Apparatus for conveying eggs

A transmission device and transmission direction technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem of vacancy in the transmission position, etc., and achieve the effect of gentle handling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

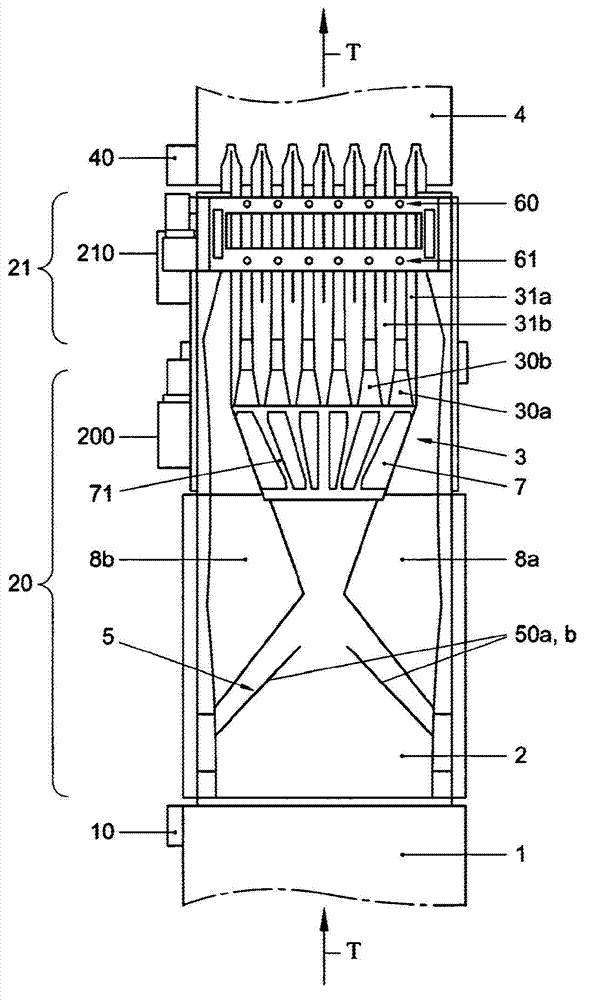

[0042] in the attached figure 1 , the diagram of the system of the present invention is shown in a top view, where the egg flow or transport direction T proceeds from the bottom of the figure to the top of the figure. The system includes (before discharge conveyor 4):

[0043] - a supply conveyor 1 with a substantially flat conveying surface for supplying products (eggs in this example) substantially horizontally and in a mutual disordered manner along the conveying direction T,

[0044] - a dispensing assembly with at least two supply channels 30 extending in the conveying direction T, each supply channel 30 serving to form a row of products, wherein at least edge elements 31 form the edges of these channels 30 over a well-defined dispensing length, And these edge elements 30 are for example arranged on the opposite conveying surface and adjacent to the opposite conveying surface.

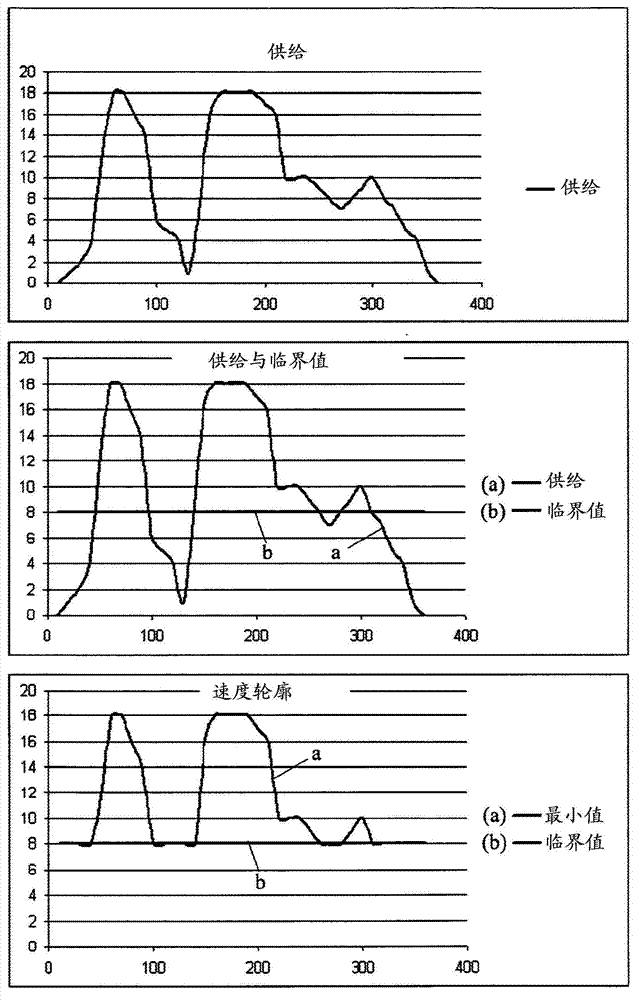

[0045] In use, (based on monitoring and control signals to be discussed below) products are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com