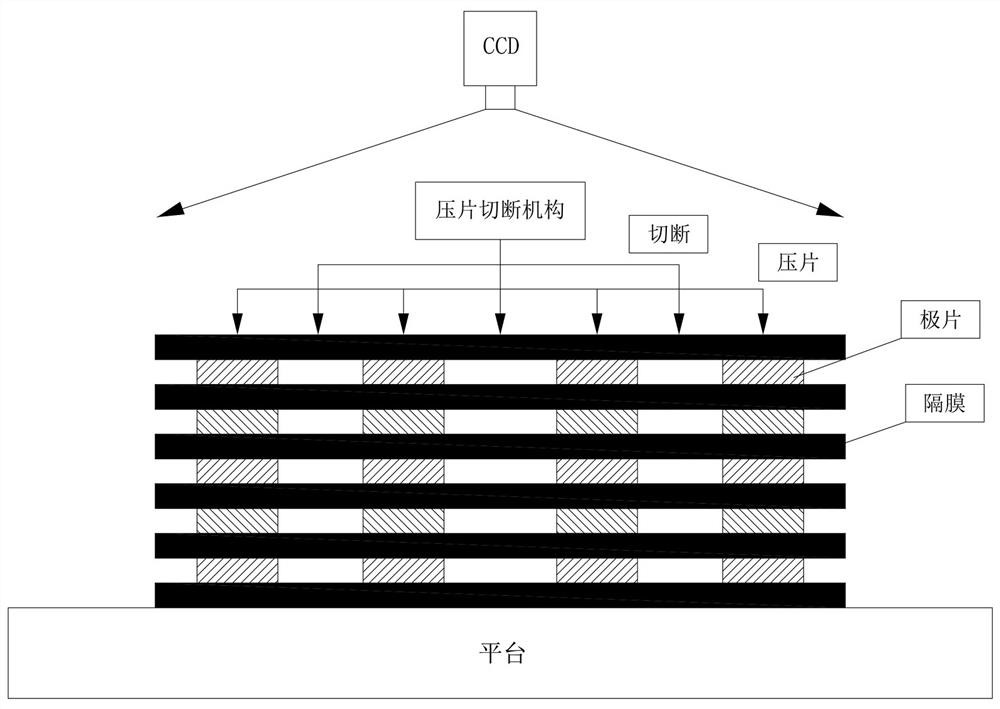

[0073] S12, CCD re-inspection: after the diaphragm layer is cut off as a whole in step S11, the single-body pole piece group is photographed and detected by the CCD mechanism.

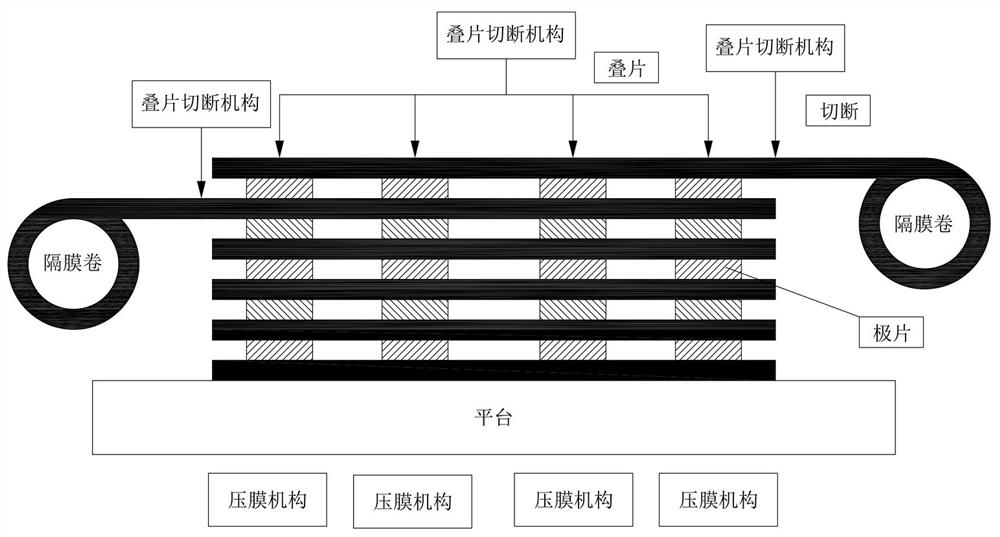

[0077] The lamination mechanism (2) comprises a lamination support (21), a lamination support plate (22), a lamination cylinder (23) and a lamination claw (24), which

[0078] The lamination cutting mechanism includes a lamination assembly (3) and a cutting assembly (4), wherein the above lamination assembly (3) includes a lamination

[0079] The cutting assembly (4) comprises a cutting support plate (41), a fixing member and a cutting wire (46), wherein the above-mentioned cutting support plate (41)

[0080] The fixing component includes a first fixing block (42), a second fixing block (43), a fixing seat (44) and a tensioning cylinder (45), which

[0081] The tablet pressing and cutting mechanism includes a support adjustment assembly (5), a cutting assembly (4) and a tablet pressing assembly (6), wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com