Multi-pole laminated diaphragm cutting process and multi-pole laminated diaphragm cutting device

A cutting device and diaphragm technology, applied in the field of lithium-ion batteries, can solve the problems of inability to guarantee lamination efficiency, inability to guarantee the accuracy of positive and negative electrodes, lack of alignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

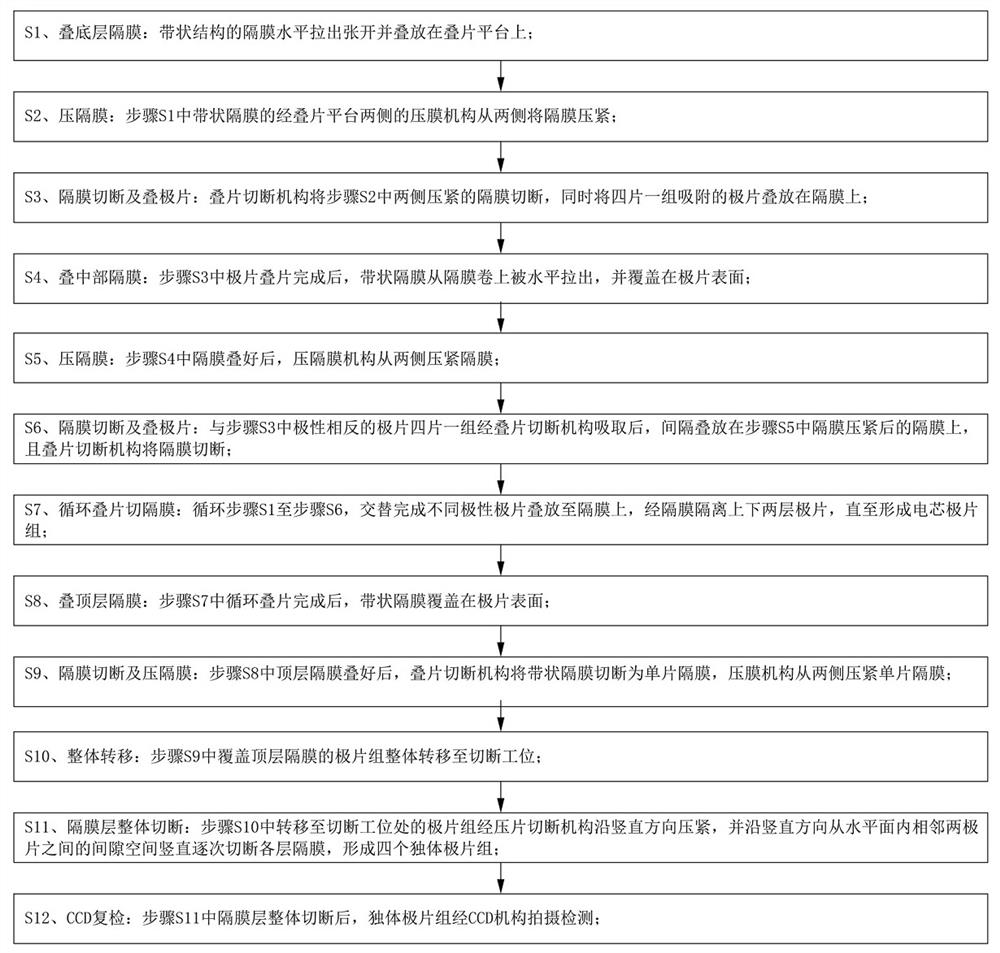

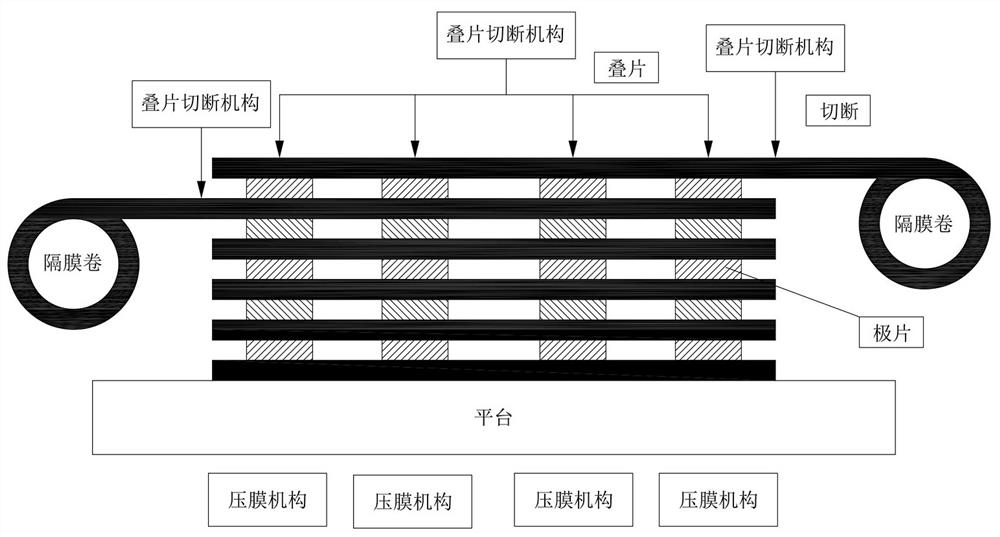

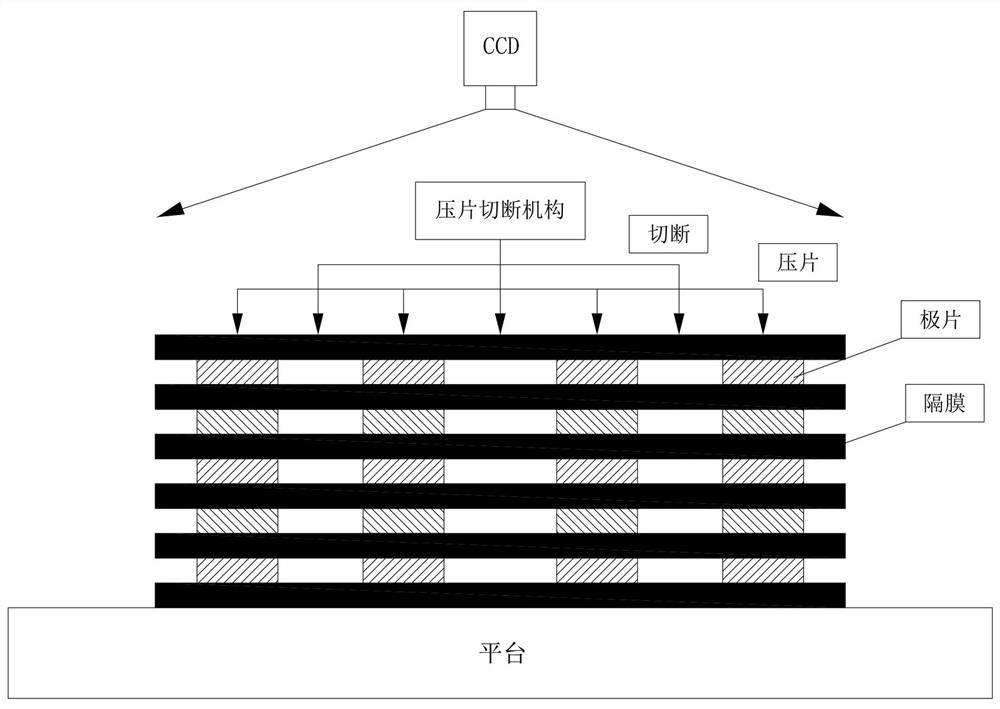

[0059] Such as Figure 1 to Figure 17 As shown, the technical scheme adopted by the present invention is as follows: a multi-pole sheet laminated diaphragm cutting process includes the following process steps:

[0060] S1. Laminated diaphragm: the strip-shaped diaphragm is pulled out horizontally and stacked on the lamination platform;

[0061] S2. Pressing the diaphragm: in step S1, the film pressing mechanisms on both sides of the strip diaphragm press the diaphragm from both sides through the lamination platform;

[0062] S3. Diaphragm cutting and pole stacking: the lamination cutting mechanism cuts off the diaphragms pressed on both sides in step S2, and at the same time stacks the adsorbed pole pieces in groups of four on the diaphragm;

[0063] S4, stacking the middle diaphragm: after the pole piece lamination is completed in step S3, the strip-shaped diaphragm is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com