Traditional Chinese medicine decoction piece drying and sterilizing integrated device and method

A technology for drying and sterilizing Chinese herbal decoction pieces, which is applied in the directions of drying solid materials, heating to dry solid materials, heating devices, etc., can solve the problems of loss of effective components, complicated operation, and difficult to control, so as to reduce the loss of effective components and reduce drying. Good uniformity, soft processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

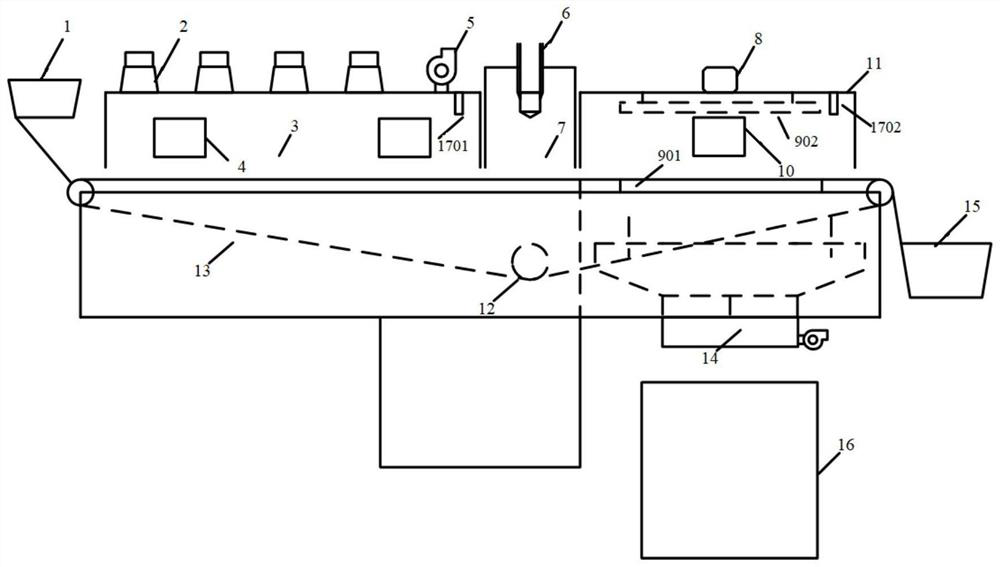

[0060] This embodiment provides an integrated device for drying and sterilizing Chinese herbal decoction pieces, such as figure 1 As shown, comprise: feeding device, drying device, detection device, sterilizing device, discharging device, conveying device and control system 16; Wherein feeding device comprises feed hopper 1, and discharging device comprises discharging hopper 15; Wherein drying The device includes a drying chamber 3, four groups of microwave generators 2, and the four groups of microwave generators 2 are all installed on the upper part of the drying chamber 3, and are evenly distributed side by side. And the dehumidification fan 5 is installed on the top of the drying chamber 3, the first temperature sensor 1701 is installed inside the drying chamber 3, and the side of the drying chamber 3 is provided with a window 4; wherein the detection device includes a detection chamber 7 and an infrared probe 6, the The infrared probe 6 is a diffuse reflection probe, and...

Embodiment example 2

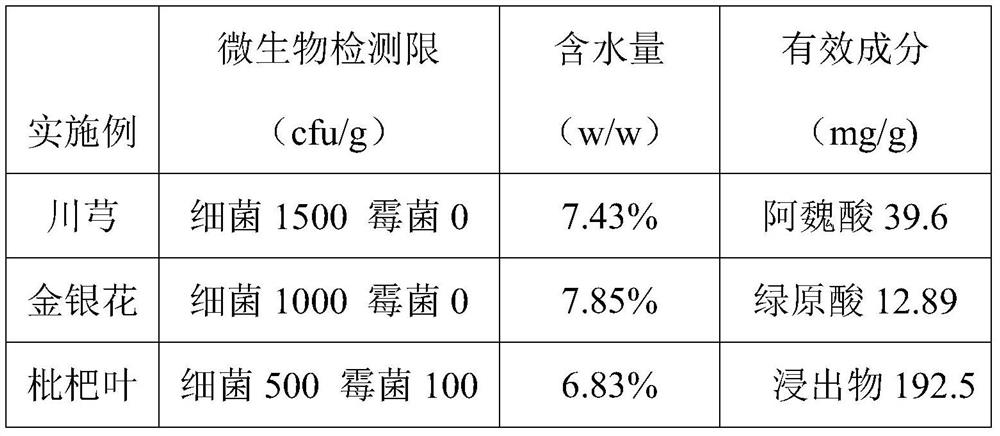

[0067] Implementation case 2: root and rhizome decoction pieces, taking Chuanxiong as an example

[0068] According to the production batch, take 100kg of Chuanxiong decoction pieces (the microbial limit test results show that the bacteria and mold contents are 50000cfu / g and 10000cfu / g respectively), open the conveyor belt through the control system, and send the materials in the hopper into the microwave drying chamber; set The power density of microwave is 0.1-0.15w / g, the final temperature of microwave drying is 60-65℃, the drying time is 45-50min, and then the drying starts.

[0069] When the drying is over, the conveyor belt will input a certain amount of material into the detection chamber for near-infrared spectrum collection and analysis of the moisture content of the material. The spectral scanning range is 4000-12500cm -1 , the number of scans is 32, and the resolution is 8cm -1 , use the built-in background of the detection chamber as a reference to collect spectr...

Embodiment example 3

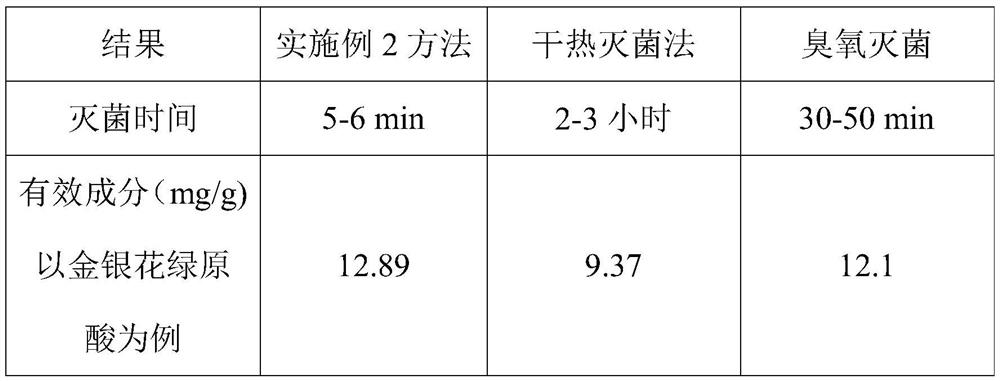

[0071] Implementation case 3: flower decoction pieces, taking honeysuckle as an example

[0072] According to the production batch, take 100kg of honeysuckle as the material (the microbial limit test results show that the bacteria and mold contents are 15000cfu / g and 20000cfu / g respectively), open the conveyor belt through the control system, and send the material in the hopper into the microwave drying chamber; set the microwave The power density is 0.08-0.10w / g, the final temperature of microwave drying is 50-55°C, the drying time is 30-35min, and then the drying starts.

[0073] When the drying is over, the conveyor belt will input a certain amount of material into the detection chamber for near-infrared spectrum collection and analysis of the moisture content of the material. The spectral scanning range is 4000-12500cm -1 , the number of scans is 32, and the resolution is 8cm -1 , use the built-in background of the detection chamber as a reference to collect spectra; if t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com