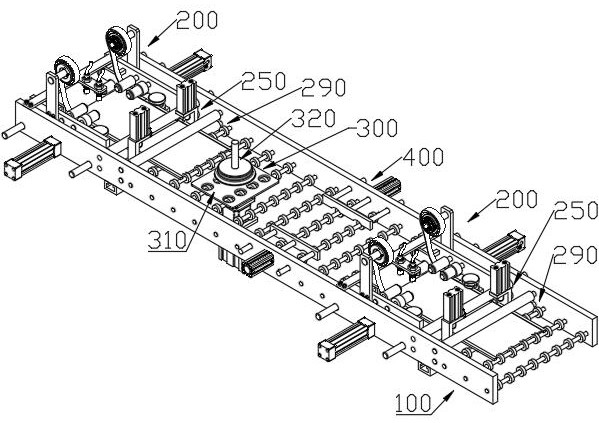

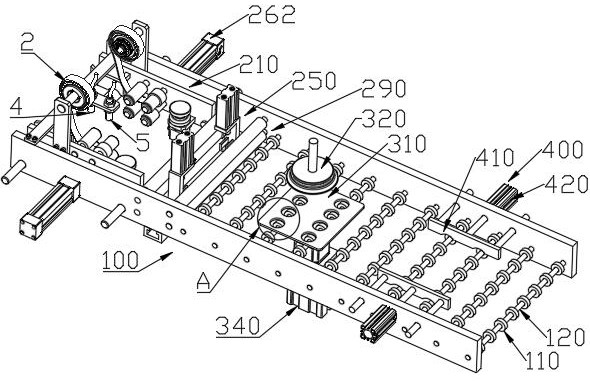

A printed circuit board edge automatic film sticking device

A printed circuit board and film sticking device technology, which is applied in the field of automatic film sticking devices on the edge of printed circuit boards, can solve the problems of low automation, low work efficiency, uniformity, etc., and achieve less manual participation, controllable sticking width, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

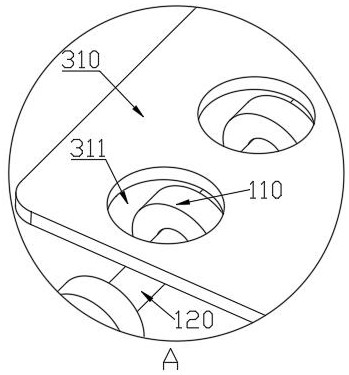

[0063] Put the circuit board 1 from the first group of film sticking mechanism 200 at the front end of the conveying track 100, before pasting the protective film 3 on the first circuit board 1, first pull out the protective film 3 on both sides from the protective film coil 2, Make the front end of the protective film 3 pass between the cylindrical rollers 221, and then start to put the circuit board 1 in, and the circuit board 1 can be fed in by conveying line transmission to improve efficiency. When the circuit board 1 enters between the cylindrical rollers 221, the protective film 3 starts to contact the top surface of the circuit board 1. After the circuit board 1 passes through the cylindrical rollers 221, the protective film 3 on the top surface has been bonded to the surface of the circuit board 1. , along with the movement of the circuit board 1, the protective film 3 is also slowly pulled out, and then the circuit board 1 passes through the bending roller 230 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com