Food cartoning machine

A cartoning machine and food technology, which is applied in packaging and other directions, can solve the problem of not being able to put food in, and achieve the effect of simple structure, simple replacement, and improved synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

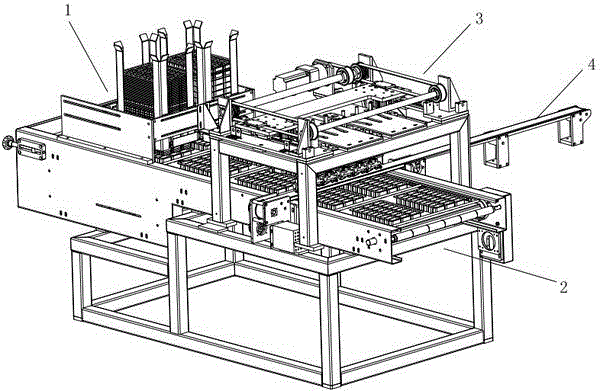

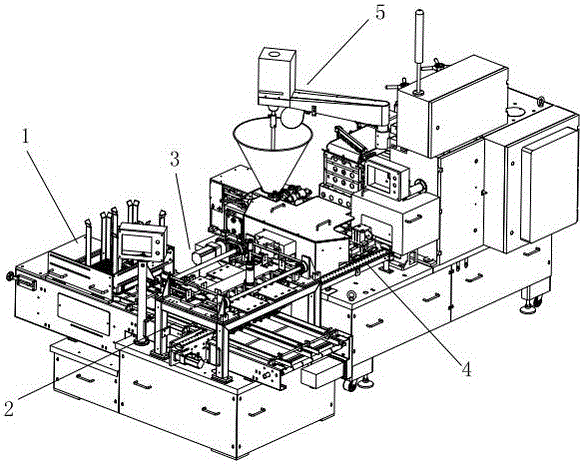

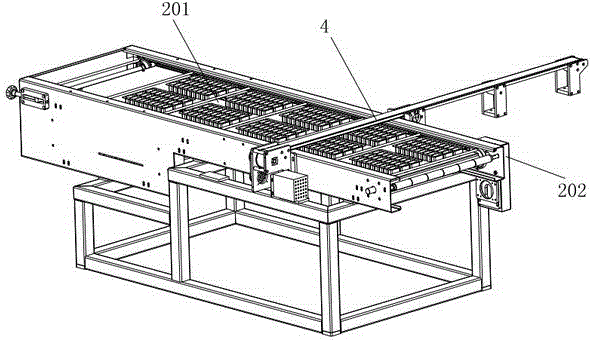

[0079] A food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a clamping mechanism 3. It is arranged at one end of the clamping mechanism 3, and one side of the clamping mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; the clamping mechanism 3 includes a mounting frame 301, and the mounting frame 301 is provided with a plurality of mechanical Jaw 302, the guide device 303 for adjusting the distance between adjacent mechanical jaws 302 is installed on the mechanical jaw 302, the horizontal drive mechanism 304 that drives it to realize horizontal movement is connected with the described mechanical jaw 302, and is also connected with a drive It realizes the vertical drive mechanism 305 that moves vertically up and down.

[0080] The conveyor belt 4 that transmits the food to be boxed transports the food to be boxed from the food forming machine 5 to the bottom of the clamping mechanism 3, and t...

Embodiment 2

[0083] A food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a clamping mechanism 3. It is arranged at one end of the clamping mechanism 3, and one side of the clamping mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; the clamping mechanism 3 includes a mounting frame 301, and the mounting frame 301 is provided with a plurality of mechanical Jaw 302, the guide device 303 for adjusting the distance between adjacent mechanical jaws 302 is installed on the mechanical jaw 302, the horizontal drive mechanism 304 that drives it to realize horizontal movement is connected with the described mechanical jaw 302, and is also connected with a drive It realizes the vertical drive mechanism 305 that moves vertically up and down.

[0084] The working principle of the cartoning machine is:

[0085] The conveyor belt 4 that transmits the food to be boxed transports the food to be boxed from the food formi...

Embodiment 3

[0106] A food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a clamping mechanism 3. It is arranged at one end of the clamping mechanism 3, and one side of the clamping mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; the clamping mechanism 3 includes a mounting frame 301, and the mounting frame 301 is provided with a plurality of mechanical Jaw 302, the guide device 303 for adjusting the distance between adjacent mechanical jaws 302 is installed on the mechanical jaw 302, the horizontal drive mechanism 304 that drives it to realize horizontal movement is connected with the described mechanical jaw 302, and is also connected with a drive It realizes the vertical drive mechanism 305 that moves vertically up and down.

[0107] The working principle of the cartoning machine is:

[0108] The conveyor belt 4 that transmits the food to be boxed transports the food to be boxed from the food formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com