Machine for conveying multiple U-shaped steel bars

A steel bar, U-shaped technology, used in metal processing machinery parts, metal processing, measuring/indicating equipment, etc., can solve problems such as reduced work efficiency, shaking at both ends of the steel bar, inability to accurately convey the length, etc., to improve work efficiency, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will combine Figure 1-13 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

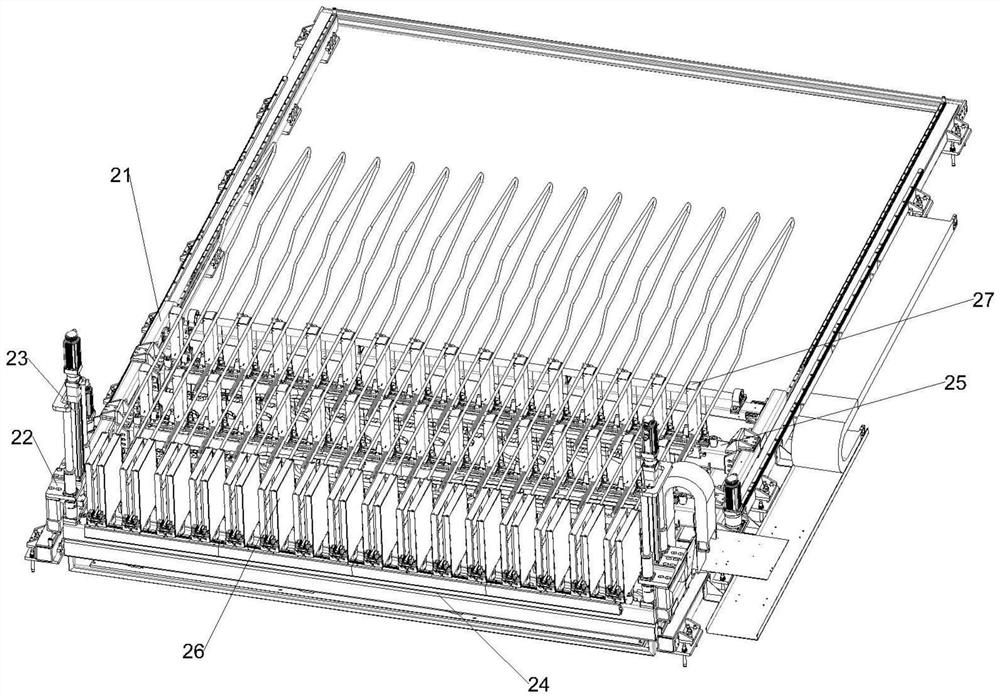

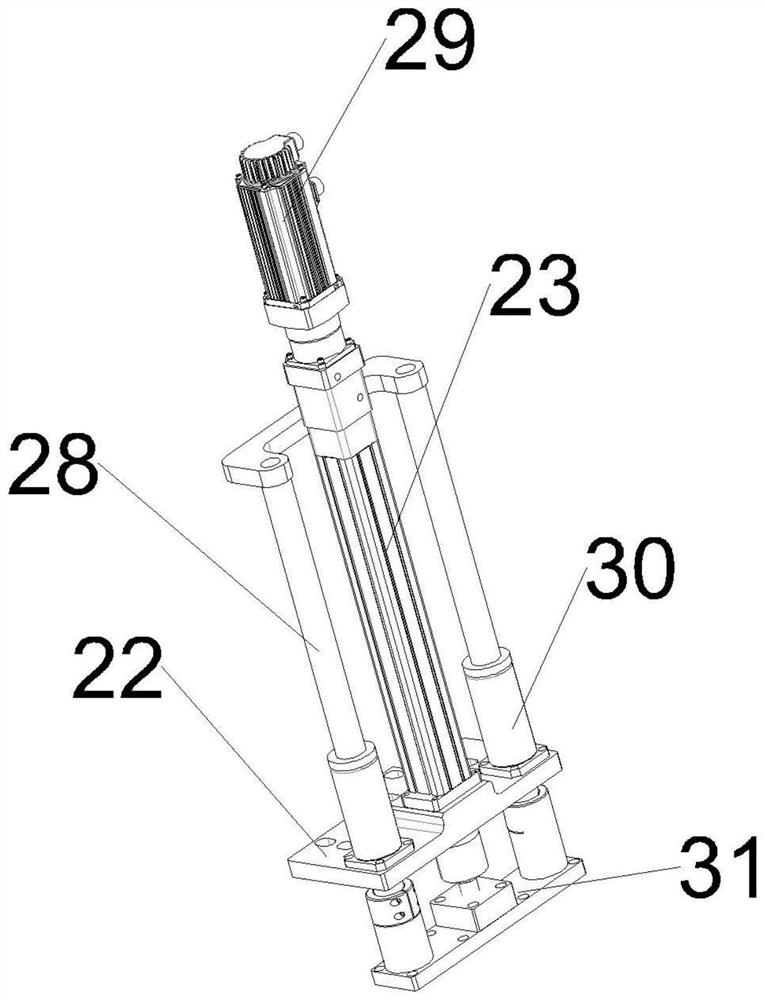

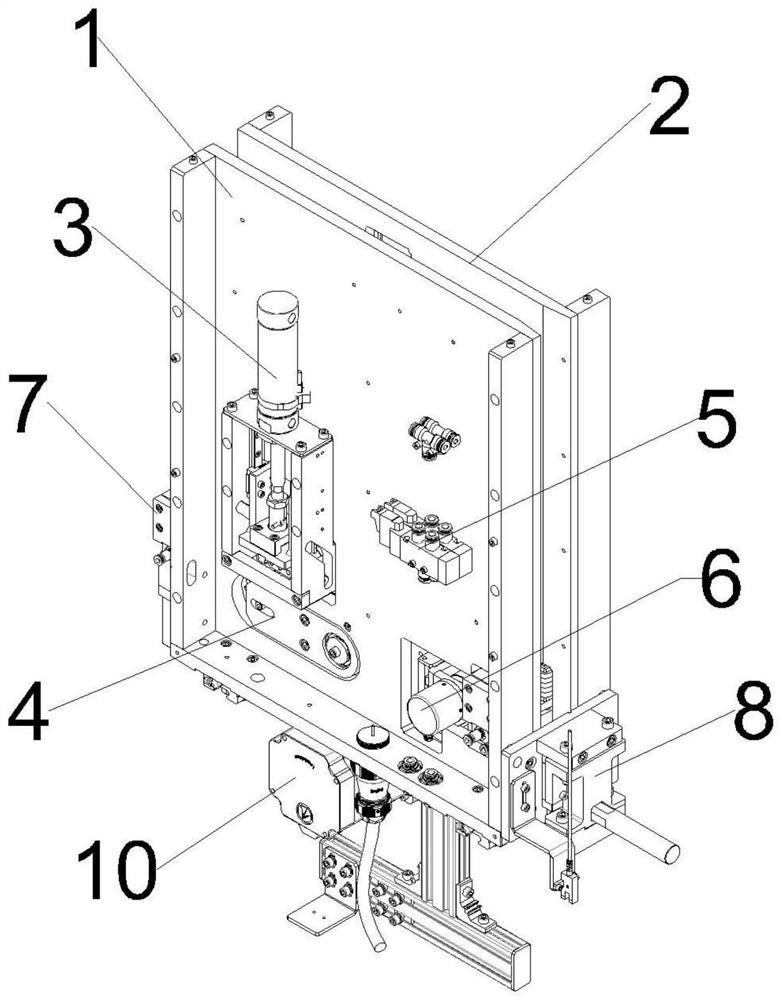

[0033]A multiple conveying machine for U-shaped steel bars, which includes a frame 21, a base plate 22 is fixed on the tops of both sides of the frame, a linear bearing 30 and an electric cylinder 23 are arranged on the base plate, and the linear bearing is internally sleeved. The guide rod shaft 28 is connected, and the top of the electric cylinder is provided with a first servo motor. On the bracket 24, several sliding feeding mechanisms 26 are arranged on the first bracket, and at least one second bracket 25 parallel to the first bracket is also arranged between the racks, and several second brackets are arranged on the second bracket. A material holding mechanism 27, one end of each described feeding mechanism is slidably inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com