Hand-operated pencil planing

A hand-cranked pencil technology, applied in the field of pencil sharpeners, can solve problems such as inconvenient use, inability to flexibly adjust the feed force of the pencil clip, and broken nibs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

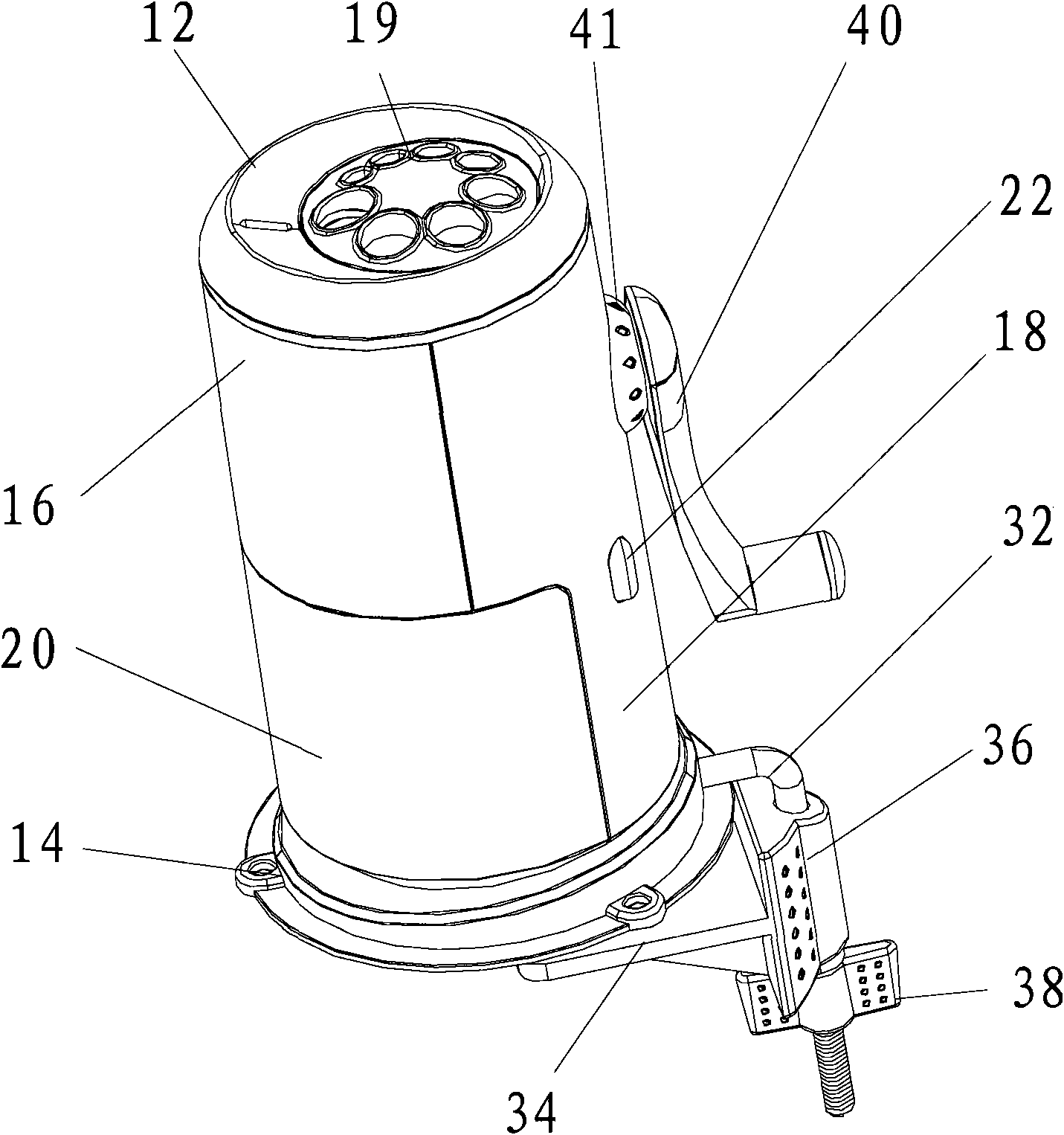

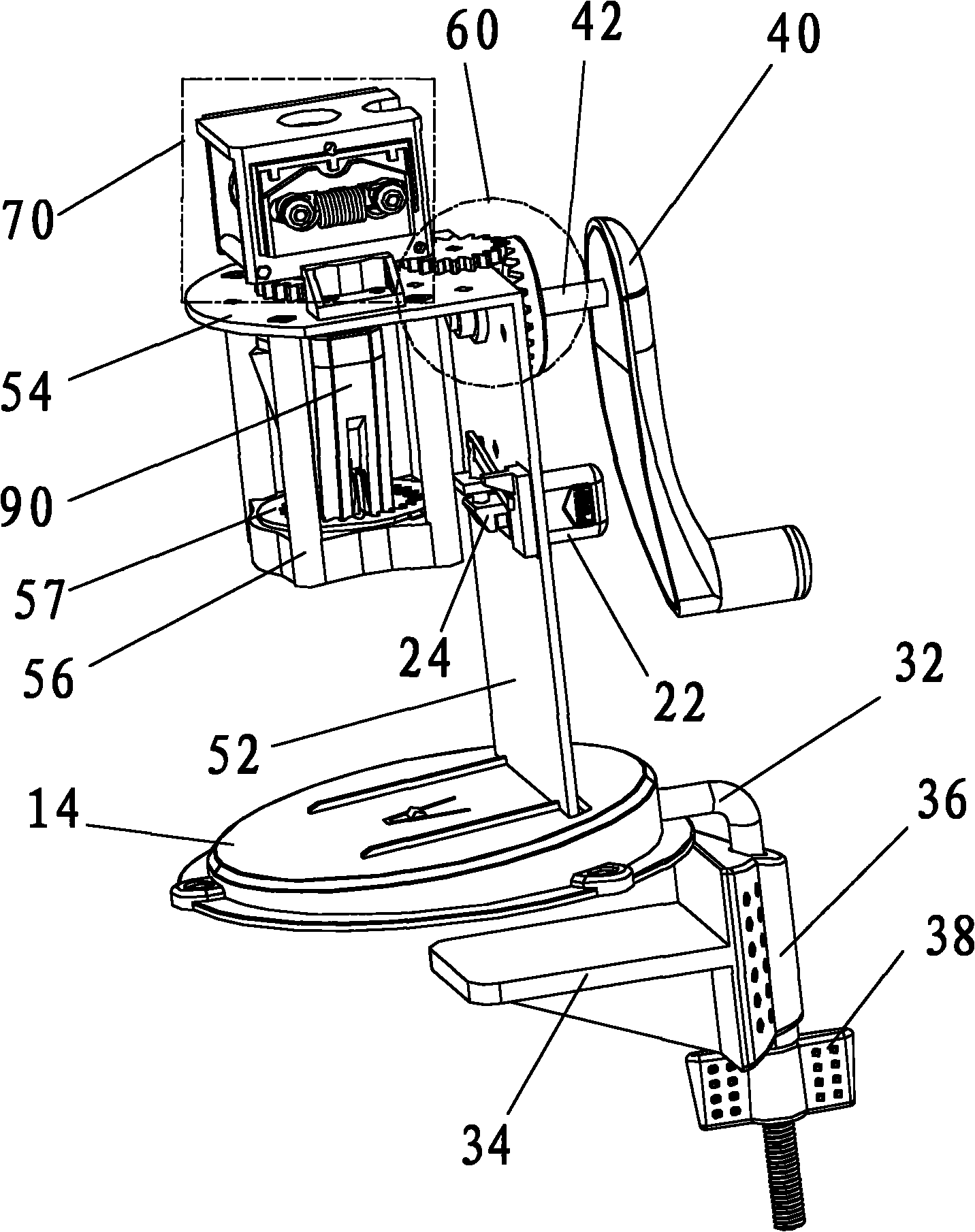

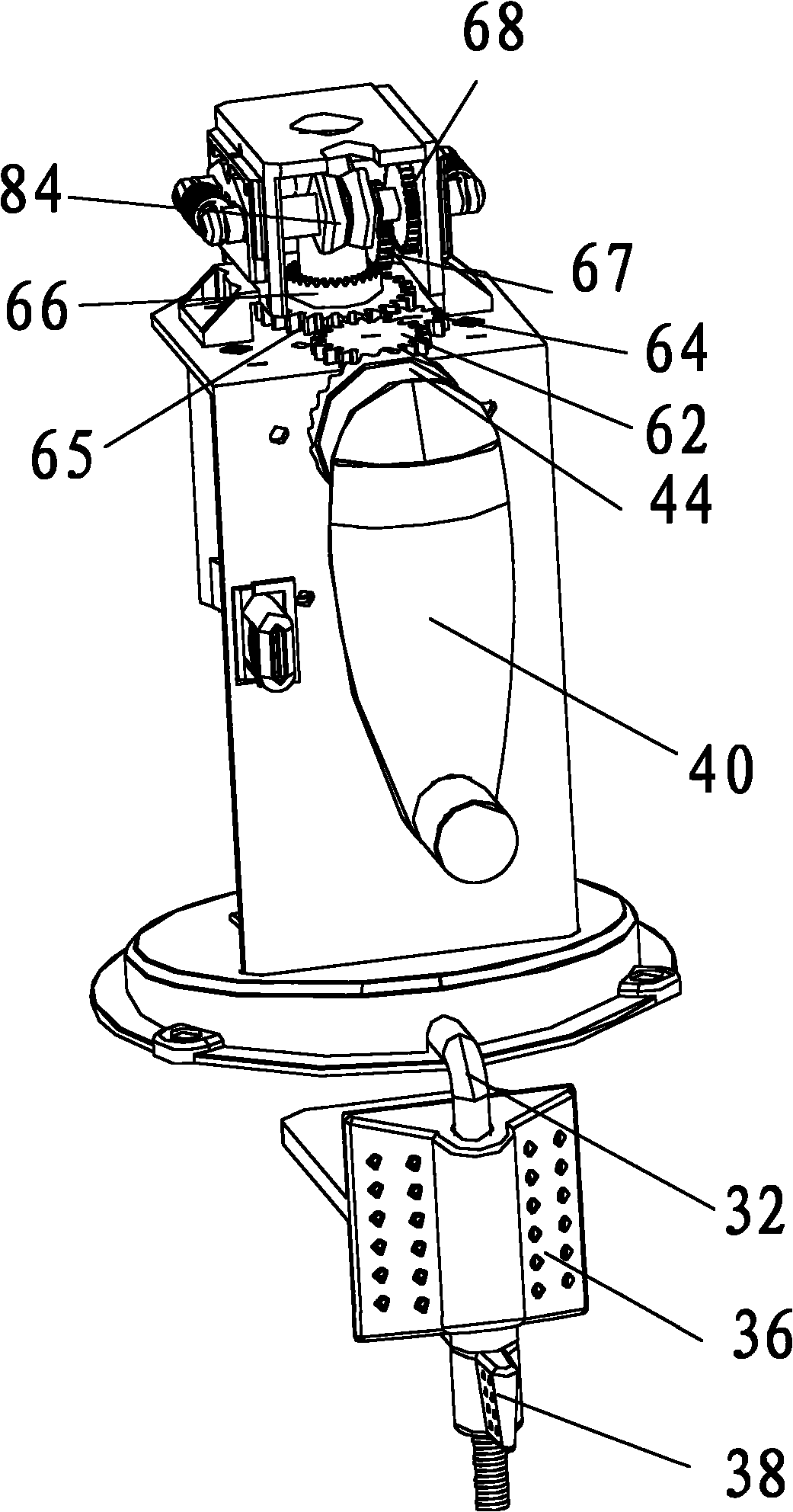

[0029] Please refer to figure 1 , a hand-operated pencil sharpener, including a housing, a screw cap 19 with several openings on the top of the housing, a rocker 40 on one side of the housing, a fixing device at the bottom of the housing, and a The pen feeding device 70, the planing device 90 and the waste box 20 are sequentially arranged in the body from top to bottom. To put it simply, in this hand-operated pencil sharpener, the pencil enters the planing device 90 for planing along the vertical pen-feeding path under the action of the pen-feeding device 70 , and the scraps after planing fall into the waste box 20 immediately. When in use, insert the pencil into the opening corresponding to the screw cap 19 and then shake the crank handle 40 to finish planing the pencil and withdrawing the pencil, which reduces the influence of manual work on the pencil planing quality, greatly improves the quality of pencil manual planing and also improves the quality of pencil planing. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com