A multi-electrode sheet group linkage tablet pressing and cutting device with width adjustment function

A technology of width adjustment and cutting device, used in electrode rolling/calendering, electrode manufacturing, battery electrodes, etc., can solve problems such as time-consuming, lack of alignment, inability to ensure the accuracy of positive and negative plates, and avoid position deviation. The effect of moving, ensuring position accuracy, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

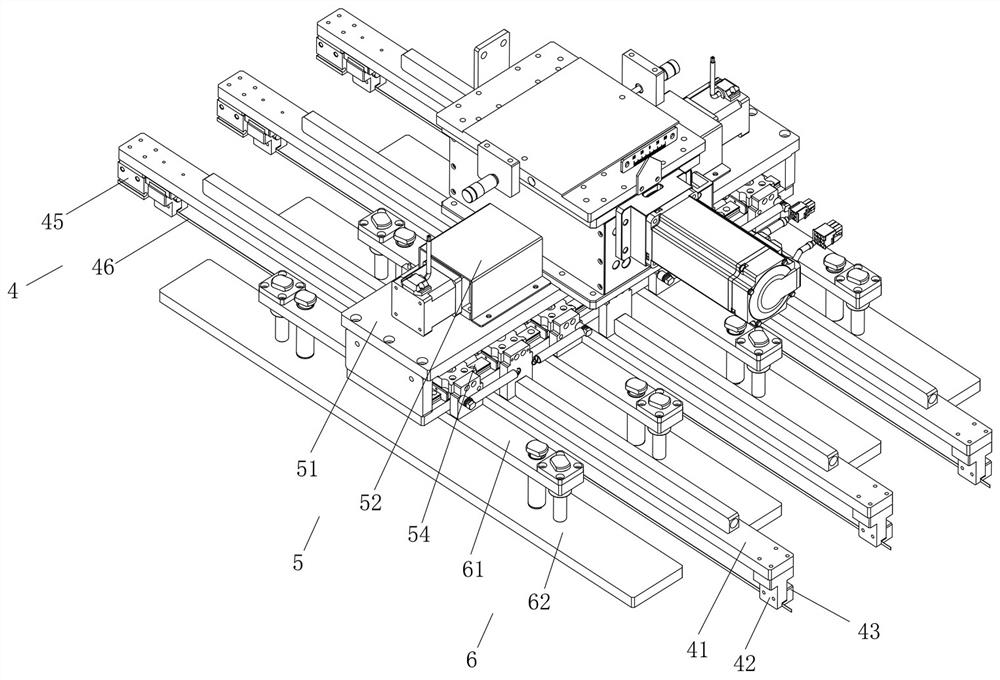

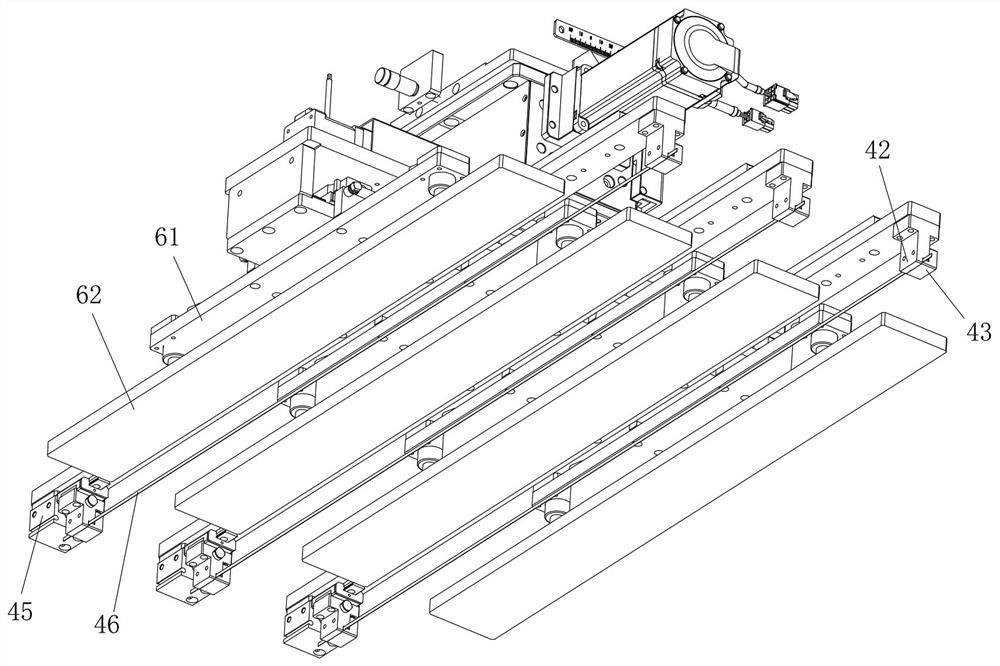

[0033] The driving component includes an adjustment cylinder 52 and an adjustment connection seat 53, wherein the above-mentioned adjustment cylinder 52 includes two

[0036] The adjustment connecting rods 56 include at least two, and the adjustment connecting rods 56 are set in two groups, and one end of the adjustment connecting rods 56 is rotatably connected.

[0038] The fixed component includes a first fixed block 42, a second fixed block 43 and a tensioning cylinder 45, wherein the above-mentioned first fixed block

[0042] The embodiment of the present invention is only to introduce its specific implementation, is not intended to limit its protection scope. technology in this industry

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com