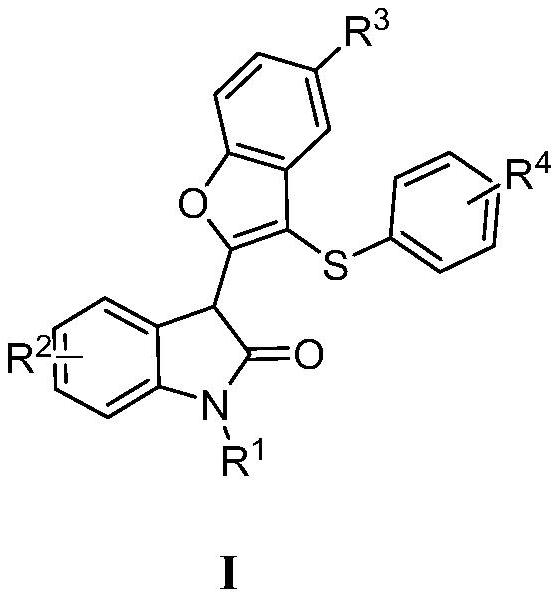

3-thiobenzofuran derivative and synthesis method thereof

A technology of benzofuran and synthesis method, applied in the field of 3-thiobenzofuran derivatives and synthesis thereof, achieves the effects of simple preparation method and operation, good functional group diversity, and improved molar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of synthetic method of 3-thiobenzofuran derivatives, comprising steps:

[0039]

[0040] For the synthesis method of 3-hydroxy-3-((2-hydroxyphenyl)ethynyl)-1-methylindol-2-one (IIa), please refer to the literature "Org. Biomol. Chem., 2018, 16, 6133" .

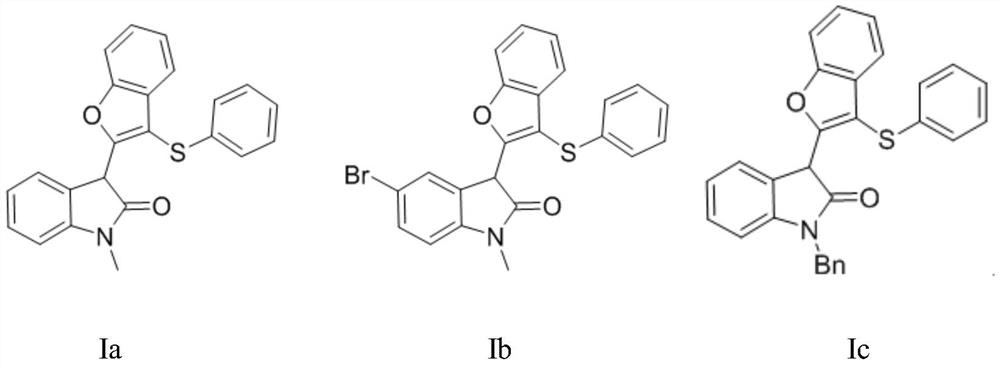

[0041]The preparation steps of compound Ia are: add compound IIa (27.9mg, 0.1mmol) in 10mL round bottom flask, methylene chloride 2ml, thiophenol IIIa (13.2mg, 0.12mmol), add boron trifluoride diethyl ether ( 17mg, 0.12mmol), reacted at 25°C for 12 hours under the protection of nitrogen. Separation by silica gel column chromatography (eluent: petroleum ether (60-90° C.) / ethyl acetate=8:1, V:V) gave light yellow solid Ia (32.3 mg, molar yield 87%) with a purity greater than 95%. The target product was confirmed by NMR and high-resolution mass spectrometry.

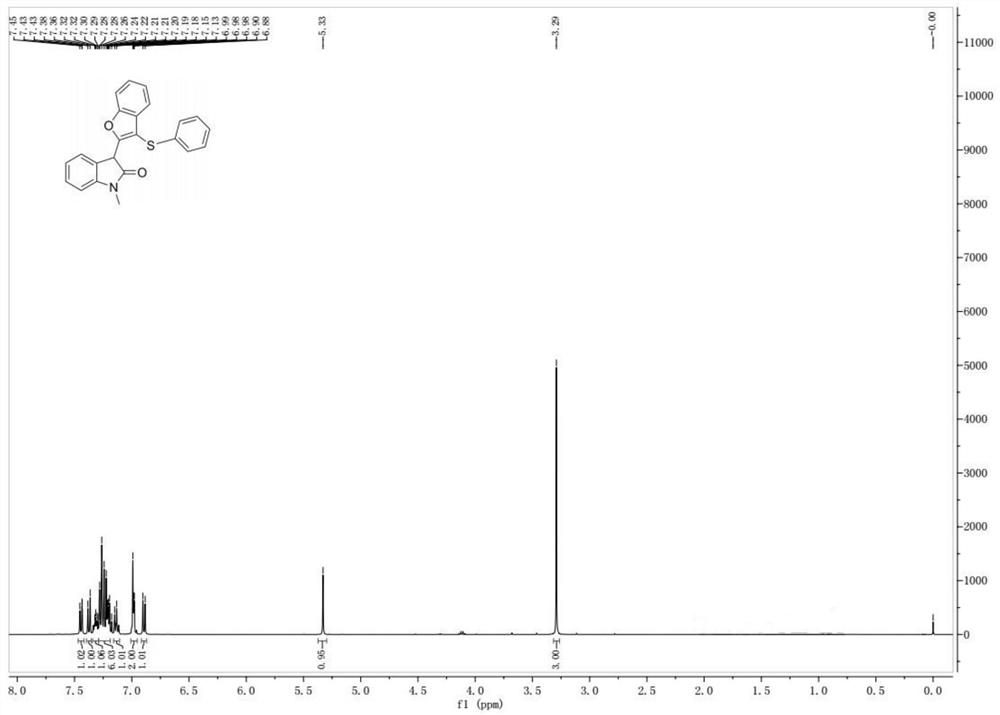

[0042] Characterization data of compound Ia: light yellow solid, melting point 197-198°C;

[0043] NMR spectrum such as figure 1 As shown, the NMR da...

Embodiment 2

[0046] A kind of synthetic method of 3-thiobenzofuran derivatives, comprising steps:

[0047]

[0048] For the synthesis method of compound IIb, please refer to the literature "Org. Biomol. Chem., 2018, 16, 6133".

[0049] The preparation steps of compound Ib are: add compound IIb (35.7mg, 0.1mmol) in 10mL round bottom flask, methylene chloride 2ml, thiophenol IIIa (13.2mg, 0.12mmol), add boron trifluoride diethyl ether ( 17mg, 0.12mmol), reacted at 25°C for 12 hours under the protection of nitrogen. Separation by silica gel column chromatography (eluent: petroleum ether (60-90° C.) / ethyl acetate=8:1, V:V) gave light yellow solid Ib (38.2 mg, molar yield 85%) with a purity greater than 95%. The target product was confirmed by NMR and high-resolution mass spectrometry.

[0050] Characterization data of compound Ib: light yellow solid, melting point 220-221°C;

[0051] The NMR data are as follows:

[0052] 1 H NMR (400MHz, CDCl3) δ7.47(d, J=7.7Hz, 1H), 7.44–7.36(m, 2H),...

Embodiment 3

[0054] A kind of synthetic method of 3-thiobenzofuran derivatives, comprising steps:

[0055]

[0056] For the synthesis method of compound IIc, please refer to the literature "Org. Biomol. Chem., 2018, 16, 6133"

[0057] The preparation steps of compound Ic are: add compound IIc (35.5mg, 0.1mmol) in 10mL round bottom flask, dichloromethane 2ml, thiophenol IIIa (13.2mg, 0.12mmol), add boron trifluoride diethyl ether ( 17mg, 0.12mmol), reacted at 25°C for 12 hours under the protection of nitrogen. Separation by silica gel column chromatography (eluent: petroleum ether (60-90° C.) / ethyl acetate=8:1, V:V) gave light yellow solid Ib (40.2 mg, molar yield 90%) with a purity greater than 95%. The target product was confirmed by NMR and high-resolution mass spectrometry.

[0058] Characterization data of compound Ic: pale yellow solid, melting point 242-243°C;

[0059] 1 H NMR (400MHz, CDCl 3 )δ7.45(d,J=7.3Hz,1H),7.42–7.35(m,3H),7.30(dt,J=13.6,5.6Hz,6H),7.26–7.18(m,4H),7.18–...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com