Patents

Literature

30results about How to "Gentle handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

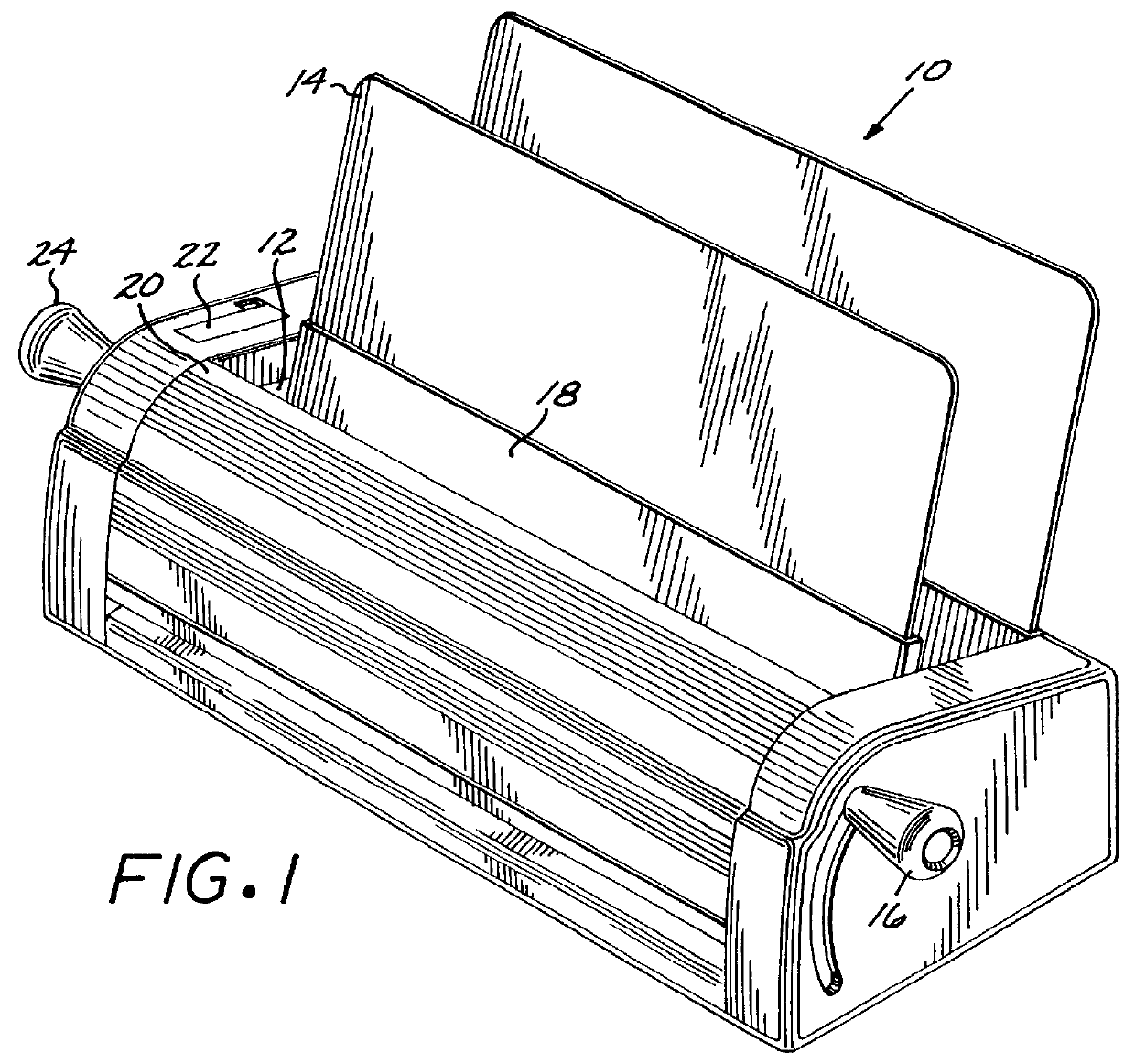

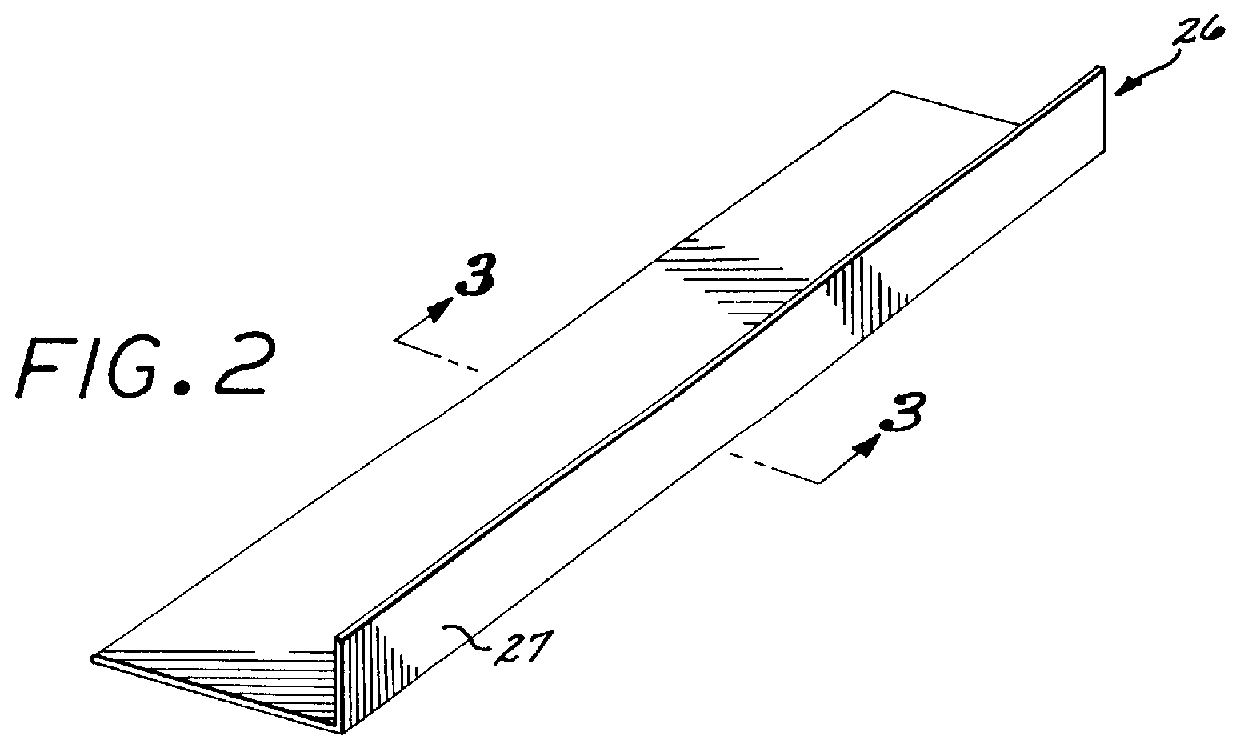

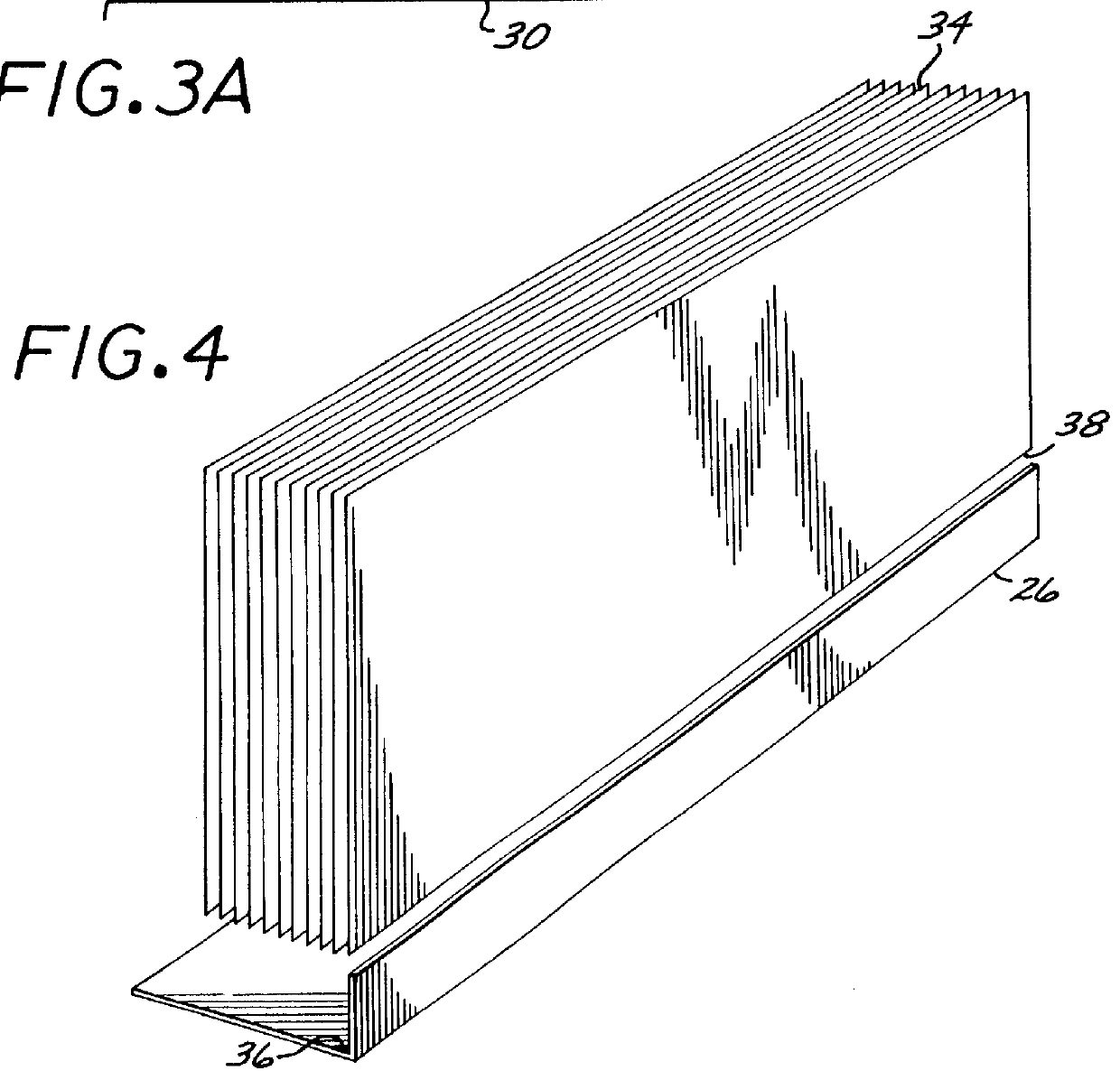

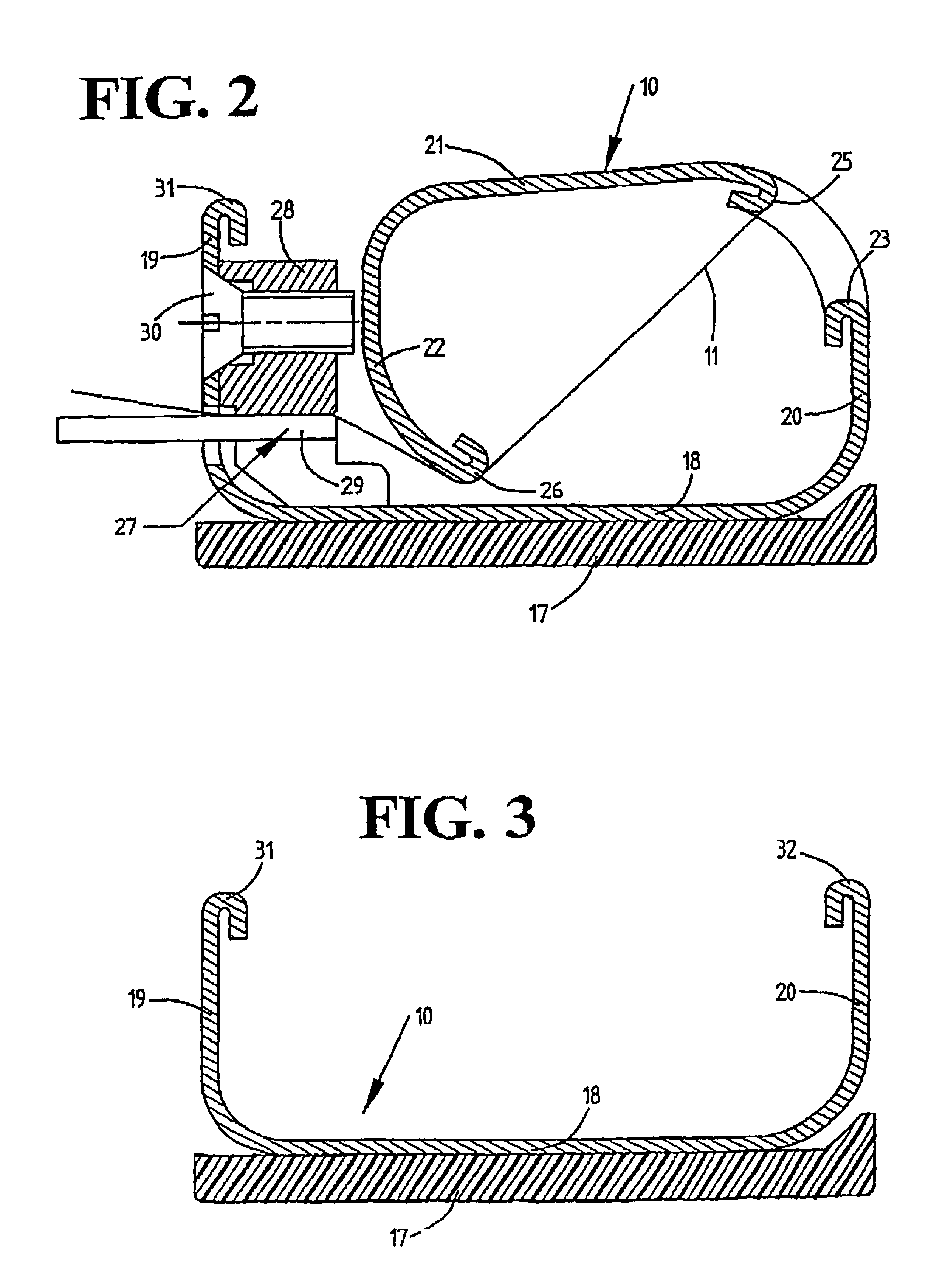

Desktop book binder having means for aligning sheets to be bound with a preformed binding material

InactiveUS6056493APrecise alignmentSimplifying binder apparatus designFilm/foil adhesivesBook coversPolytetrafluoroethyleneSheet material

Owner:ADVANCED HI TECH CORP

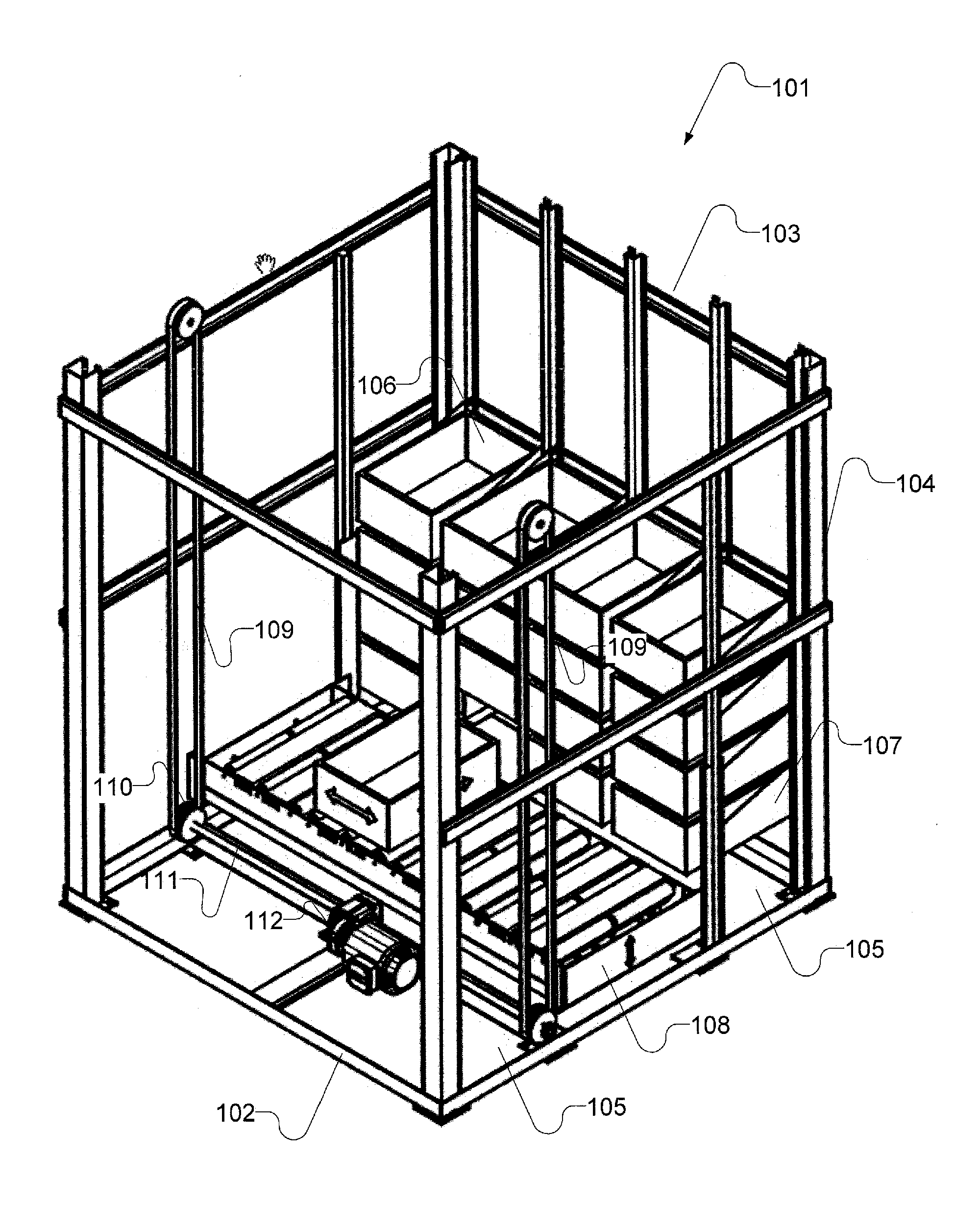

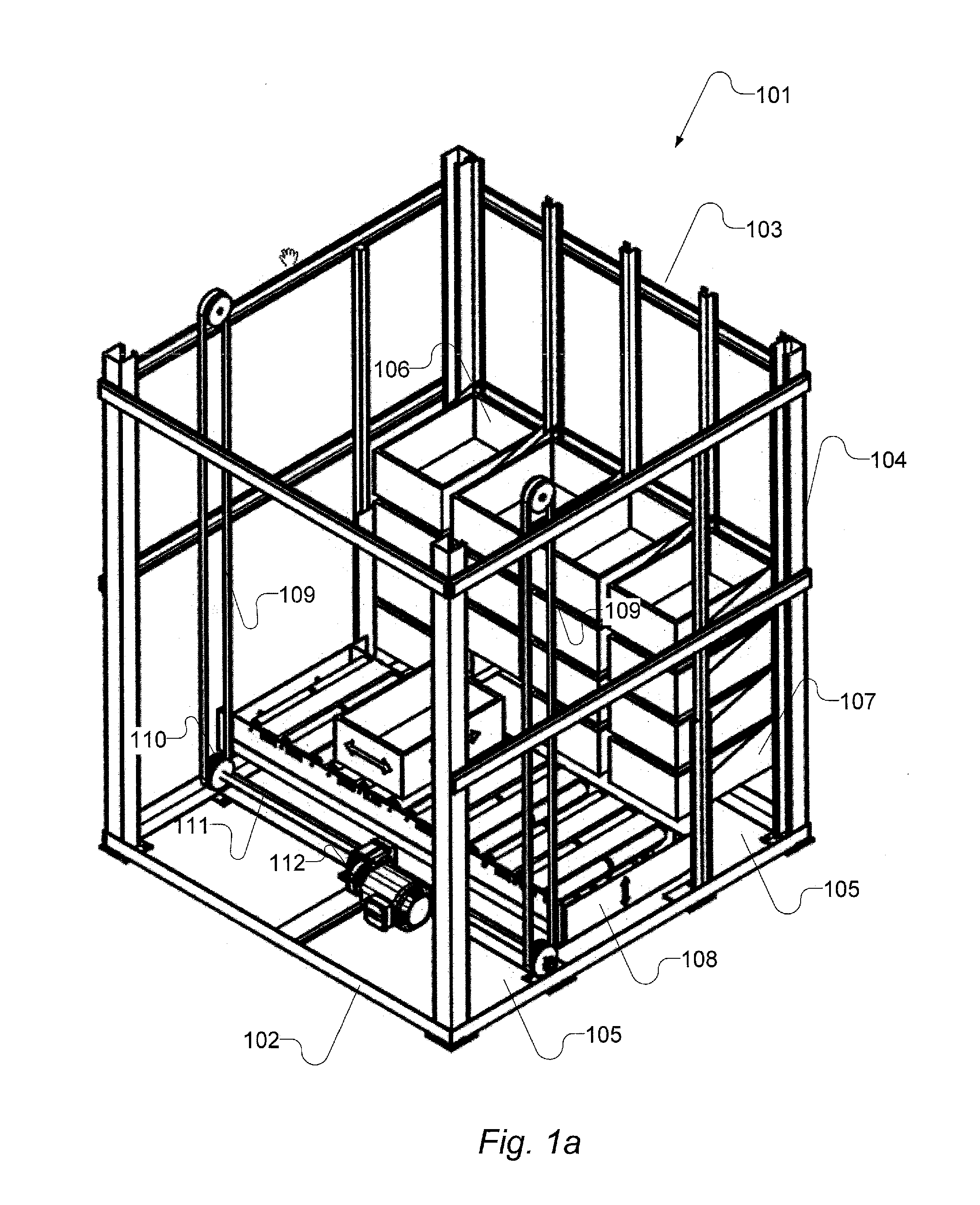

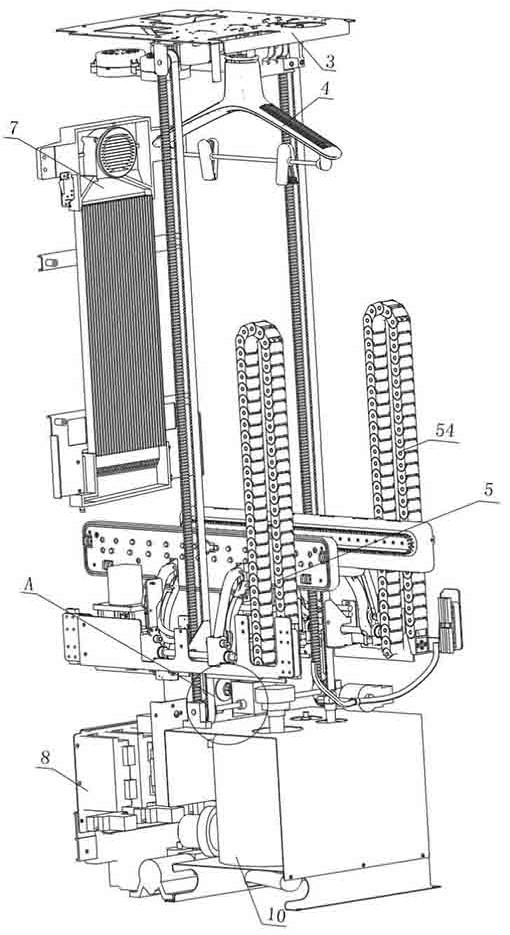

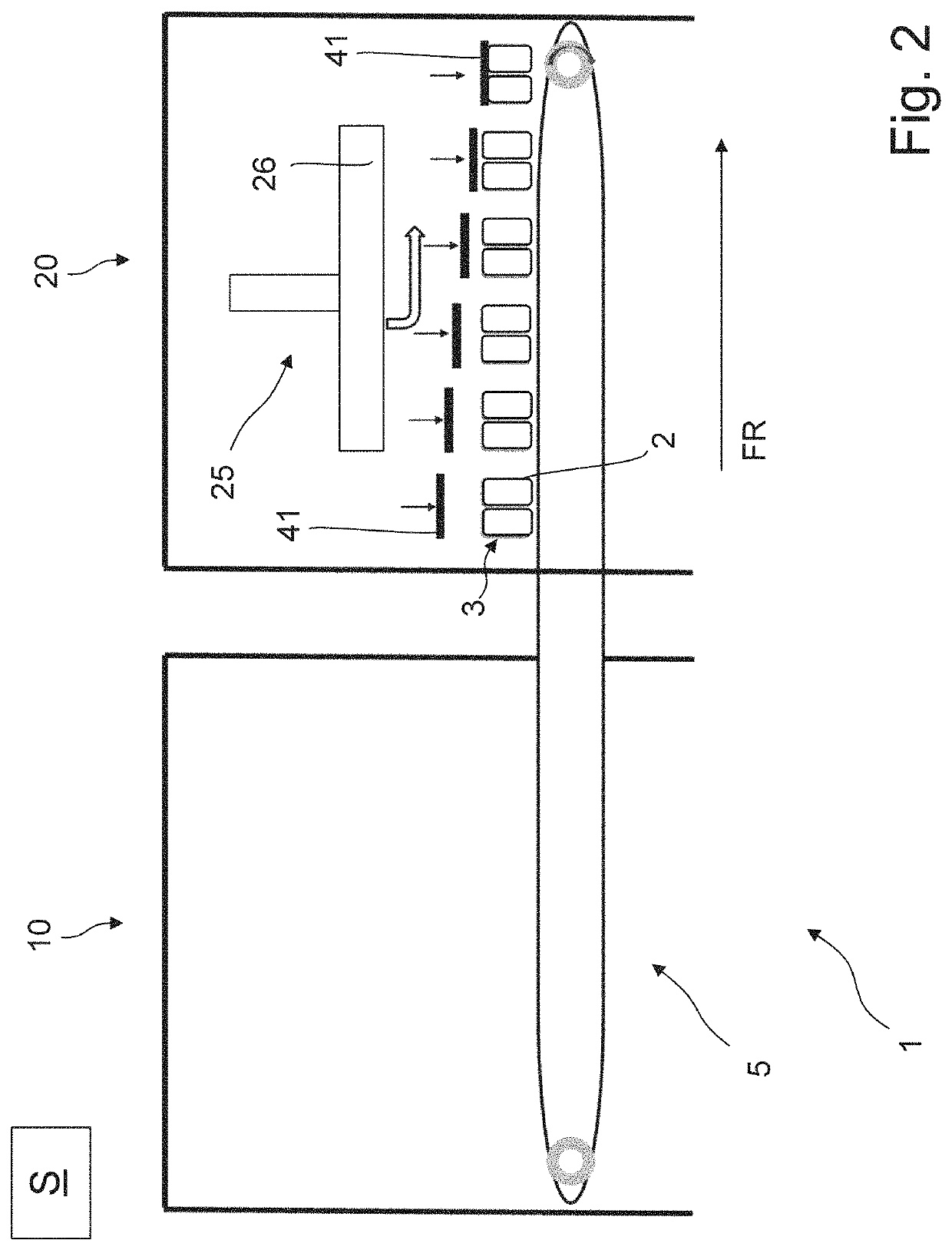

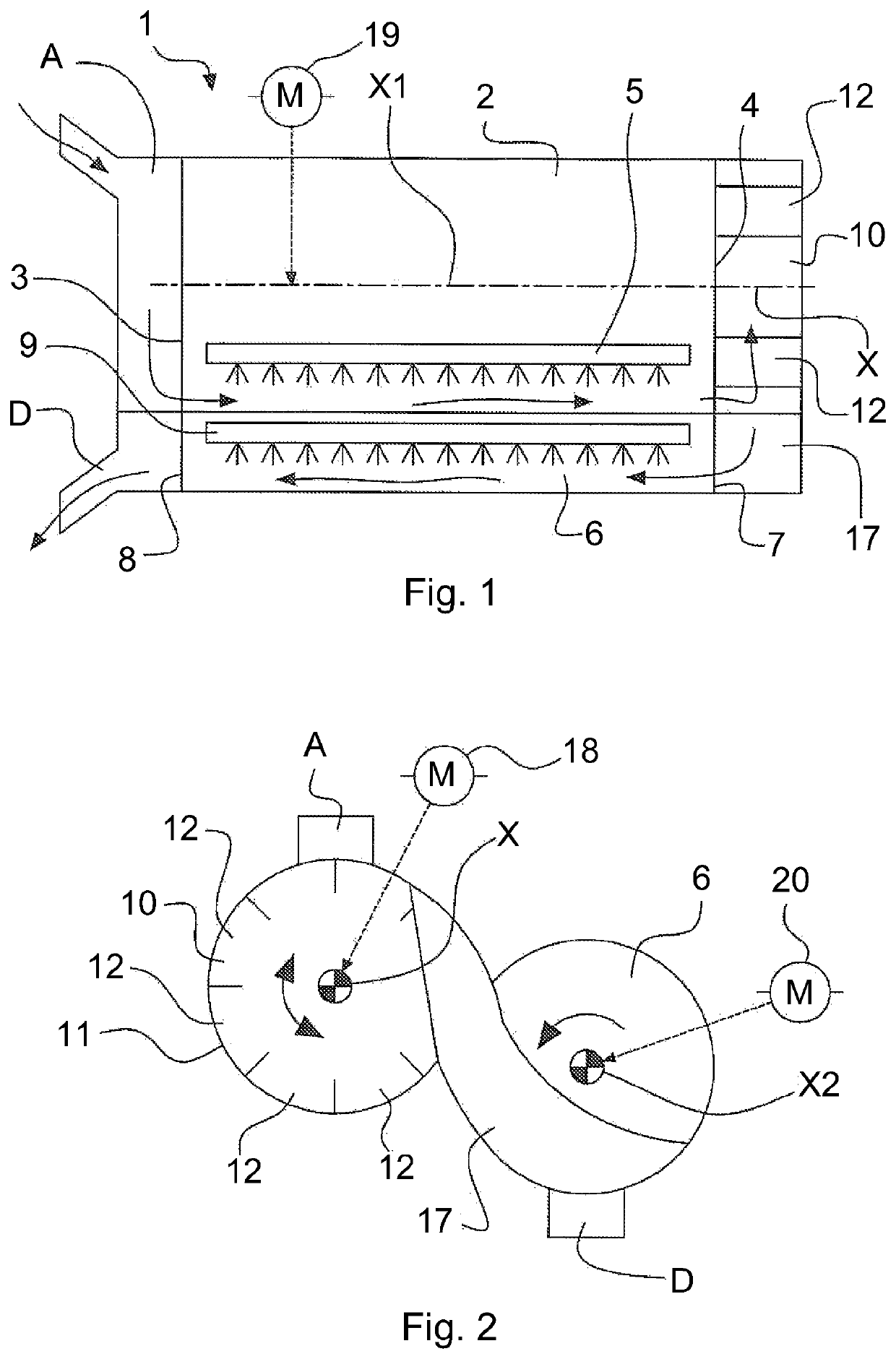

Vertical lift storage system and a method of operating a lift

ActiveUS20140301811A1Gentle handlingImprove lateral stabilityDigital data processing detailsLoading/unloadingLoad unitElectrical and Electronics engineering

There is provided a vertical lift storage system (101), comprising a storage rack (105) configured to store load units and a lift system with an upwardly and downwardly movable carrier structure (108), where the carrier structure (108) is configured to carry multiple load units at respective sections and with first transportation means configured to insert and withdraw respective load units into and from the storage rack. The system is characterized in that the carrier structure is configured with second transportation means to shift load units sideways on the carrier structure between its sections. In some embodiments the first transportation means comprises telescopic arms and the second transportation means comprises rollers. There is also provided a method of operating such a carrier structure in a vertical lift storage system,

Owner:EFFIMAT STORAGE TECH

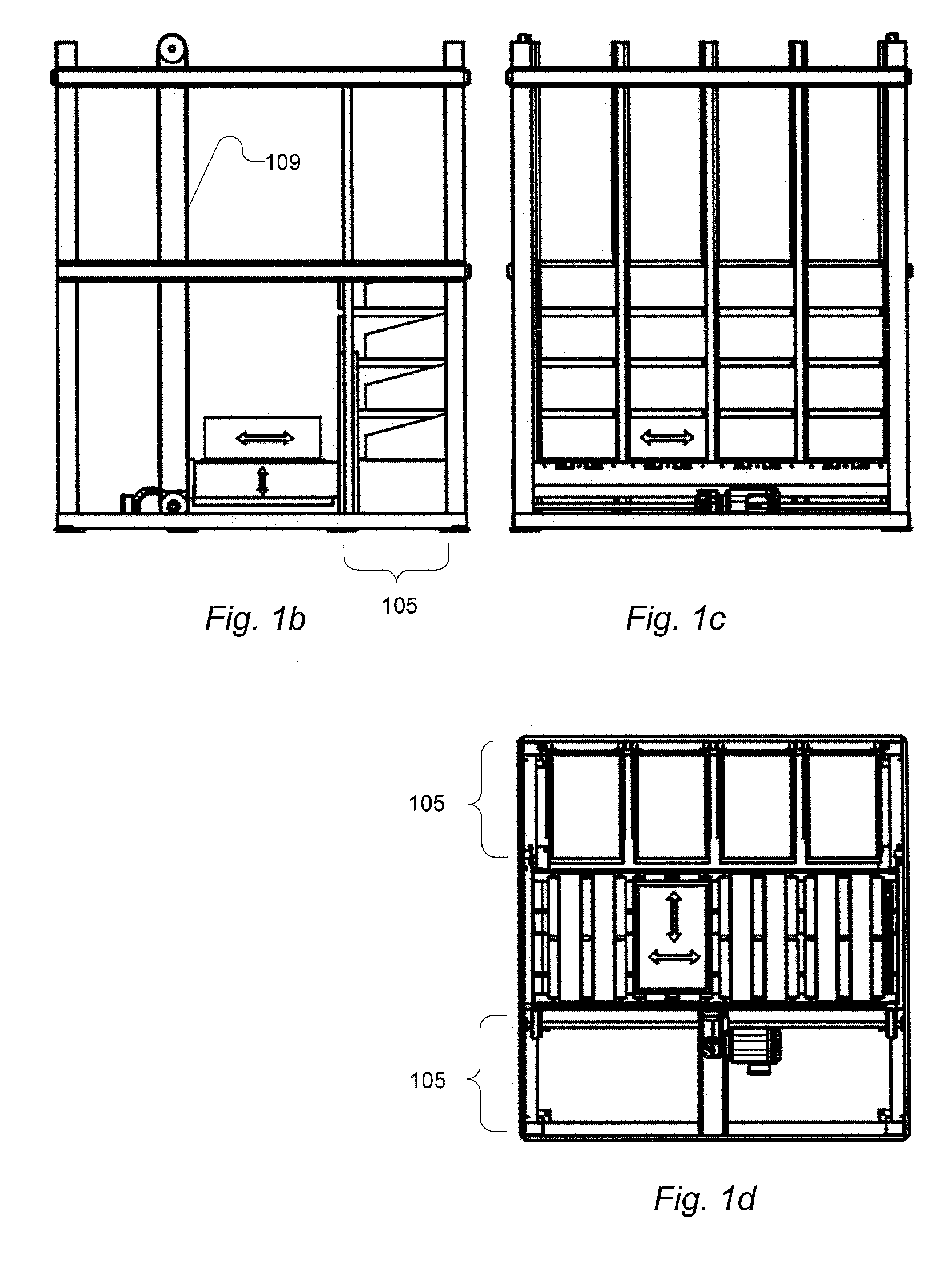

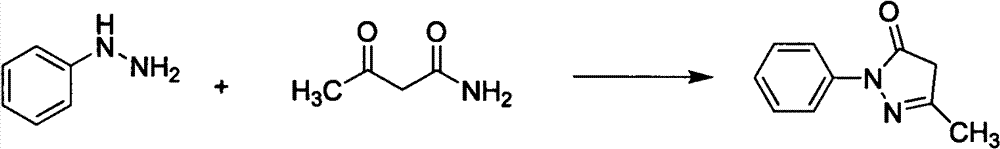

Preparation method for edaravone

The invention discloses a preparation method for edaravone. The preparation method comprises a step of subjecting hydrazinobenzene and ethyl acetoacetate to a cyclization reaction under a solvent-free condition and action of an acid so as to prepare edaravone, wherein the usage amount of the acid is 0.02 to 10 equivalent of the molar weight of hydrazinobenzene. The preparation method provided by the invention has the advantages of mild conditions, fast reaction, safety, reliability, easy and convenient operation, low cost, almost quantitative completion of the reaction, capacity of obtaining a high purity (greater than 98%) crude product which accords with medicinal standards after simple recrystallization, and suitability for industrial production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

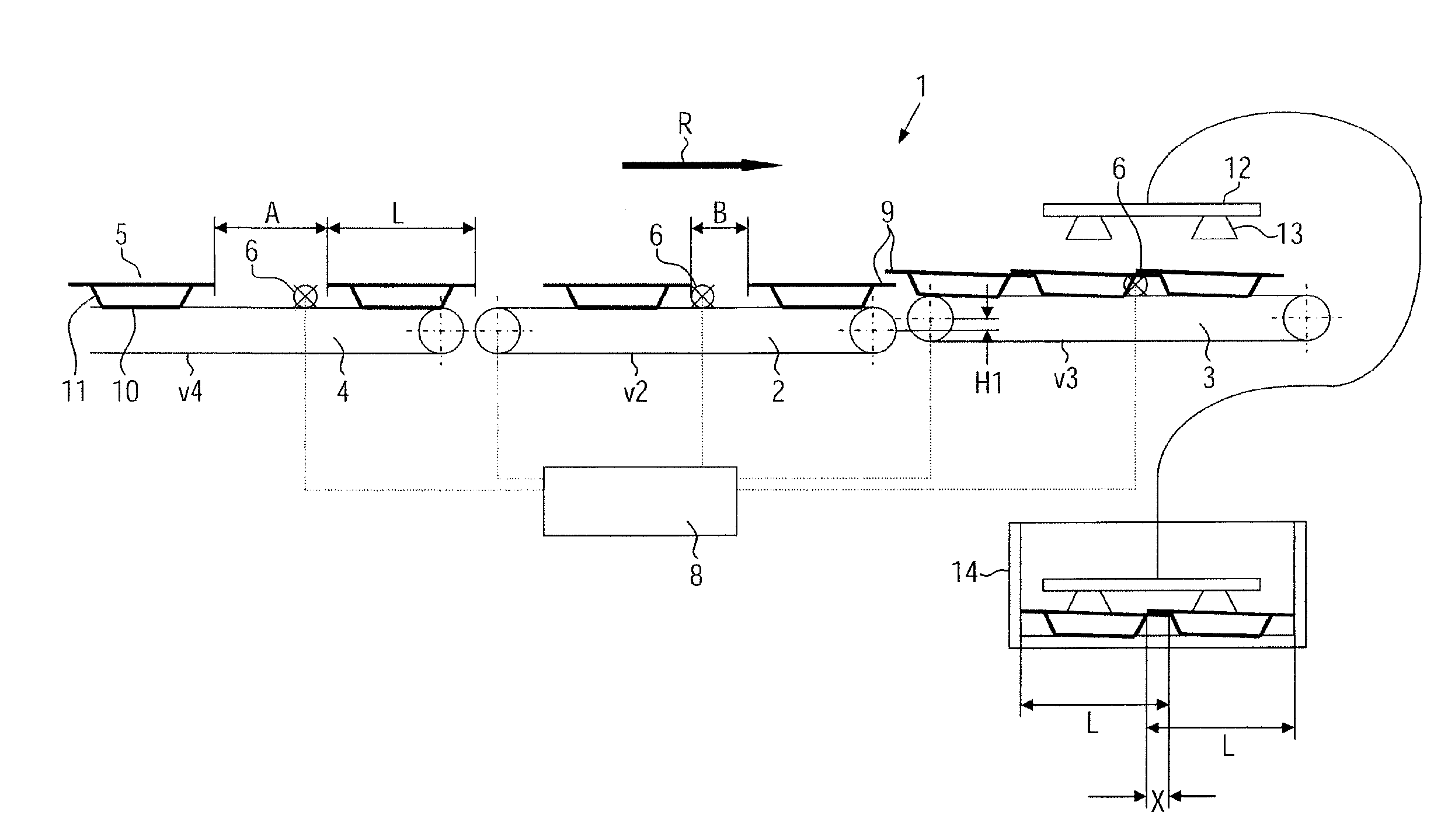

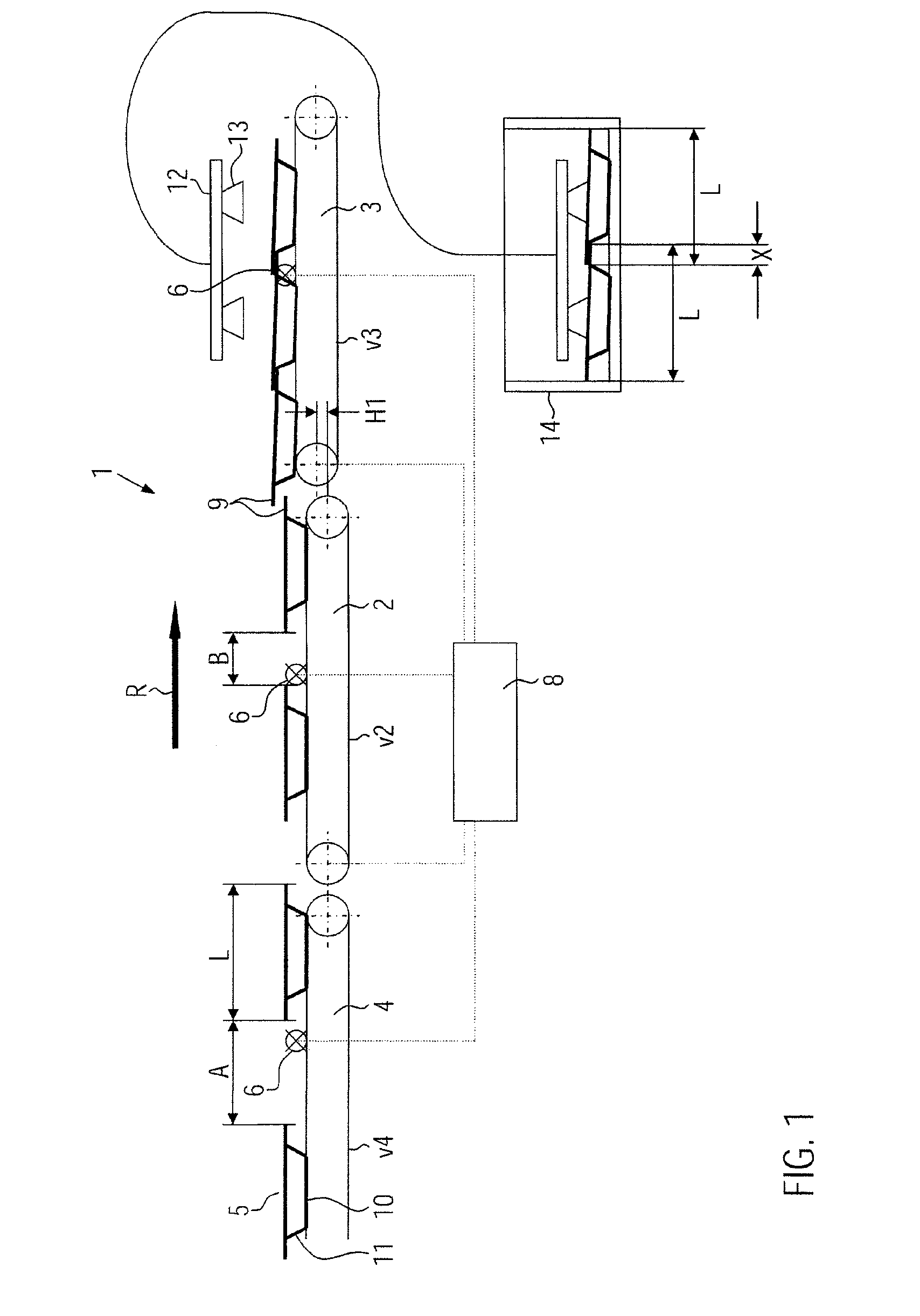

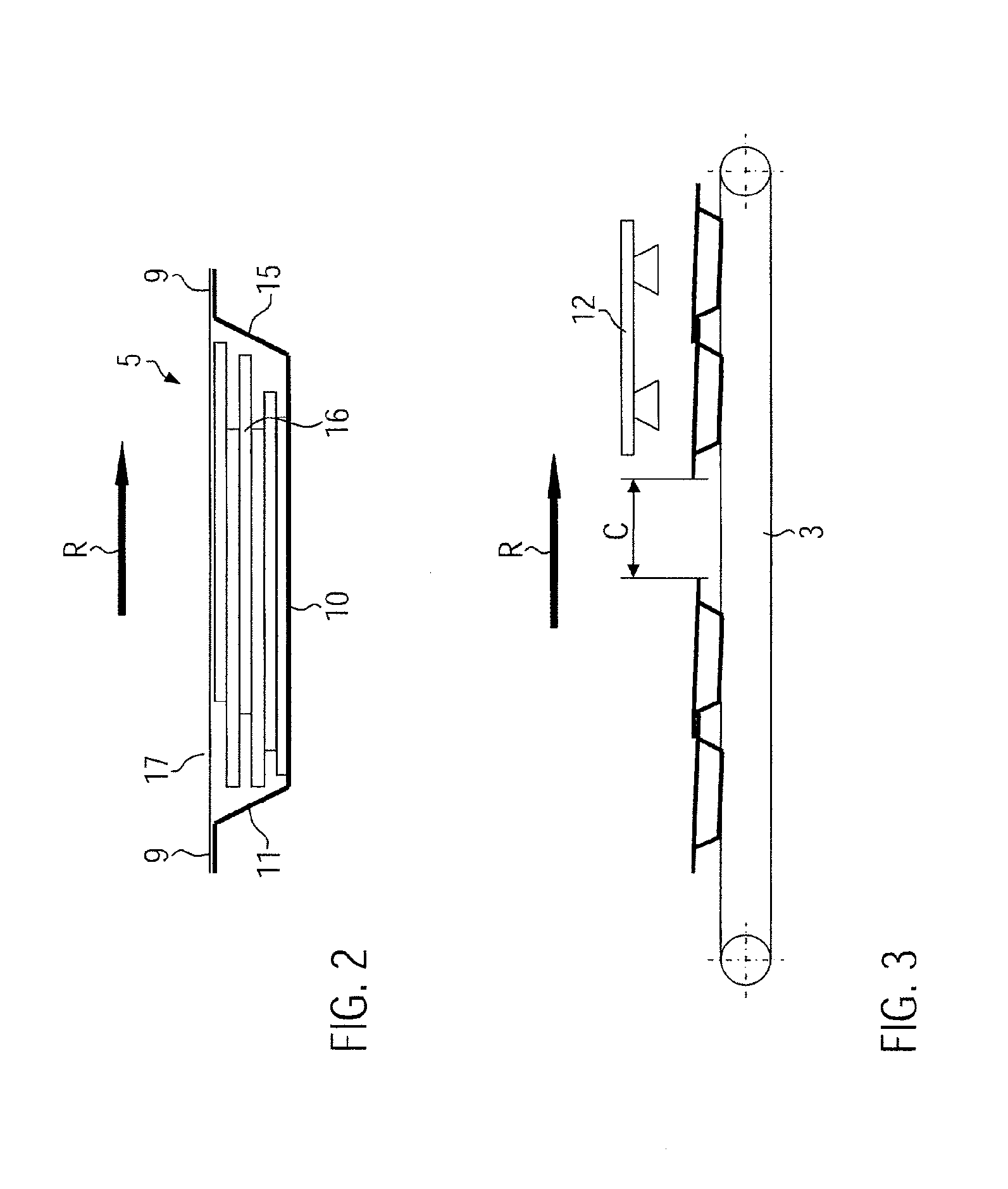

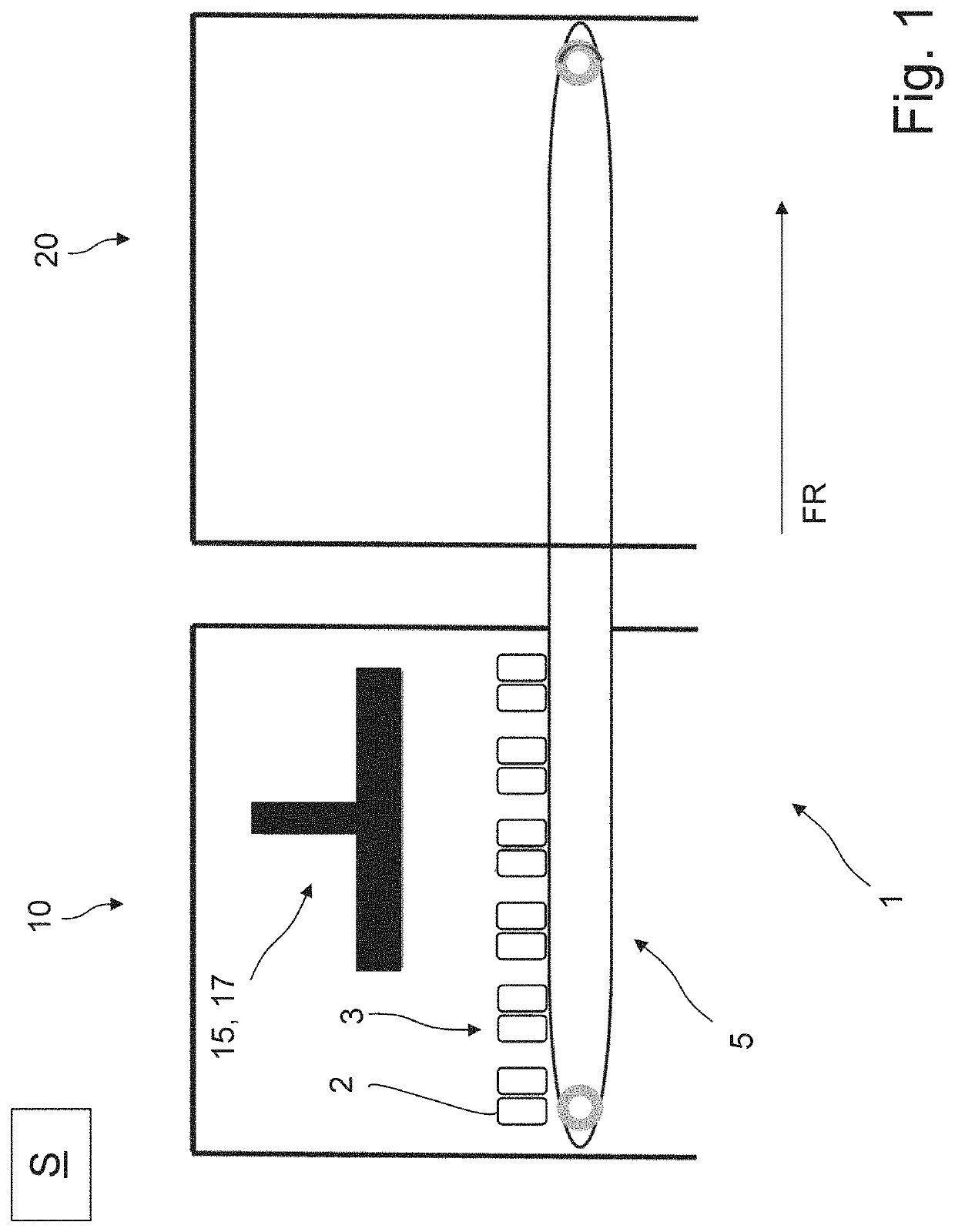

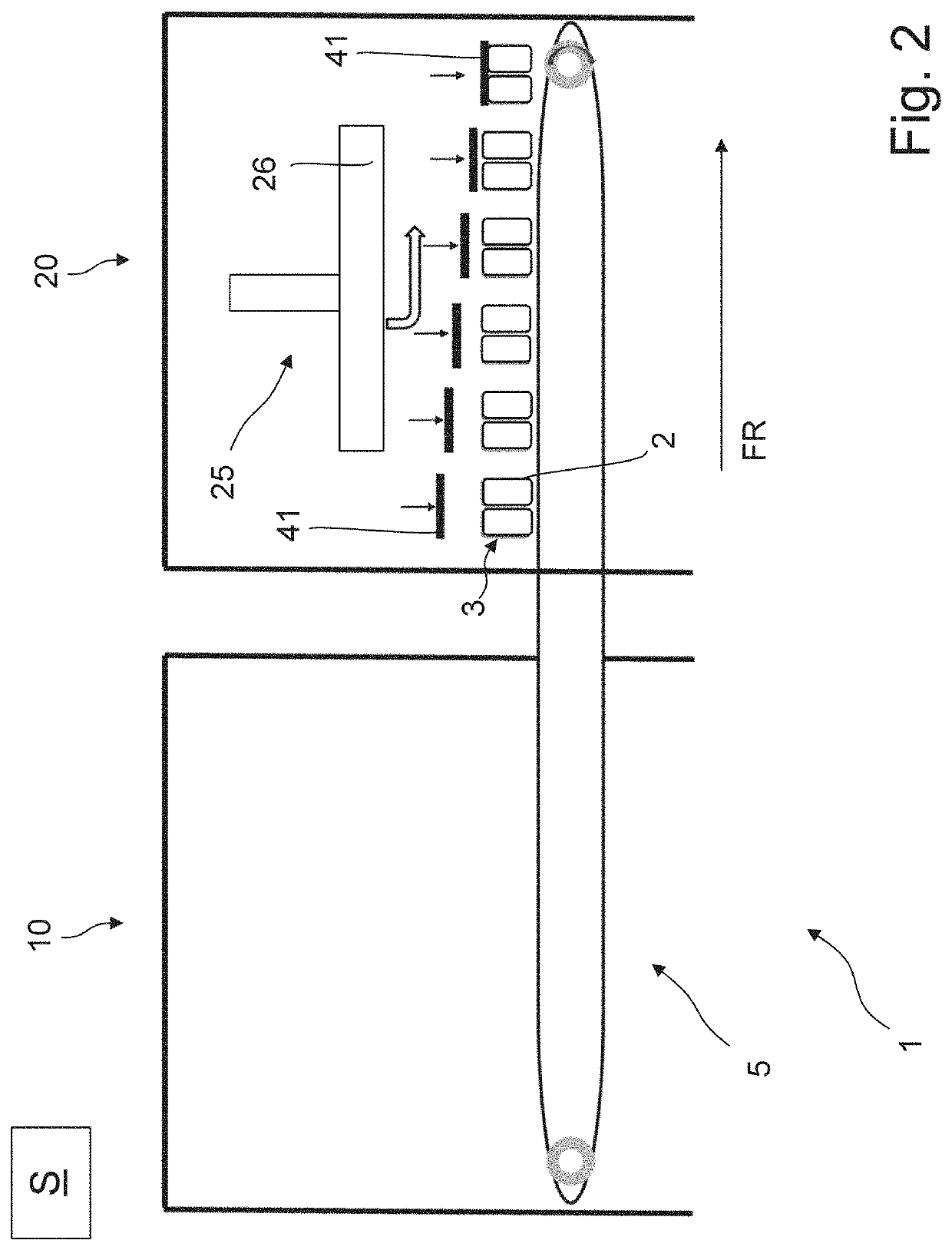

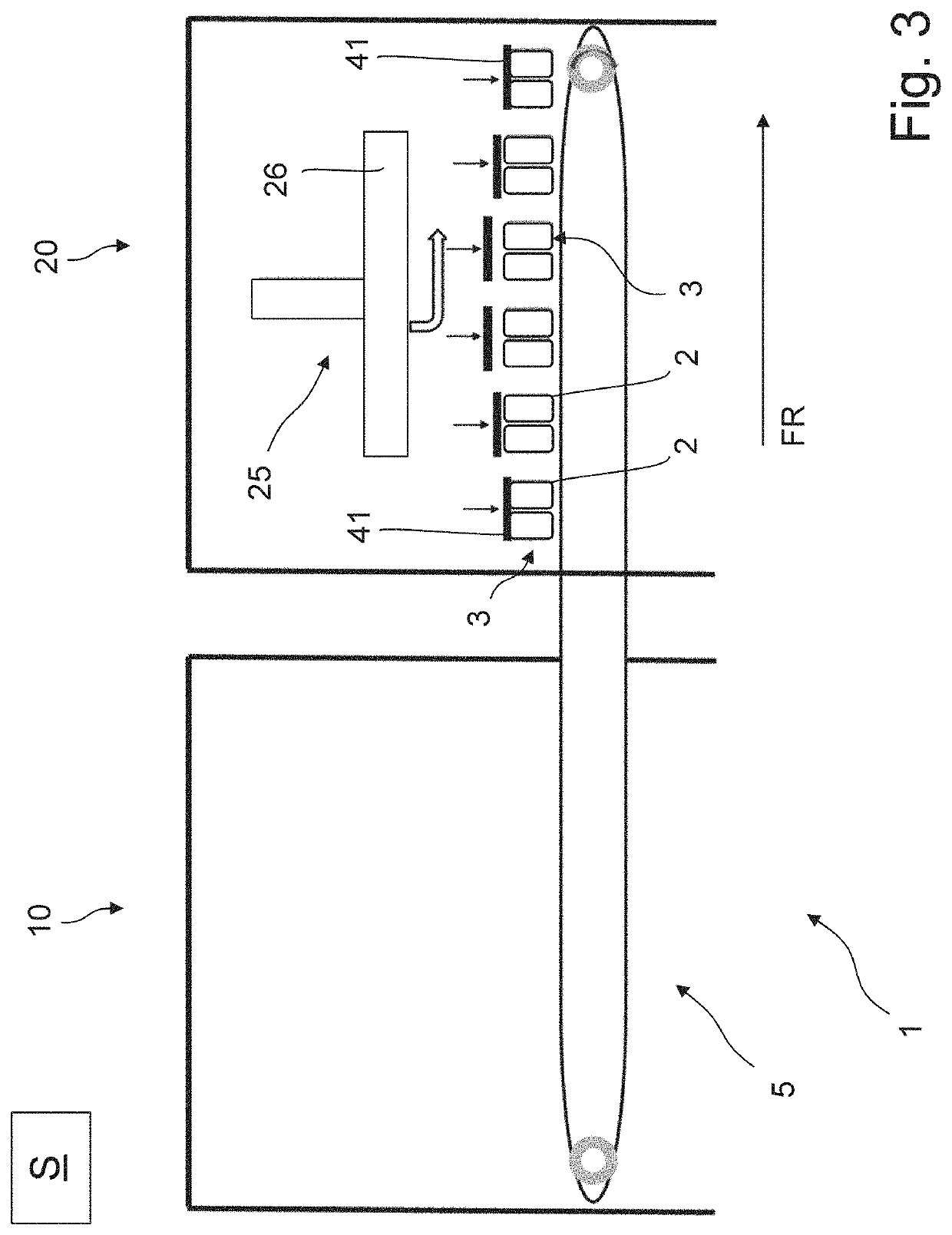

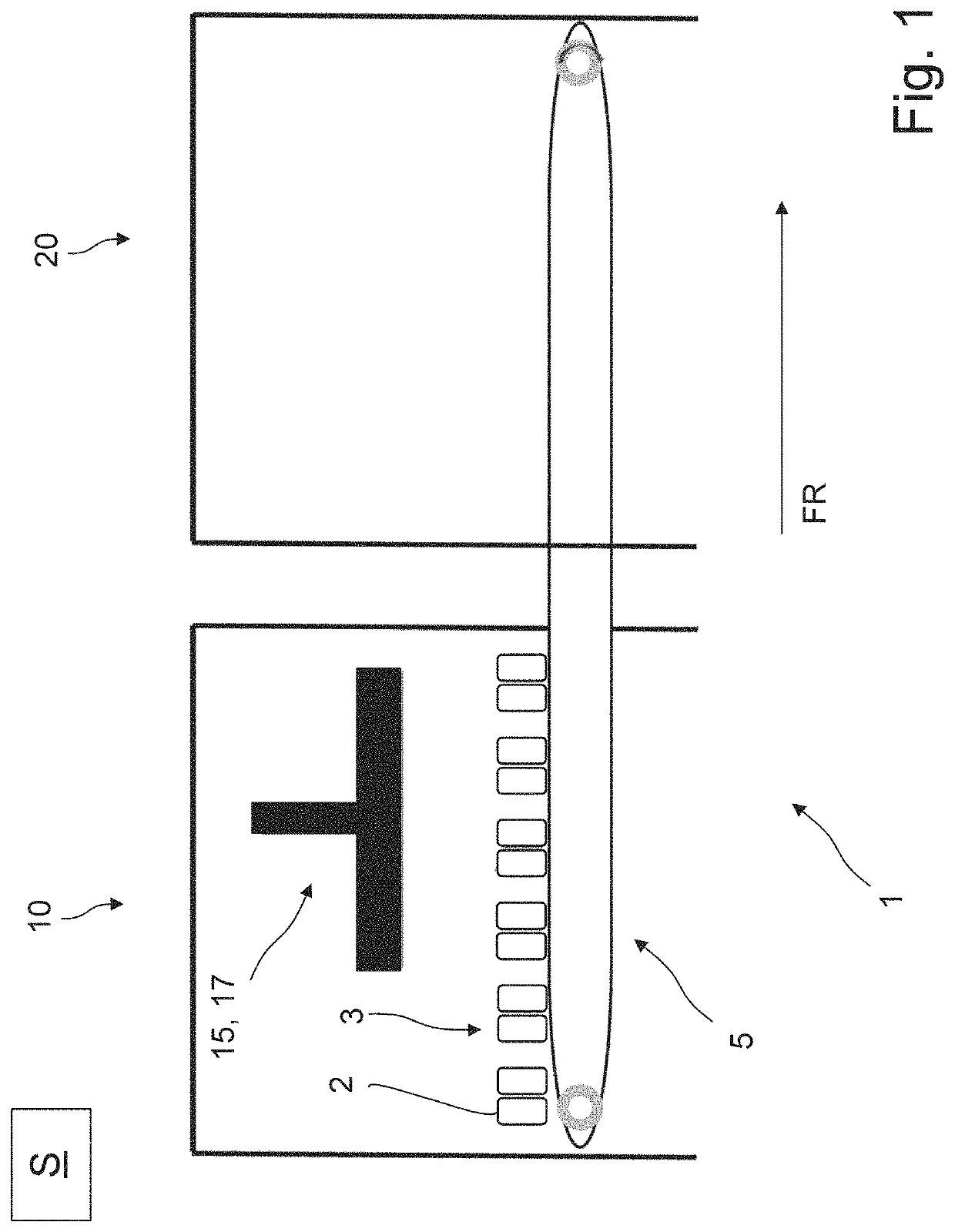

Device and method for grouping packages

The disclosure relates to a device (1) with at least one grouping belt (3) for the transport and / or grouping of packages (5) with a dimensionally stable protruding edge (9) and including means for moving two adjacent packages towards one another and for overlapping the protruding edges (9), whereby the edge (9) of the preceding package comes to rest over the edge (9) of the following package on the grouping belt (3). The disclosure further relates to a method of operating a device (1) of this nature preferably in packaging systems with deep-draw packaging machines or tray sealing machines and to the use of appropriate packages (5) which are then placed into an outer packaging in a space-saving manner. With the above device and method, space saving of the packages (5) in an outer packaging (14) can be achieved in a simple manner.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

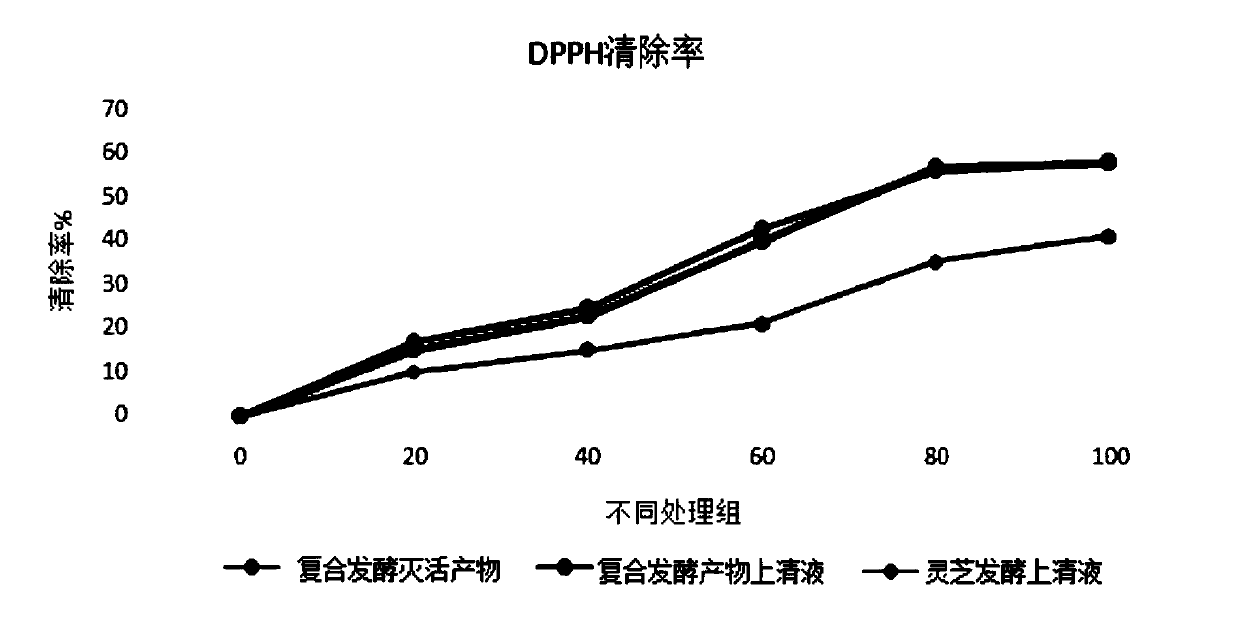

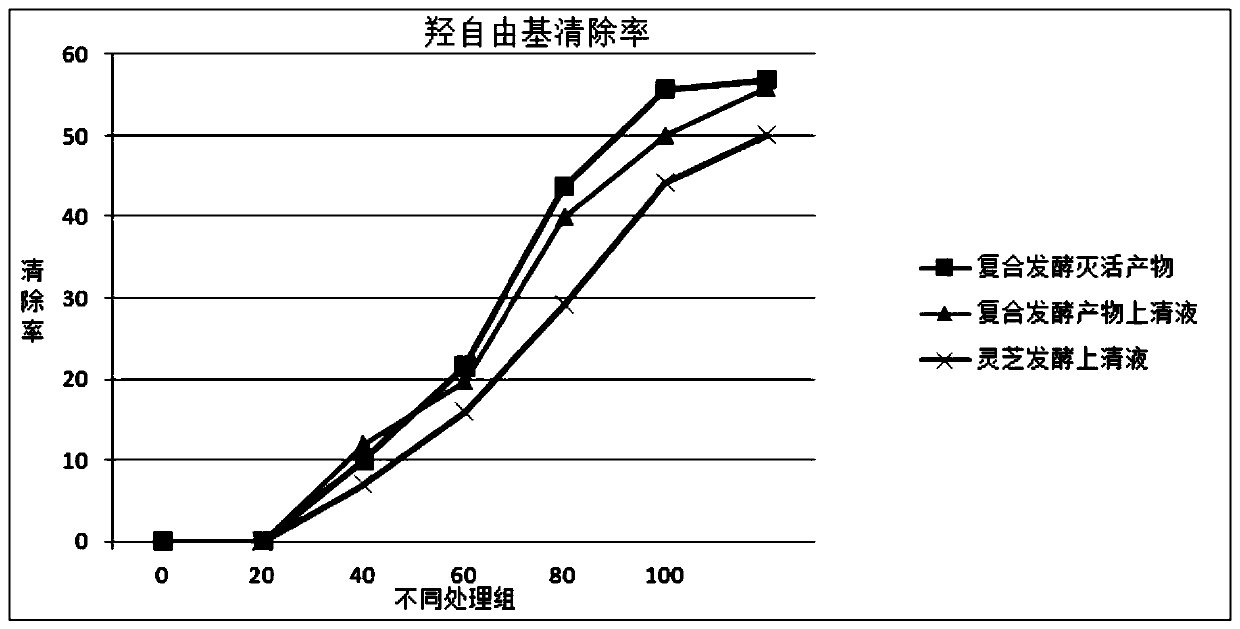

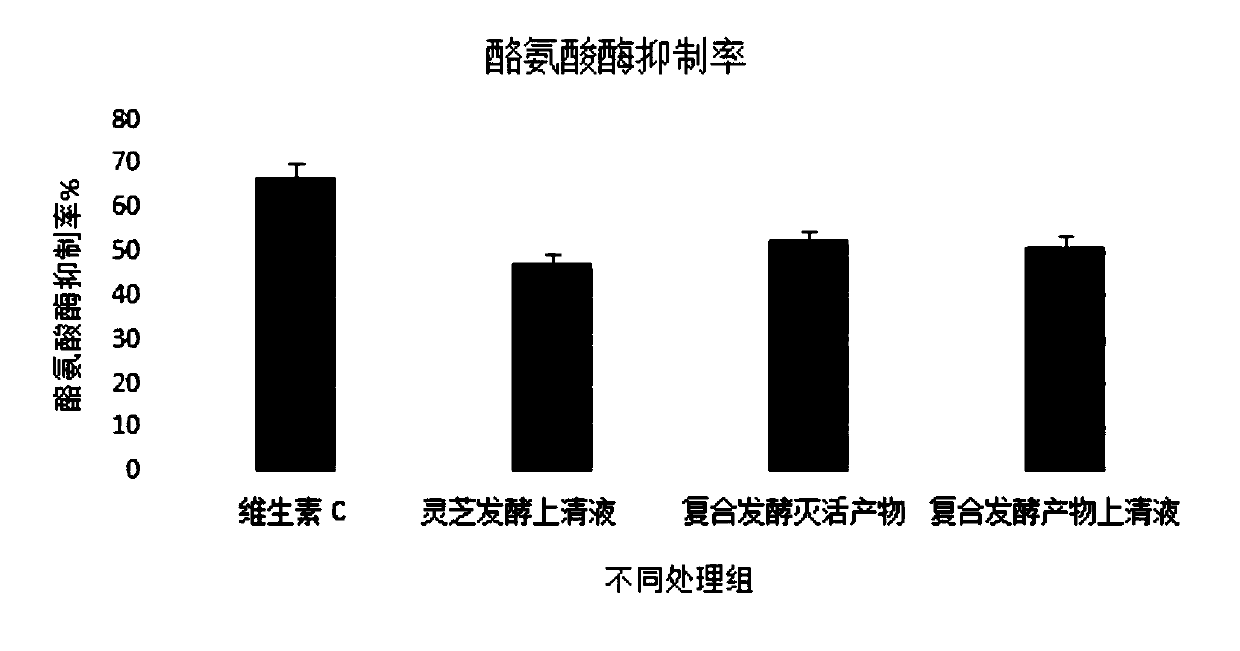

Lucid ganoderma-probiotic composite fermentation product, and preparation method and application thereof

InactiveCN111053711AImprove antioxidant capacityFast absorptionCosmetic preparationsToilet preparationsBiotechnologyCentrifugation

The invention discloses a lucid ganoderma-probiotic composite fermentation product and a preparation method and application thereof. The lucid ganoderma-probiotic composite fermentation product comprises a lucid ganoderma fermentation supernatant, a probiotic fermentation liquid and functional nutritional ingredients. The preparation method comprises the following steps: fermenting lucidum ganoderma mycelia, carrying out centrifuging, taking the supernatant, and mixing the supernatant with the functional nutritional ingredients; then adding the probiotic fermentation liquid into a mixture obtained in the previous step, and carrying out fermentation; and finally, subjecting a fermentation product to inactivation or centrifugation to obtain the composite fermentation product. The composite fermentation product contains rich nutritional ingredients such as polysaccharides, polypeptides and organic acids and is easily and fully absorbed by the skin, and the composite fermentation product contains ingredients such as microelements which can promote repair and recovery of injured skin, so the composite fermentation product has a good skin care effect. The composite fermentation product is beneficial for skin health and is not polluted by enzymes, chemicals and the like; the whole fermentation system is mild in conditions; and the preparation method is simple to operate and controllable in cost, and is beneficial for large-scale production.

Owner:山东凤凰生物科技股份有限公司

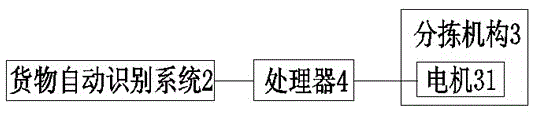

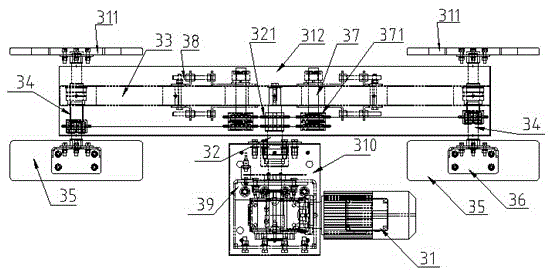

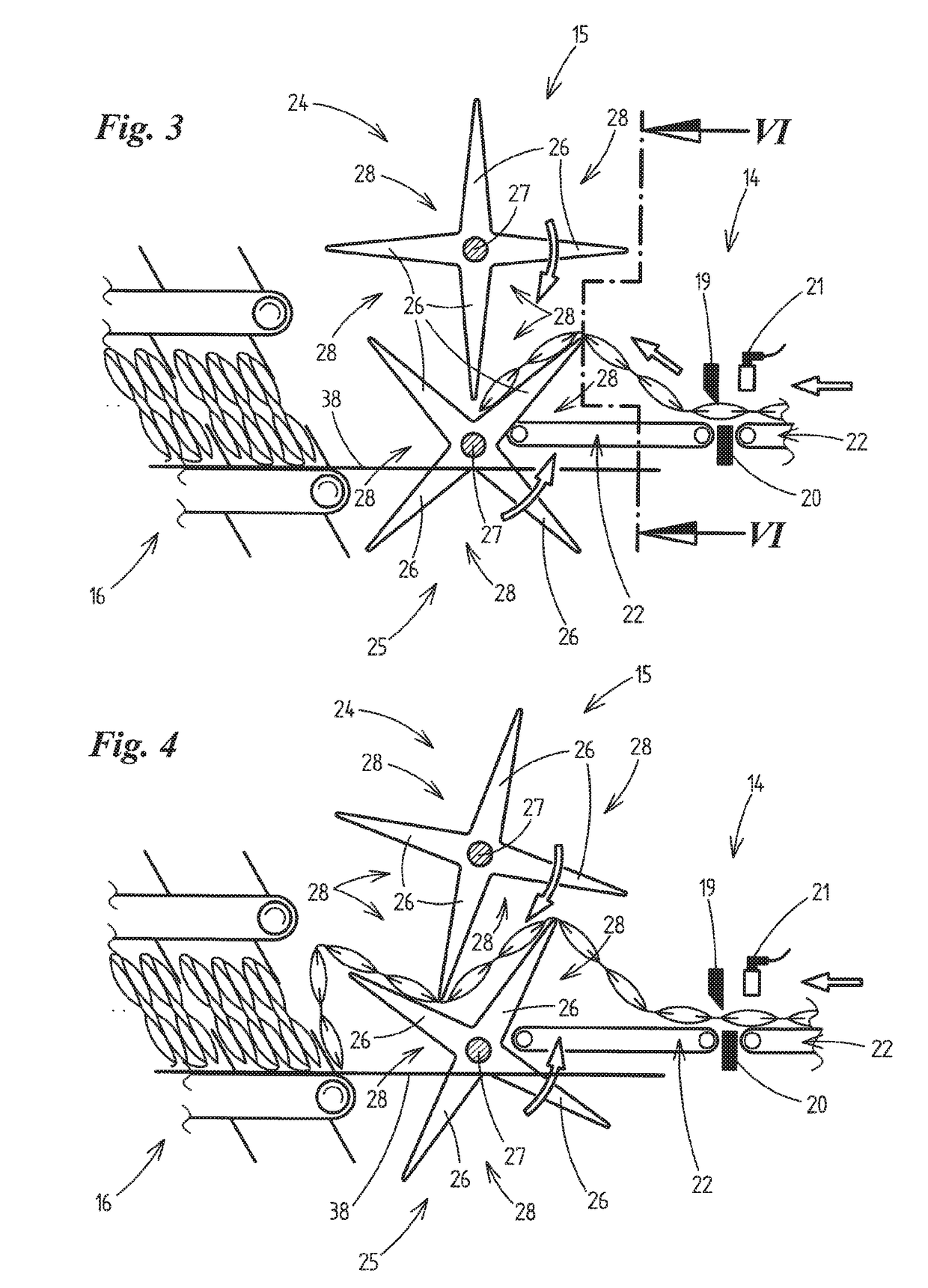

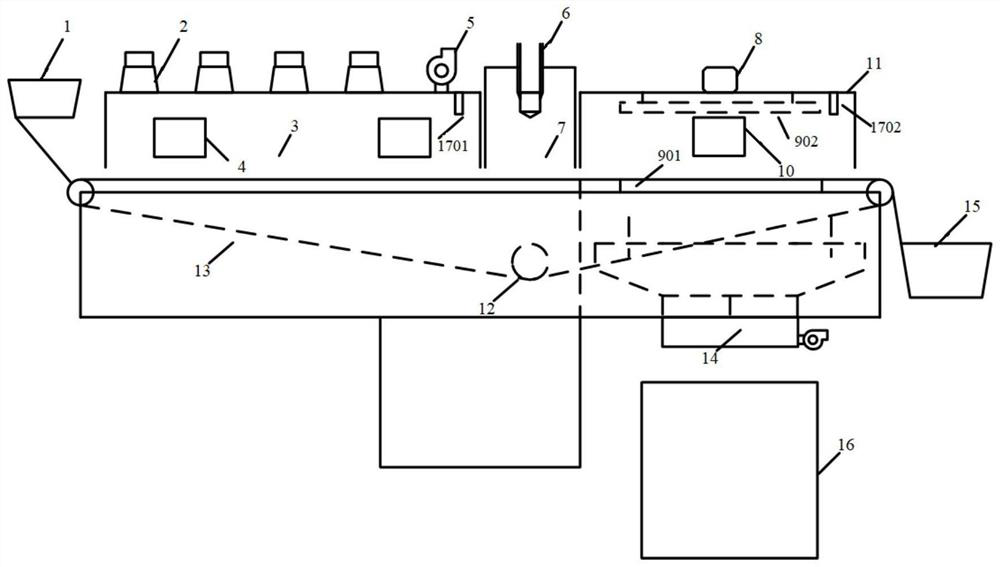

Rotary sorting system and use method thereof

InactiveCN105665287AGentle sorting processEfficient equipment operationSortingSolid of revolutionDrive shaft

The invention provides a rotary sorting system and a use method thereof. Sorting and conveying branches are arranged at one side of a conveyer; sorting mechanisms, corresponding to the sorting and conveying branches, are arranged at the other side of the conveyer; a cargo automatic identification system is arranged corresponding to the sorting mechanisms; each sorting mechanism comprises a motor, a driving shaft and a rotating body, wherein the rotating body is transversely arranged and the middle part of the rotating body is fixedly connected to the upper end of the driving shaft, pushing rotating shafts are vertically arranged at two ends of the rotating body in a rotatable manner, the pushing rotating shafts are in transmission connection to the driving shaft, pushing plates are arranged corresponding to the pushing rotating shafts, the pushing plates are fixed to the corresponding pushing rotating shafts through connecting parts, and the cargo automatic identification system and the motors in the sorting mechanisms are connected to a processor. The rotary sorting system provided by the invention solves the problem that an existing sorting mechanism is relatively low in sorting efficiency, and meanwhile, the sorting machine is not limited by mechanical conveying equipment and can prevent other non-sorted cargoes from being intervened. The rotary sorting system and the use method provided by the invention belong to the sorting field.

Owner:苏州九鲤机电科技有限公司

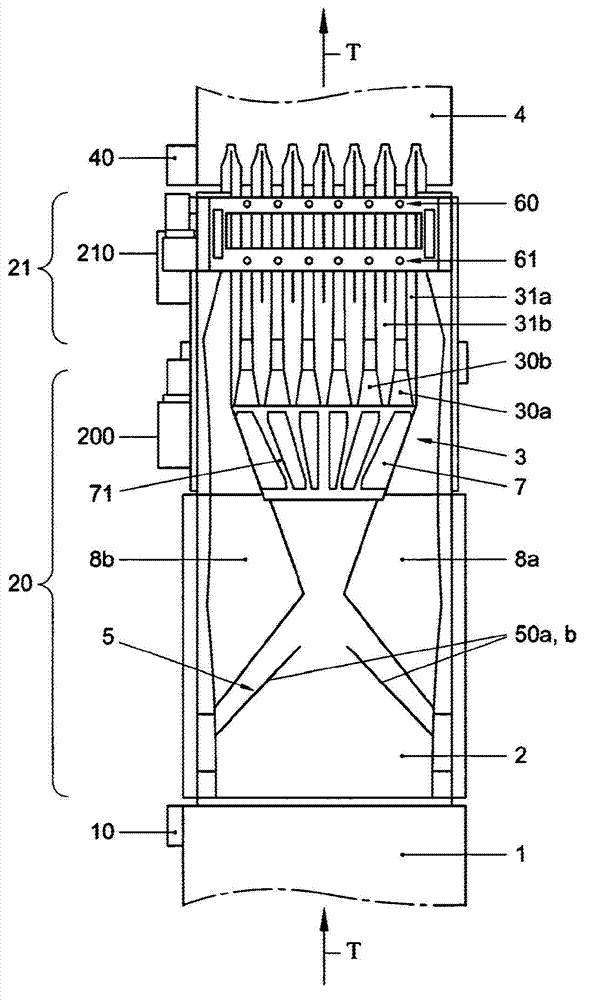

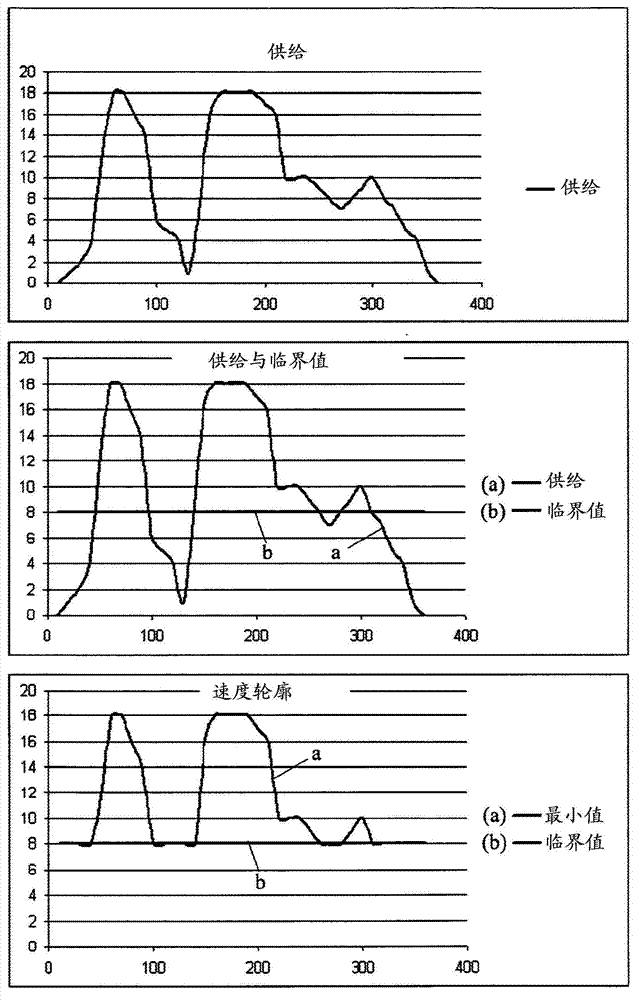

Apparatus for conveying eggs

InactiveCN102892692AGentle handlingGentle processabilityControl devices for conveyorsMechanical conveyorsControl signalEngineering

The invention relates to a system and a method for, in a conveying direction T during conveyance, continuously distributing a flow or products, for instance eggs, comprising: - a distributing assembly with at least two feed channels extending in a conveying direction T for each forming a single row of products, wherein at least edge elements compose the edges of these channels over a well-defined distribution length and wherein these edge elements are provided above and adjacent a conveying surface at the downstream end of a feed conveyor, and - a control for monitoring and controlling the distribution of the products over the channels, wherein, based on monitoring signals and control signals, from the downstream end of the channels, only two products are transferred simultaneously to the conveyor, wherein the control, based on the monitoring signals and control signals, increases or reduces the speed of the conveyor according to a continuous adjustment.

Owner:FPS FOOD PROCESSING SYST BV

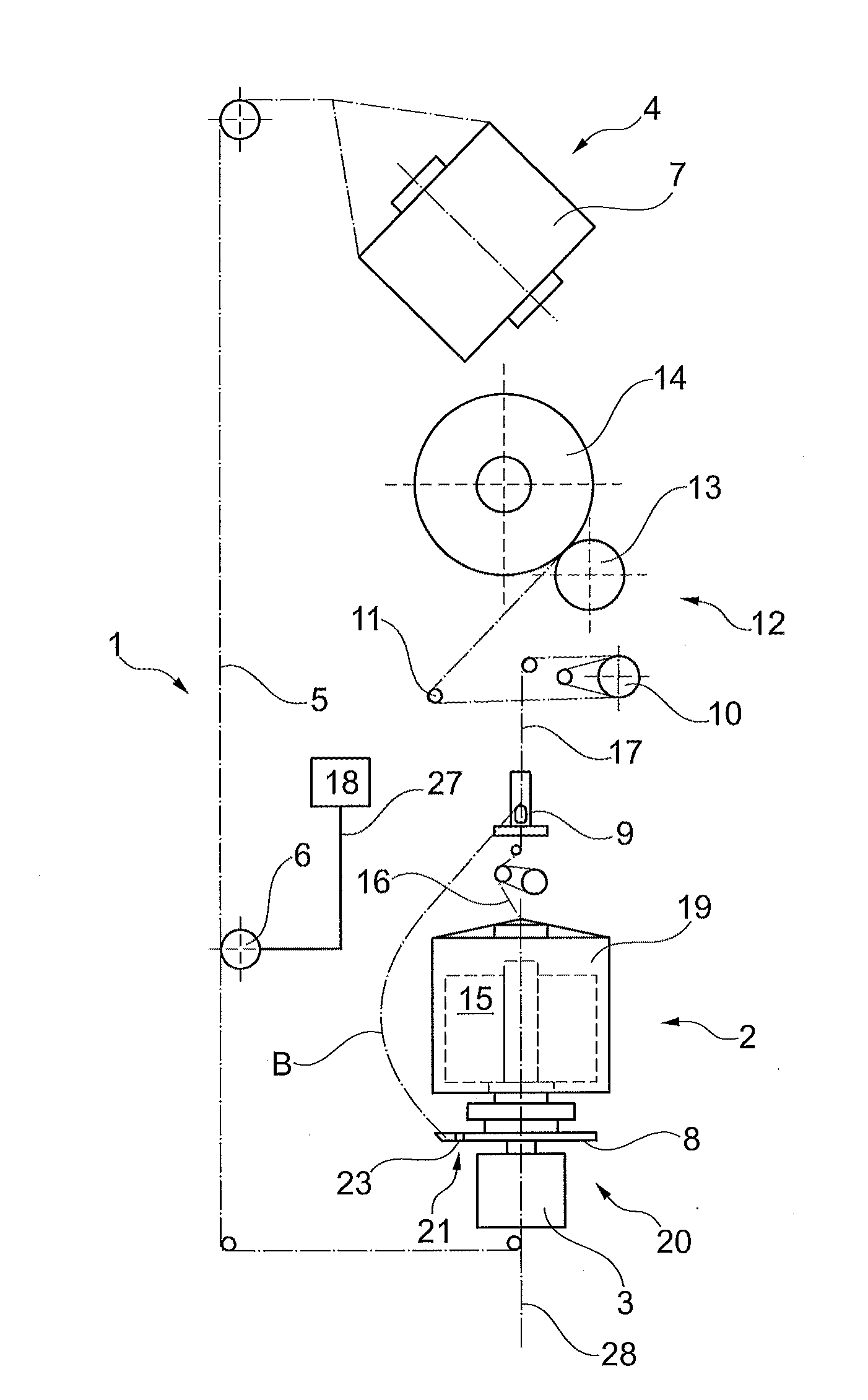

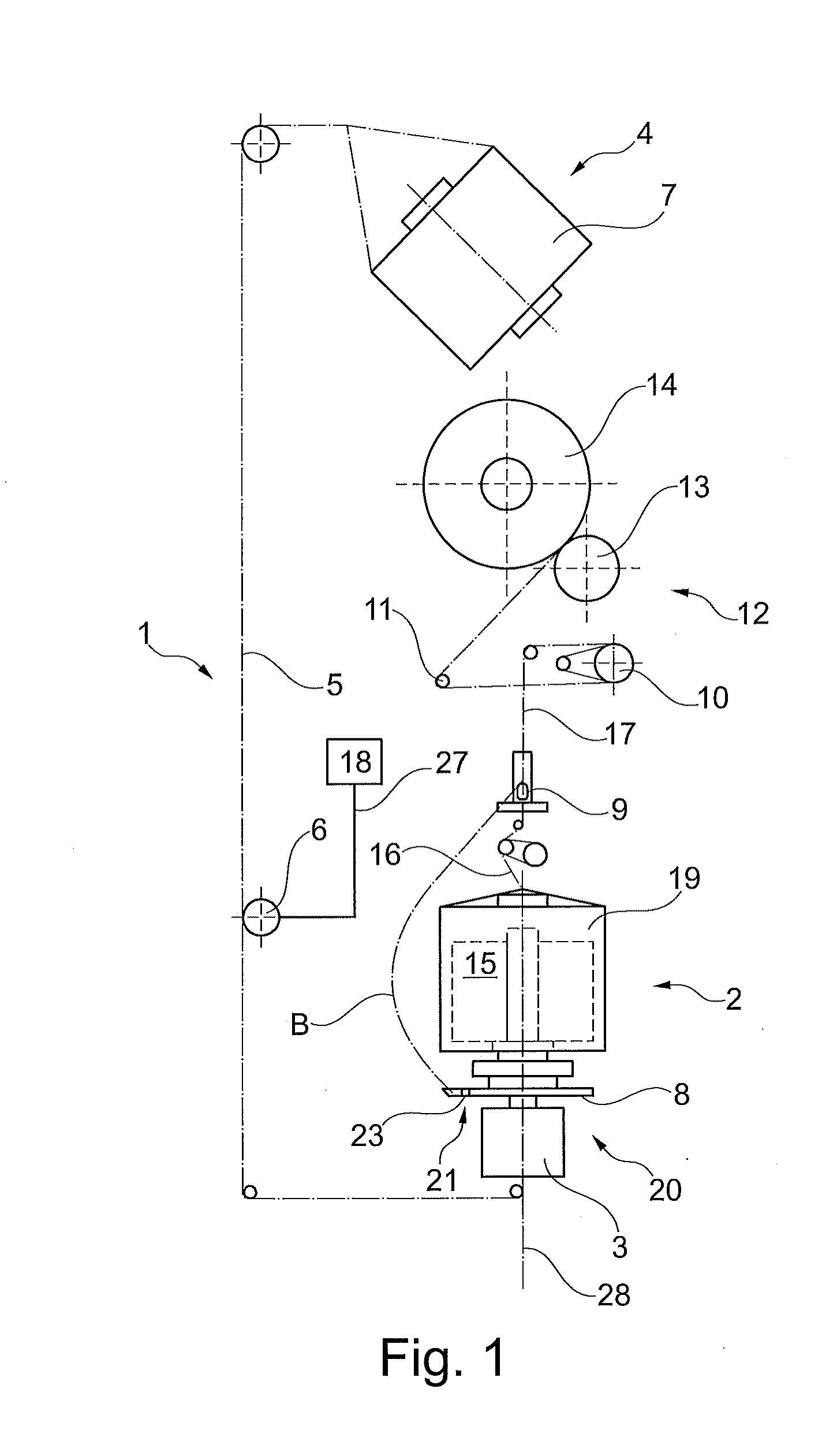

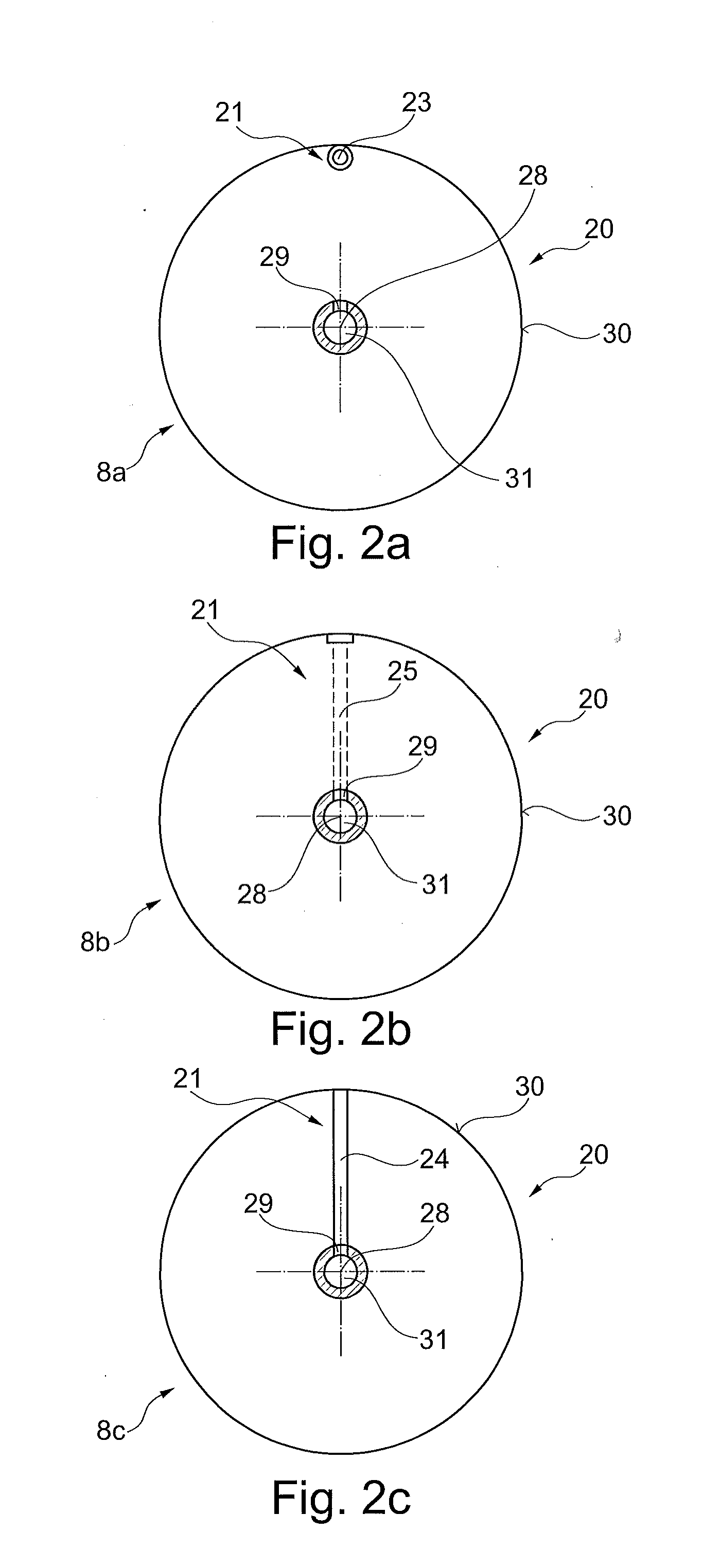

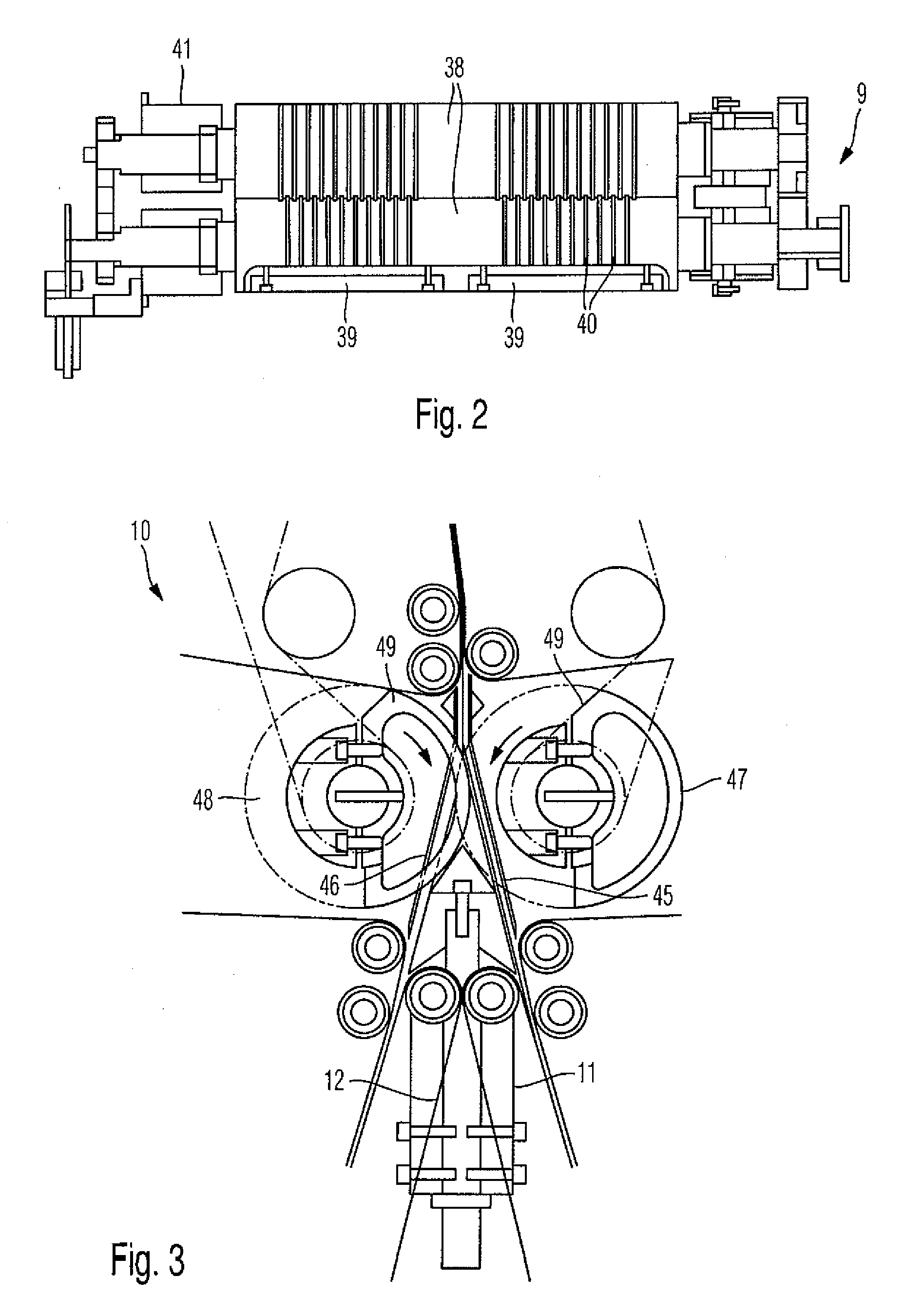

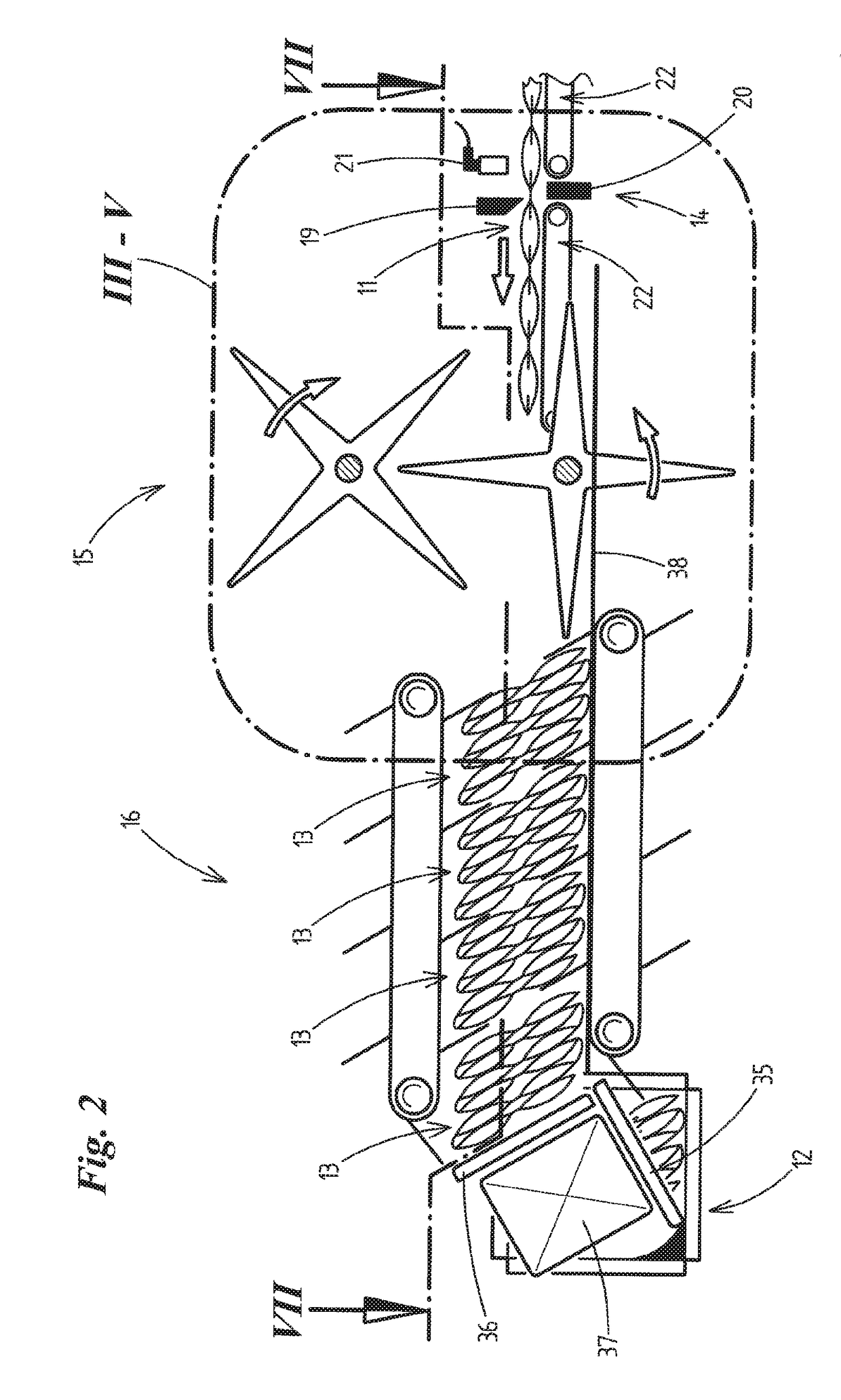

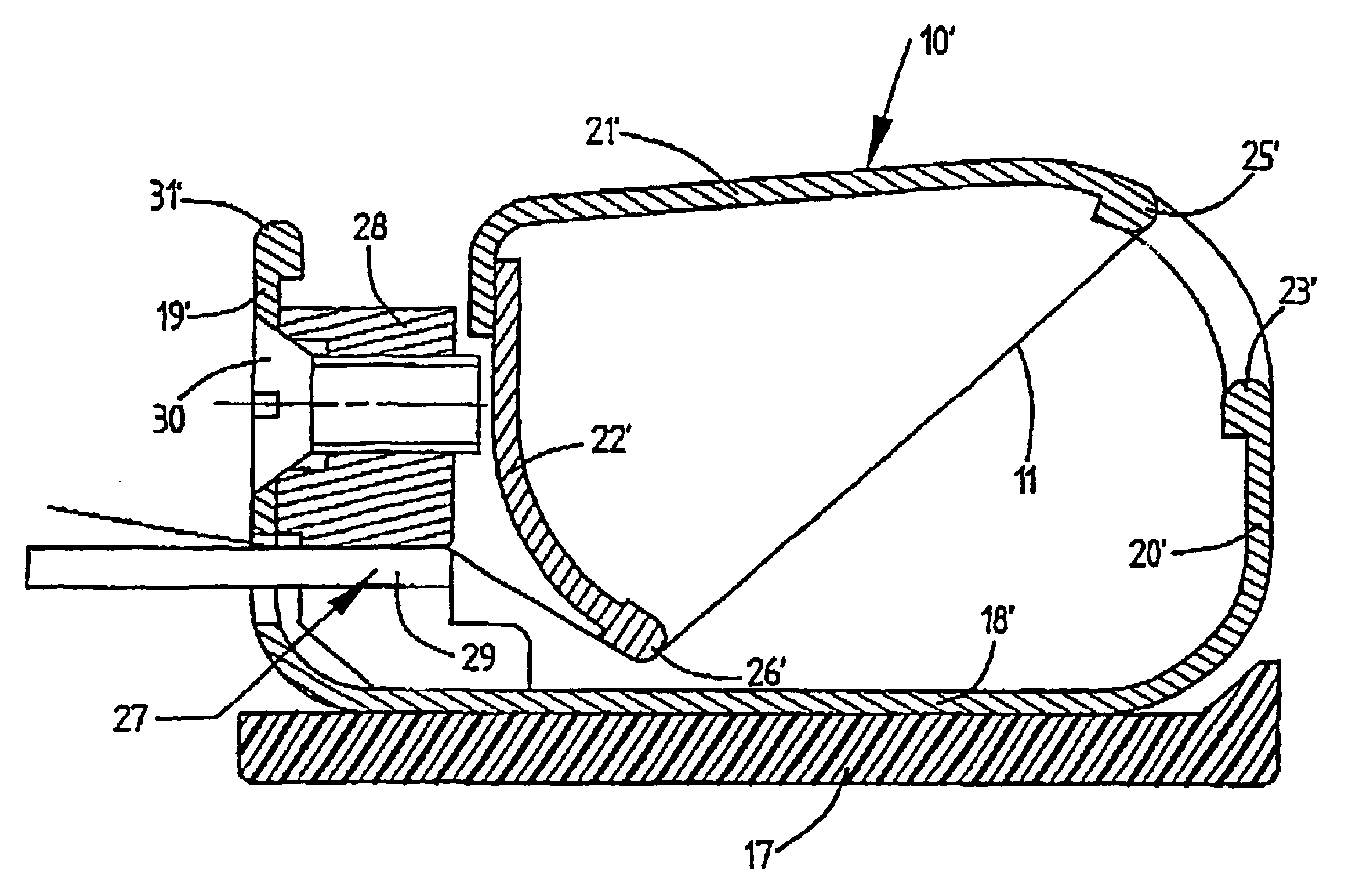

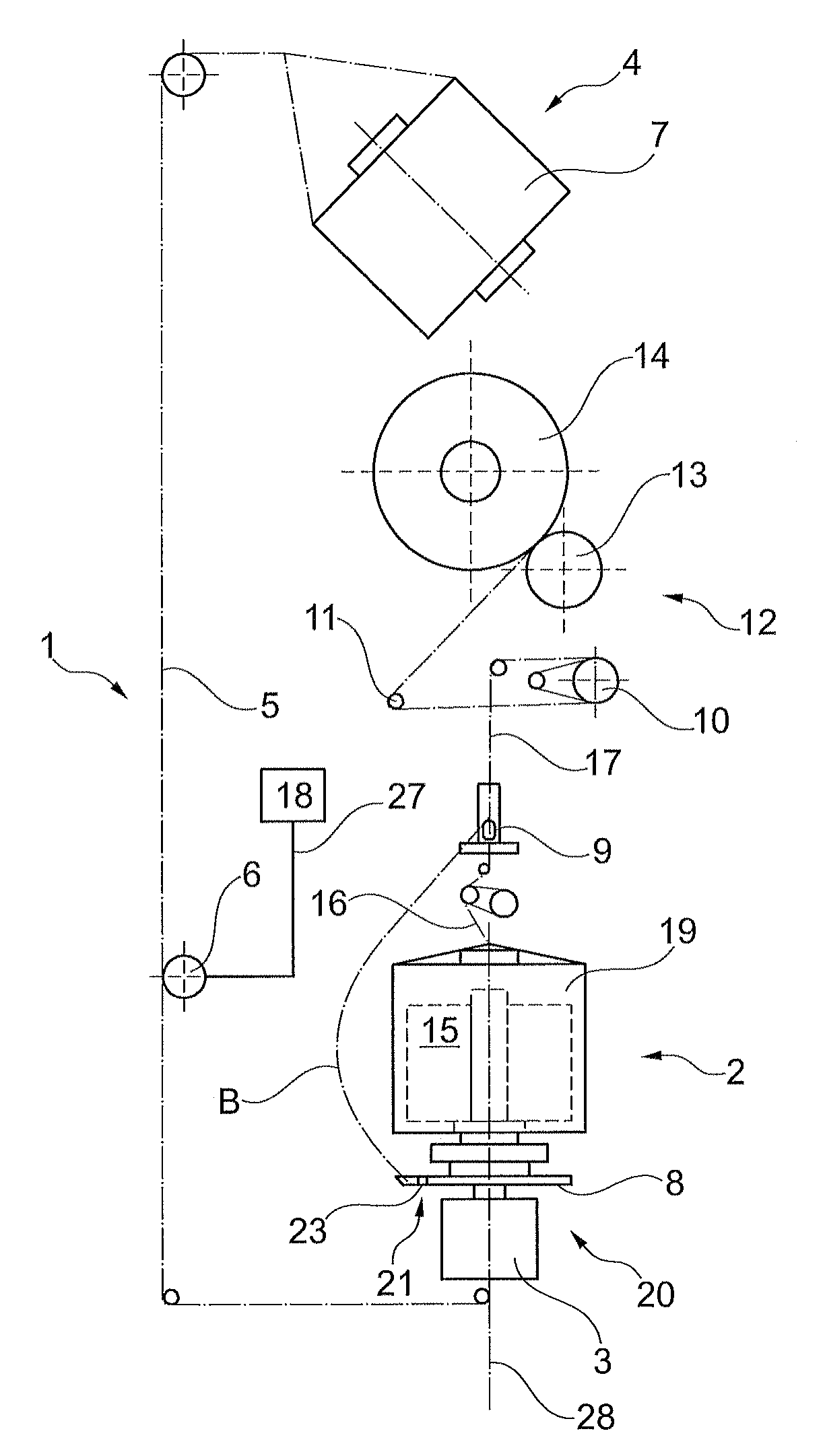

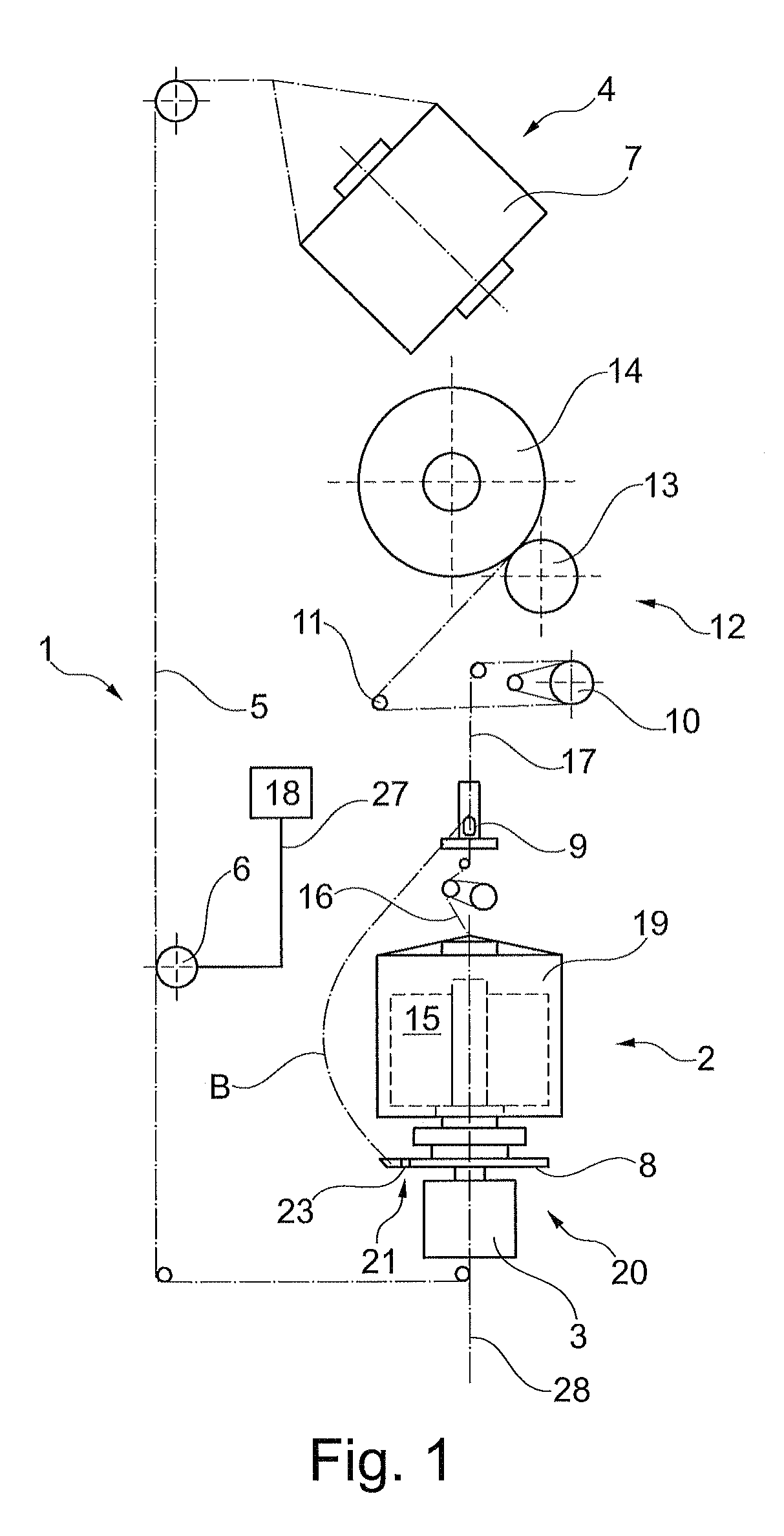

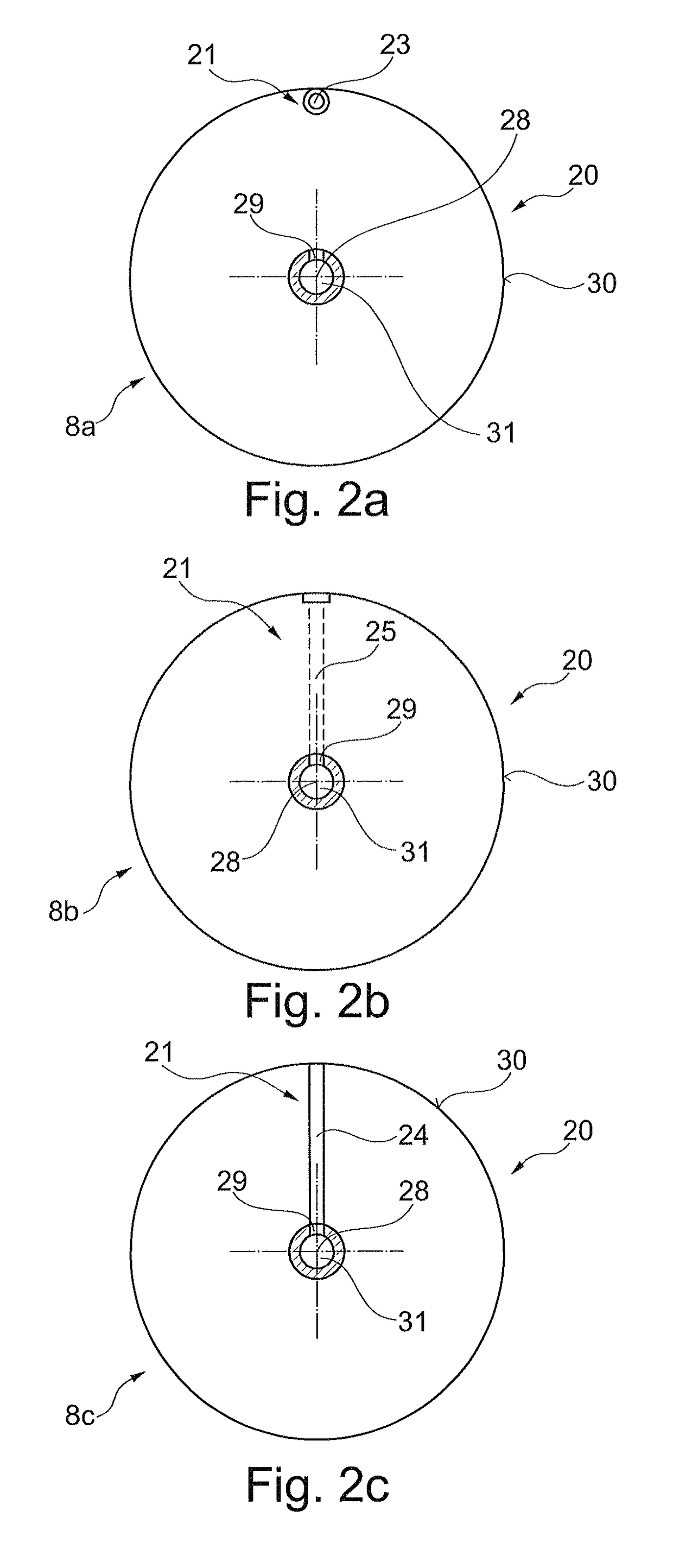

Method for operating a spindle of a two-for-one twisting or cabling machine and associated two-for-one twisting or cabling machine

InactiveUS20160319468A1Diameter minimizationGood power balancePiercing arrangementsContinuous wound-up machinesCable machineYarn tension

A method for operating a spindle (2) of a two-for-one twisting or cabling machine, in which an outer yarn (5) is drawn off a first feed package (7) and the spindle (2) rotates in a yarn balloon (B), wherein the spindle (2) comprises a device (6) for influencing the balloon yarn tension of an outer yarn (5), which is connected to a control circuit (18), and has a spindle pot (19) for receiving a second feed package (15), a yarn deflection device (20), a balancing system (9) for forming a twisting or cabling point as well as a spooling and winding device (12). The drive of the yarn balloon (B) is performed via a fixed throw-off point (21) on the yarn deflection device (20).

Owner:SAURER TECH GMBH & CO KG

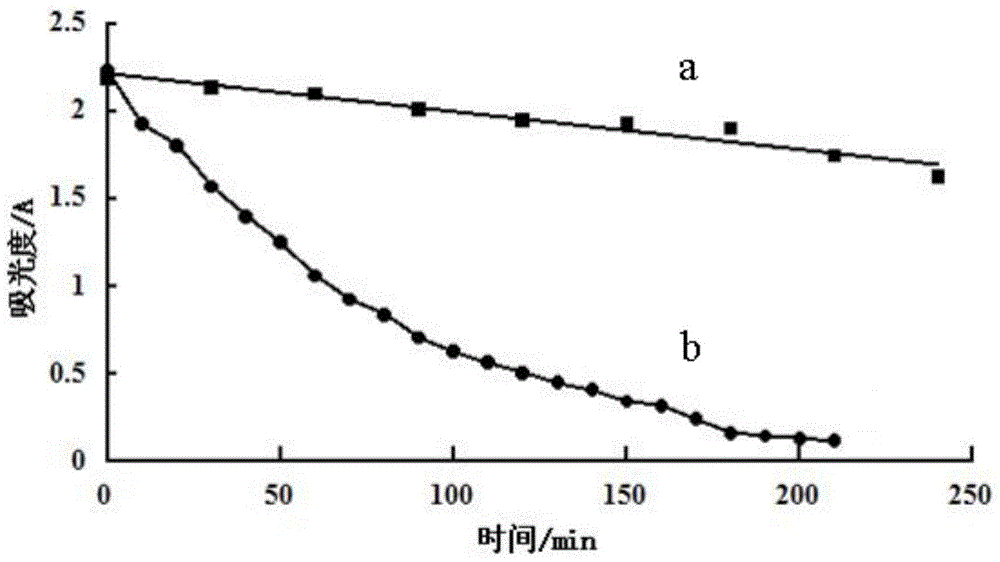

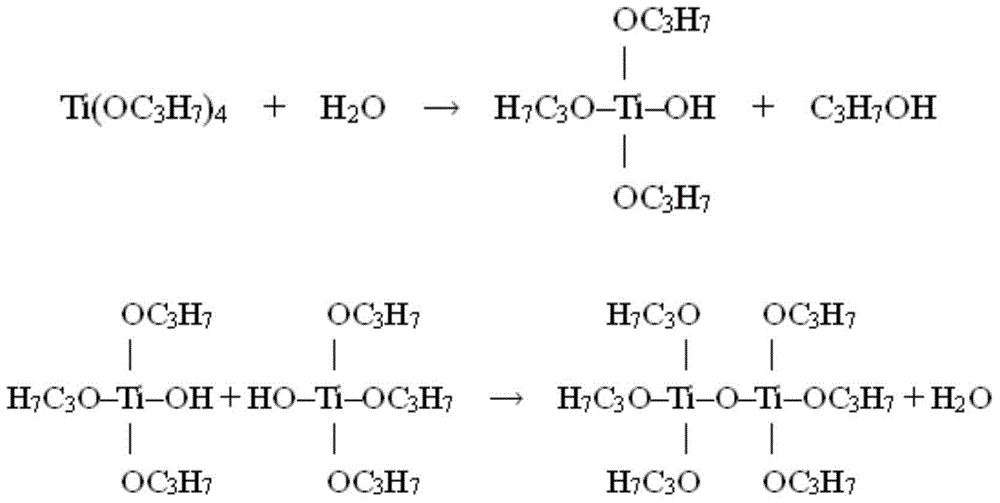

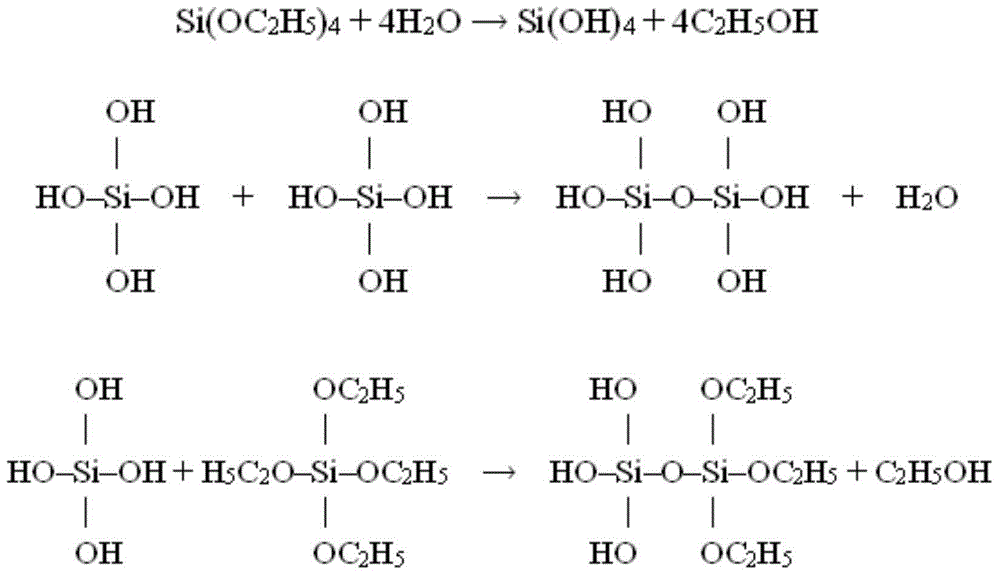

Dye wastewater photocatalytic treatment method

InactiveCN105000625ASimple preparation conditionsGood lookingWater/sewage treatment by irradiationGramUltraviolet lights

The present invention relates to a dye wastewater photocatalytic treatment method, pertaining to the technical field of environmental protection. According to the treatment method, parameters of a sol-gel method are optimized; a silicon dioxide-titanic dioxide composite monolithic column is prepared; 15.64 grams of the silicon dioxide-titanic dioxide composite monolithic column is added to dye wastewater per liter; condensed water is added; air is blown into the wastewater; and the wastewater is irradiated under the ultraviolet light for 4 hours. The silicon dioxide-titanic dioxide composite monolithic column provided by the invention is good in appearance, good in mechanical strength, and high in catalytic efficiency. The photocatalytic treatment method is capable of effectively degrading the dye wastewater, recycling the silicon dioxide-titanic dioxide composite monolithic column and solving dye sewage treatment and recycling problems, and has high practical value in treating dye wastewater.

Owner:HUANGGANG NORMAL UNIV

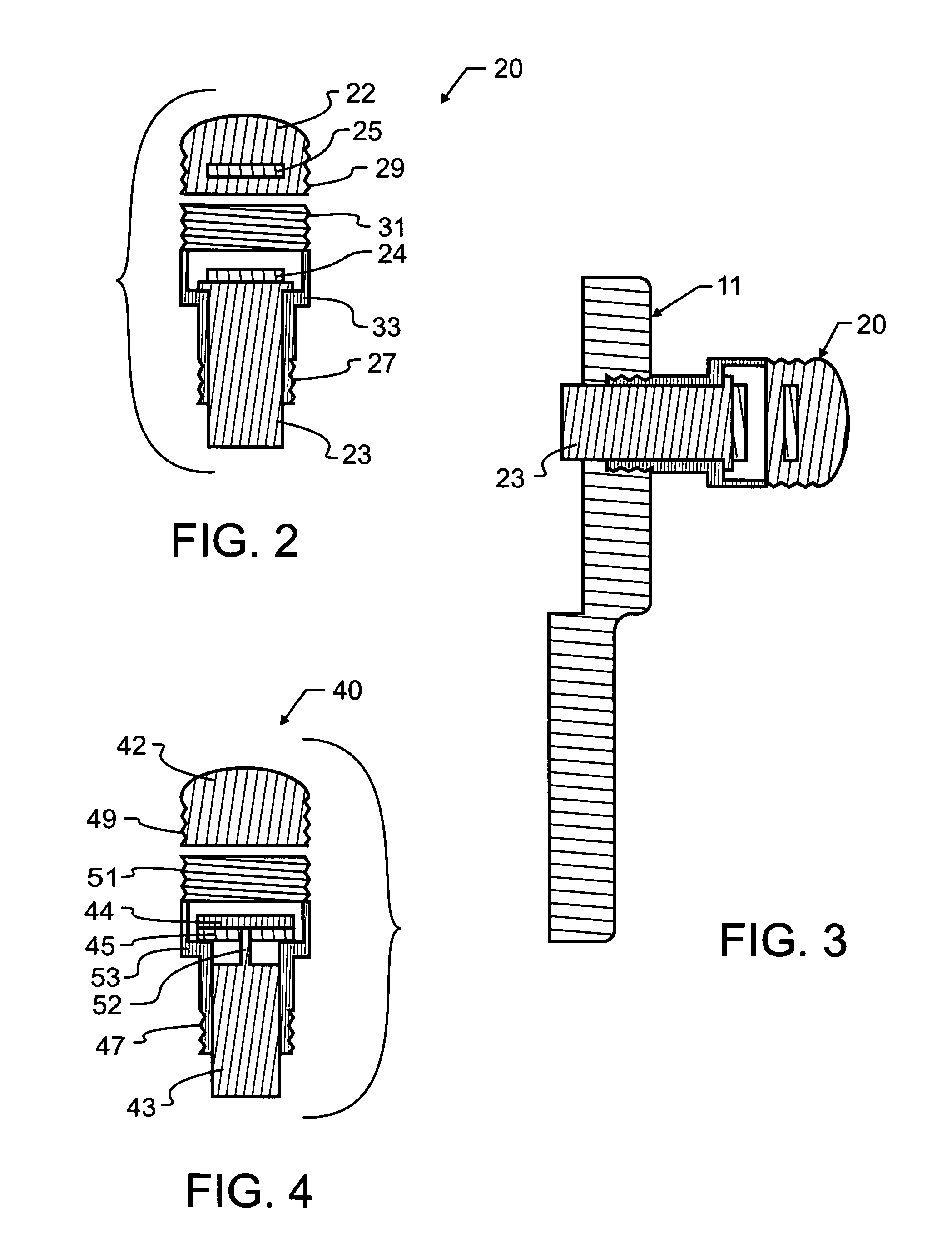

Magnetic paint ball gun apparatus

InactiveUS8006680B1Lower resistanceGentle handlingAmmunition loadingCompressed gas gunsMagnetic tension forceCoupling

A paint ball gun barrel indexing pin includes a plunger, cover, body, and first and second magnets that bias the plunger within the barrel. Magnetic coupling is used between rigid components that are used to position paint balls within a paint ball gun. In a “push-push” arrangement, a pair of magnets are oriented with like poles facing each other. When force is applied to one of the pair of magnets, the force will be transmitted through the magnetic fields to the second magnet. This magnetic coupling offers low resistance to movement when the magnets are in an initial substantially spaced apart relationship. Such low force coupling ensures gentle handling of the paint balls. However, as the limits of travel are approached, the magnetic coupling will exponentially increase forces between the magnets, preventing a “bottoming out” of the coupling.

Owner:SQUIRE ROB

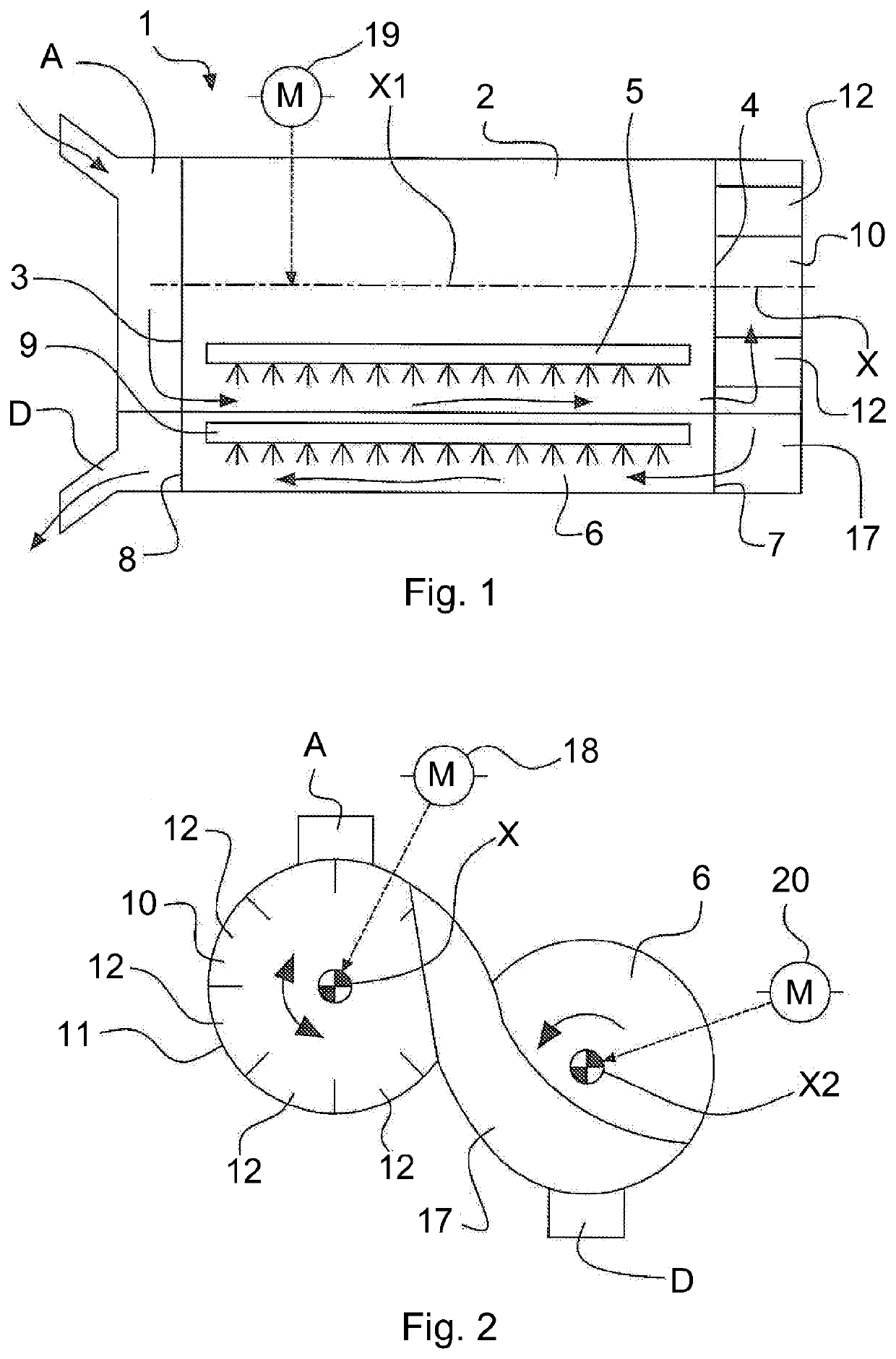

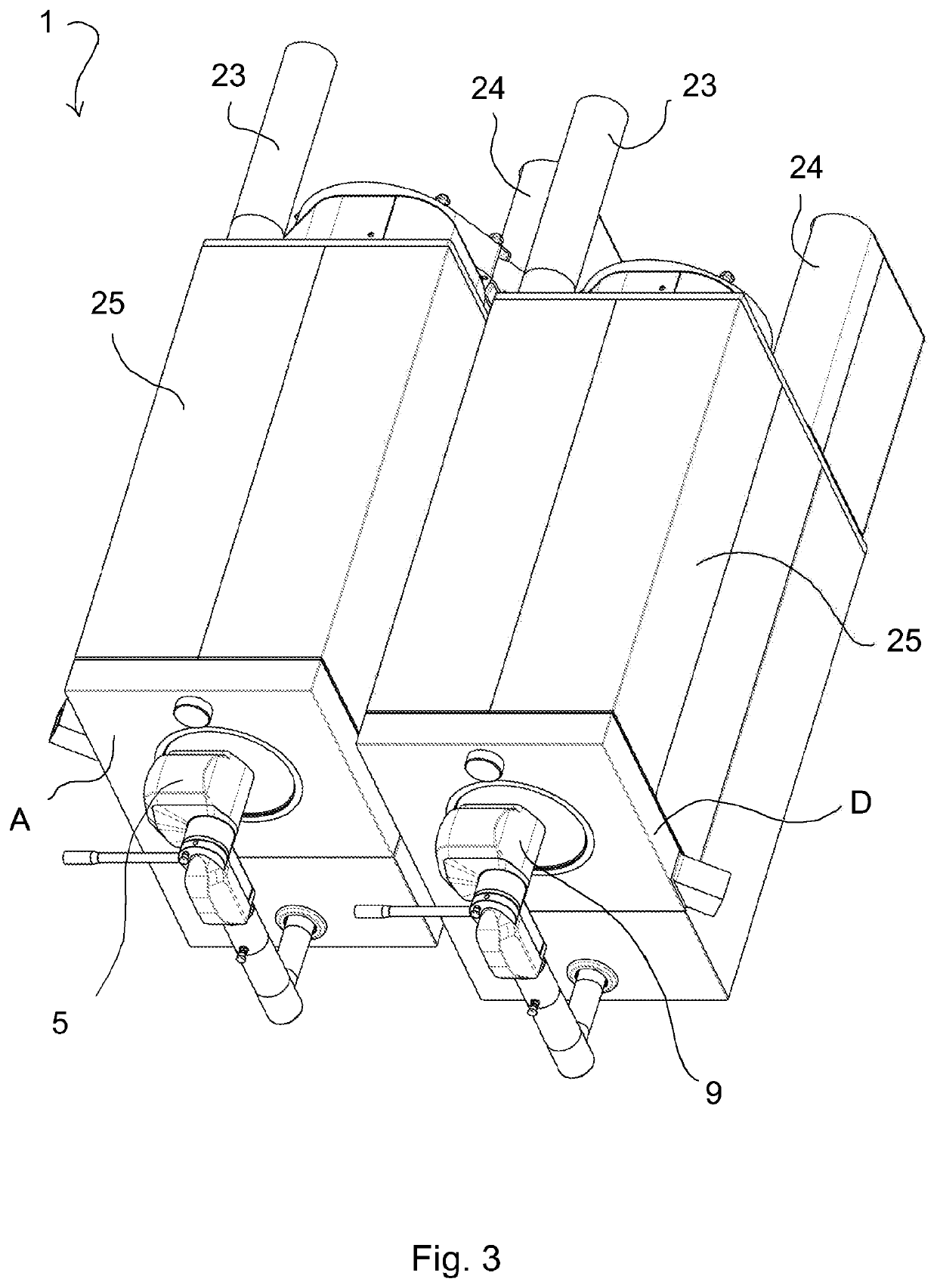

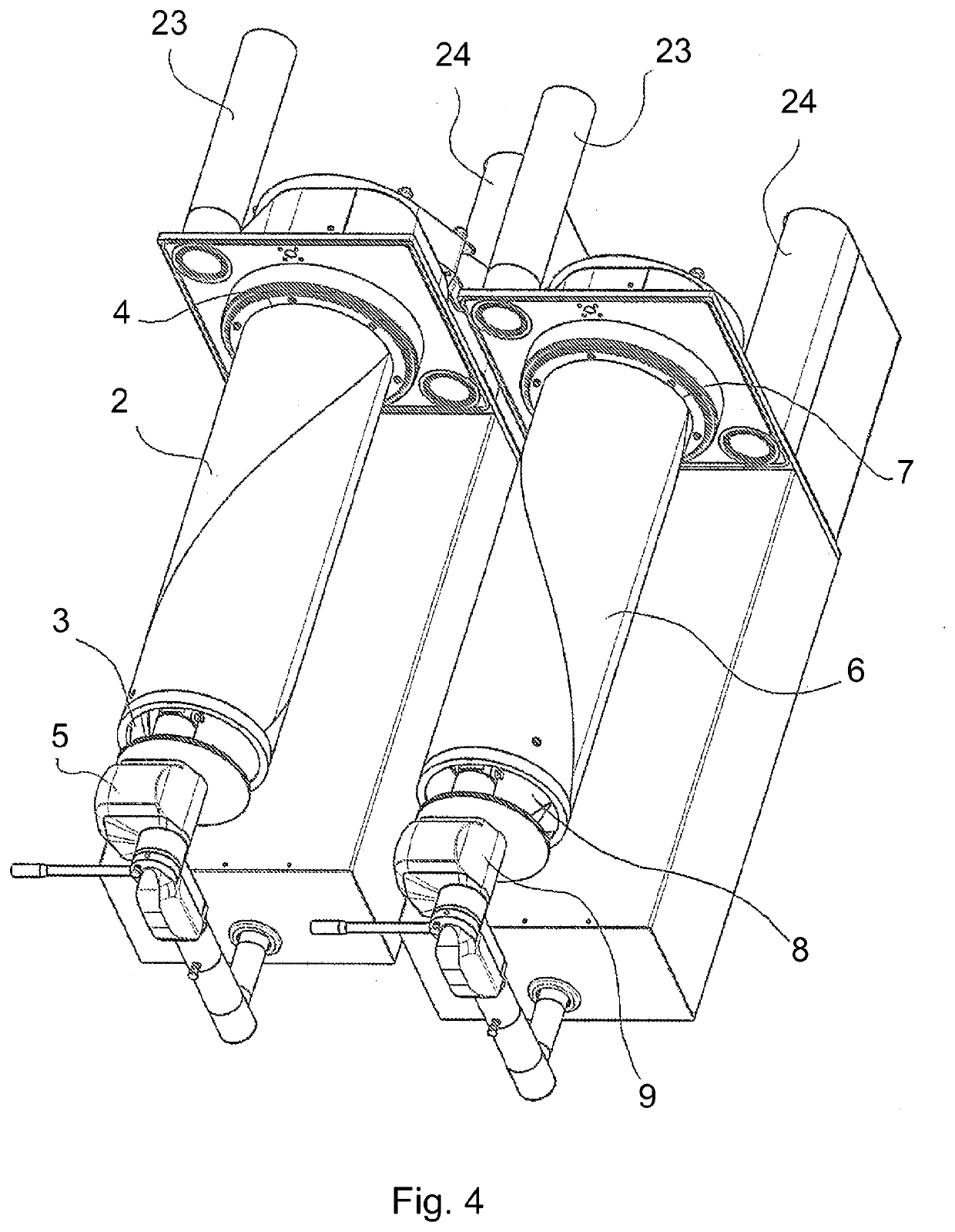

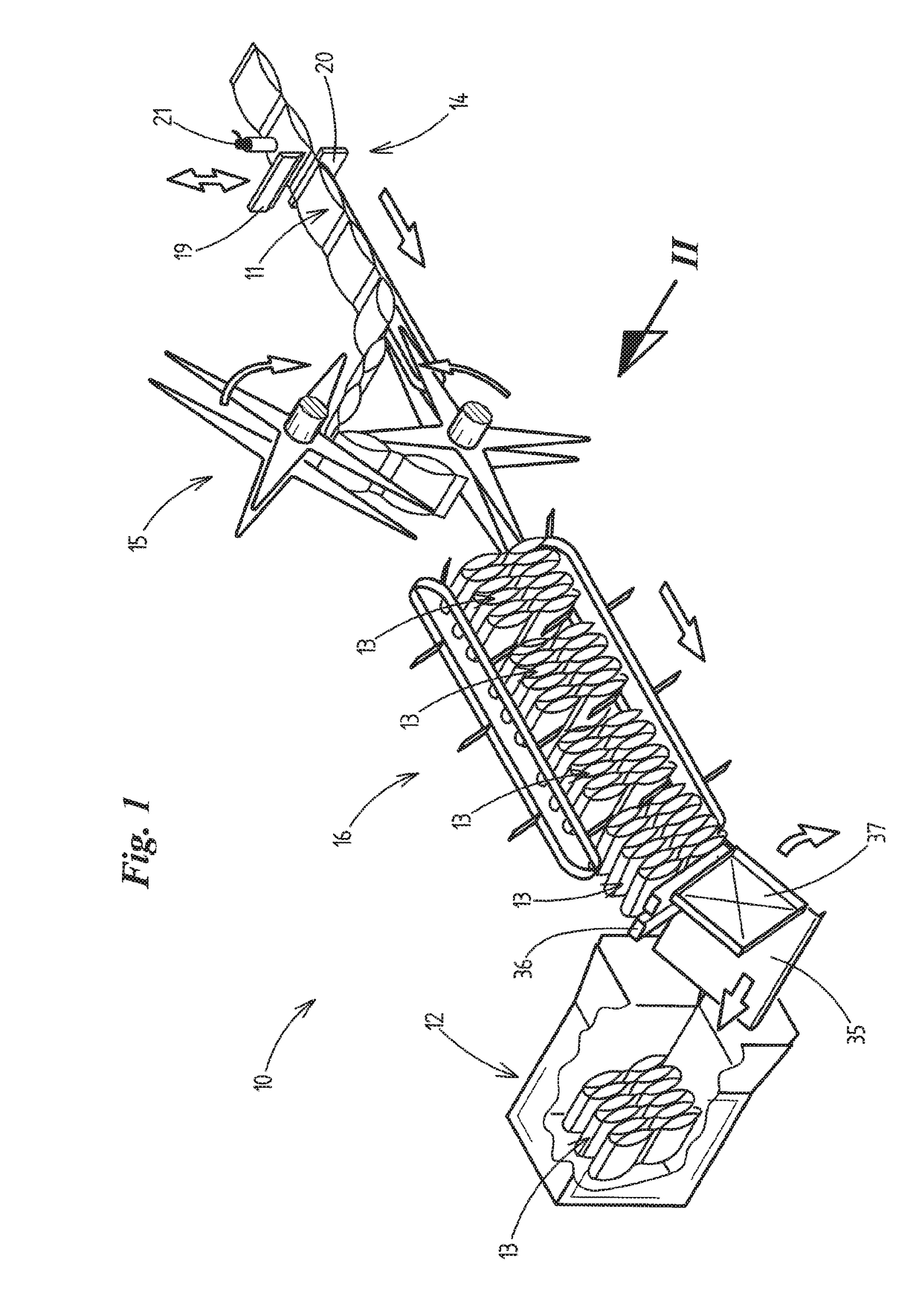

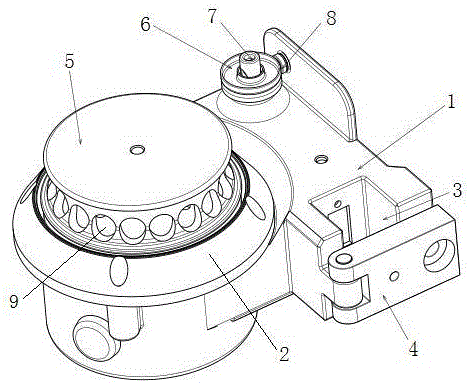

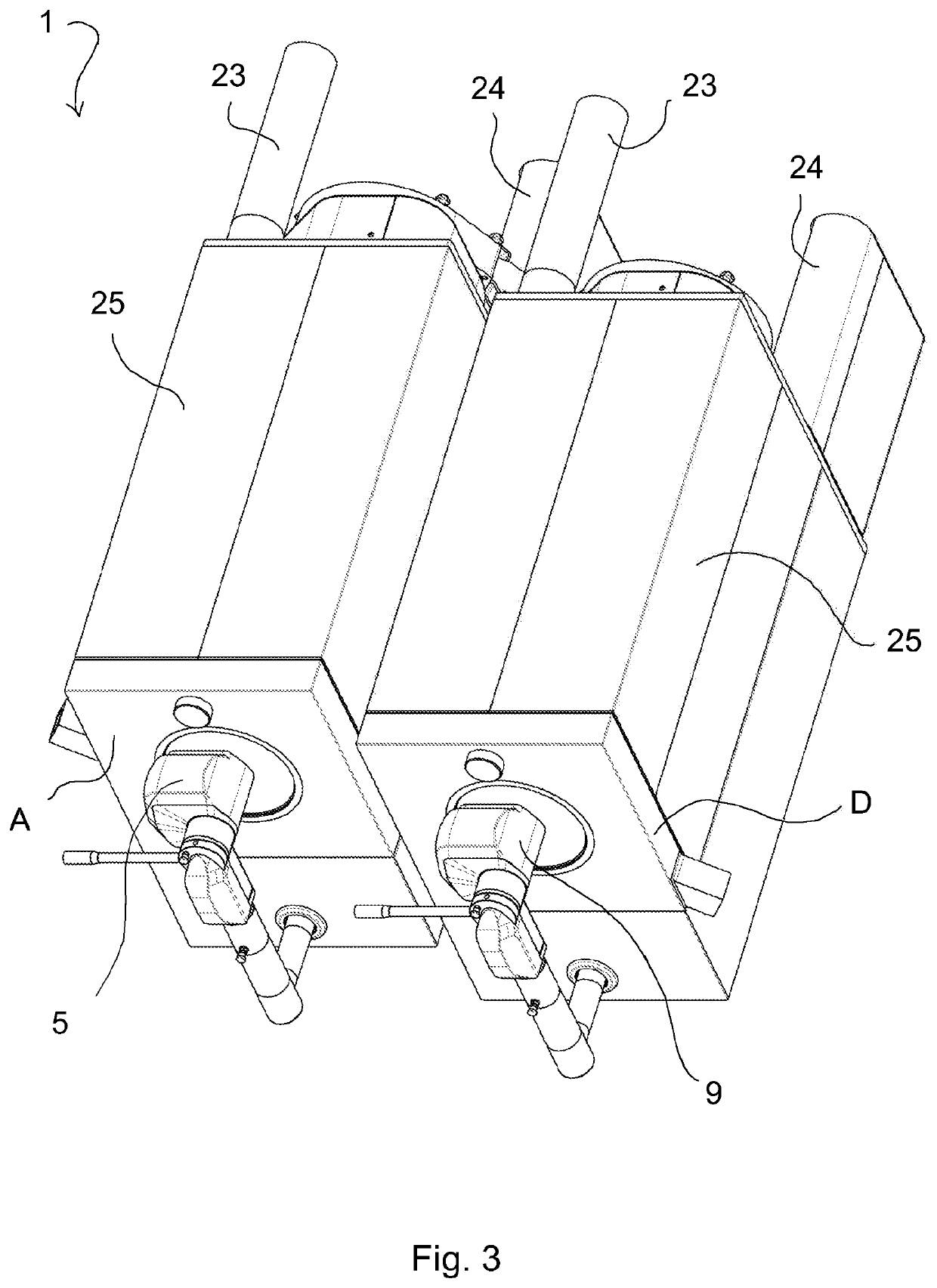

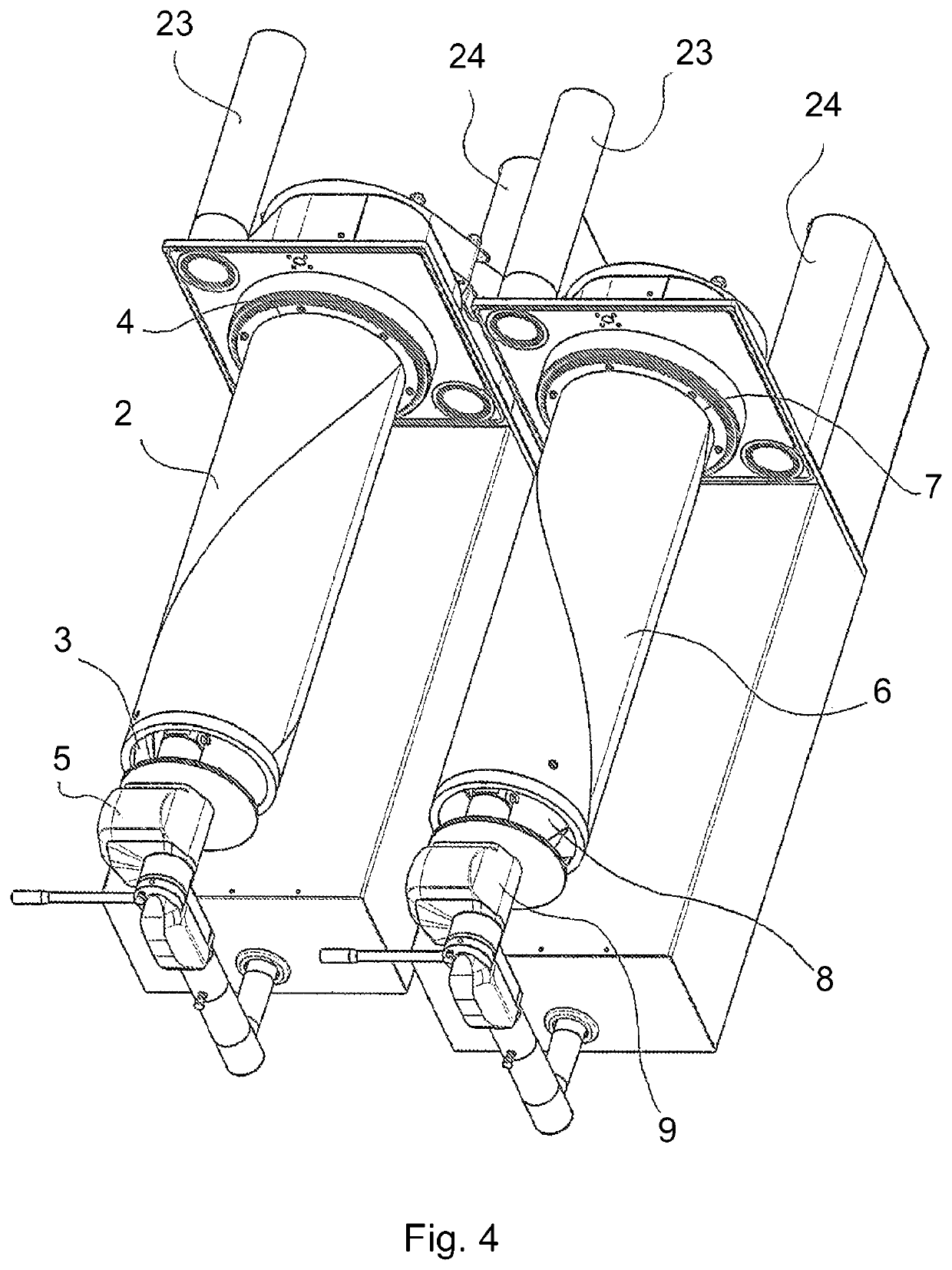

Method for coating bulk material

ActiveUS20200055079A1Simple and effective regulationGentle handlingGas treatmentLiquid surface applicatorsComposite materialManufacturing engineering

Method for coating bulk material comprises: starting a coating apparatus (1; 101) according to a start procedure on a discrete load of bulk material to be coated; operating the coating apparatus (1; 101) in stationary mode, by introducing a continuous flow of uncoated bulk material into the coating apparatus (1; 101) and obtaining at the outlet of said coating apparatus (1; 101) a continuous flow of coated bulk material having a predetermined stationary coating weight gain (W %); in which the coating apparatus (1; 101) comprises a first rotatable tubular container (2; 102) provided with a first dispensing device (5; 105) for dispensing coating material on the bulk material (M) in a plurality of internal successive adjacent spray zones between a first inlet and a first outlet of the first container (2; 102); a second rotatable tubular container (6; 106) arranged to receive bulk material (M) coming from the first container (2), the second rotatable tubular container (6; 106) being provided with a second dispensing device (9; 109) for dispensing coating material on the bulk material (M) in a plurality of internal successive adjacent spray zones between a first inlet and a second outlet of the second container (6, 106); conveying means arranged to convey the bulk material (M) from the first container (2; 102) to said the second container (6, 106); and in which the start procedure comprises in succession: dispensing coating material onto the load, maintaining the coating material inside the first container (2; 102) until coated bulk material is obtained with said predetermined stationary coating weight gain (W %); a transition phase to the stationary mode in which a flow of the load of coated bulk material is transferred from the first container (2; 102) to the second container (6; 106) and is supplied with an equal flow rate of bulk material to be coated to the first container (2; 102); dispensing coating material on the same flow rate of bulk material to be coated entering the first container (2; 102) activating in sequence the spray zones inside first container (2; 102) to obtain at the first outlet a coated bulk material with an established weight gain (U %); dispensing coating material on the same flow rate of bulk material to be coated having the established weight gain (U %) entering the second container (6; 106), activating in sequence the spray zones inside the second container (6; 106) to obtain a coated bulk material with the predetermined stationary coating weight gain (W %).

Owner:IMA IND MASCH AUTOMATICHE SPA

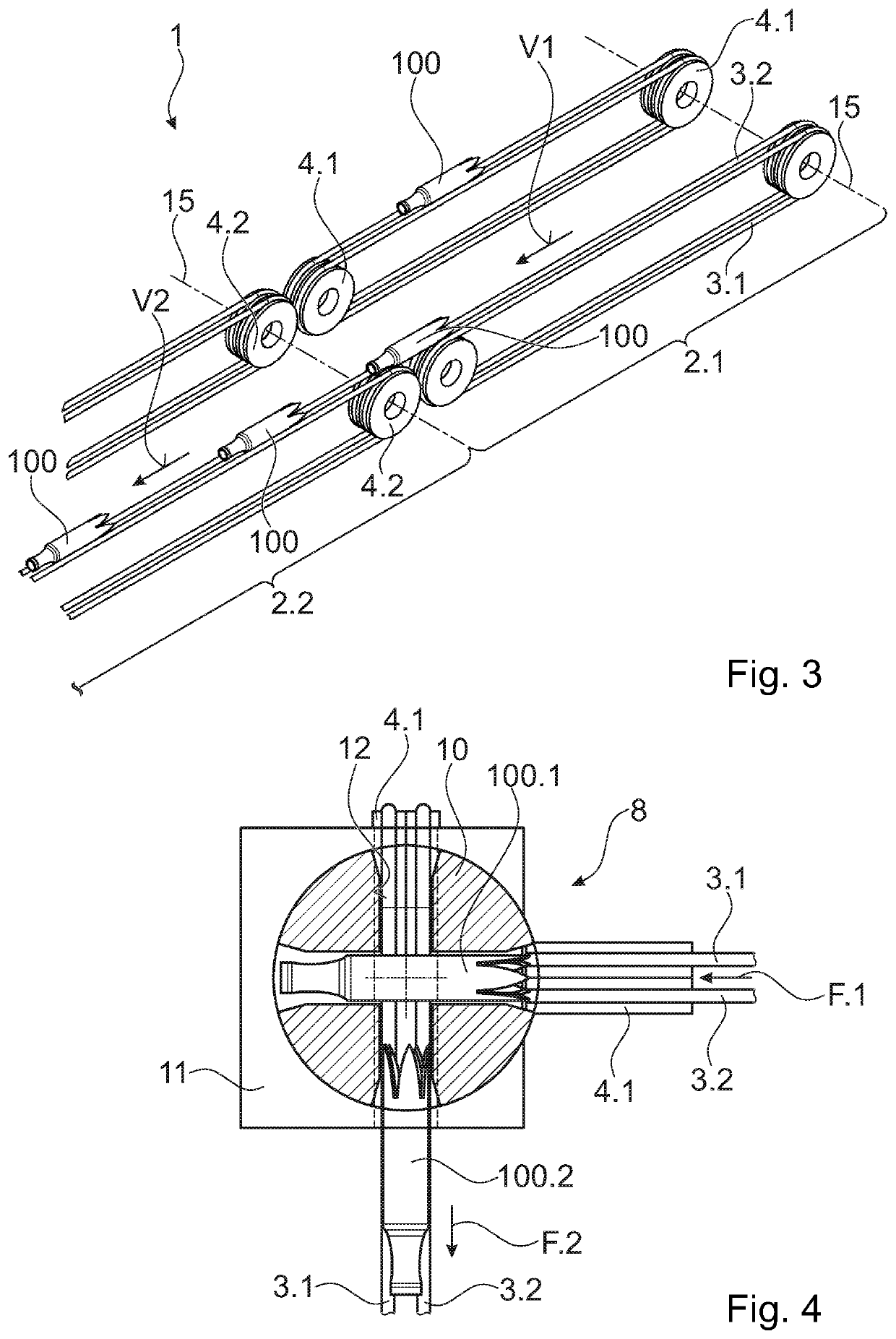

Method and apparatus for producing a multipack with several beverage containers

ActiveUS20200361645A1Reduce forceGentle handlingWrapping material feeding apparatusRigid containersMechanical engineeringFood science

Owner:KRONES AG

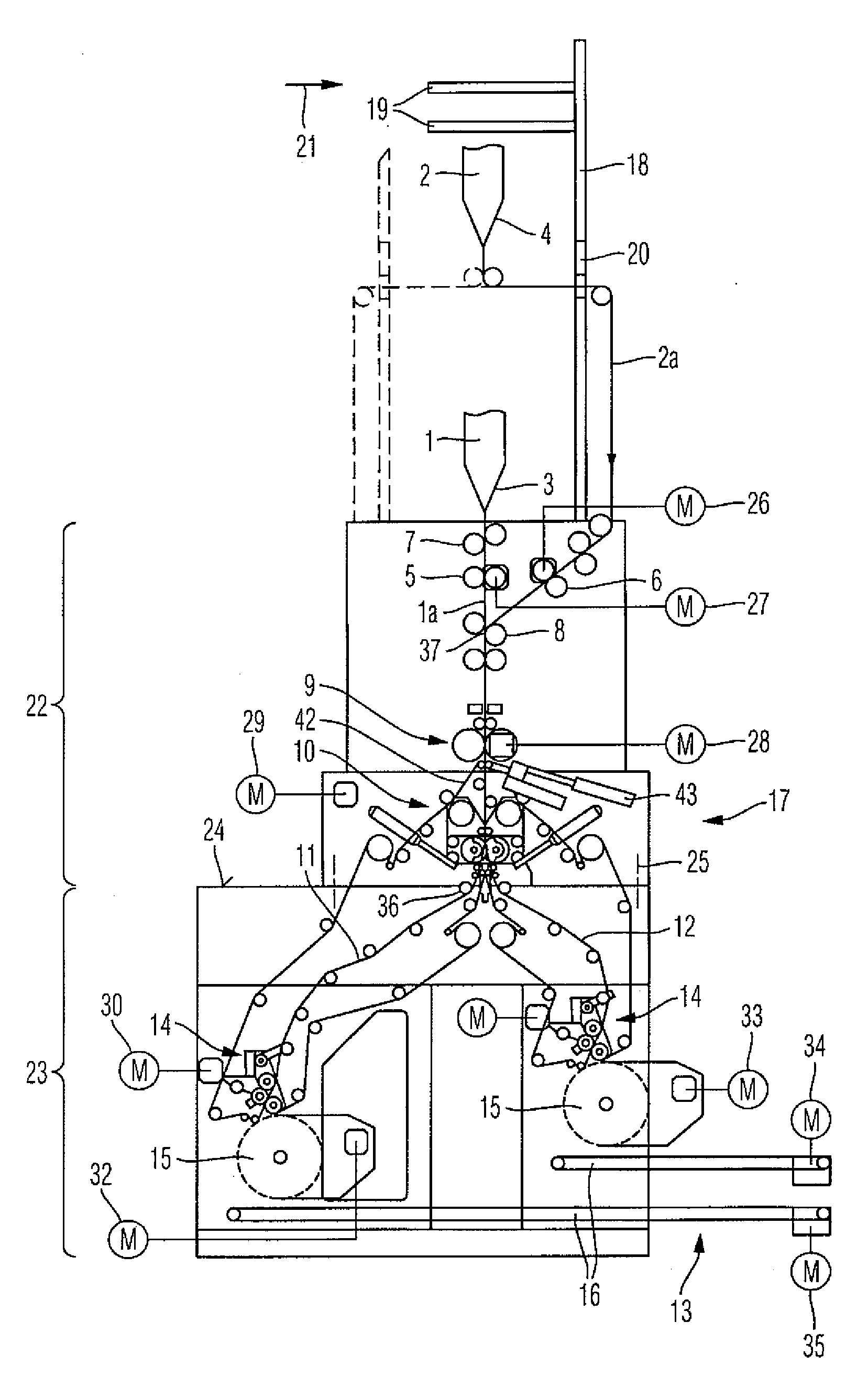

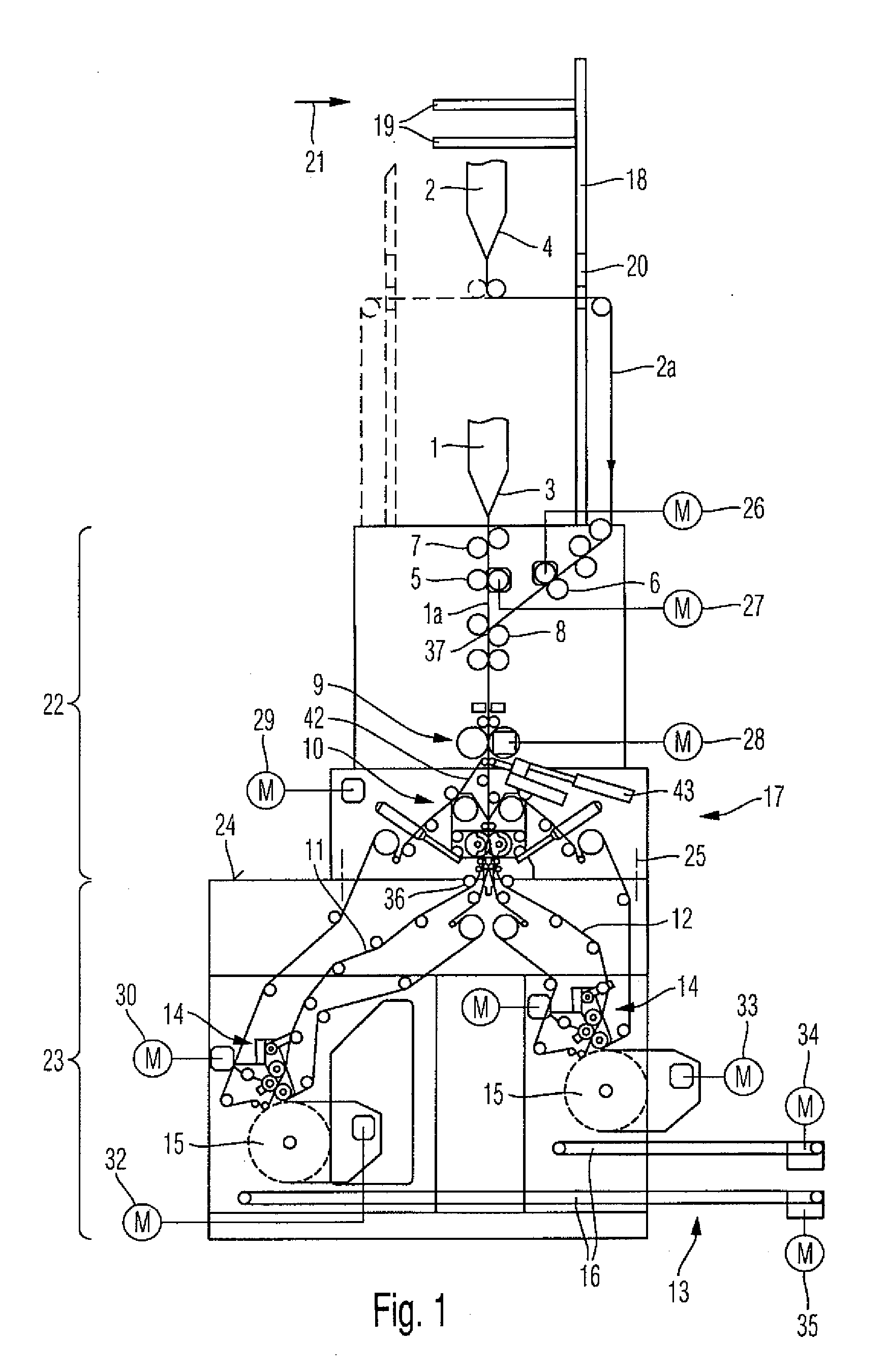

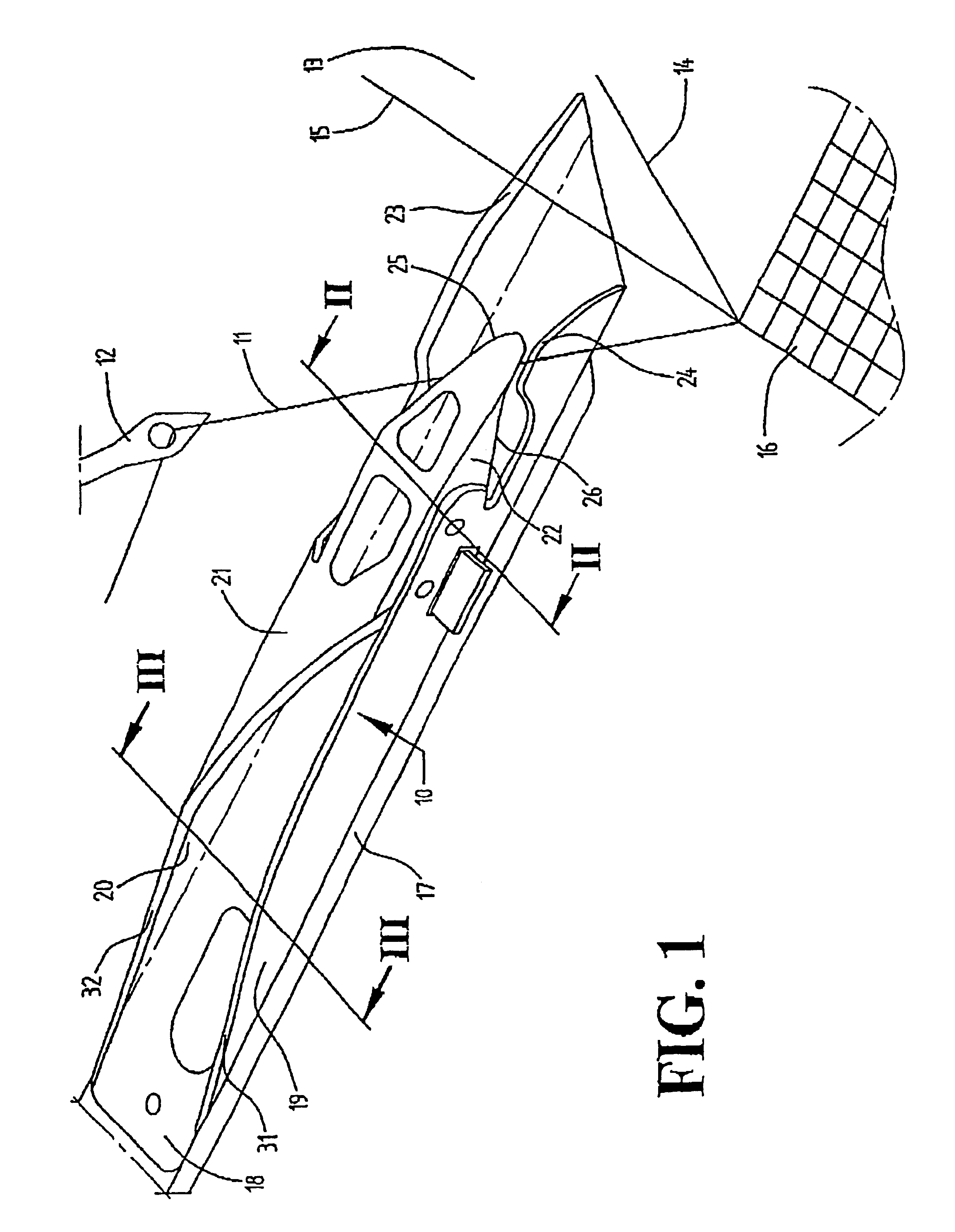

Apparatus For Producing Longitudinally Folded Products

InactiveUS20090305860A1Increase flexibilityGentle handlingEnvelopes/bags making machineryMechanical working/deformationDrive motorEngineering

An apparatus for producing longitudinally folded products has a machine frame (17) which is arranged below a former arrangement which can be charged with web material. Transporting and processing units are arranged in tandem in the machine frame (17), and a superstructure wall (18) which carries web guiding members (19) associated with the former arrangement is mounted on the machine frame (17). At least one web ribbon (2a) is guided through the superstructure wall (18). The machine frame (17) has at least two modules (22, 23) arranged one above the other which are rotatable by 180° relative to one another and can be connected to one another. Each module (22, 23) has its own at least one drive motor, and every unit provided in the region of the dividing line (24) between modules (22, 23) which are rotatable relative to one another is constructed symmetrically with respect to a center working plane containing the axis of rotation.

Owner:MANROLANAD AG

Method and device for handling bag chains

A method and device for handling a bag chain, wherein the bag chain is folded into layers to form a stack, and wherein the layers each include one or multiple bags of the bag chain. The bag chain is folded by at least one folding member which engages between the bags of the bag chain to fold the bag chain.

Owner:FOCKE & CO (GMBH & CO KG)

Extruder

Owner:约瑟夫·布拉赫

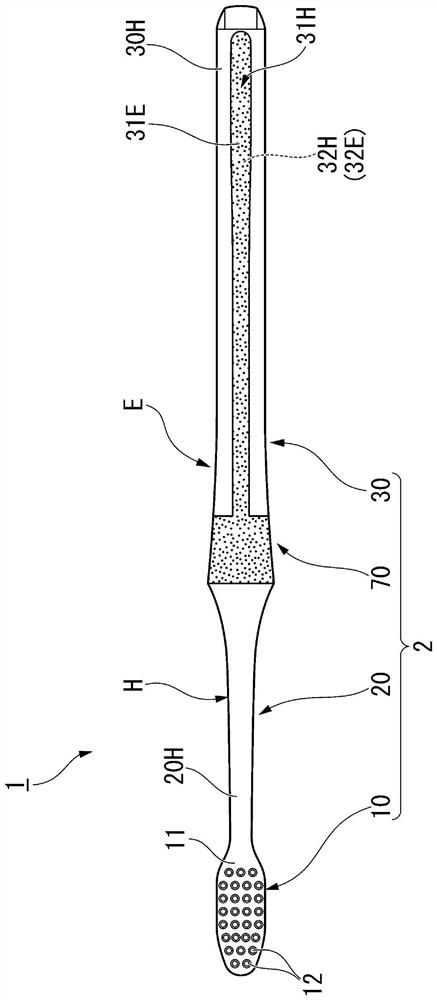

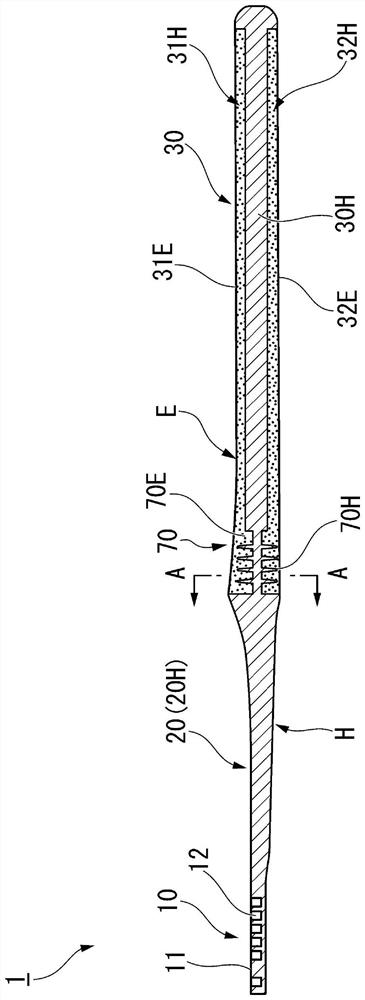

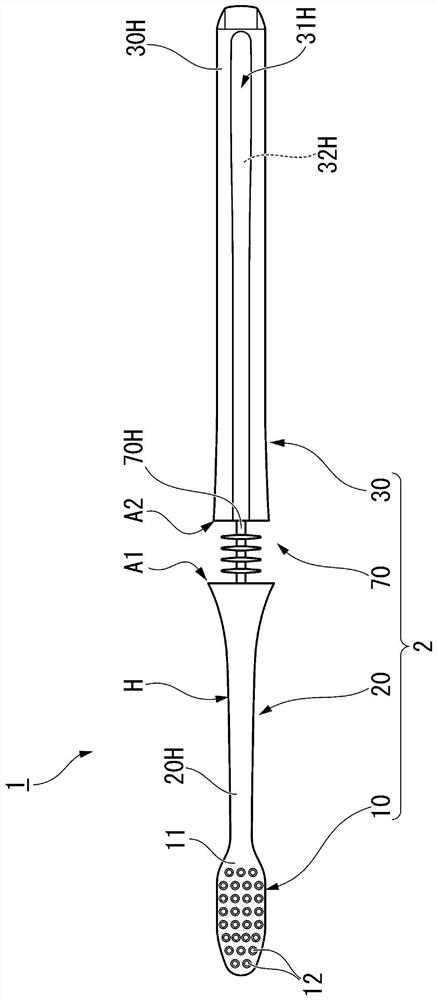

Toothbrush

The purpose of the present invention is to provide a toothbrush that is gentle on the teeth and gums and that gives useability with a pleasant sensation, while easily preventing overbrushing. This toothbrush comprises: a head part (10) that is provided at a distal end in a longitudinal direction and that has a bristle surface (11); a gripping part (30) disposed further toward a rear end than the head part; a neck part (20) disposed between the bristle surface and the gripping part; and a deformation part (70) that includes a hard section (70H), which is disposed further toward the rear end than the bristle surface and which is formed from a hard resin, and a soft section (70E), which is formed from a soft resin and which coats at least a portion of the hard section. The deformation part is deformed by an external force in a first direction which orthogonally intersects the bristle surface and is compressed as a result of the hard section sandwiching the soft section in the longitudinal direction.

Owner:LION CORP

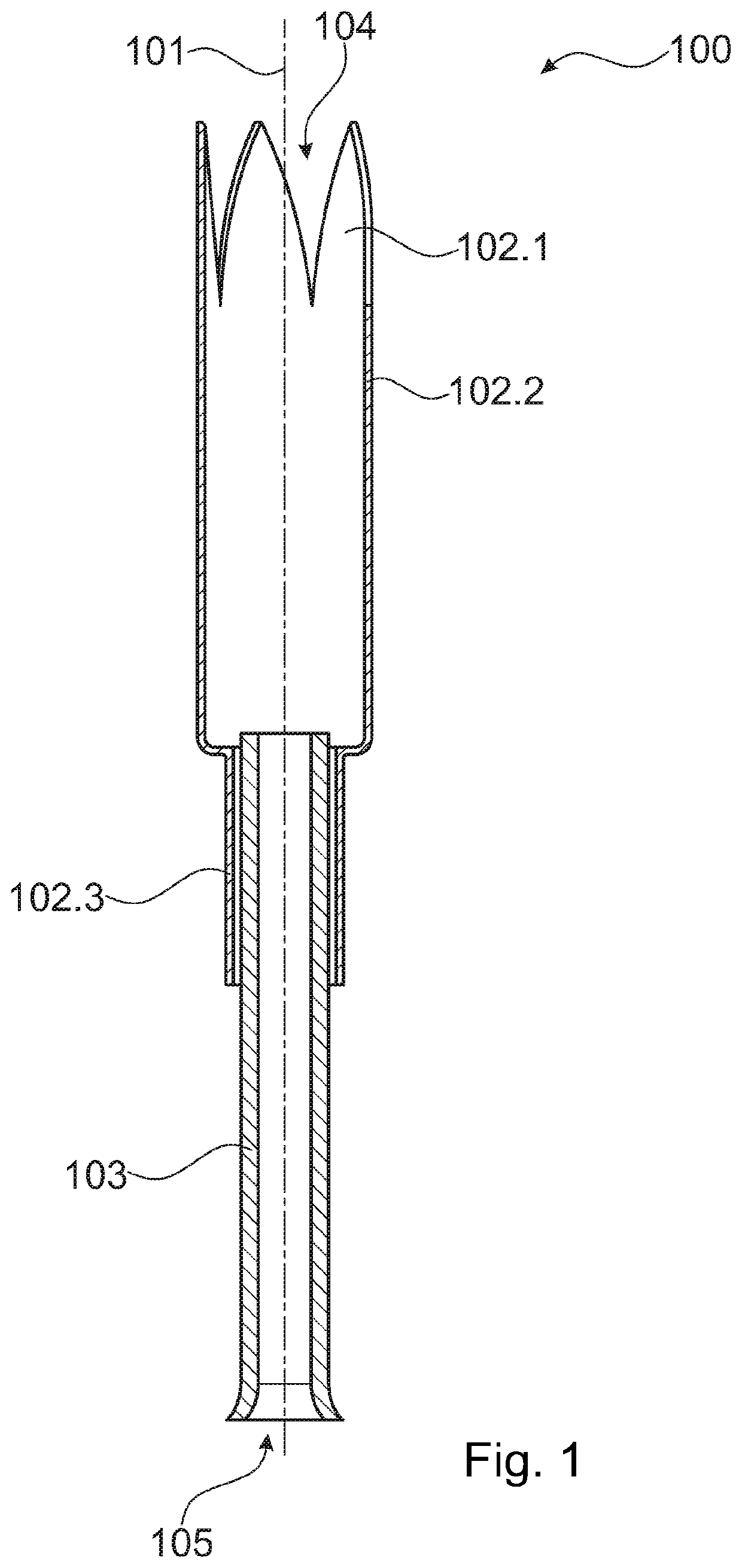

Gripper, in particular pneumatically actuated gripper in the form of a suction gripper or gripper jaws

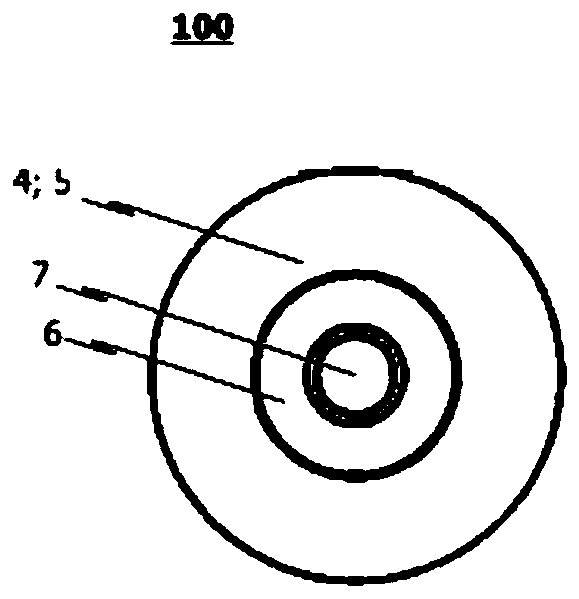

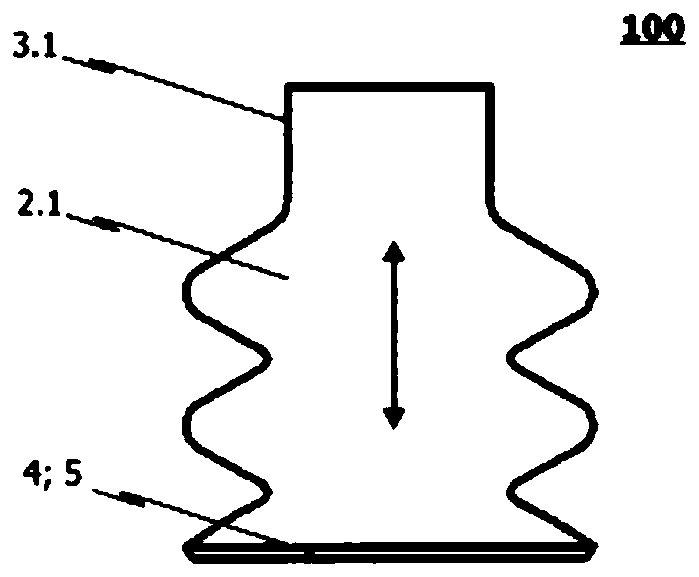

The present invention relates to a gripper (100) and in particular a pneumatically operated gripper (100) in the form of a vacuum gripper or gripping tongs. The gripper (100) comprises a gripper holder (3.1, 3.2) via which the gripper (100) is preferably detachably connectable to a manipulator, robotic arm or the like. The gripper (100) further comprises at least one gripping member (2.1, 2.2) connected to the gripper holder (3.1, 3.2) and realized such that an object to be gripped or workpiece can be gripped by manipulating the at least one gripping member (2.1, 2.2). In order to achieve thegripper (100) being able to gently grip an object to be gripped, whereby both the object to be gripped as well as the at least one gripping member of the gripper are effectively protected against damage while the object to be gripped is being manipulated, the invention provides for the at least one gripping member (2.1, 2.2) to have a flocking (5) at least in the area which comes into contact withthe object to be gripped / workpiece during the manipulating of the at least one gripping member (2.1, 2.2).

Owner:FIPA控股有限(责任)公司

Household intelligent ironing robot

InactiveCN114672977AGentle handlingNot easy to damageIroning apparatusTextiles and paperHome useControl system

The invention discloses a household intelligent ironing robot, relates to the technical field of clothes ironing, and aims to solve the problems that a large amount of traditional clothes ironing products depend on manual operation, the ironing function effect of nursing machine products is weak, and the daily ironing flatness requirement cannot be met. The steam ironing module is connected with the up-down driving mechanism and used for providing close-range targeted steam to soften and iron the clothes; the air blowing and sucking module is used for being matched with the ironing process and controlling the inflatable clothes hanger to blow and suck air; the main control system is connected with the steam ironing module and the air blowing and sucking module respectively, judges the type of ironed clothes according to different input signals, controls the air blowing and sucking module and the steam ironing module to carry out corresponding ironing processes, simulates manual ironing elements in a mode of mutual cooperation of software and hardware, achieves the effect close to manual ironing, liberates manpower, and is small in whole machine structure and convenient to operate. The device is small in space limitation, very suitable for household use and easy to popularize.

Owner:杭州优地工业设计有限公司

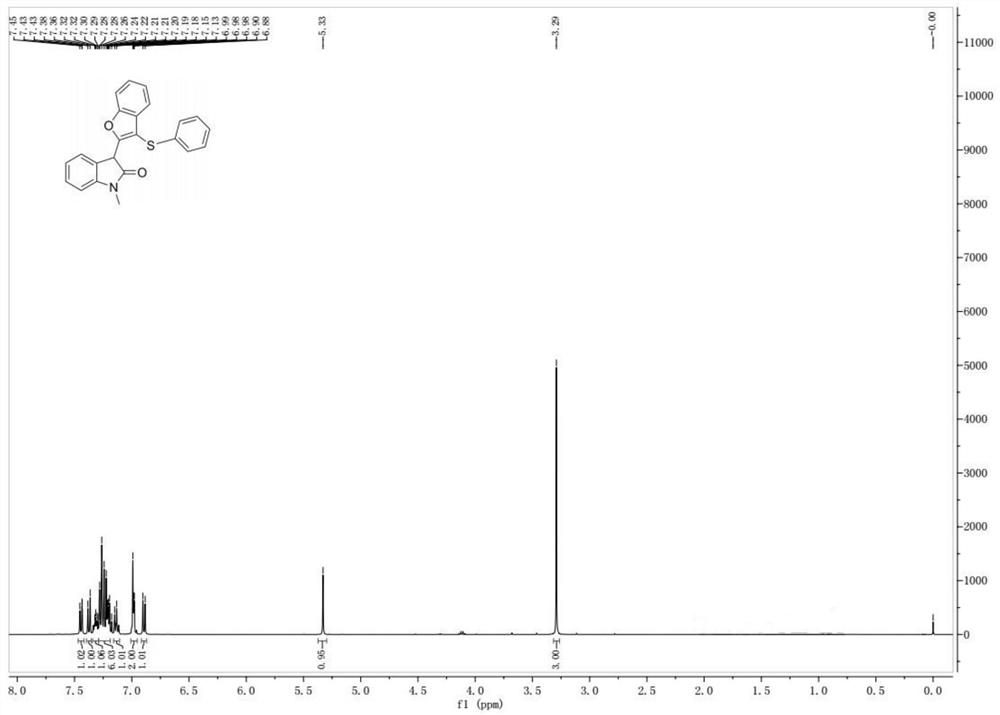

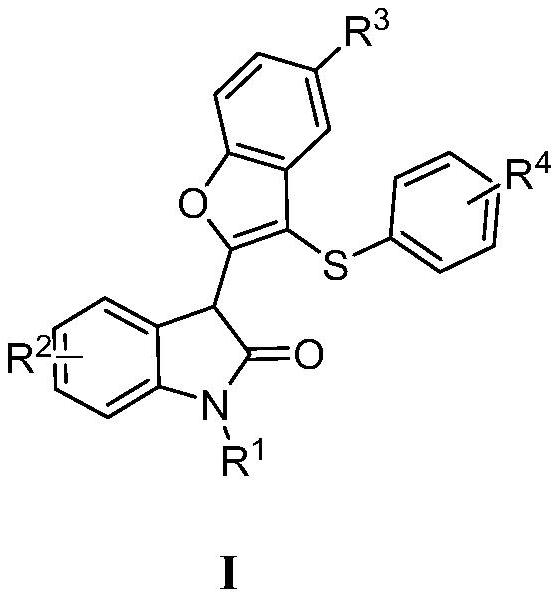

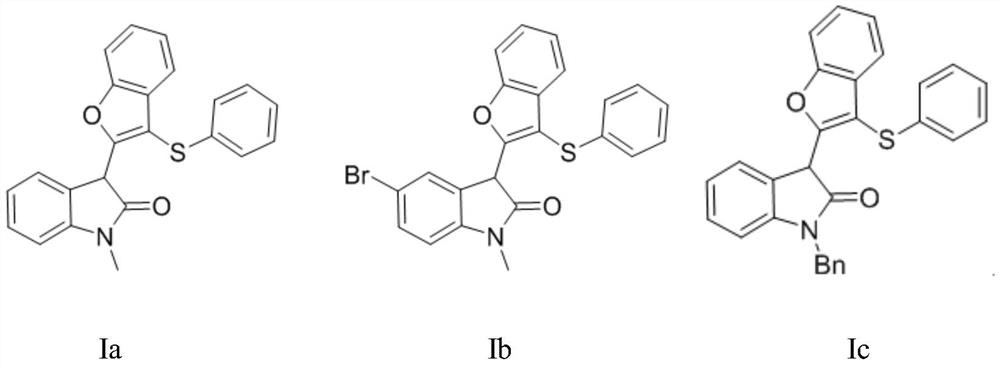

3-thiobenzofuran derivative and synthesis method thereof

The invention provides a 3-thiobenzofuran derivative and a synthesis method thereof. The preparation method comprises the steps of carrying out Meyer-Schuster rearrangement / nucleophilic addition / intramolecular cyclization reaction on an isatin-derived propargyl alcohol compound and thiophenol in an organic solvent under the action of an acidic reagent to obtain the 3-thiobenzofuran derivative. The raw materials are cheap and easy to obtain, the steps are simple, the reaction conditions are easy to realize, the 3-sulfo and 2-substituted benzofuran derivative can be prepared by a one-pot method, the yield of the target product is high, and the product has very good functional group diversity and is beneficial to subsequent application.

Owner:QILU UNIV OF TECH

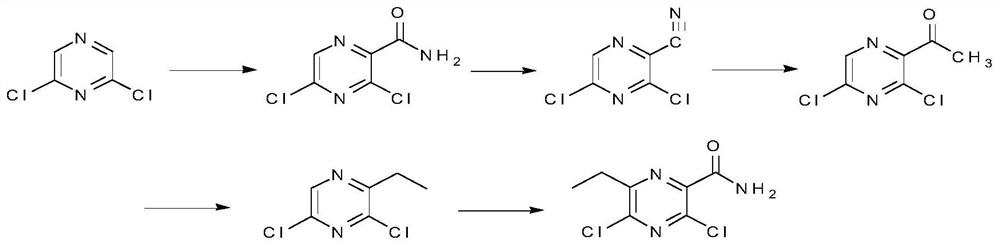

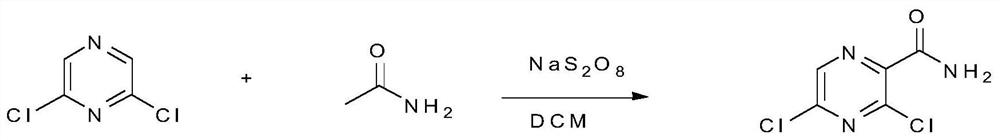

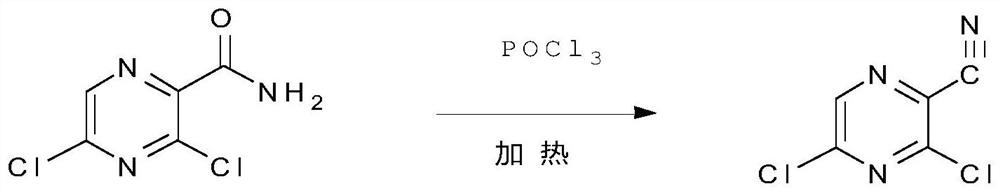

Synthesis method of 3,5-dichloro-6-ethylpyrazineformamide

The invention discloses a synthetic method of 3,5-dichloro-6-ethylpyrazine formamide, and relates to the technical field of intermediate for synthesizing gilteritinib. The method is technically characterized by comprising the following steps: heating 2,6-dichloropyrazine and formamide to 70-130 DEG C, and carrying out free radical oxidation reaction under the action of persulfate to obtain 3,5-dichloropyrazine formamide; carrying out heating reflux on 3,5-dichloropyrazine formamide for 3-6 h under the action of a dehydrating agent, and synthesizing 3,5-dichloropyrazine formonitrile through dehydration; carrying out a Grignard reactionon the 3,5-dichloropyrazine formonitrile in an organic solvent A under the action of a methylation reagent to prepare 3,5-dichloro-2-acetylpyrazine; under theaction of an acidic catalyst and a silicon-hydrogen reducing agent, reducing the 3,5-dichloro-2-acetyl pyrazine in an organic solvent B to obtain 3,5-dichloro-2-ethyl pyrazine; and heating the 3,5-dichloro-2-ethyl pyrazine and formamide to 50-120 DEG C, and carrying out free radical oxidation reaction under the action of persulfate to obtain the 3,5-dichloro-6-ethylpyrazine formamide. According to the invention, the operation method is simple, the reaction conditions of the synthesis process are mild, the cost is reduced, and meanwhile high economic benefits can be brought.

Owner:上海鑫凯化学科技有限公司

Method and apparatus for producing a multipack with several beverage containers

ActiveUS11390405B2Gentle handlingConstant speedWrapping material feeding apparatusRigid containersBiologyMechanical engineering

Owner:KRONES AG

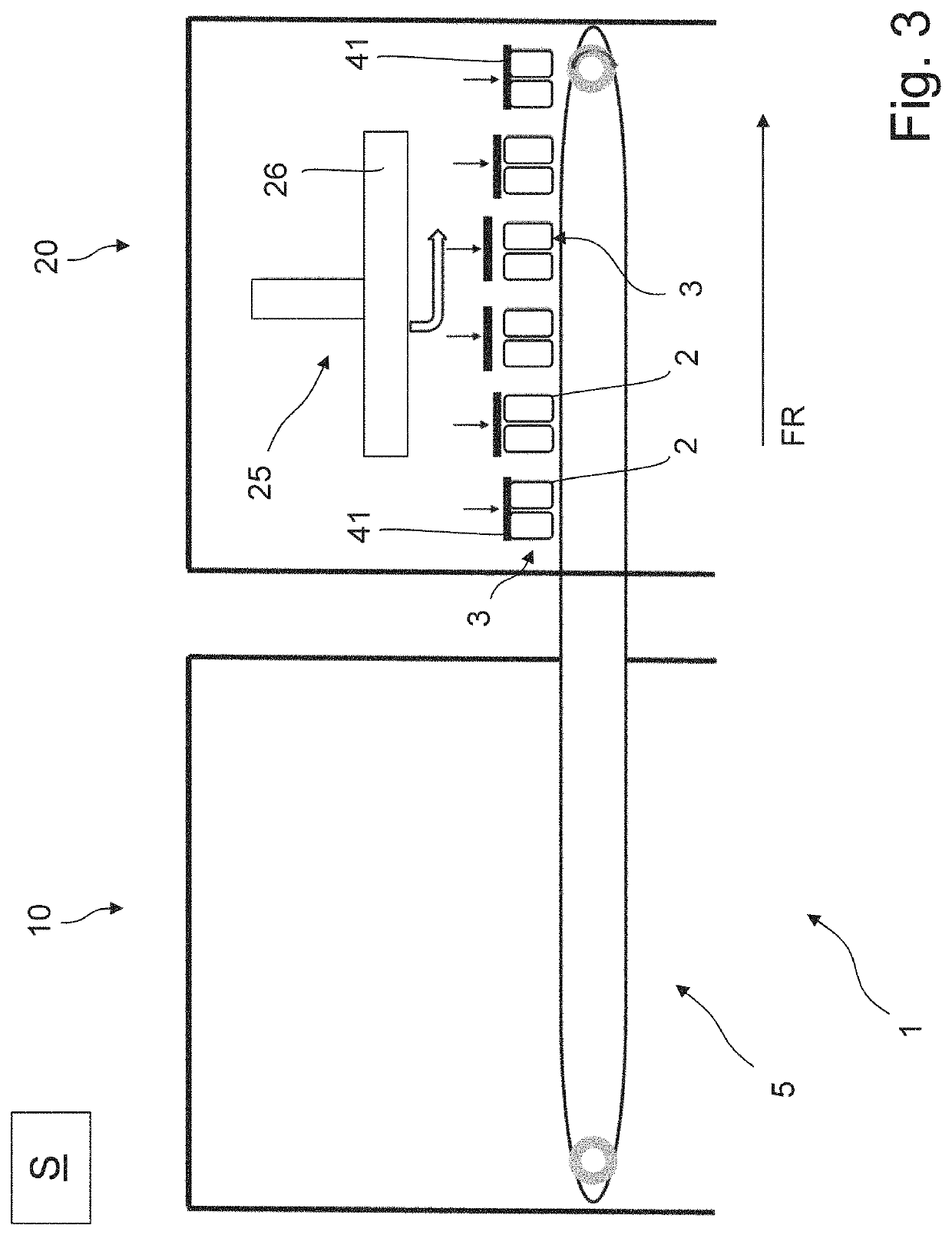

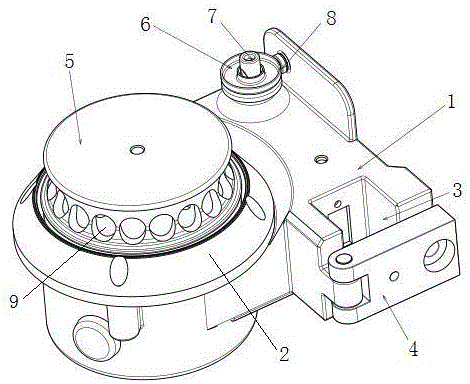

Glass fiber zero-degree tensioner

ActiveCN105862213AGentle handlingNo wearWarping machinesOther manufacturing equipments/toolsGlass fiberEngineering

The invention relates to the technical field of warping machines, in particular to a glass fiber zero-degree tensioner. The glass fiber zero-degree tensioner comprises an installation base, the two adjacent sides of the installation base are provided with an installation groove and a fixing cavity respectively, a motor is arranged in the installation groove, the motor is provided with a rotating wheel, holes are circumferentially distributed on the rotating wheel, and one side of the fixing cavity is provided with a fixing block; the installation base is provided with a yarn pressing sheet and a yarn poteye, one side of the yarn pressing sheet is provided with a lead-in poteye, the rotating wheel is made of aluminum, and the surface of the rotating wheel is plated with hard chrome. The glass fiber zero-degree tensioner can softly treat yarn, the rotating wheel does not damage any filament yarn and cannot generate any abrasion, and the generated yarn tension can enable the speed to always keep consistent compared with an ordinary eddy current brake.

Owner:KARL MAYER CHINA

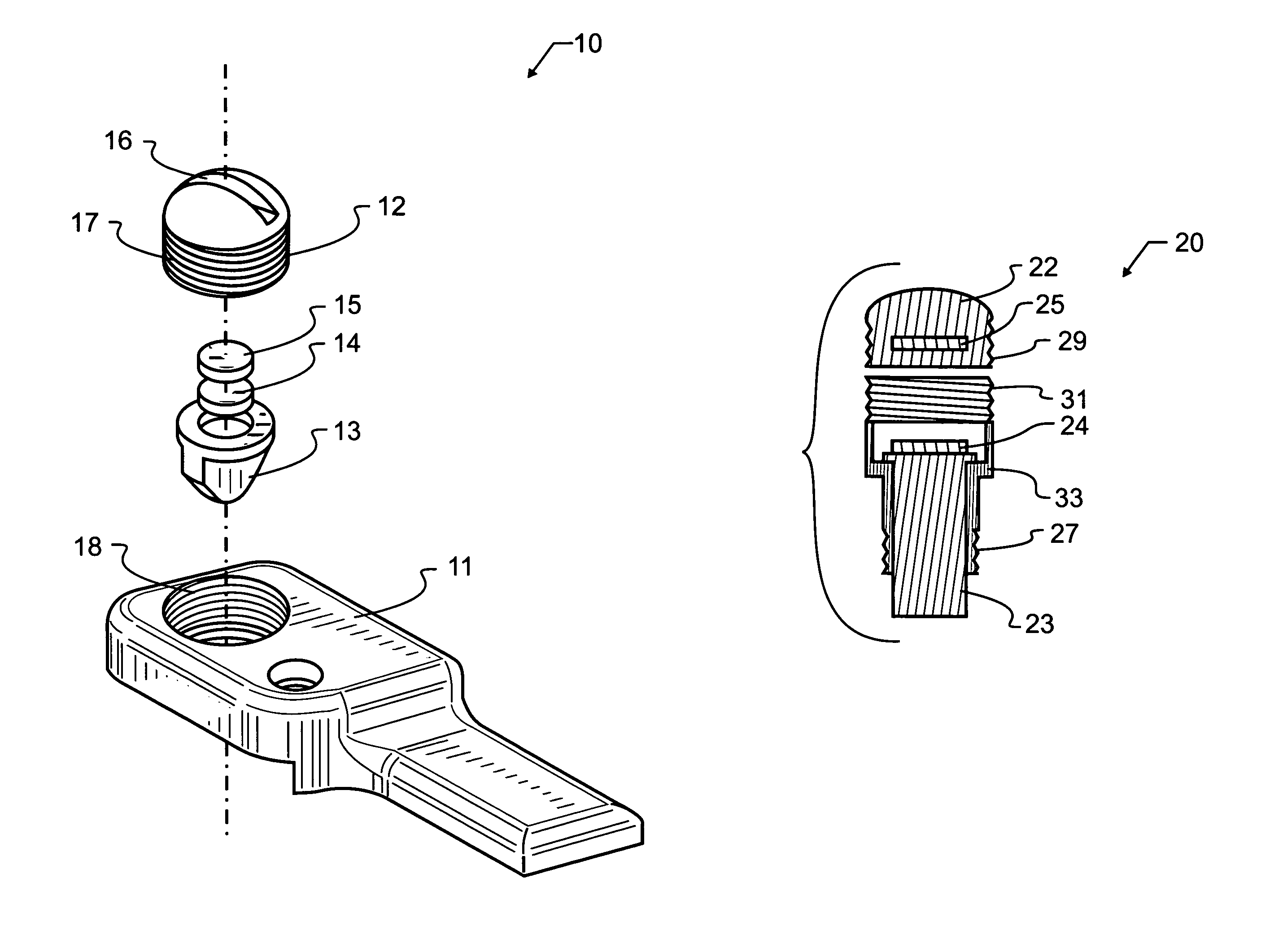

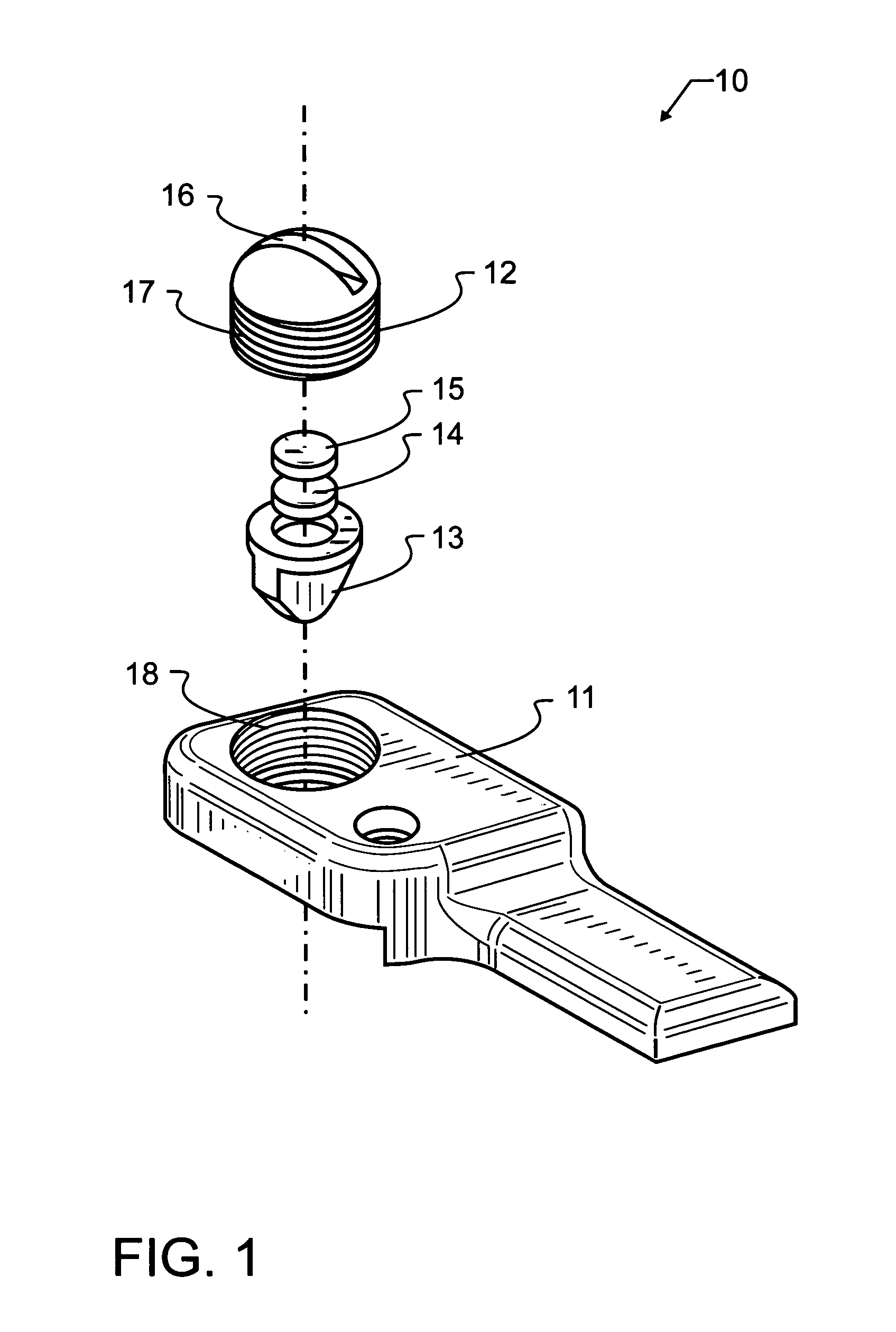

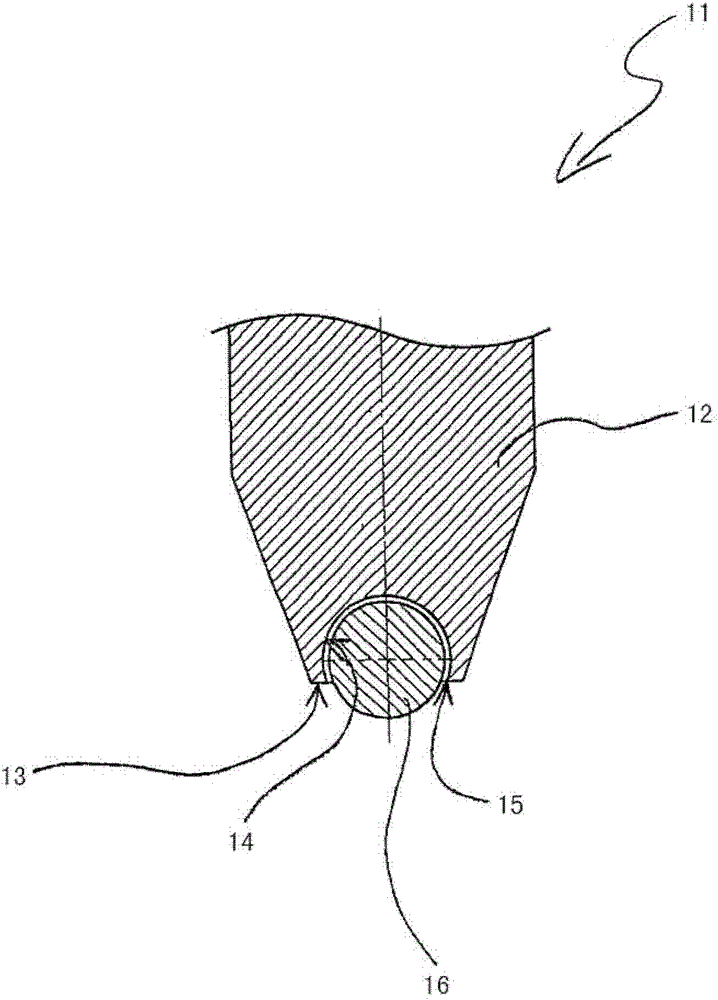

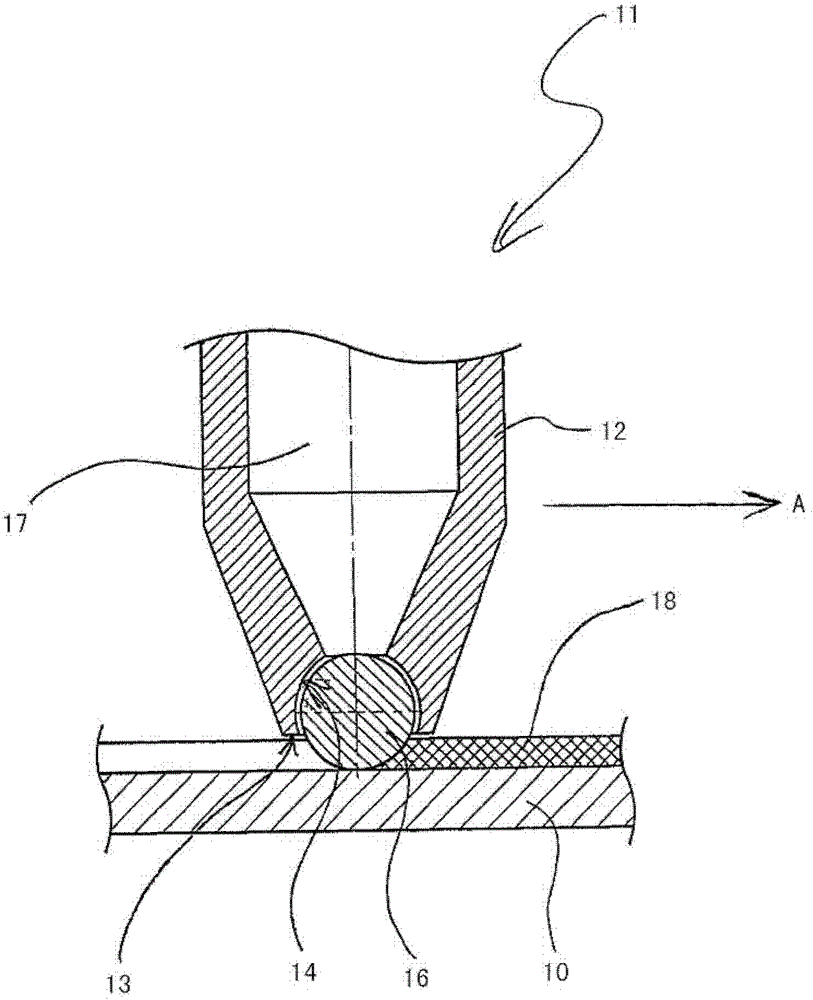

Tool for sheet metal working machine and method for cutting film

The tool (11) has a rotatably supported ball (16) designed such that a film (18) is separated from a metal sheet (10) by rolling movement of the ball. A ball retaining device (12) has a retaining area (14) at an end that is turned towards the sheet metal, where diameter of the ball is less than 1 mm. The retaining device has a hollow cavity (17) for accommodating lubricant for reducing friction coefficients between a surface of the ball and an inner surface of the retaining area. The hollow cavity is connected with the retaining area, where the ball is made from ceramics. An independent claim is also included for a method for separating a film from sheet metal.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

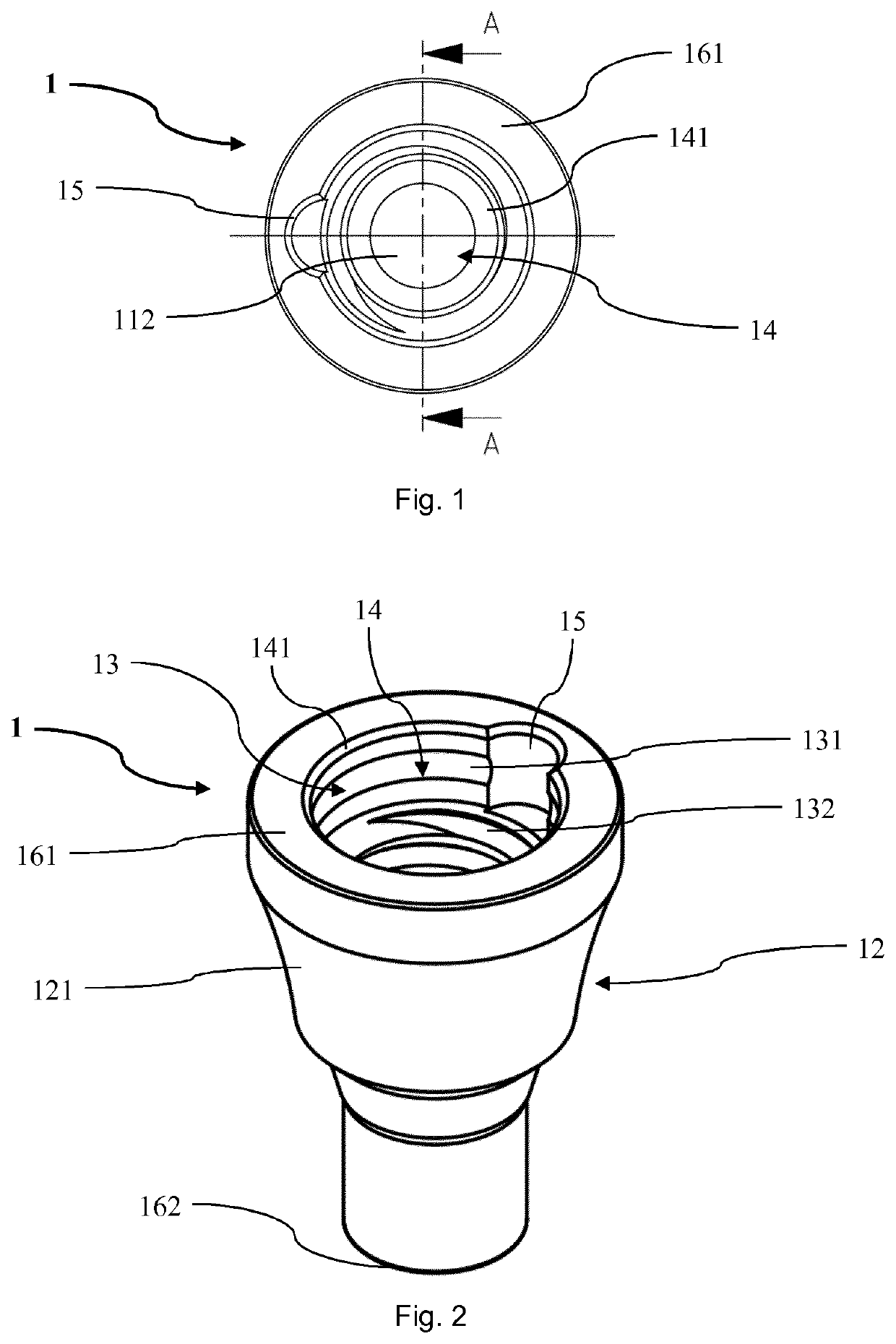

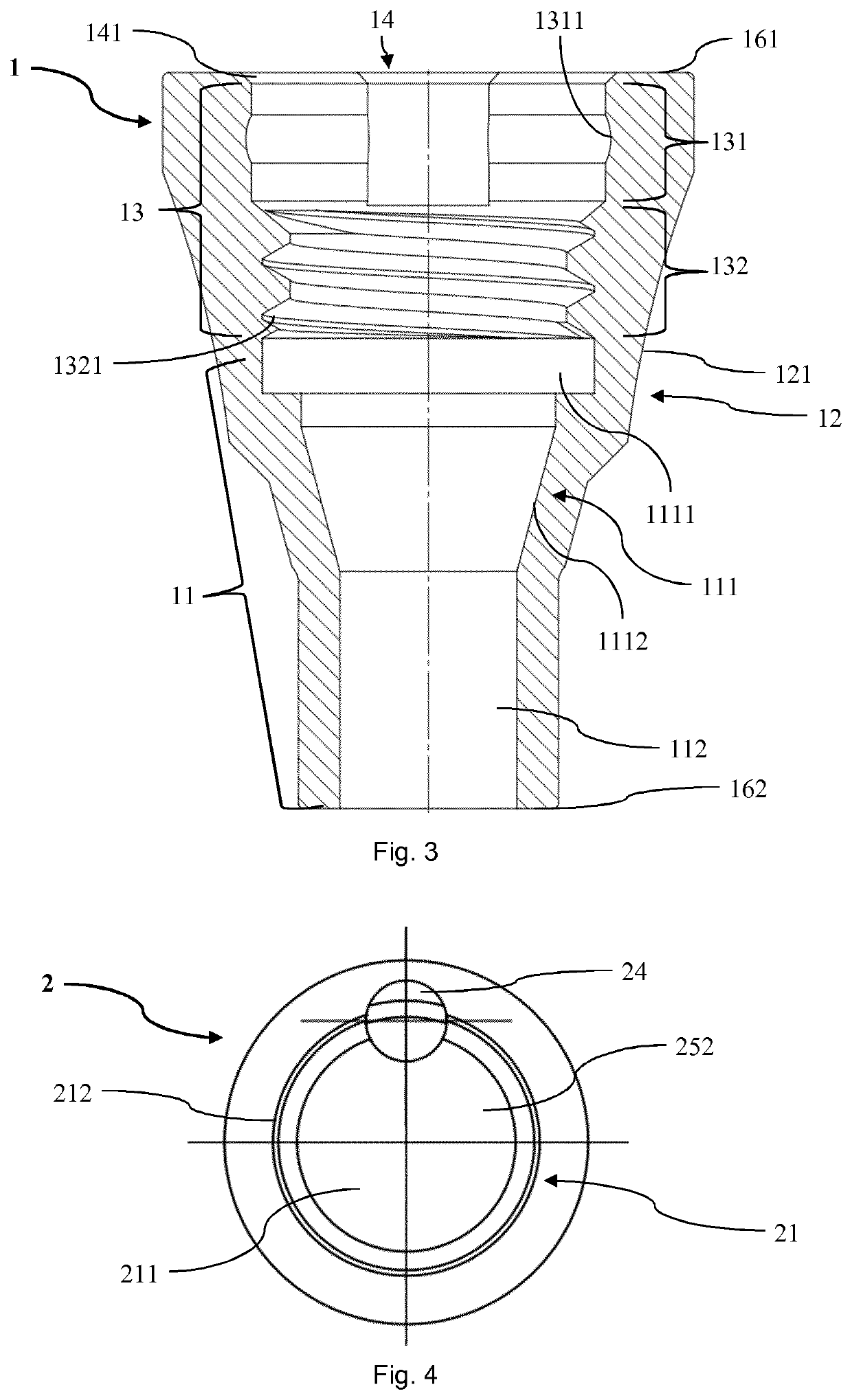

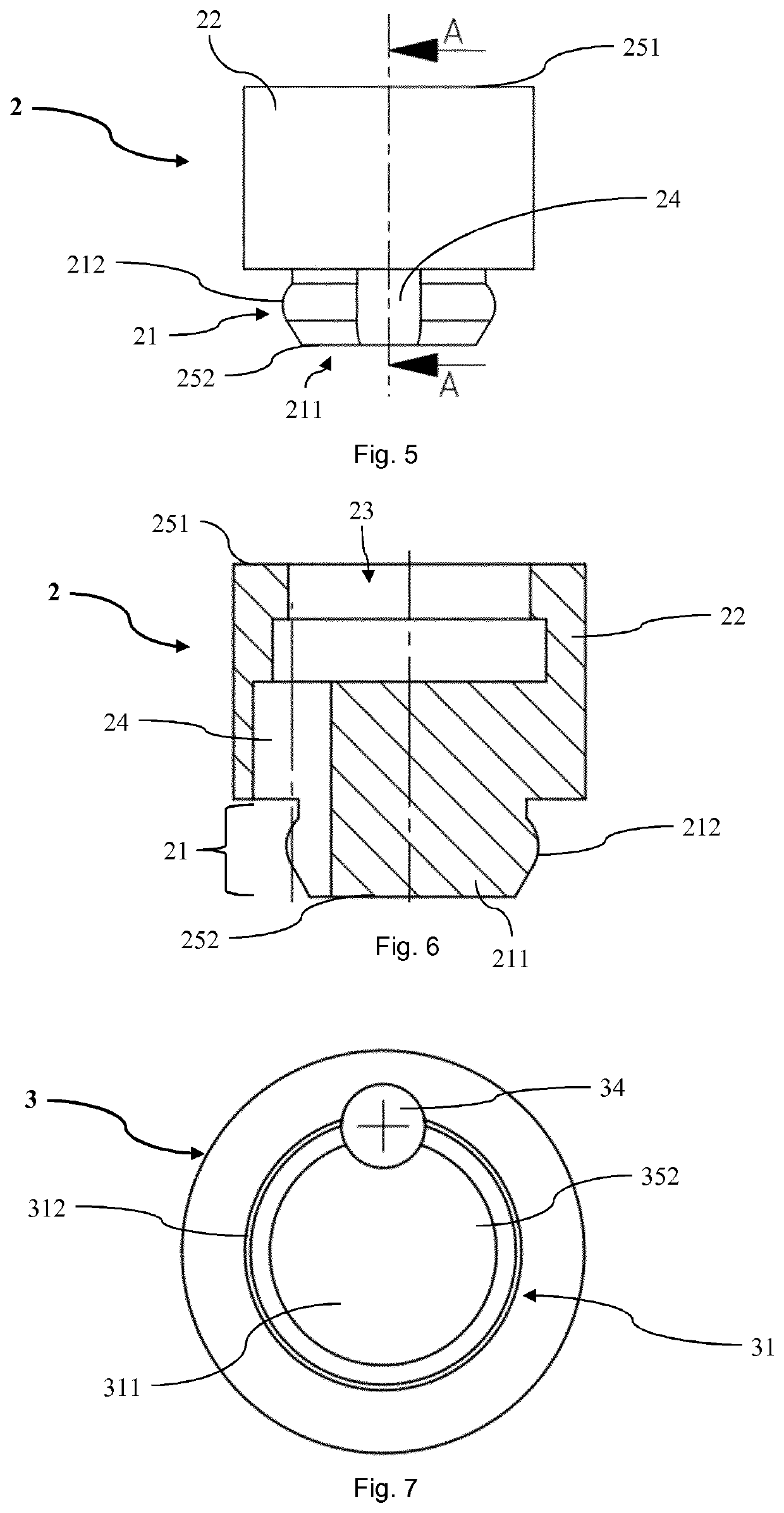

Gingiva former, bite support and dental healing system

PendingUS20210220095A1Efficient settingsGentle handlingDental implantsFastening prosthesisJaw boneDentistry

A gingiva former (1) comprises an implant fixing structure (11) configured to fix the gingiva former (1) to an implant construction fixed to a jaw of a patient, and an emergence profile portion (12) configured to be positioned within a gingiva of the patient when the gingiva former (1) is mounted to the implant construction. It further comprises a mounting structure (13) configured to connect an intermediate element to the gingiva former (1) such that the intermediate element extends towards an oral cavity of the patient when the gingiva former (1) is mounted to the implant construction. The mounting structure (13) has a clipping geometry (131) configured to snap-fit with a corresponding clipping structure of the intermediate element to temporarily mount the intermediate element to the gingiva former (1).

Owner:INSTITUT STRAUMANN AG

Method for coating bulk material

ActiveUS11123762B2Simple and effective regulationGentle handlingLiquid surface applicatorsGas treatmentContinuous flowCoating

A method for coating bulk material uses a coating apparatus to produce a continuous flow of coated material having a predetermined stationary coating weight gain. Coating material is sprayed on the bulk material in two phases within respective first and second rotatable tubular containers of the coating apparatus. In the first rotatable container, the bulk material is partially coated with a pre-set weight gain. In the second rotatable container, the bulk material is sprayed with a coating material to obtain a bulk material coated with the predetermined stational coating weight gain. A transition phase is provided between the two spray periods during which a load of coated bulk material from the first container is transferred at a transfer flow rate to the second container while a new load of bulk material is fed to the first container at the same flow rate as the transfer flow rate.

Owner:IMA IND MASCH AUTOMATICHE SPA

Glass fiber zero tensioner

ActiveCN105862213BGentle handlingNo wearWarping machinesOther manufacturing equipments/toolsGlass fiberEngineering

The invention relates to the technical field of warping machines, in particular to a glass fiber zero-degree tensioner. The glass fiber zero-degree tensioner comprises an installation base, the two adjacent sides of the installation base are provided with an installation groove and a fixing cavity respectively, a motor is arranged in the installation groove, the motor is provided with a rotating wheel, holes are circumferentially distributed on the rotating wheel, and one side of the fixing cavity is provided with a fixing block; the installation base is provided with a yarn pressing sheet and a yarn poteye, one side of the yarn pressing sheet is provided with a lead-in poteye, the rotating wheel is made of aluminum, and the surface of the rotating wheel is plated with hard chrome. The glass fiber zero-degree tensioner can softly treat yarn, the rotating wheel does not damage any filament yarn and cannot generate any abrasion, and the generated yarn tension can enable the speed to always keep consistent compared with an ordinary eddy current brake.

Owner:KARL MAYER CHINA

Method for operating a spindle of a two-for-one twisting or cabling machine and associated two-for-one twisting or cabling machine

InactiveUS10011924B2Good power balanceReduce the overall diameterPiercing arrangementsContinuous wound-up machinesEngineeringYarn tension

A method for operating a spindle (2) of a two-for-one twisting or cabling machine, in which an outer yarn (5) is drawn off a first feed package (7) and the spindle (2) rotates in a yarn balloon (B), wherein the spindle (2) comprises a device (6) for influencing the balloon yarn tension of an outer yarn (5), which is connected to a control circuit (18), and has a spindle pot (19) for receiving a second feed package (15), a yarn deflection device (20), a balancing system (9) for forming a twisting or cabling point as well as a spooling and winding device (12). The drive of the yarn balloon (B) is performed via a fixed throw-off point (21) on the yarn deflection device (20).

Owner:SAURER TECH GMBH & CO KG

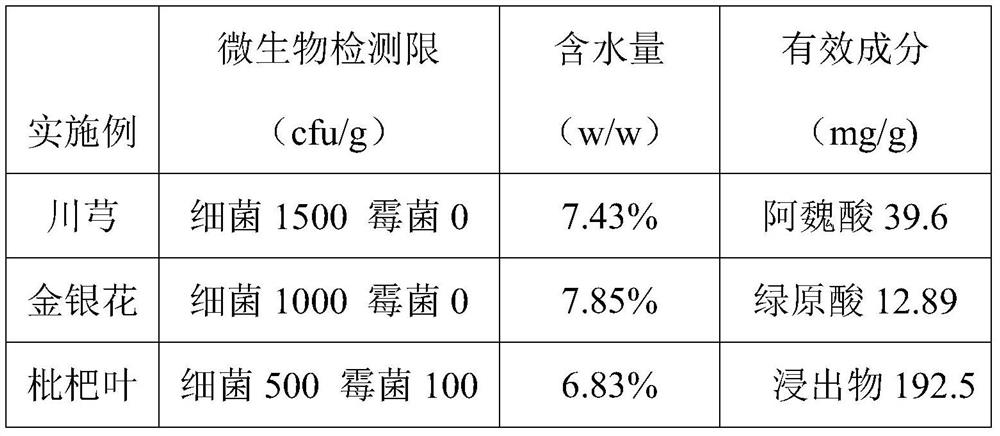

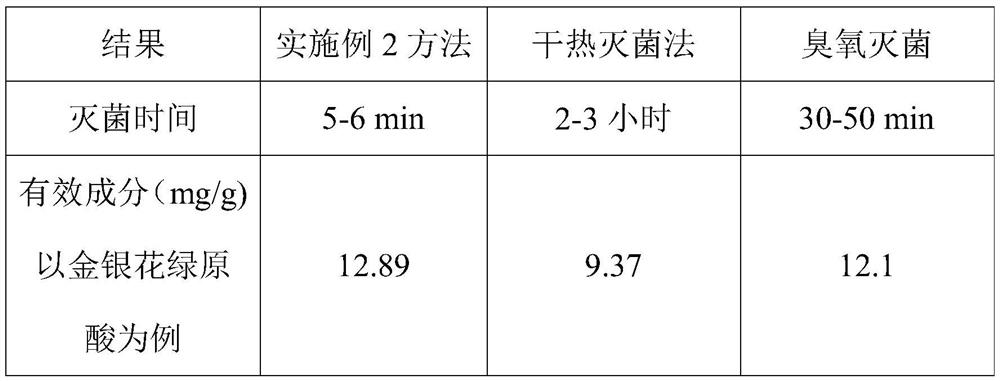

Traditional Chinese medicine decoction piece drying and sterilizing integrated device and method

InactiveCN112683042AAchieve serializationImprove stabilityDrying solid materials with heatHeatMicrowaveProcess engineering

The invention relates to a traditional Chinese medicine decoction piece drying and sterilizing integrated device and method. The device comprises a drying device, a sterilizing device and a detecting device. The drying device comprises a microwave generator; the sterilizing device comprises a radio frequency generator and a hot air device; Low-frequency microwaves are selected for drying treatment, so that the advantages of high penetrability, easiness in power regulation, good drying uniformity and the like are achieved, energy conservation and emission reduction can be better realized, and the drying time is shortened; the loss of effective components in the drying process of the traditional Chinese medicine decoction pieces can be reduced; and a radio frequency-hot air combined sterilization mode is selected, so that the applicability is wide, the stability is good, and large-batch materials are easy to treat.

Owner:ANHUI CHINA RESOURCES JINCHAN PHARMA CO LTD

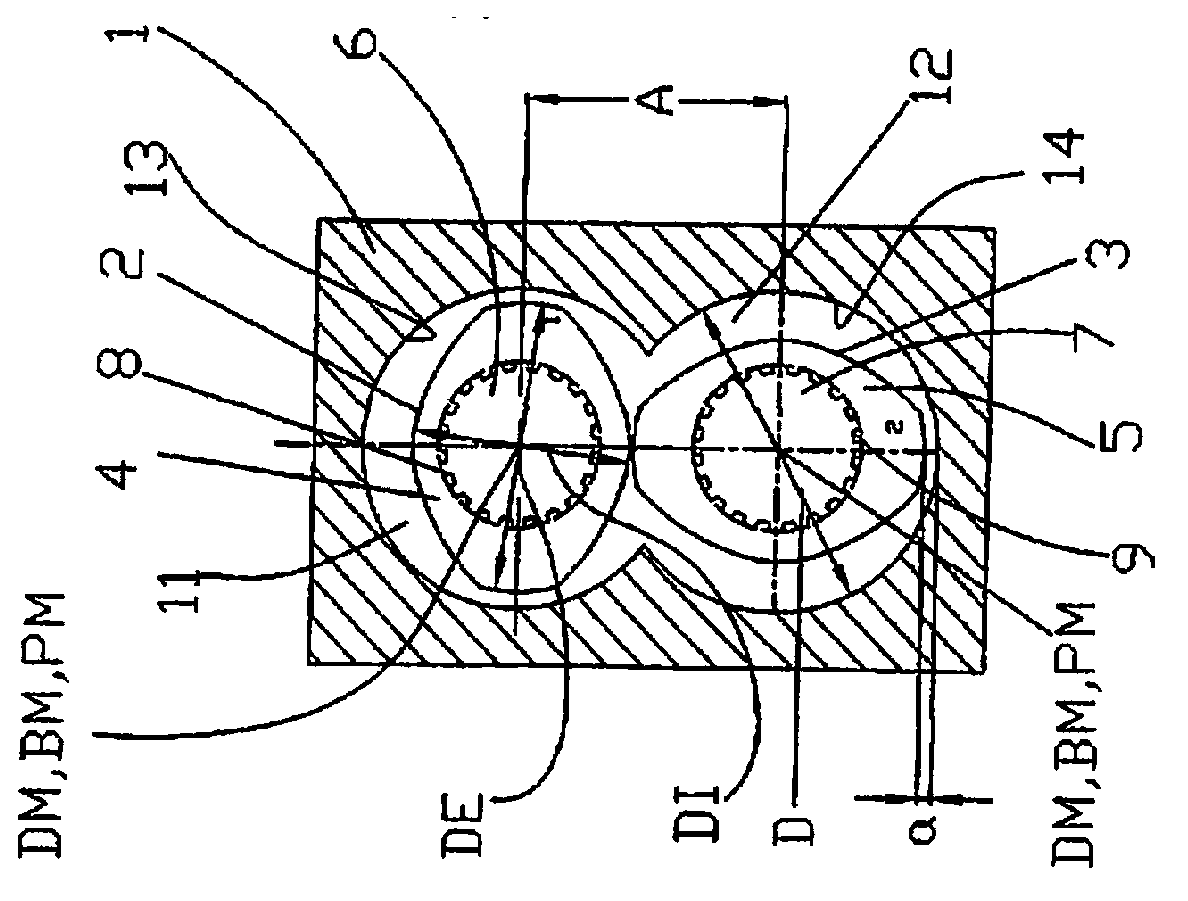

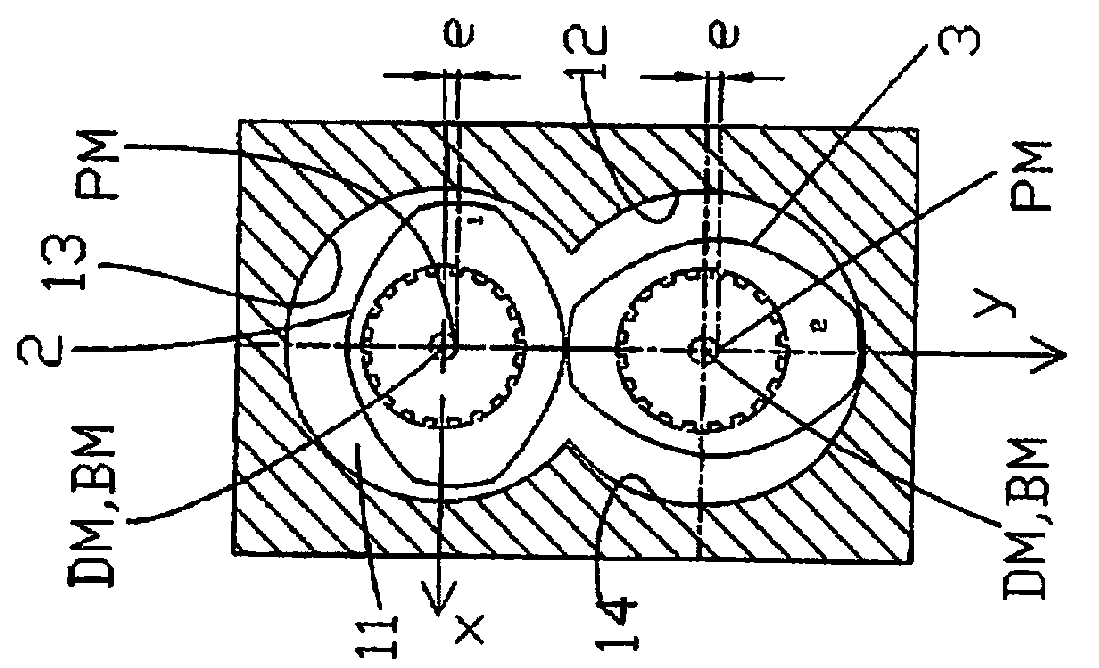

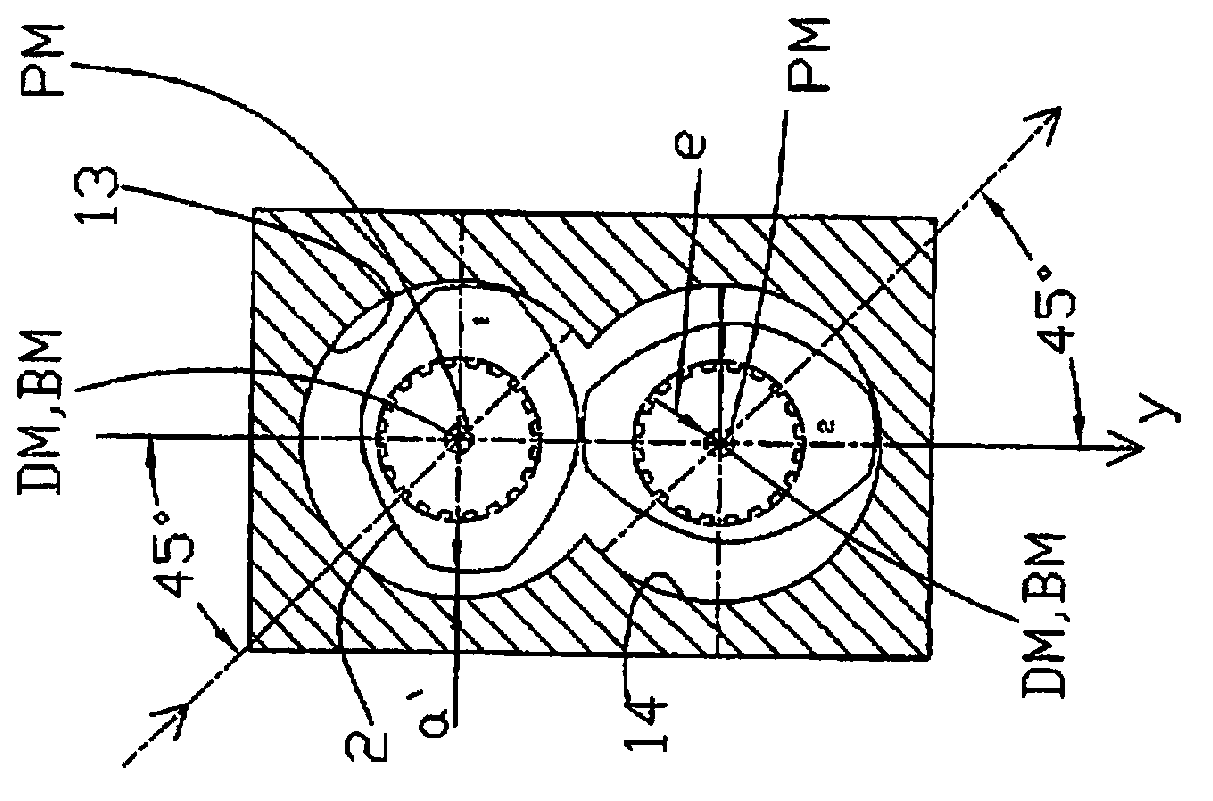

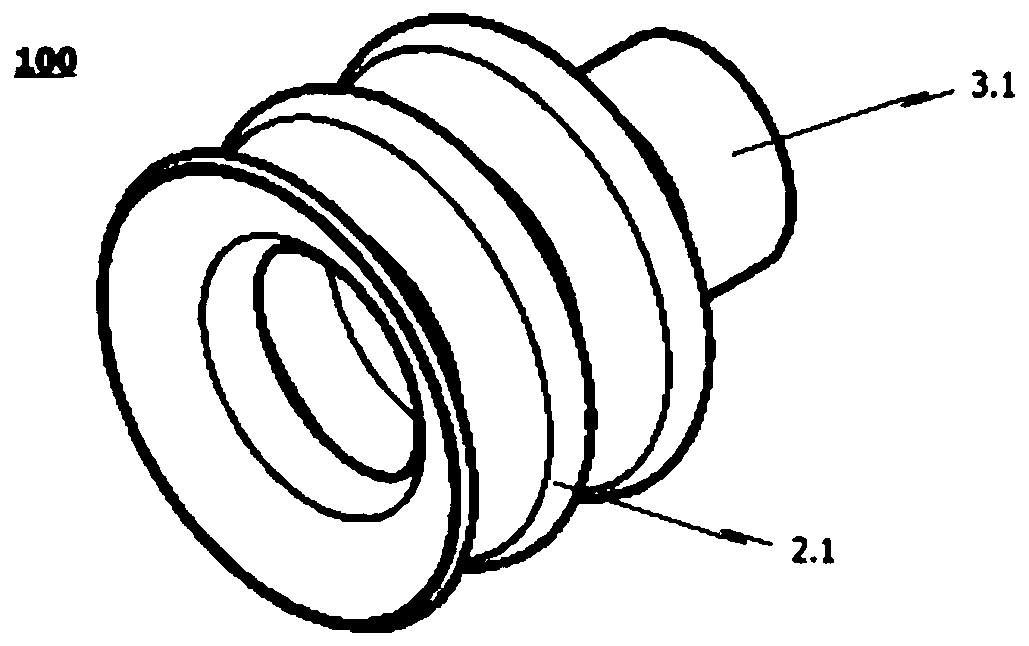

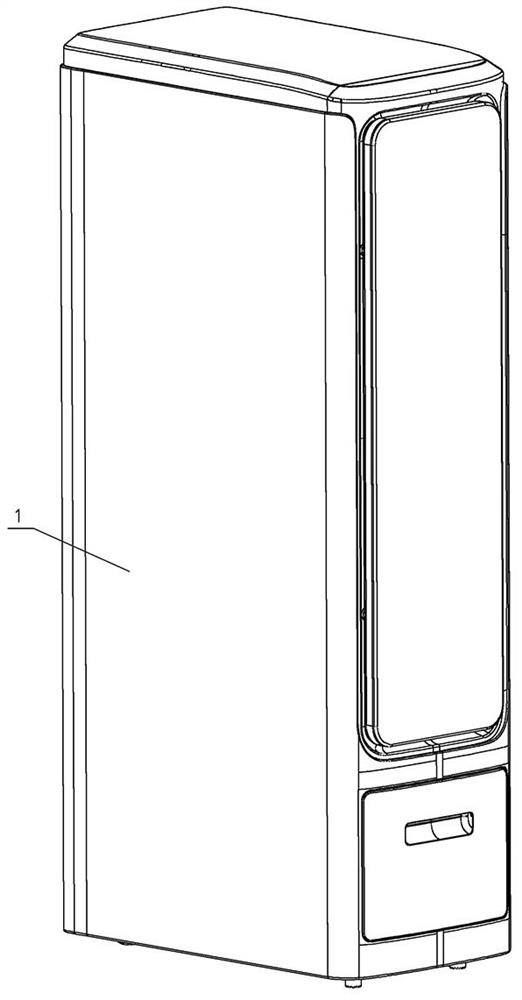

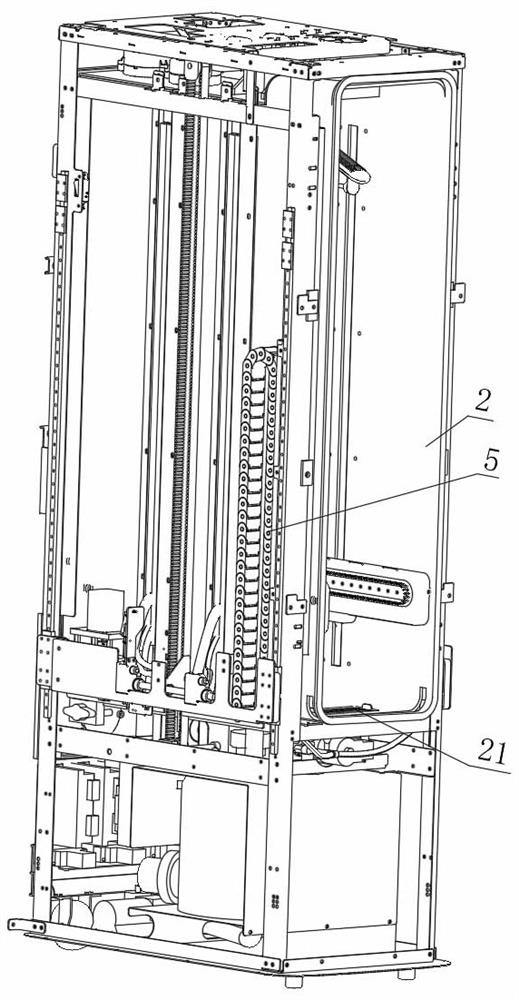

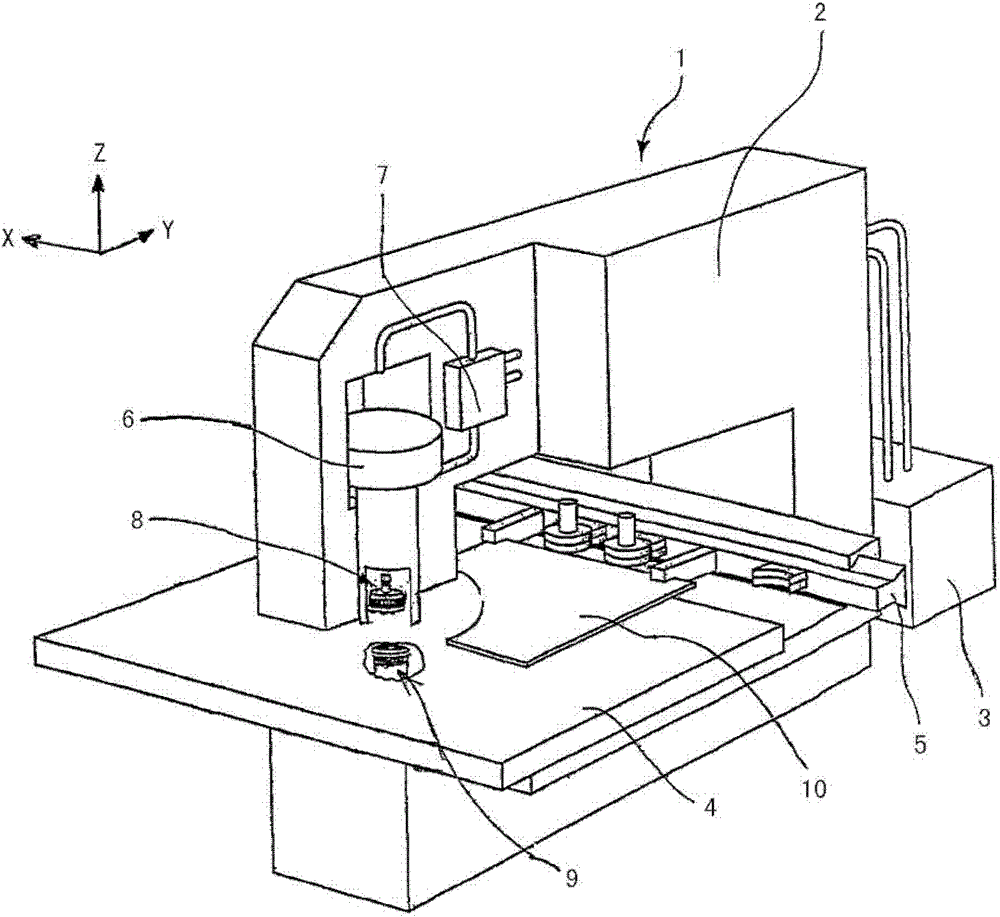

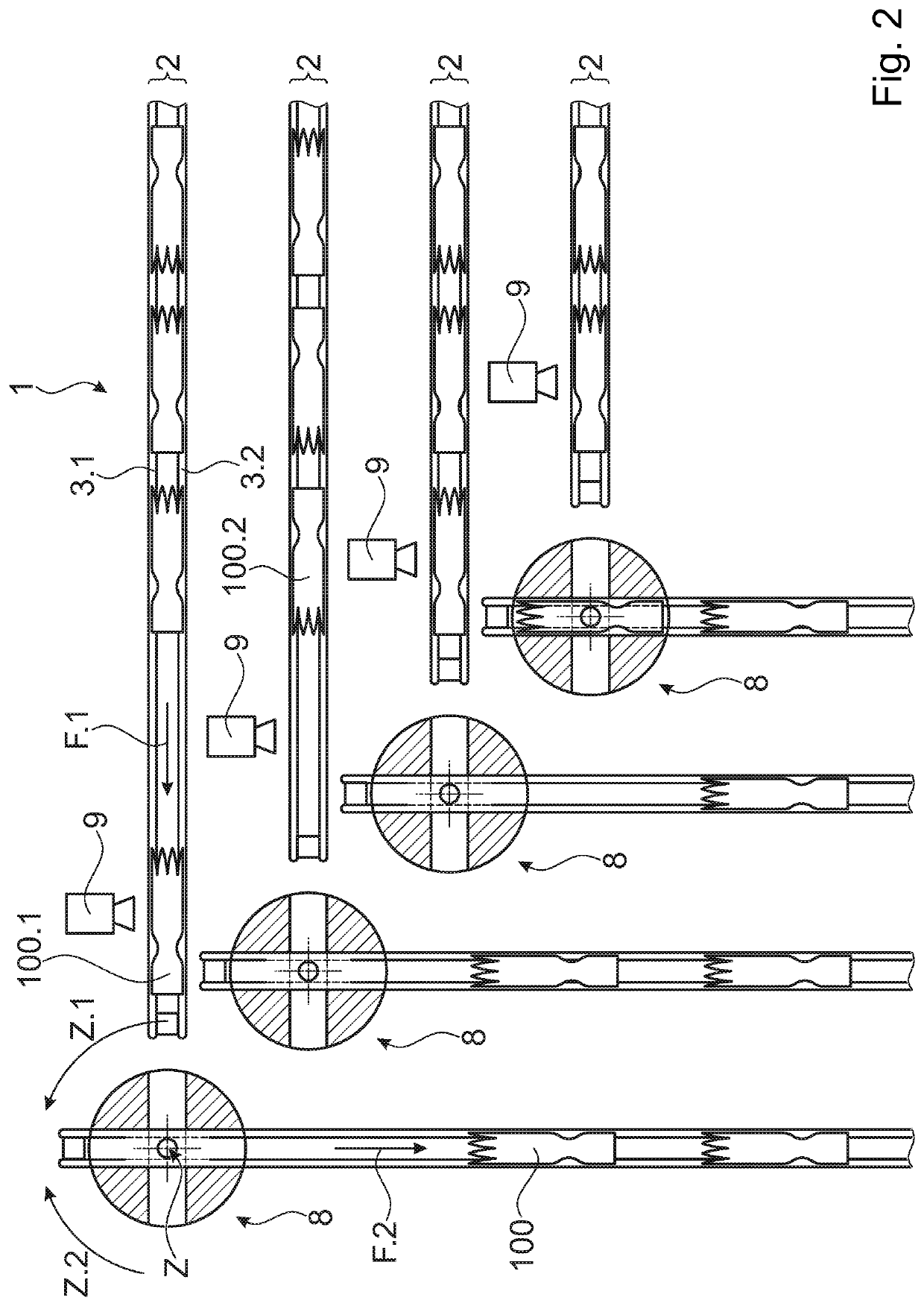

Conveying apparatus and method of conveying tampon applicators

ActiveUS20210292102A1Gentle handlingOvercome disadvantagesConveyorsCharge manipulationStructural engineeringTampon

The present invention relates to a conveying apparatus for tampon applicators 100, having a first conveyor track 2, which comprises two transport belts 3.1, 3.2 which are arranged spaced apart from each other. The transport belts each have a bearing axis L1, L2. The conveying apparatus according to the invention furthermore has a first conveyor drive 4 for driving at least one of the two spaced-apart transport belts 3.1, 3.2, and transport belts which are arranged spaced apart from each other in such a manner that a tampon applicator 100 which is to be conveyed rests on the two transport belts in an intermediate space D between the transport belts. The bearing axes L1, L2 of the transport belts 3.1, 3.2 are arranged parallel; in particular in the case of transport belts having the same conveying direction F. The present invention furthermore relates to a method of conveying tampon applicators.

Owner:RUGGLI PROJECTS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com