An automatic bagging production line for infusion bags

A technology for infusion bags and production lines, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of fixed structure, inability to adapt products of different sizes, and low production efficiency of a single assembly line, so as to improve feeding Efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

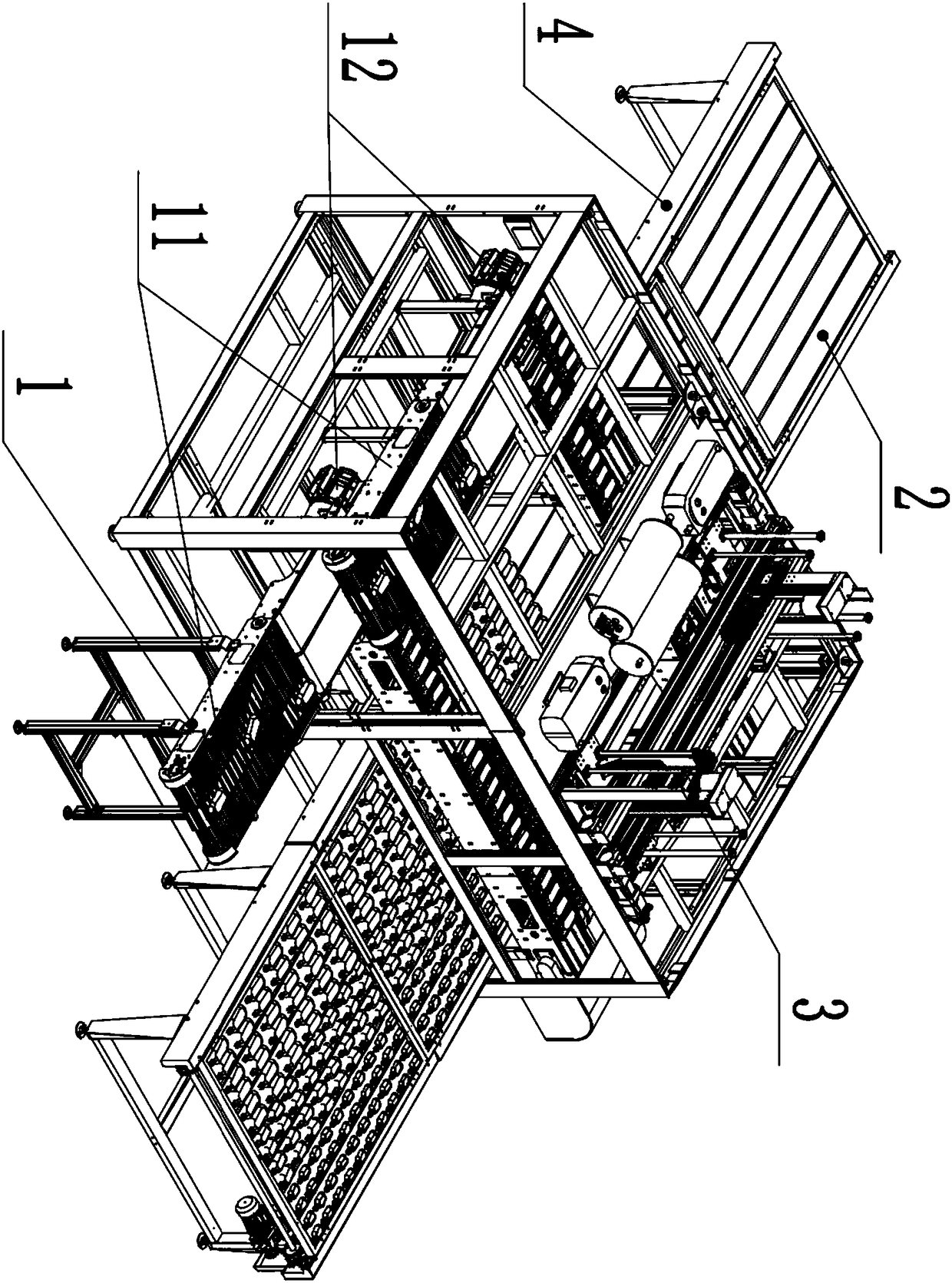

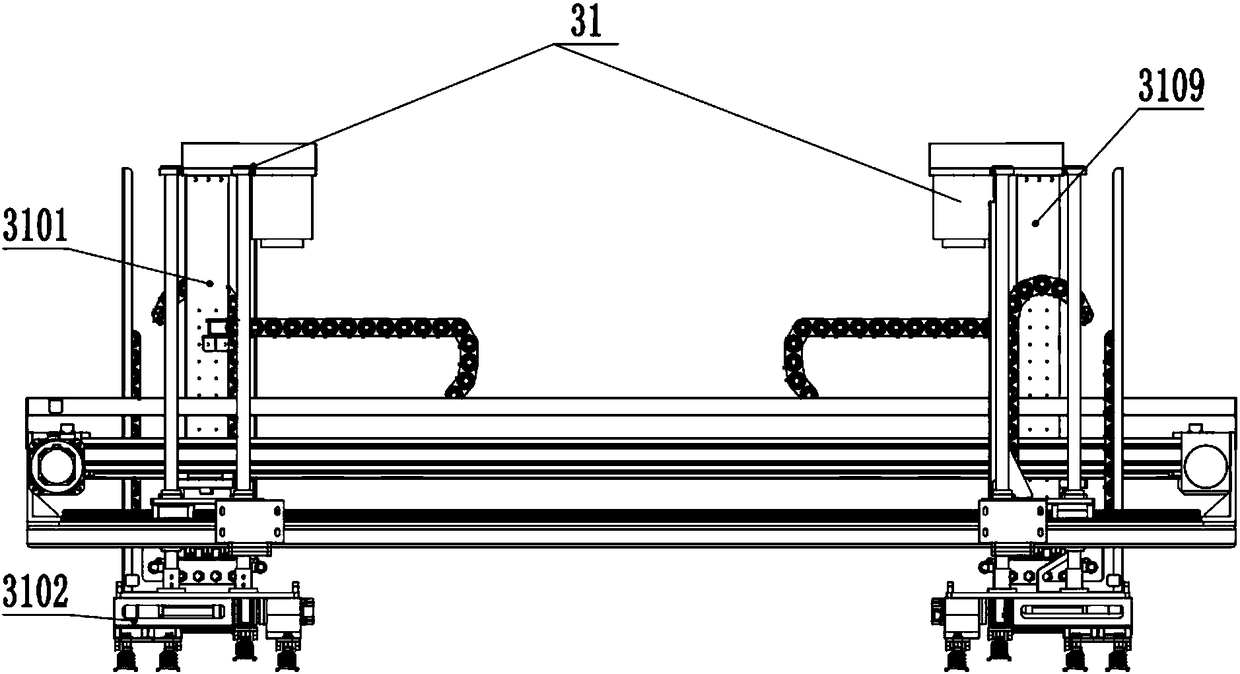

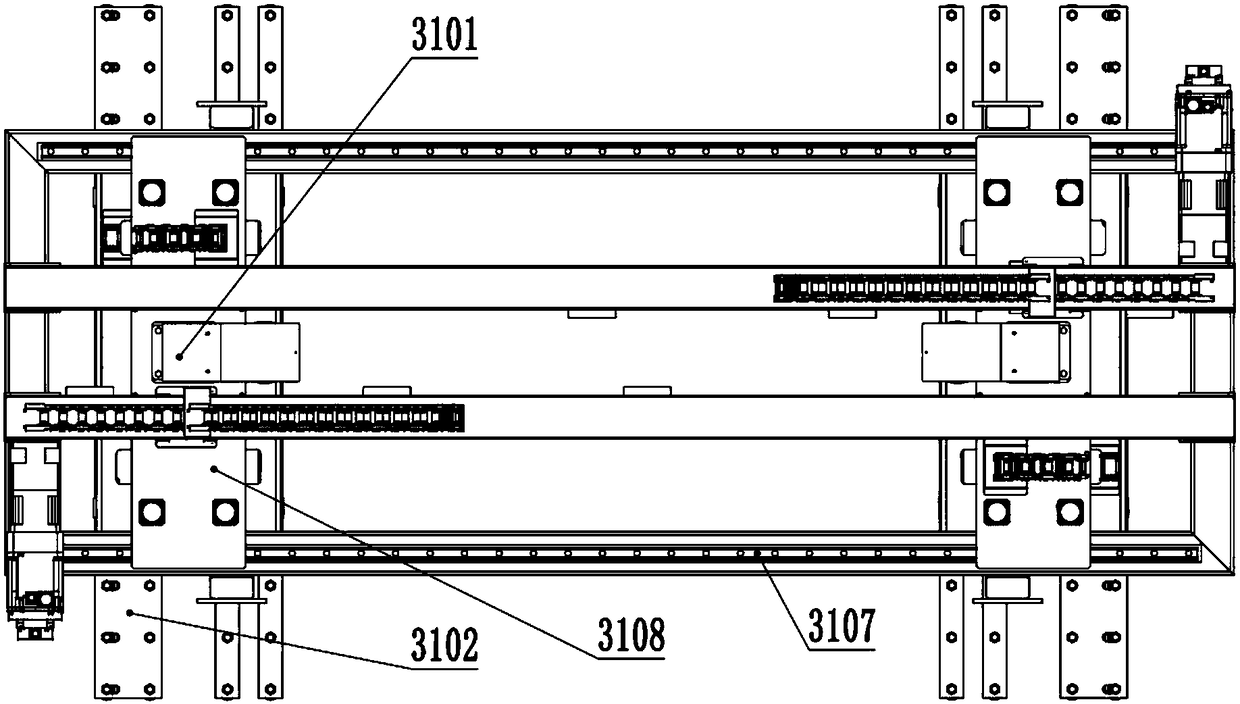

[0025] as attached figure 1 The automatic bagging production line for infusion bags includes a feeding line 1, an infusion bag tray 2, and a feeding manipulator 3 for grabbing the infusion bag from the feeding line 1 to the infusion bag tray 2; the feeding line 1 includes The shunt device 11 that splits the single-way infusion bag into two branches and the infusion bag of each branch that is shunted out by the shunt device 11 are respectively delivered to the delivery line 12 at the infusion bag tray 2, and the delivery line 12 The number is equal to the number of branches branched out by the branching device 11 ;

[0026] There are two loading lines 1, and the heights of the two loading lines 1 are different from the ground and they are mutually staggered in the direction of the top view. The projections of the two loading lines 1 in the direction of the top view hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com