Extruder

A technology of extruder and conveyor, applied in the field of extruder, to reduce material load and avoid fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

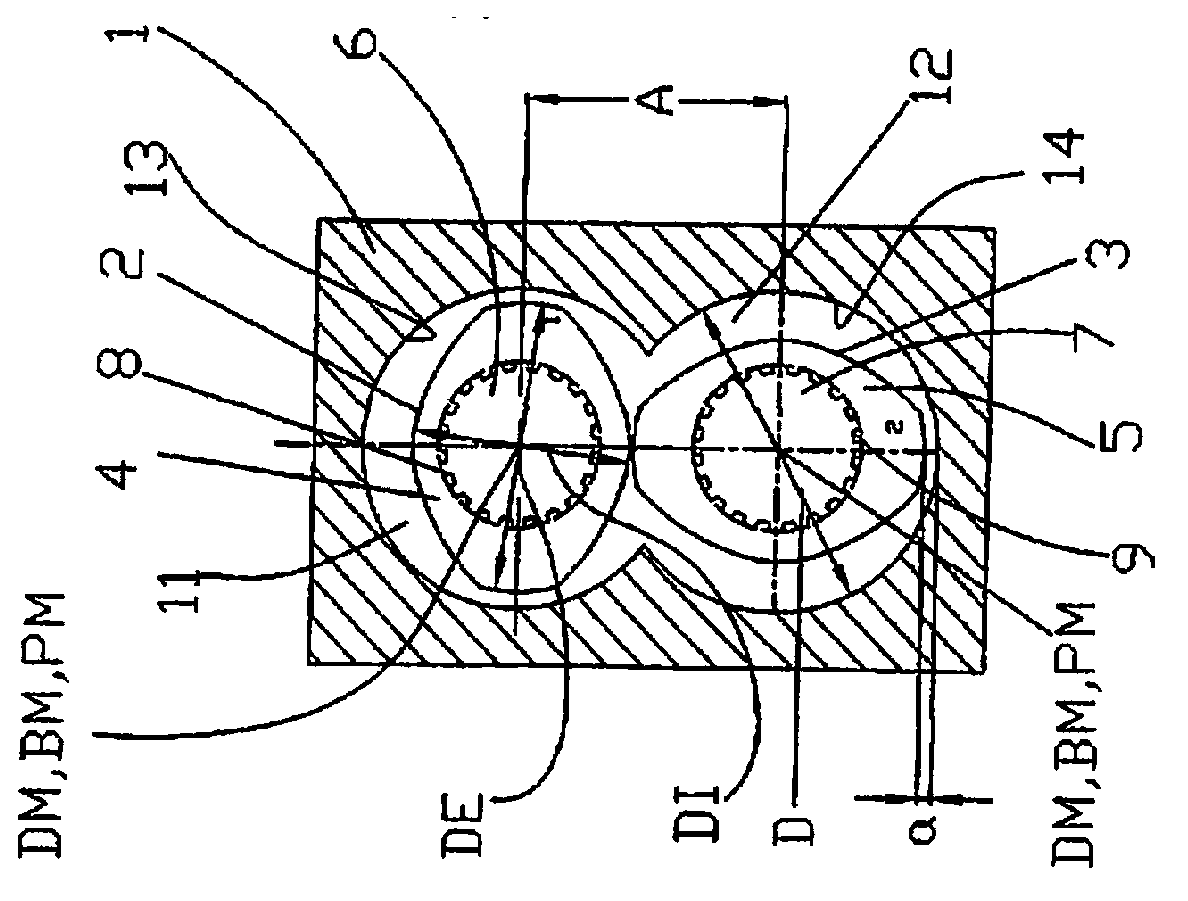

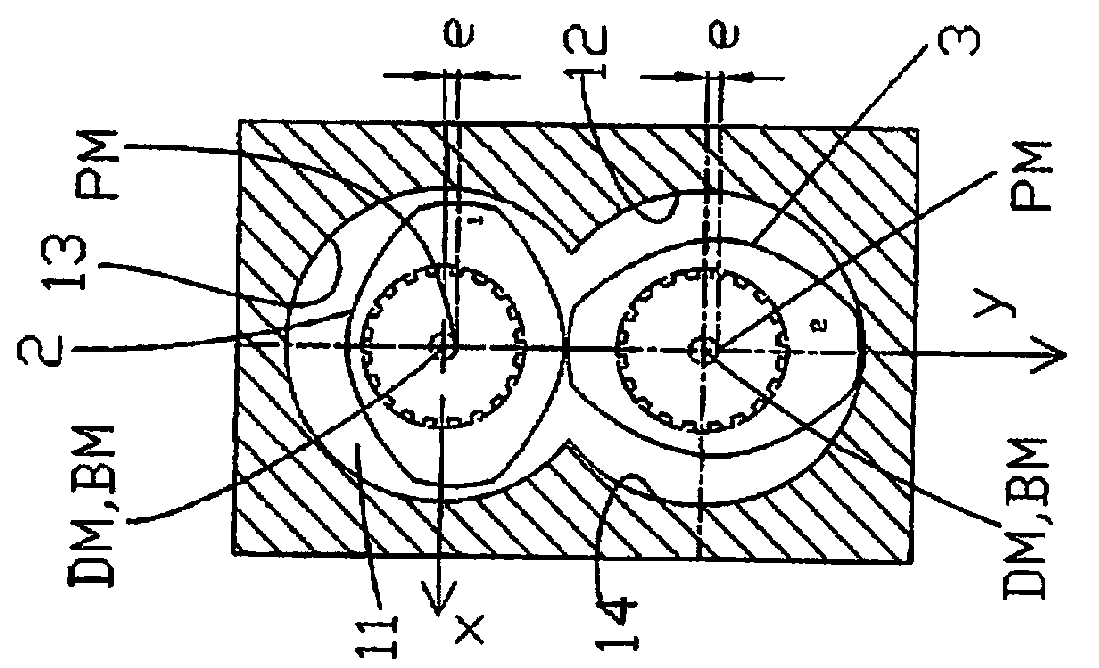

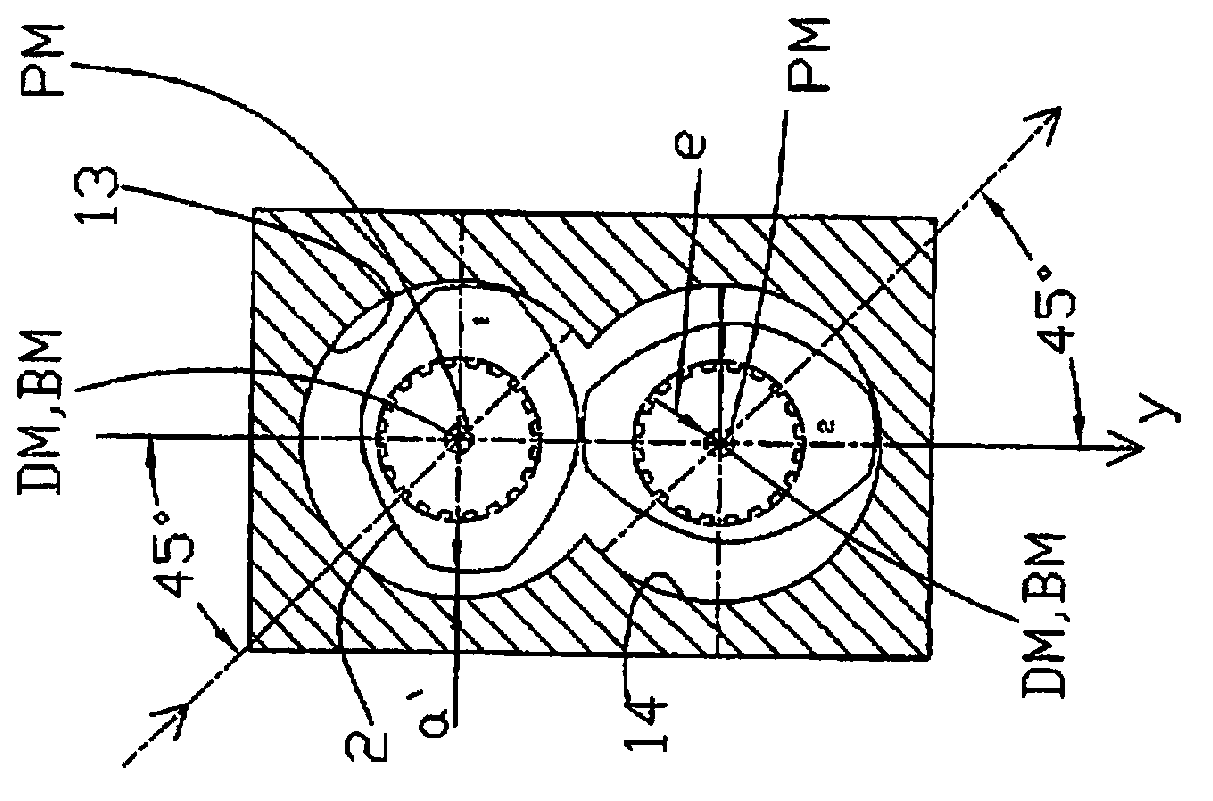

[0046] according to figure 1 , the twin-screw extruder comprises two twin-screw conveyor shafts 2, 3 arranged in the housing 1, which respectively have transmission elements 4, 5, each transmission element is rotatably fixed, for example via teeth 8, 9 On the support shafts 6,7.

[0047] The conveyor shafts 2, 3 are arranged to be driven in the same direction within the two housing holes 11, 12, wherein the hole walls 13 and 14 of the holes 11, 12 are connected to the center BM and the conveyor shaft extending through the housing holes 11, 12. The axes of rotation of the conveyor shafts 2, 3 are concentric with the center of rotation DM of the conveyor shafts 2, 3.

[0048] The bores 11 , 12 are therefore designed cylindrically or conically, wherein in the case of cylindrical bores 11 , 12 the axes of rotation are parallel to each other, in the case of conical bores the axes run at an angle towards each other.

[0049] The housing bores 11 , 12 have a diameter D. The axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com