Tool for sheet metal working machine and method for cutting film

A metal plate and processing machine technology, applied in metal processing and other directions, can solve the problem of inability to process small radius curves and contours, and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

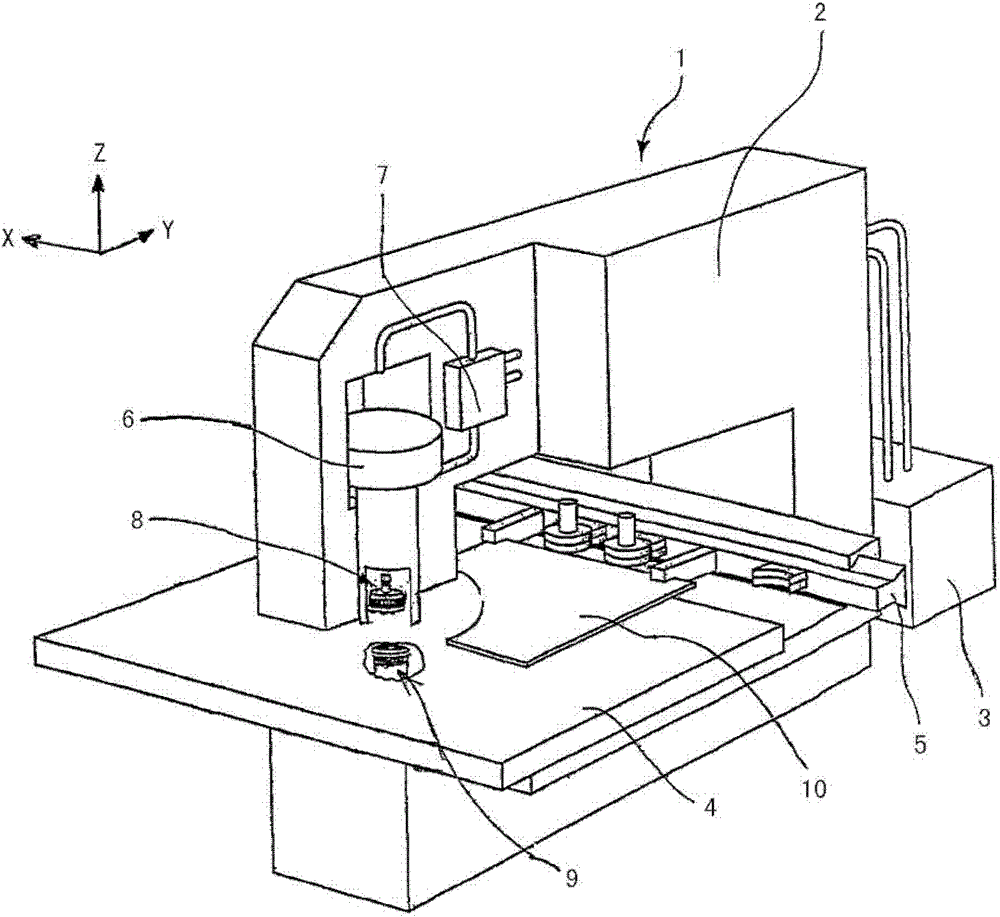

[0012] figure 1 A punching machine 1 is shown according to one embodiment as a sheet metal working machine. However, laser processing machines such as laser cutting machines or laser welding machines or combined stamping / laser cutting machines are also possible, for example.

[0013] The press machine 1 includes a C-shaped frame 2 as a main member. The C-frame 2 consists of a torsionally rigid welded structure made of steel. At the rear end of the C-shaped frame 2 is arranged a hydraulic power unit 3 as a power source for the punching movement.

[0014] Furthermore, the punching machine 1 comprises mechanical control means (not shown) connected to all actuators of the punching machine 1 and controlling said actuators.

[0015] A workpiece supporting device 4 in the form of a processing table for placing workpieces is provided on the inner side of the lower part of the C-shaped frame 2 . Here, the workpiece is a sheet metal panel 10 .

[0016] Also provided on the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com