Ridging film mulching machine

A technology of mulching machine and ridge field, which is applied in the field of agricultural machinery, can solve the problems of difficulty in cultivating soil, breaking the film, and too deep insertion of the cultivating plow, so as to achieve the effect of easy transportation and storage, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

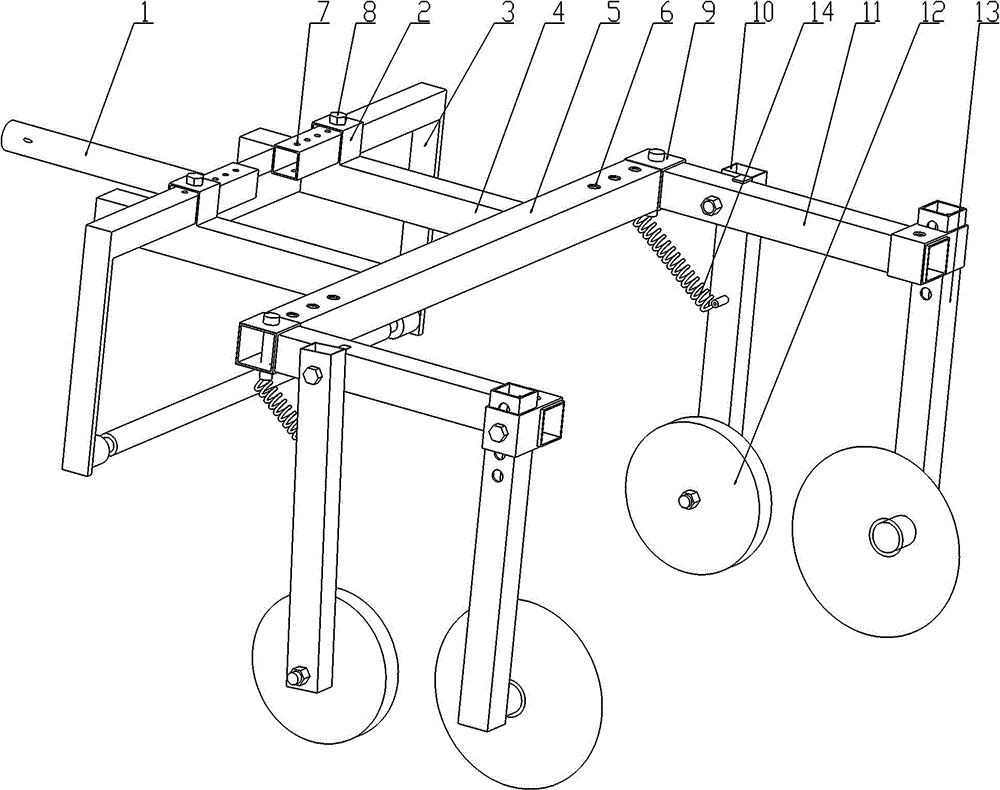

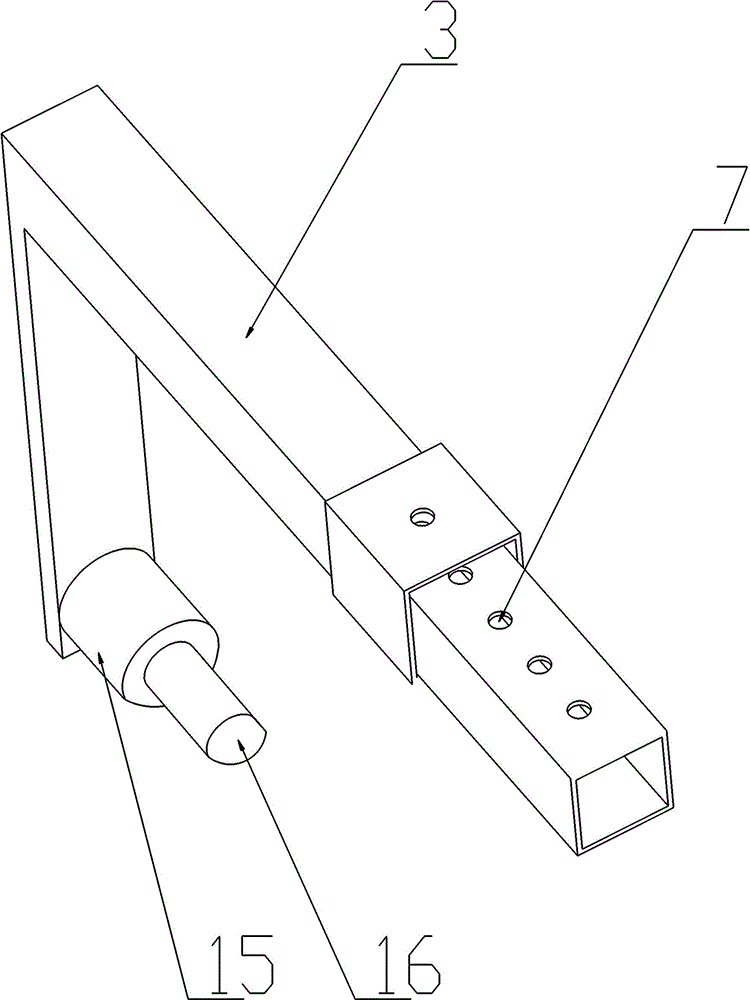

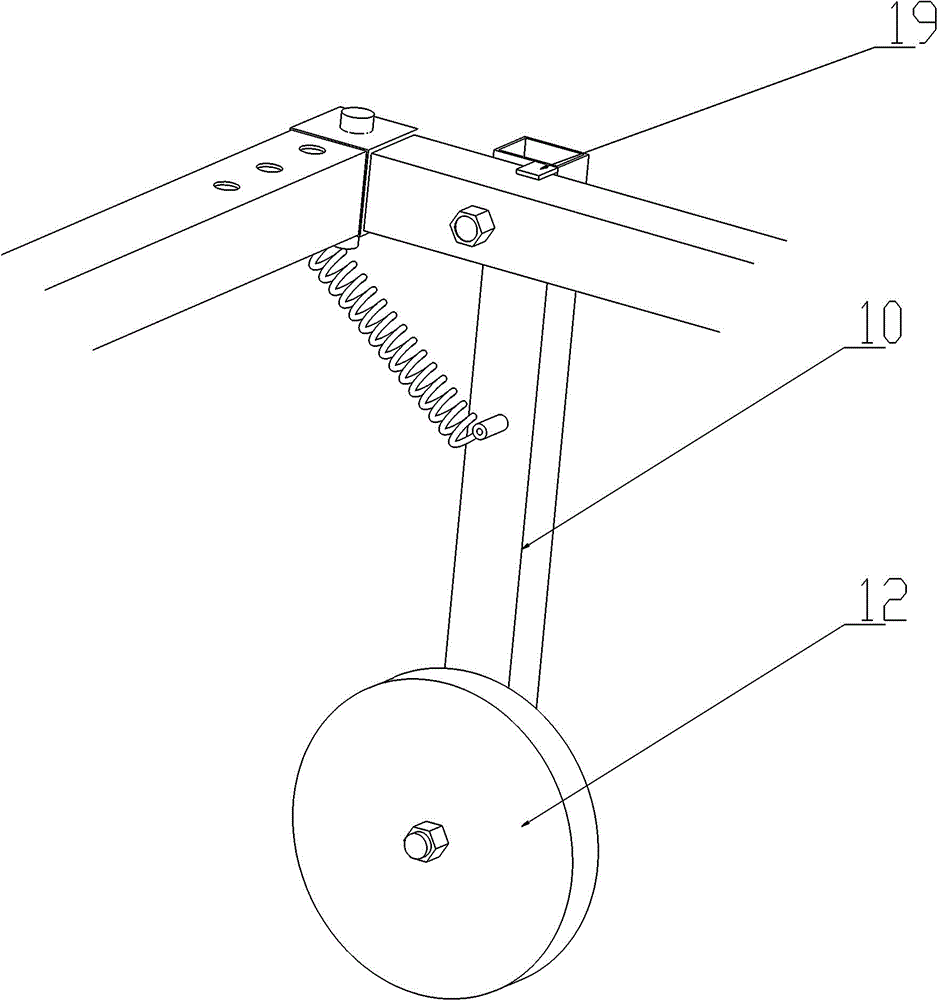

[0023] Such as Figure 1-4 Among them, a ridge-ground laminating machine includes a bracket, the front end of the bracket is provided with an adjustable width film hanging rod 3, the two sides of the bracket are provided with auxiliary bracket rods 11 in an adjustable width manner, and the auxiliary bracket rods 11 are arranged from the front to the front. Behind are provided with a film wheel frame 10 and a soil covering plate frame 13. With this structure, films of different widths can be used according to the ridge width. Therefore, the adaptability of the present invention is increased, that is, it is suitable for different crops, especially suitable for mountainous terrain. In this case, the front refers to figure 1 The upper left in the middle, the back refers to figure 1 In the bottom right.

[0024] In the optimized solution, a traction rod 1 is also provided at the front end of the bracket. With this structure, it is convenient to connect with the traction machinery, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com