Product transfer control device and method

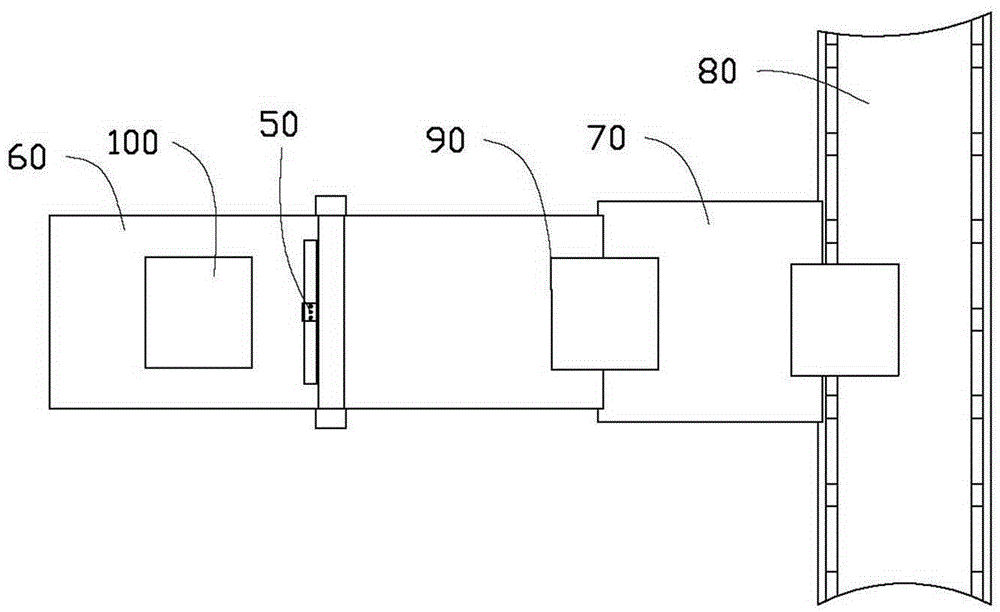

A transmission control and control device technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of transmission device failure, product spacing cannot be automatically adjusted, conveyor belt blockage, etc., to achieve the effect of automatic spacing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

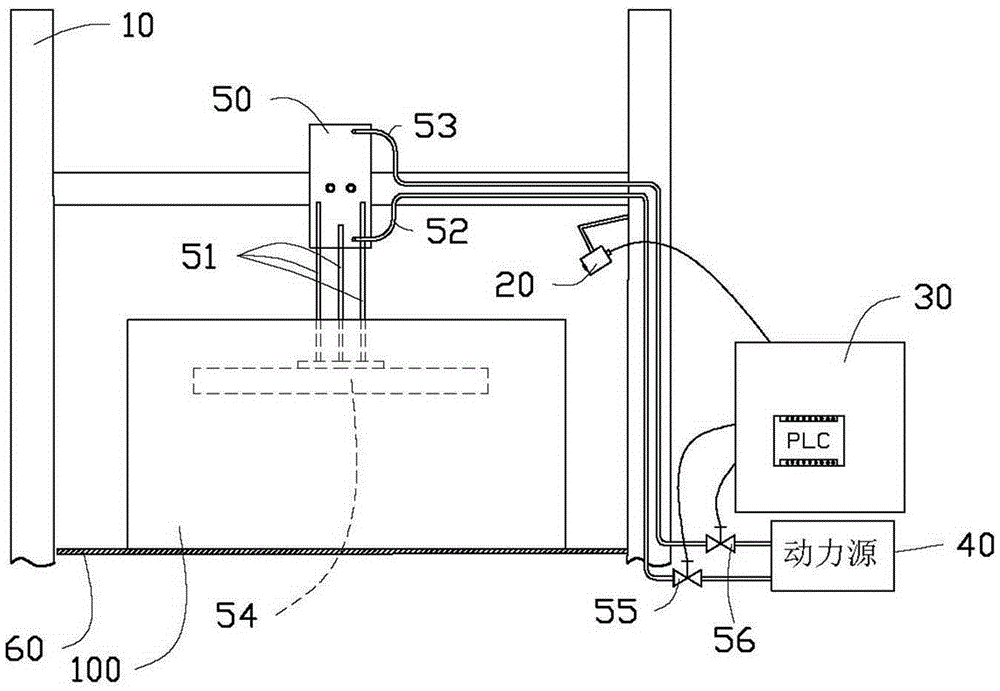

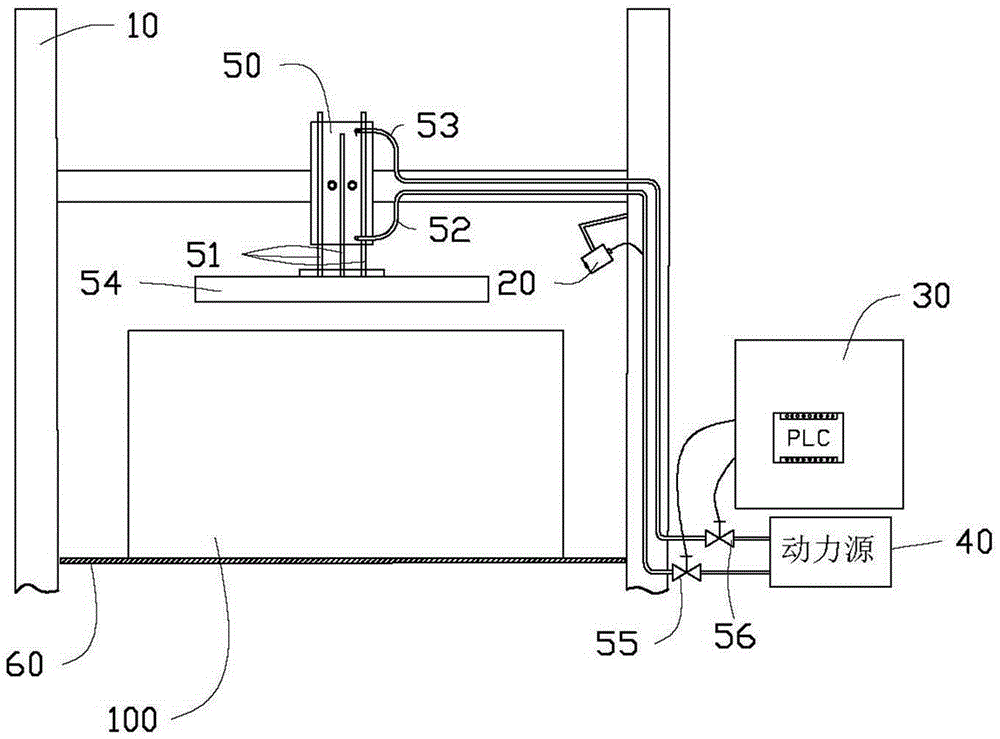

[0026] See Figure 4 , Is a flowchart of a control method for product delivery using the above product delivery control device. A preferred embodiment of the product delivery control method includes the following steps:

[0027] S401: The sensing device 20 senses product transmission information on the first transmission line 60, and sends a sensing signal when the first product 90 passes through the blocking device 50;

[0028] S402: The control chip 30 receives the sensing signal, and the control chip 30 presets a blocking time according to the sensing signal and sends a first control signal to the blocking device 50;

[0029] S403: The first control valve 55 of the blocking device 50 receives the first control signal and opens, and the power source 40 provides power to the first conveying pipe 52 to control the blocking rod 54 to approach the first transmission line 60 When moving in the direction of, the blocking rod 54 blocks the passage of the second product 100 on the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com