Patents

Literature

49 results about "Brushed metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brushed or dull polished metal is metal with a unidirectional satin finish. It is produced by polishing the metal with a 120–180 grit belt or wheel then softening with an 80–120 grit greaseless compound or a medium non-woven abrasive belt or pad.

Scratch resistant brushed metal imitating composite decorative film

InactiveCN105459532AGood semi-matte finishHigh glossNatural patternsSynthetic resin layered productsBoPETResin coating

The invention provides a scratch resistant brushed metal imitating composite decorative film. A BOPET film subjected to painting and hardening treatment and a PVC film layer are bonded together through a composite adhesive layer. The lower surface of the BOPET film is provided with a primer layer, and the primer layer surface is printed with a brushed metal imitating pattern layer. The upper surface of the BOPET film is provided with an adhesion reinforced resin coating, the surface of which is provided with a scratch resistant hardened coating. The scratch resistant brushed metal imitating composite decorative film provided by the invention can be compounded to the surfaces of color steel plates and a variety of decorative materials to reach the decorative effect of brushed metal, and has the advantages of strong metal texture, soft luster, and beautiful and novel appearance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

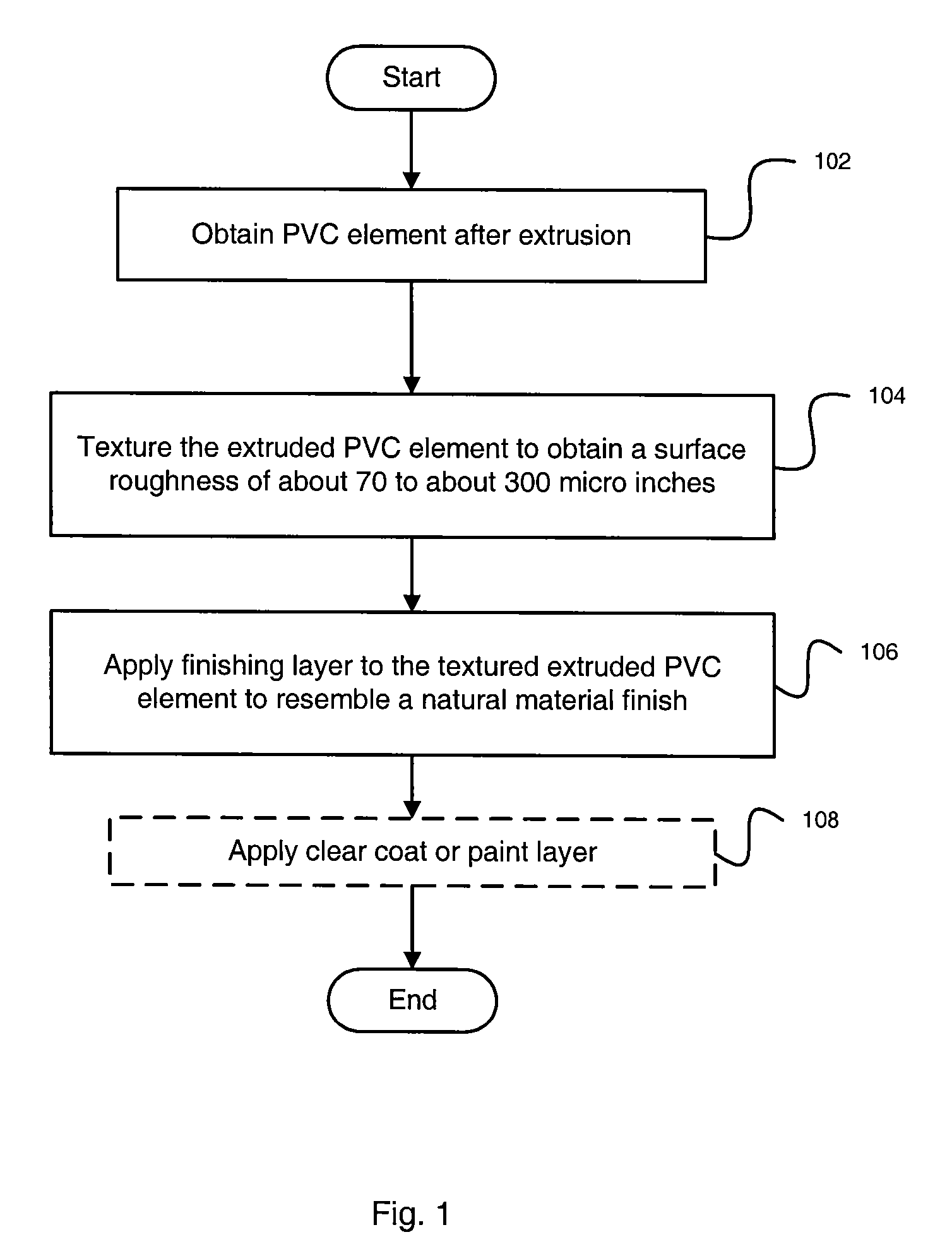

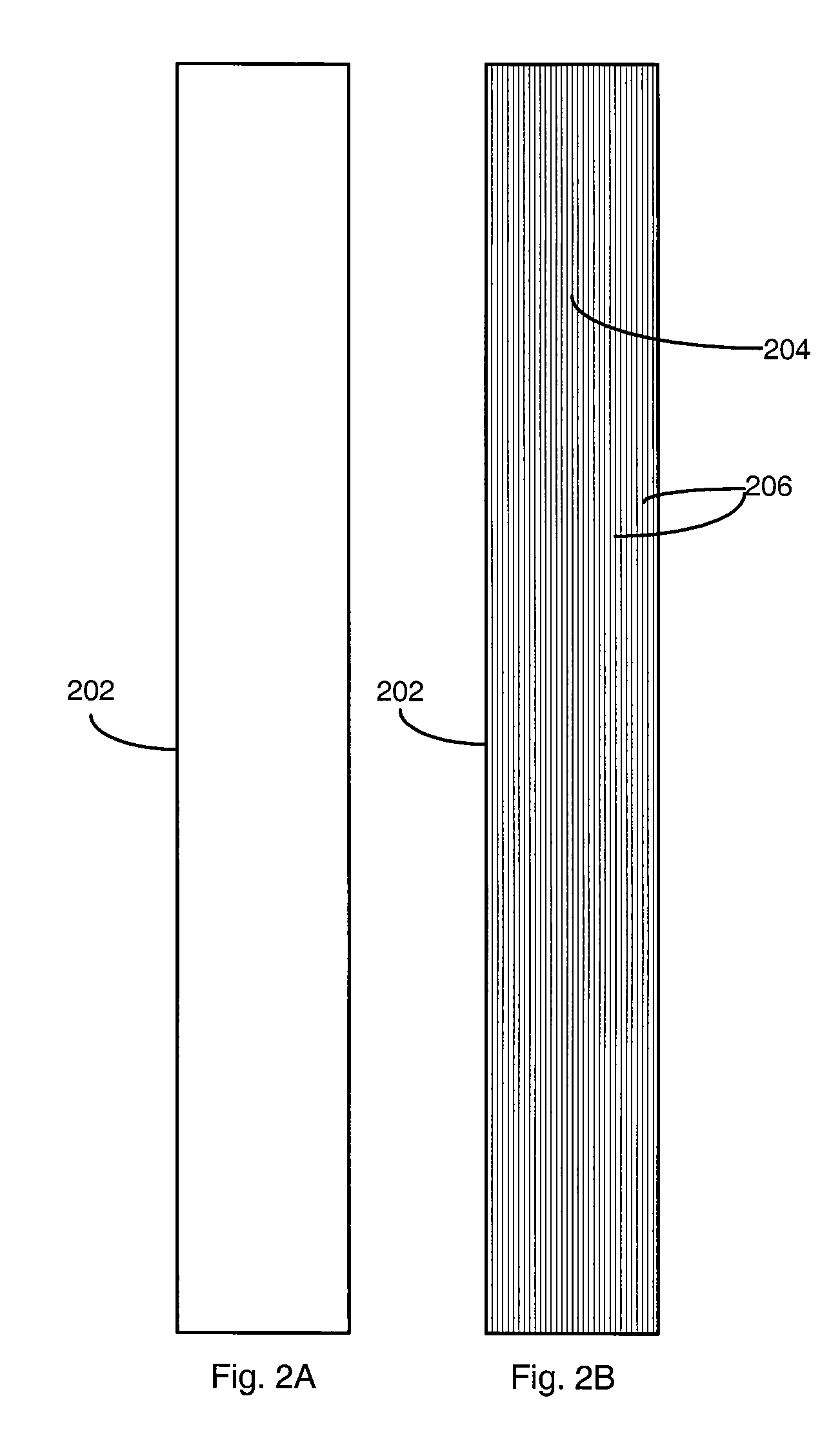

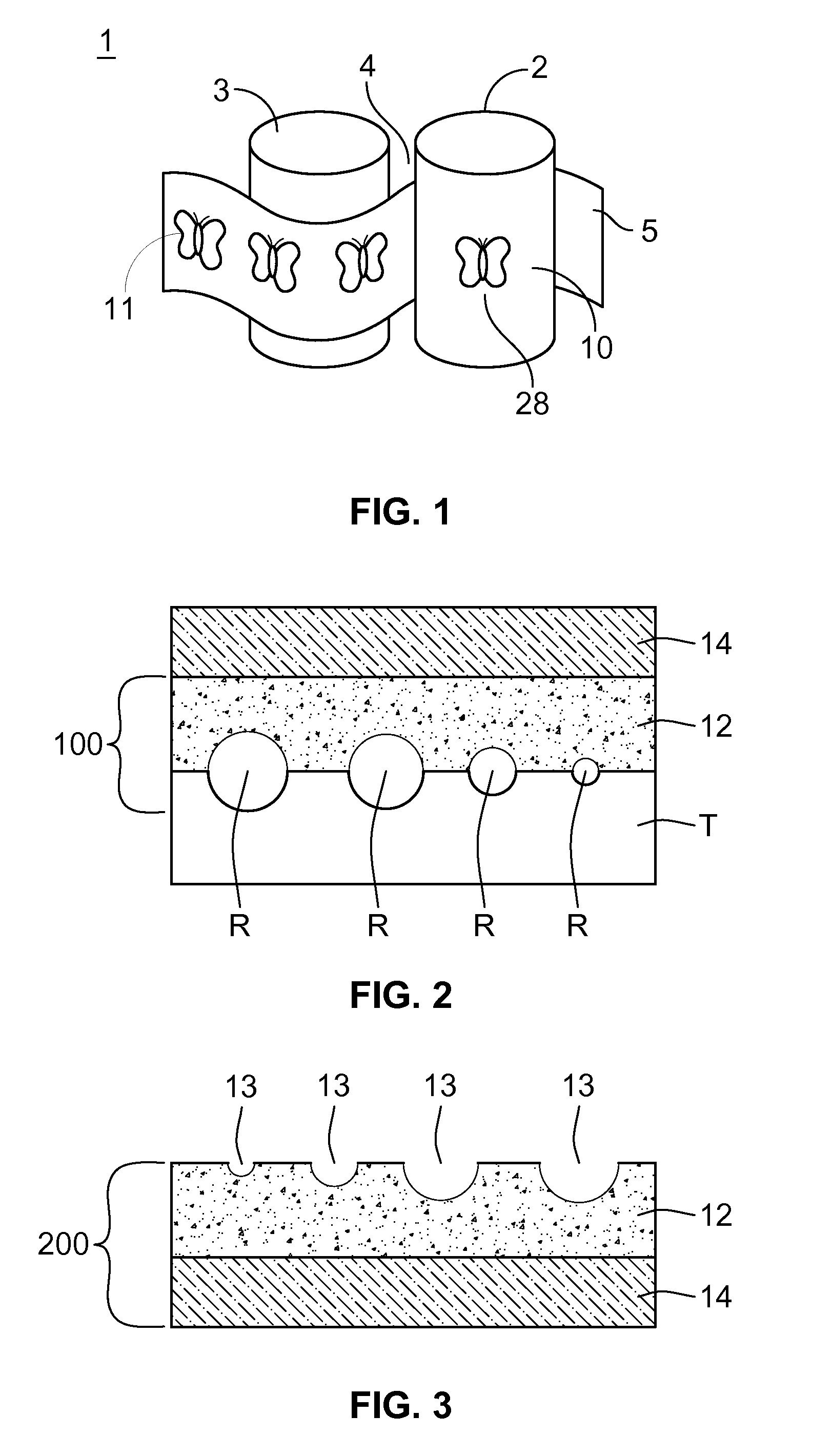

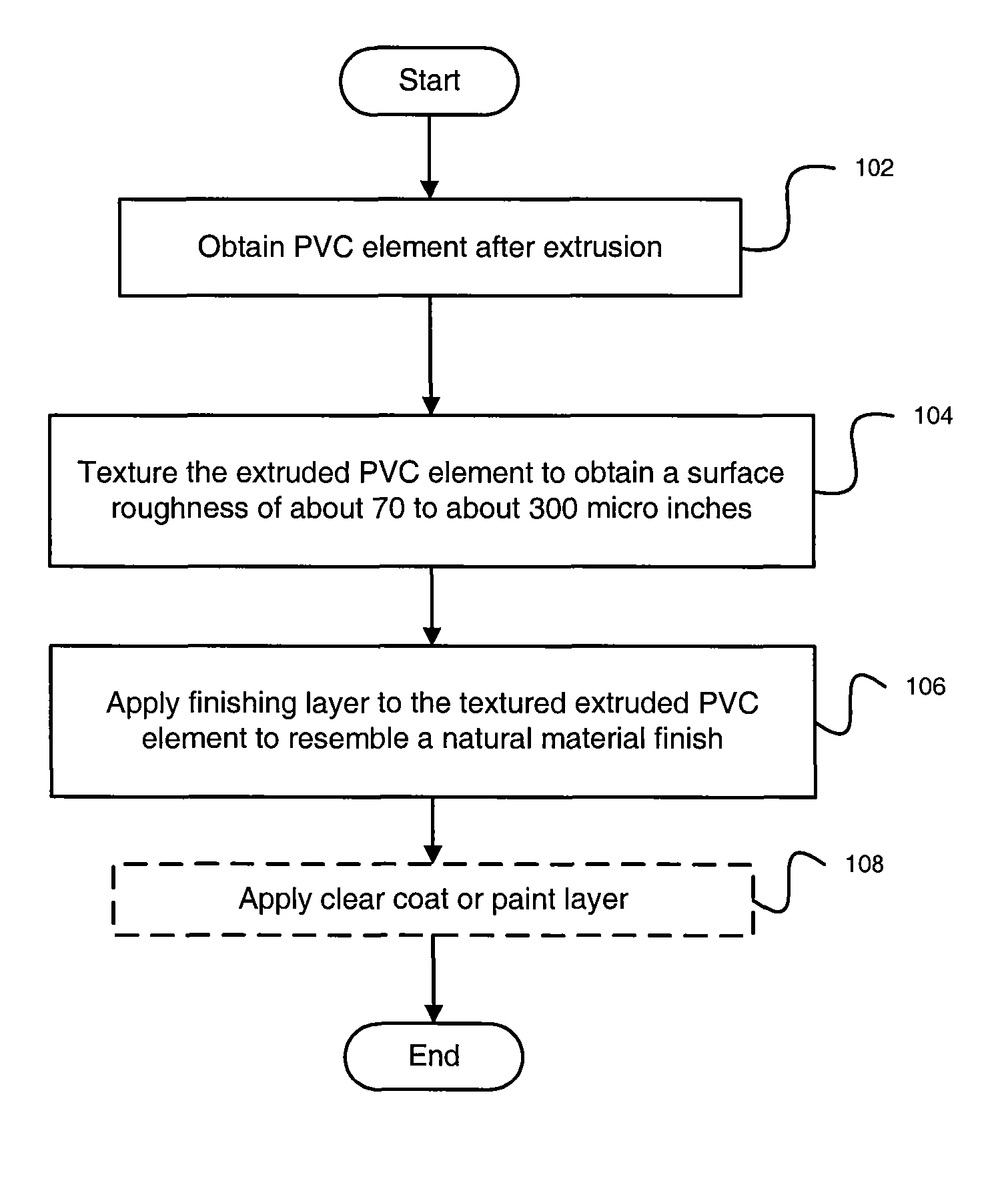

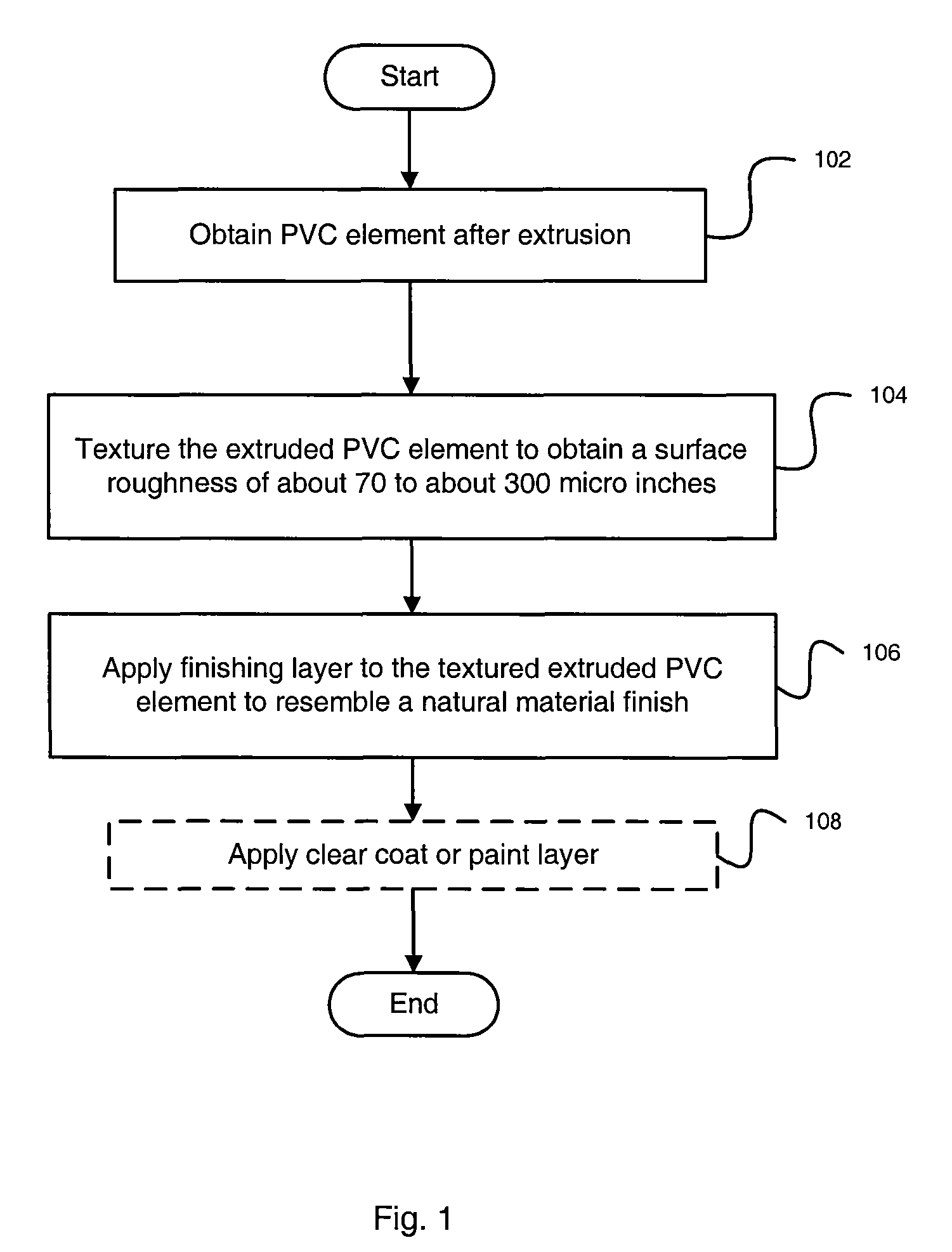

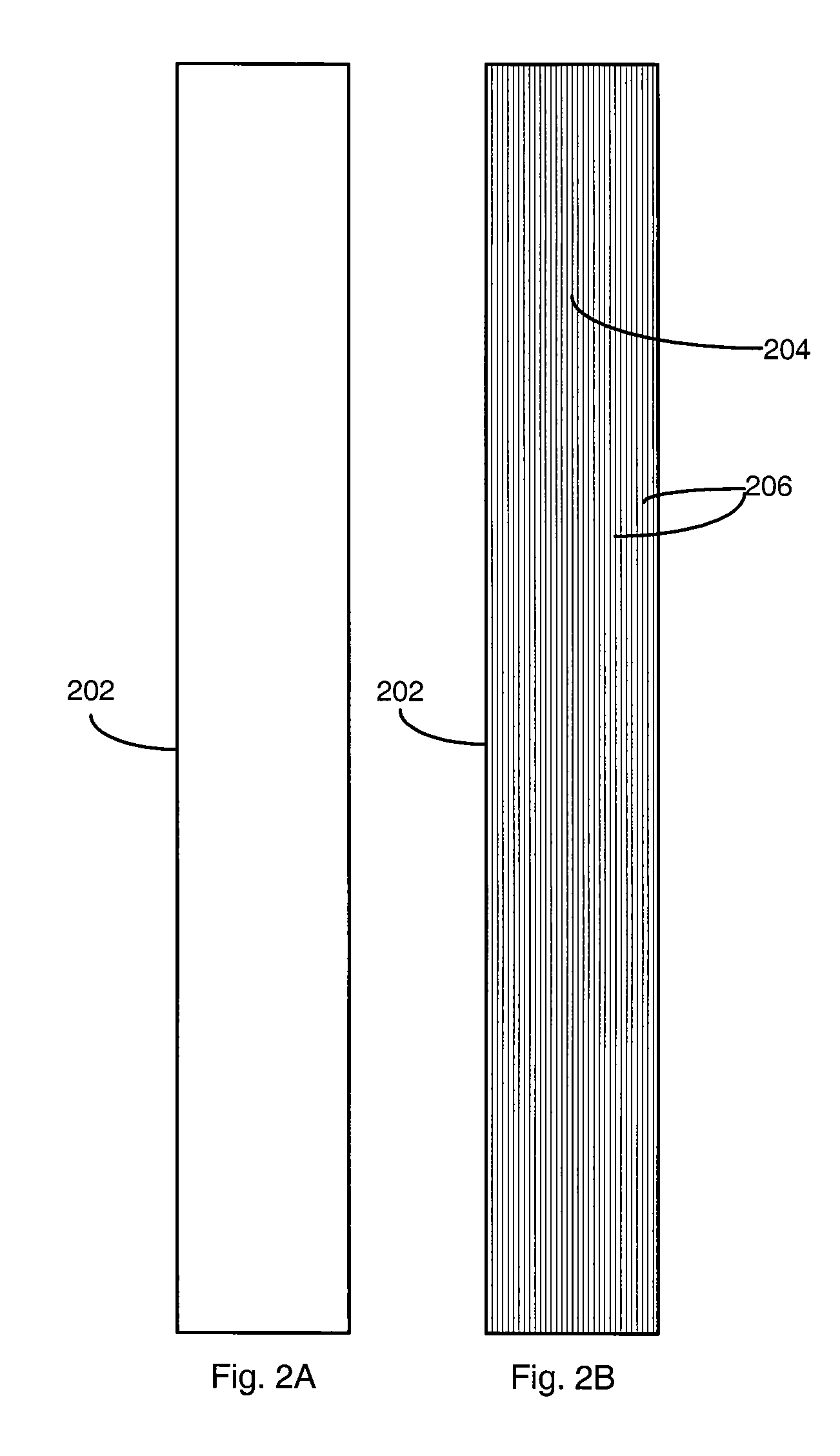

Method of texturing synthetic material extrusions

ActiveUS20090098339A1Radiation applicationsDecorative surface effectsPolyvinyl chlorideSurface roughness

A method of texturing a synthetic material, such as polyvinyl chloride (PVC), to resemble a natural material is provided. The method can include texturing a PVC profile after extrusion in order to achieve a surface roughness of about 70 to about 300 micro inches roughness average. The method can include producing a line pattern surface roughness to make the textured PVC resemble a wood finish, particularly when the method includes applying a paint or stain to the textured PVC. The method can include producing a radial pattern surface roughness to make the textured PVC resemble a brushed metal finish. The method of the present invention can be applied to existing PVC elements, such as extruded elements, either at the manufacturing level or at the consumer level. A kit can also be provided including a texturing means, a paint or stain, and instructions.

Owner:DALLAIRE INDS

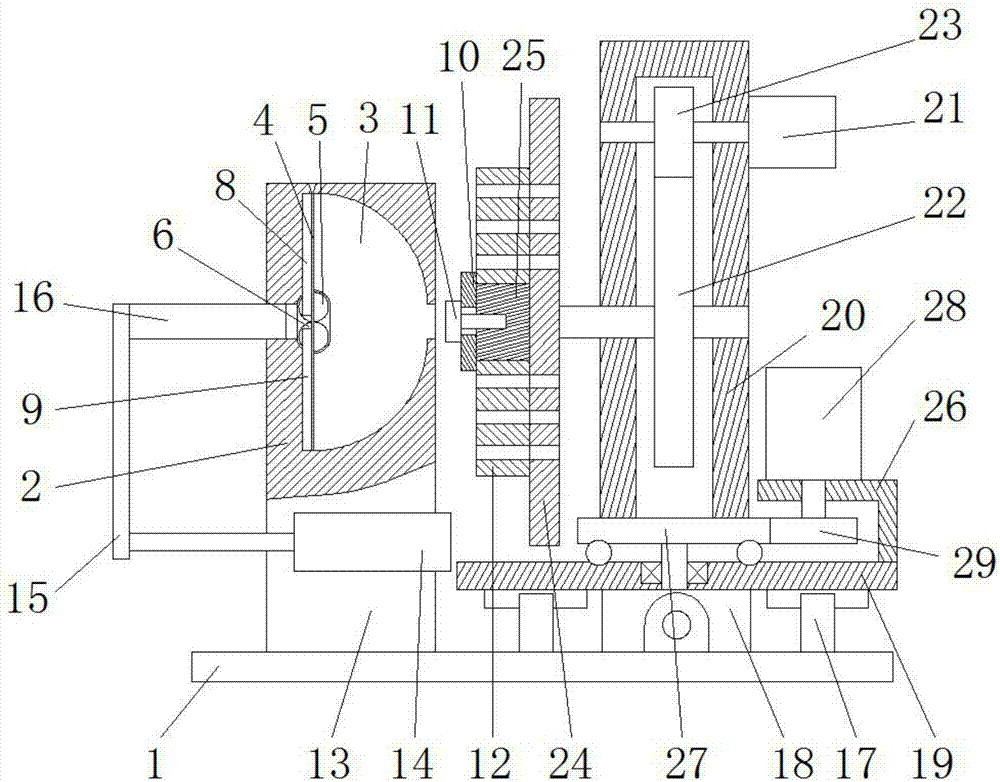

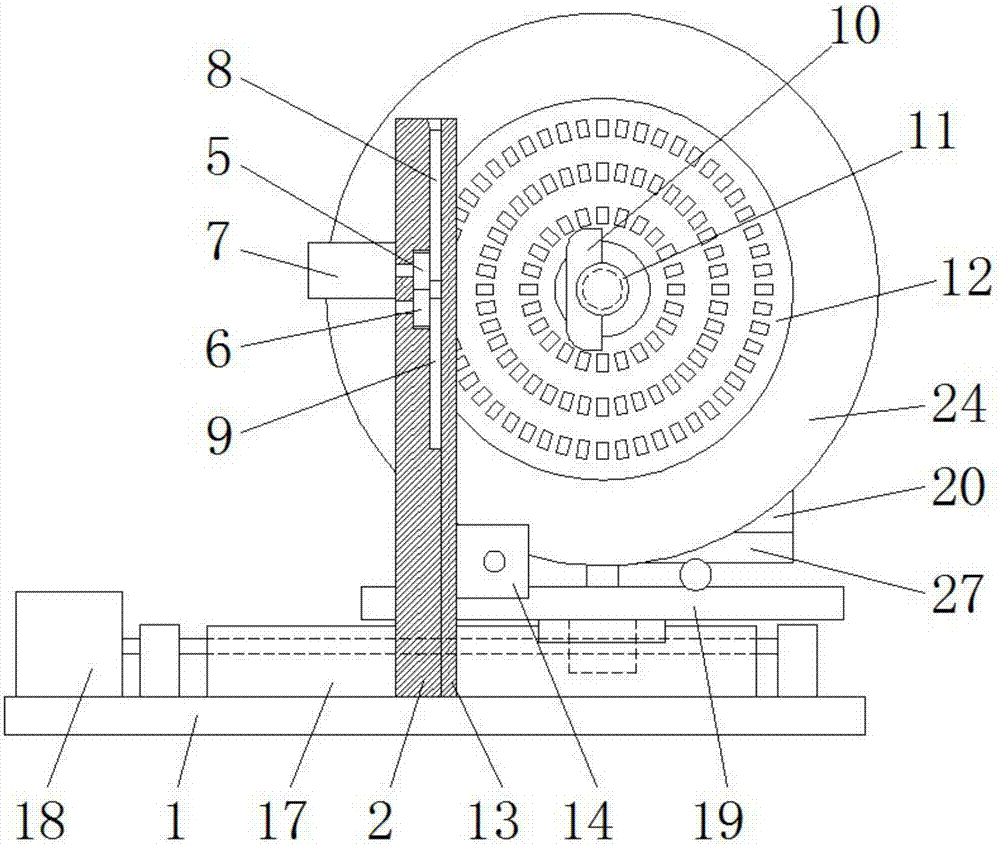

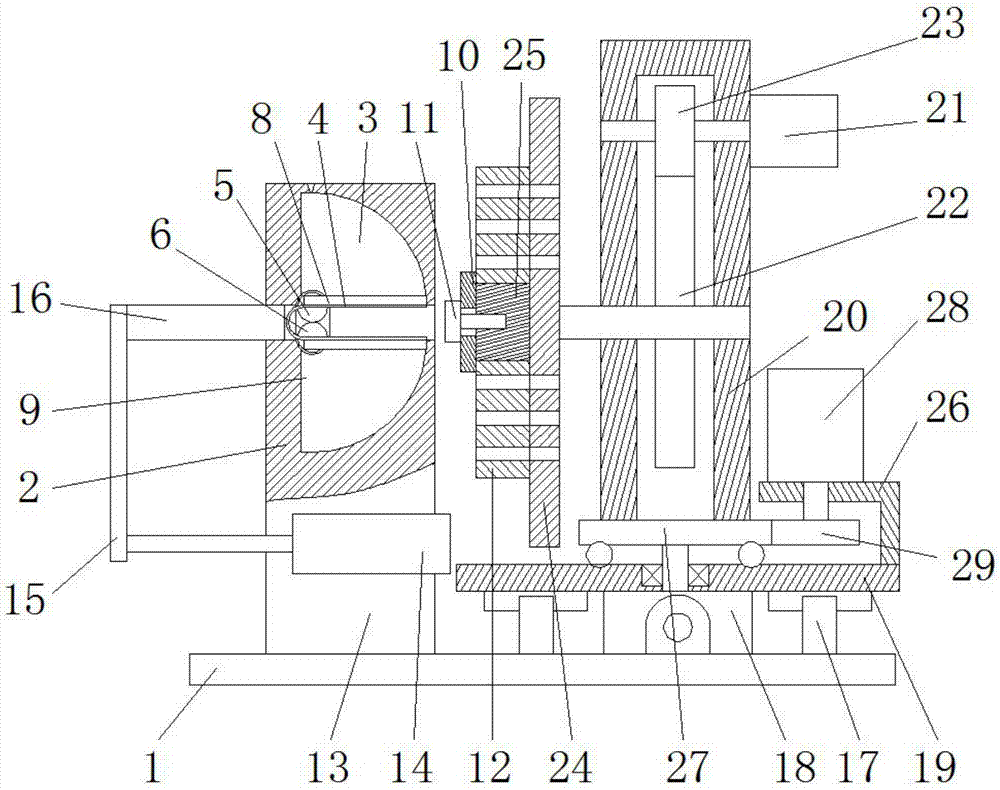

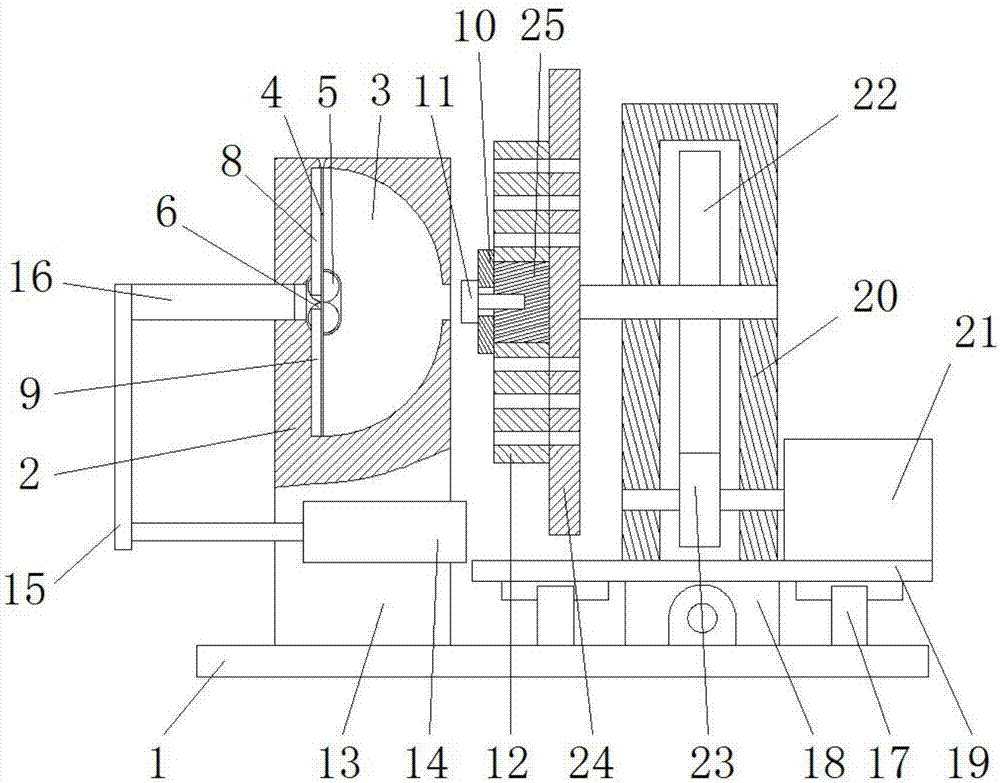

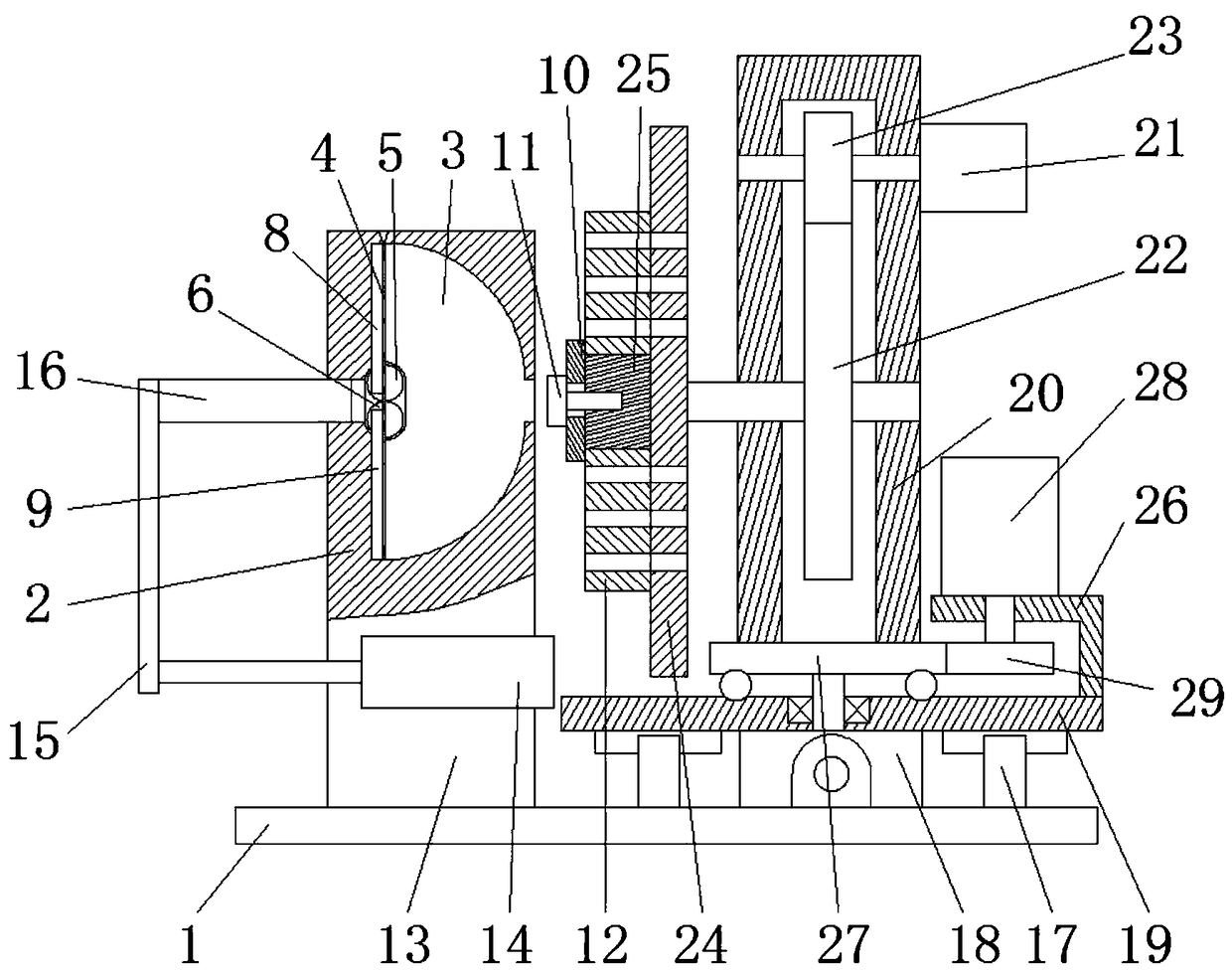

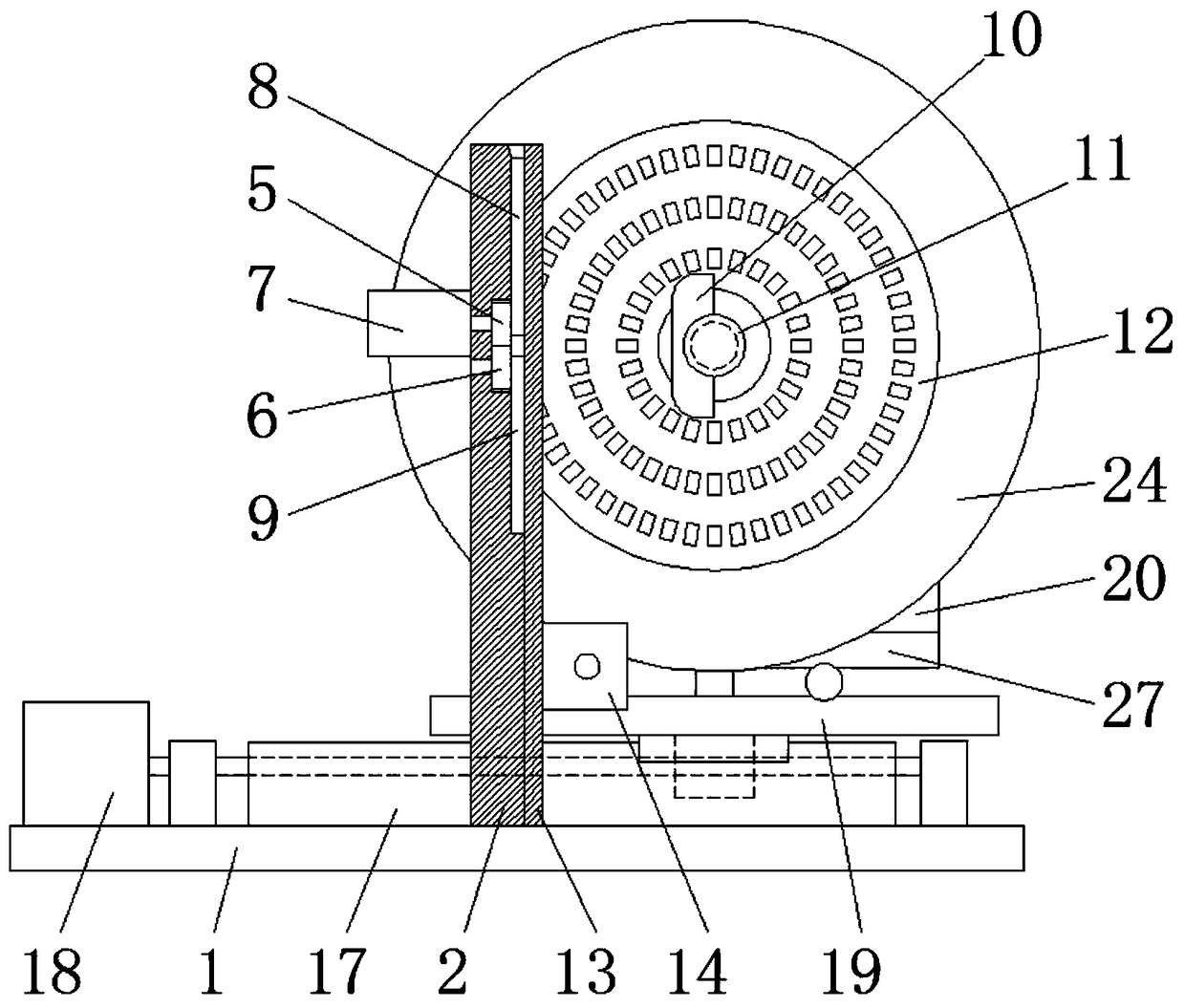

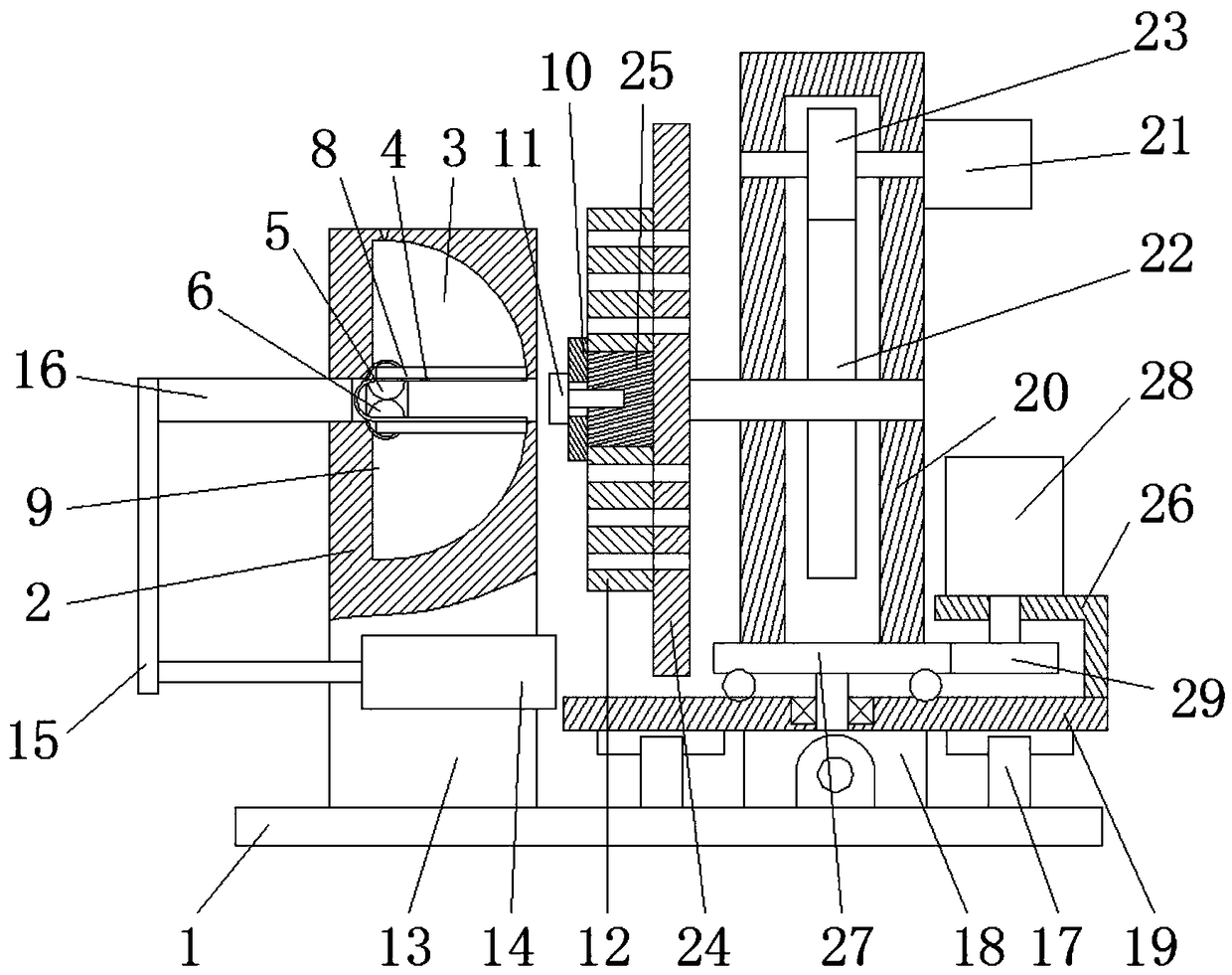

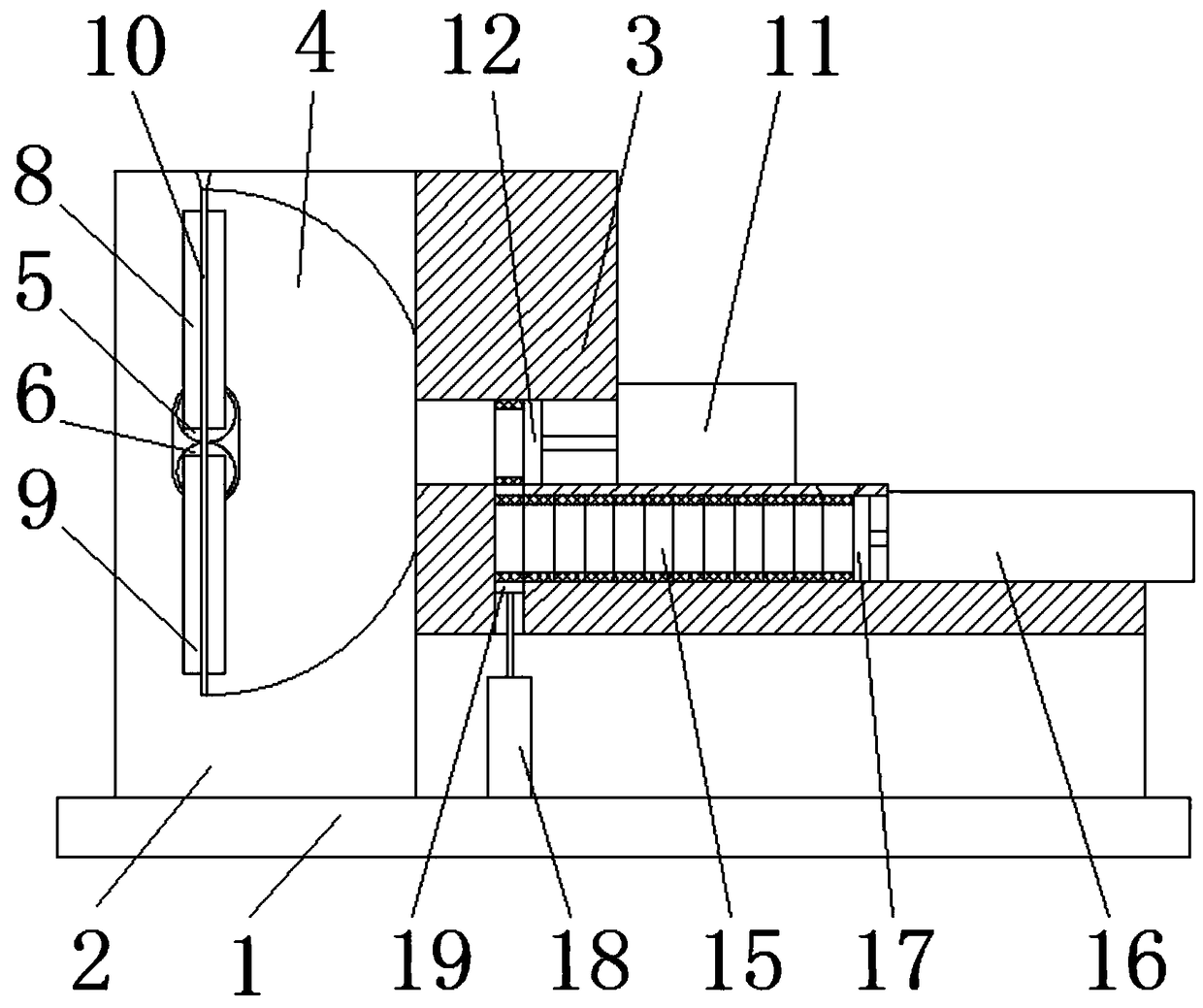

Multifunctional disc brush metal brush wire cutting device

The invention discloses a multifunctional disc brush metal brush wire cutting device. The multifunctional disc brush metal brush wire cutting device comprises a base, a bending device and a positioning device, the bending device comprises a supporting plate, the supporting plate is internally symmetrically provided with an upper bending gear and a lower bending gear, an upper bending arm and a lower bending arm which are symmetrically arranged are fixedly connected to the outer side faces of the upper bending gear and the lower bending gear respectively, metal brush wires are arranged at the right side faces of the upper bending arm and the lower bending arm, the positioning device comprises a guide rail and a positioning motor, a mobile base plate is erected on the guide rail, a fixed angle large gear and a fixed angle motor are installed on the mobile base plate, a fixed angle small gear is connected to the output end of the fixed angle motor, a support is fixedly installed on the fixed angle large gear, and a graduation large gear and a graduation small gear are installed in the support. In the multifunctional disc brush metal brush wire cutting device, a bending device is adopted to automatically bend and automatically cut the metal brush wires, the time and labor are saved, the work efficiency is high, the manpower cost is drastically saved, the universality is high, and the multifunctional disc brush metal brush wire cutting device has high application and popularization value.

Owner:安徽长中刷业有限公司

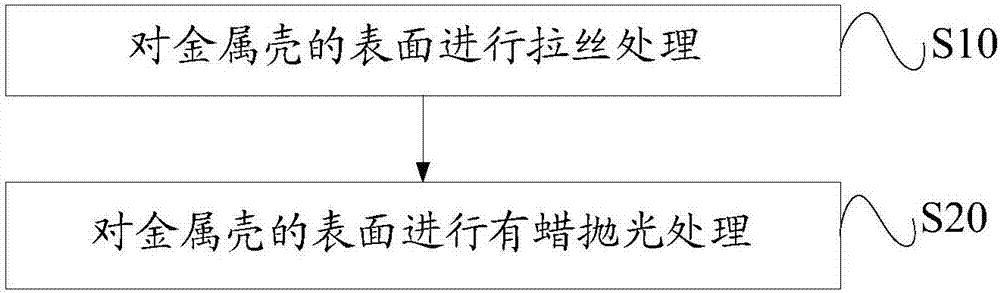

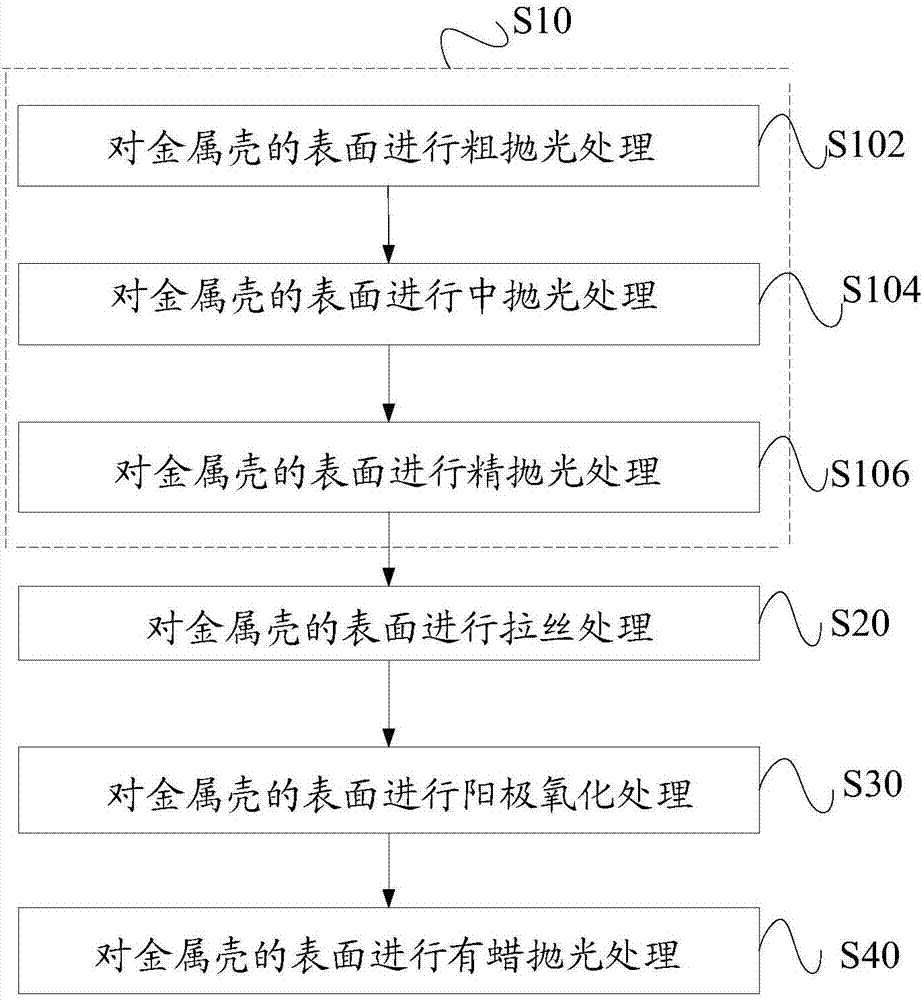

Metal shell as well as surface treatment method and electronic equipment thereof

The invention provides a metal shell as well as a surface treatment method and electronic equipment. The surface treatment method of the metal shell comprises the following steps: carrying out brushed treatment on the surface of the metal shell, and carrying out wax polishing treatment on the surface subjected to brushed treatment of the meal shell. The surface treatment method of the metal shell breaks the processing thinking of the conventional metal shell surface treatment; the surface is subjected to wax polishing treatment after the surface of the metal shell is subjected to brushed treatment; the texture and the beauty of the brushed metal shell are optimized; a novel appearance process is increased for the metal shell. The process is capable of meeting various reliability test requirements of metal mobile phone shells and achieving the ID design pursuit of various colors, is also capable of achieving normal batch production, and is relatively suitable for appearance design of mid-to-high end mobile phones.

Owner:MEIZU TECH CO LTD

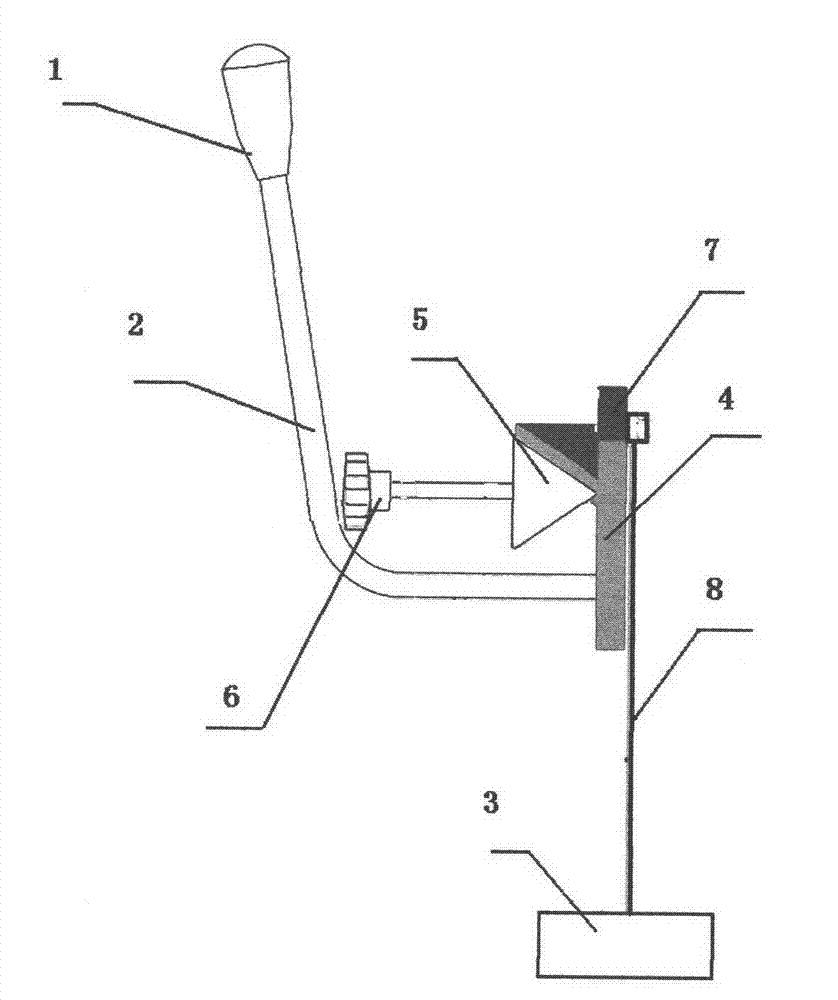

Handle-type main brush fine adjusting device

The invention discloses a handle-type main brush fine adjusting device. The handle-type main brush fine adjusting device comprises a handle, a controlling connecting rod and a rolling brush, wherein one end of the controlling connecting rod is connected with the handle, and the other end of the controlling connecting rod is connected with a rotator; a tapered block is arranged on the rotator; a cross handle controls the advance and the recession of the tapered block by a screw rod in a rotating manner, and a wedged iron block matched with the tapered block can also move upwards and downwards; and the wedged iron block is connected with one end of a brushed metal, and the other end of the brushed metal is connected with the rolling brush. The control of the upwards and the downwards of the rolling brush plays a vital role to the service life of the rolling brush. The handle-type main brush fine adjusting device adopts brushed metal to control the upward and downward of the rolling brush, so as to effectively control the optimal joint point between the rolling brush and the ground through fine adjusting of the screw rod (cross handle); and the sweeping is clean and the service life of the rolling brush is improved.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

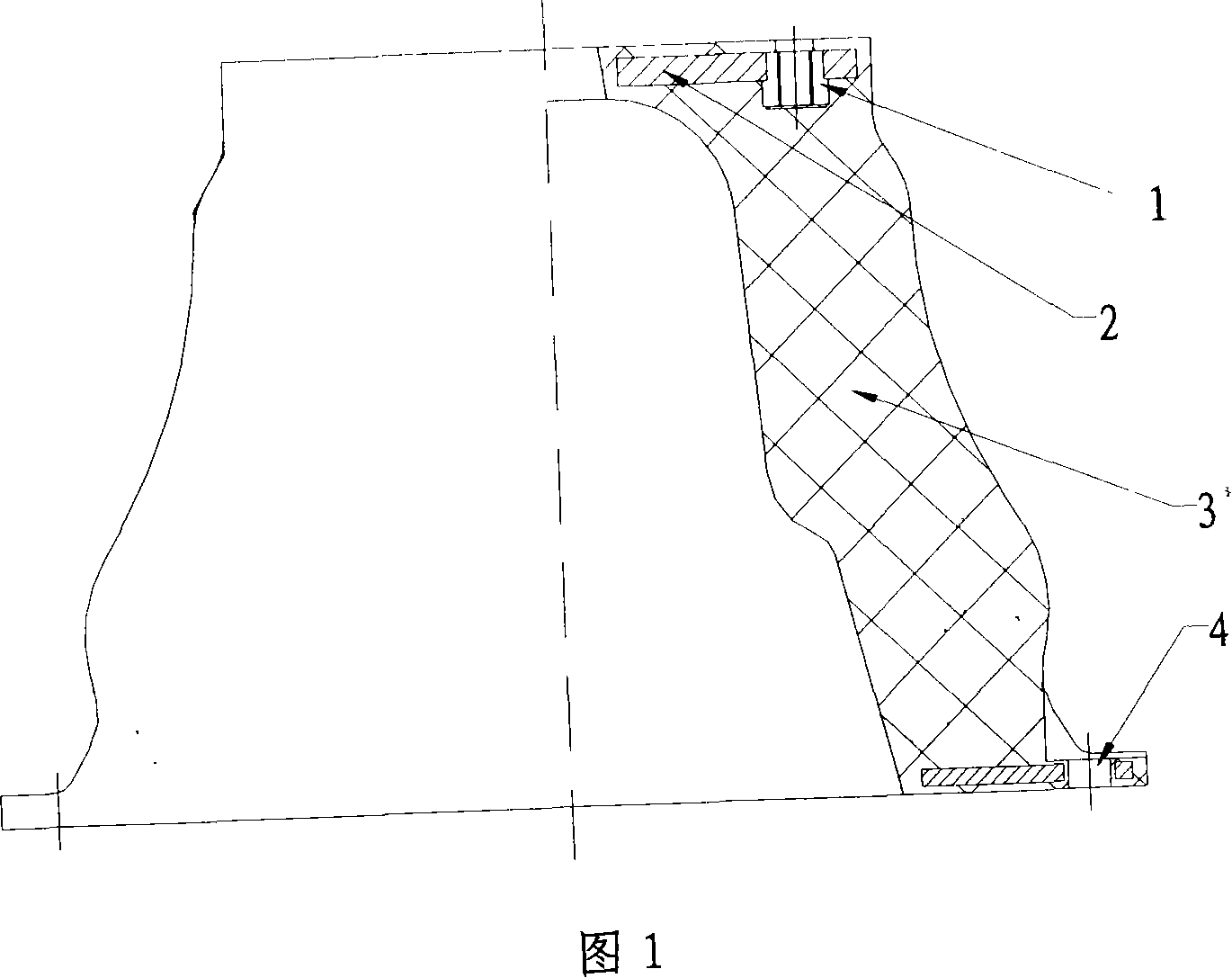

Large cone rubber guard rail and its making method

InactiveCN101148192AImprove energy absorptionImprove bending resistanceVessel cleaningHullsAbrasive blastingHigh stiffness

The present invention is one kind of large rubber ship fender and its making process. The technological scheme of the present invention is that the hollow conic rubber ship fender has built-in nuts and steel plate skeleton in the front plane and holes for screws in the back plane. The hollow conic rubber ship fender is made through the following steps: 1. cutting steel plate, sanding to derust, brushing metal adhesive and coating the steel plate with rubber; 2. mixing raw rubber 50-58 wt%, vulcanization accelerator 2-2.6 wt%, carbon black 35-50 wt%, softening agent 3-5 wt% and antiager 2-3 wt%; and 3. co-extruding the mixture obtained in the step 2 and the skeleton steel plate obtained in the step 1, vulcanizing, demolding and trimming. The present invention is applied for guarding berth and ship, and has high stiffness, high bending and shearing strength, high corrosion resistance and other advantages.

Owner:YANTAI TAIHONG RUBBER

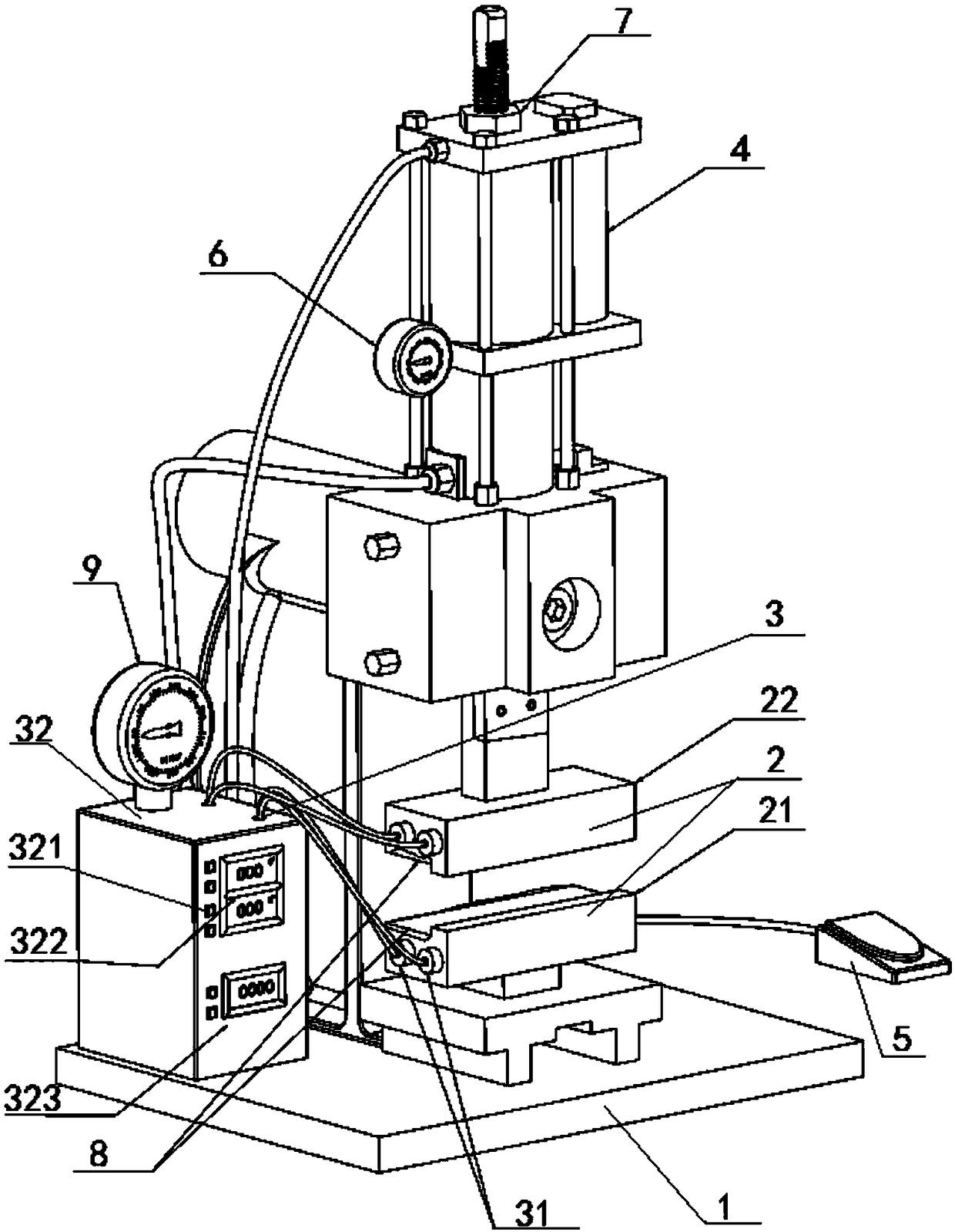

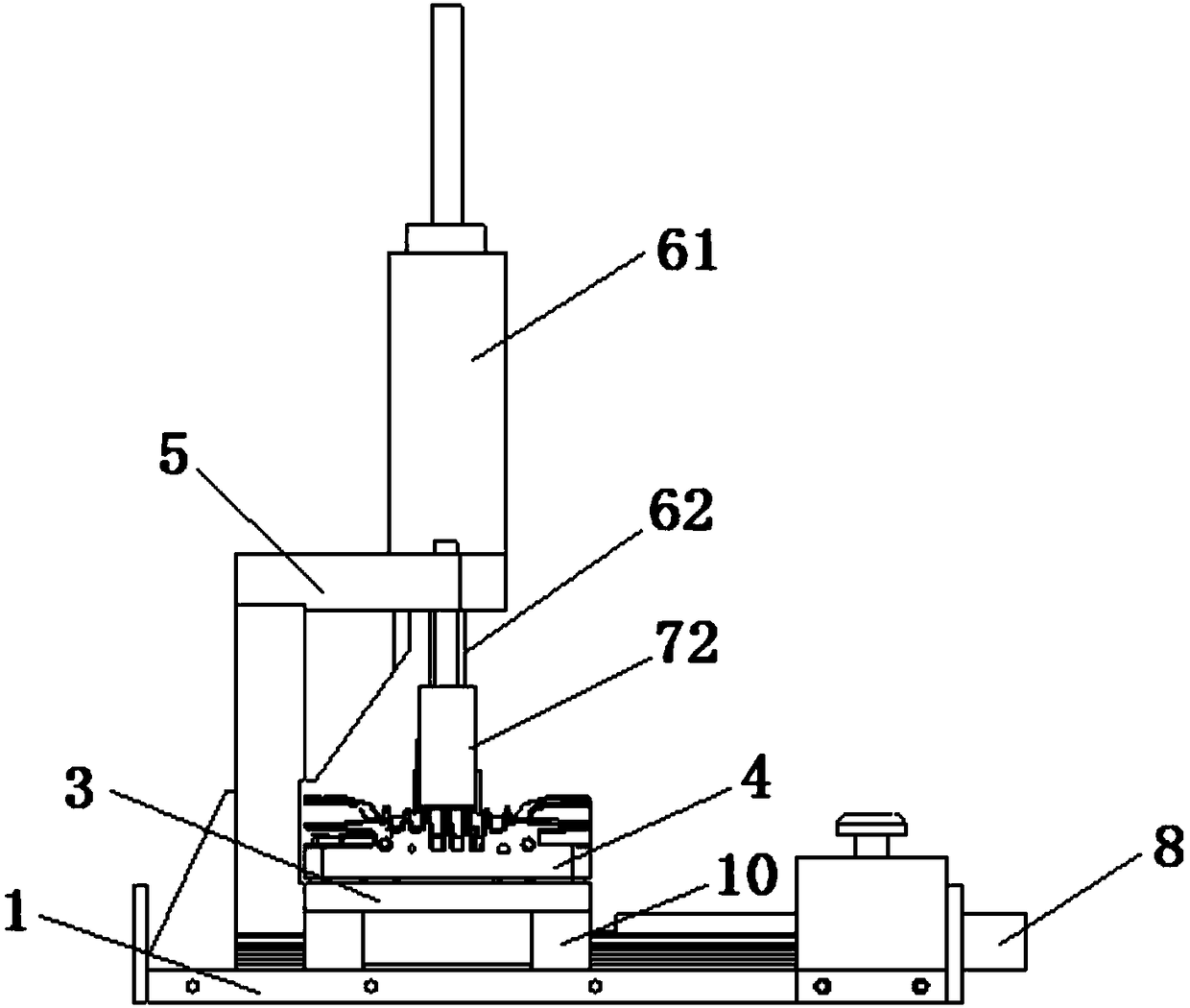

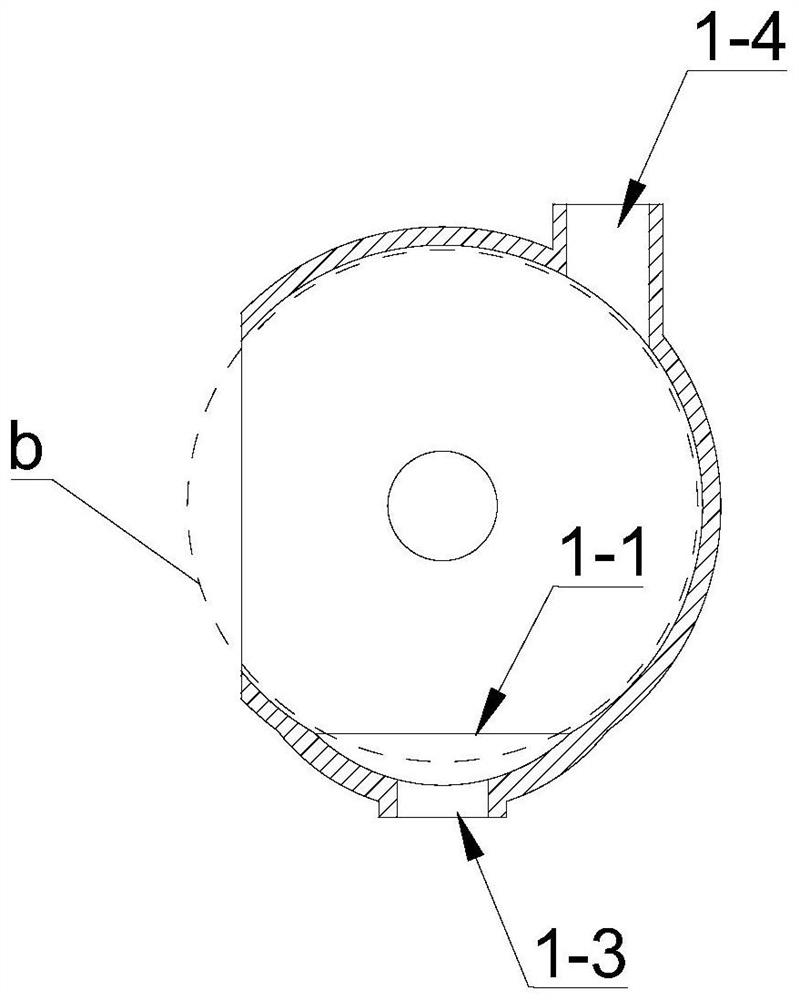

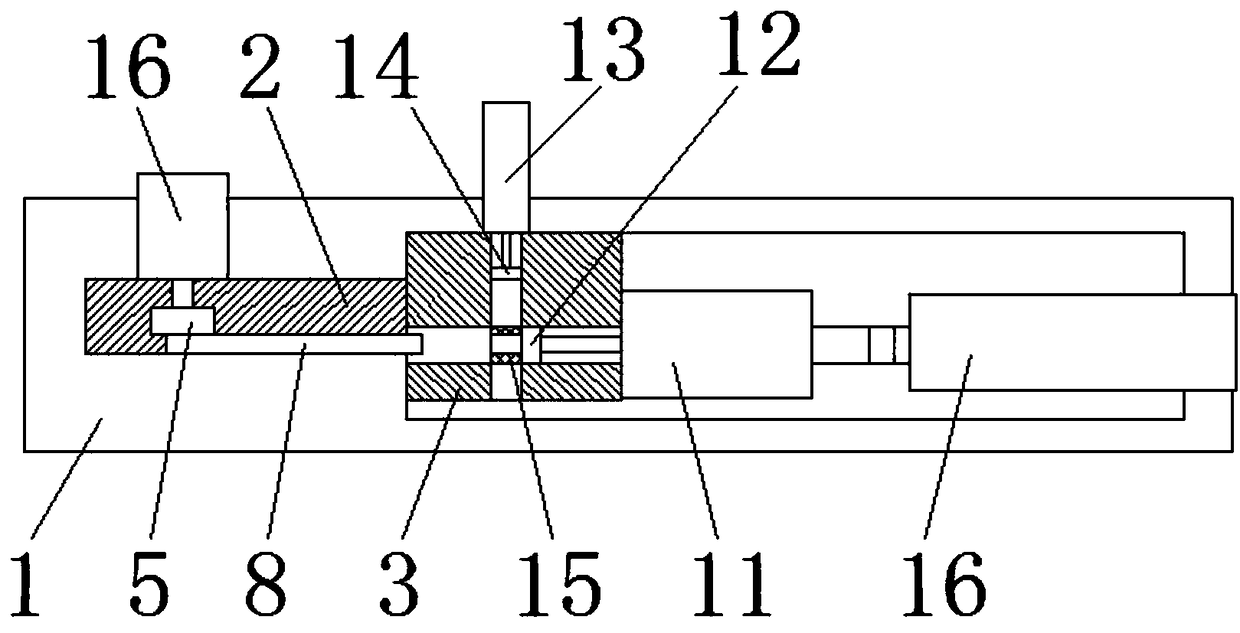

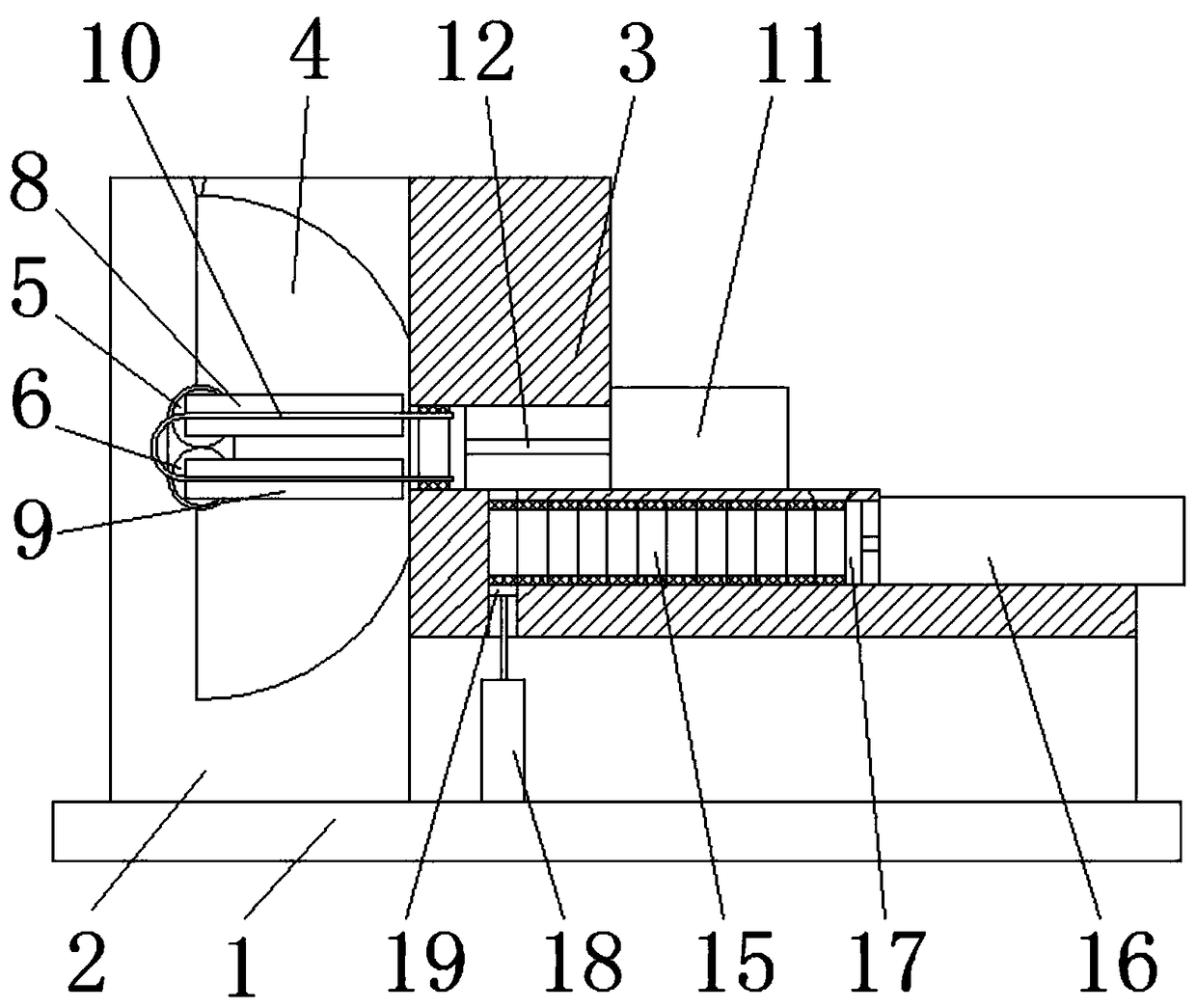

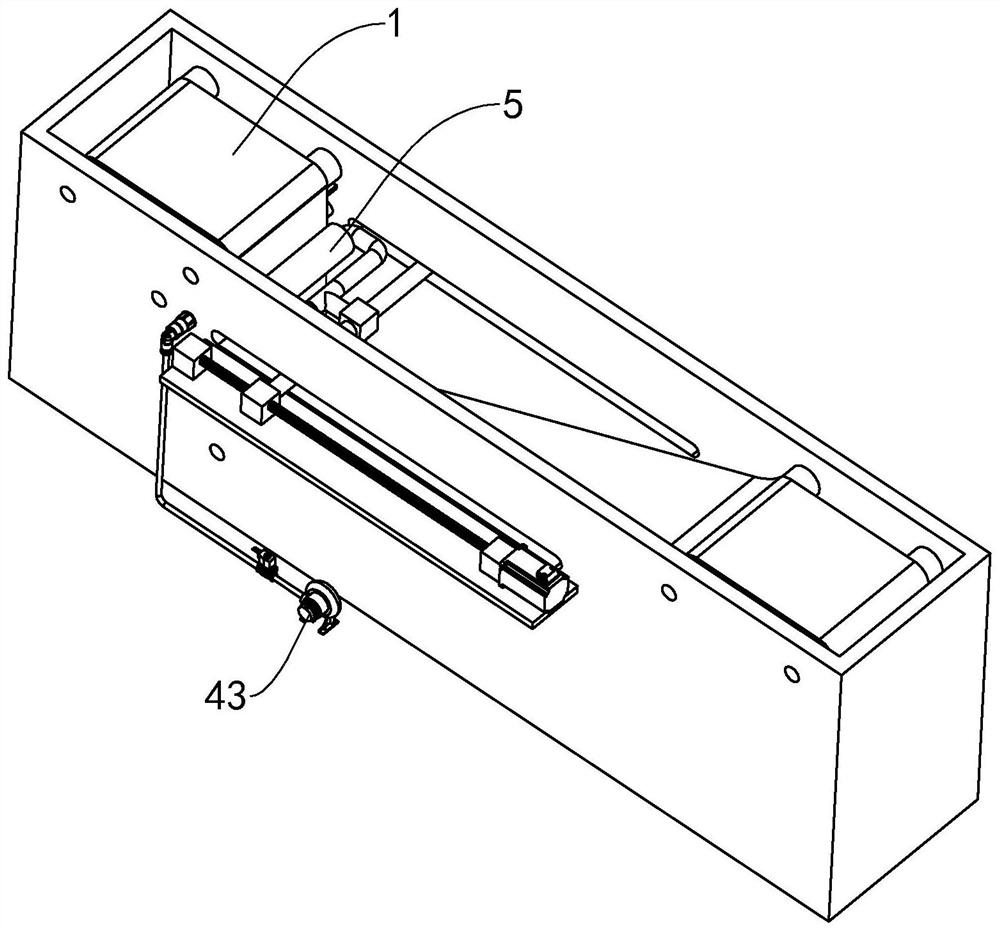

Cosmetic brush metal opening pipe pressing machine

PendingCN108907015AUniform expansion forceAvoid crackingShaping toolsBrushesEngineeringBrushed metal

The invention discloses a cosmetic brush metal opening pipe pressing machine. The cosmetic brush metal opening pipe pressing machine comprises a rack and further comprises an extrusion device and a heating device, wherein the extrusion device is arranged on the rack and used for extruding a metal opening pipe, and the heating device is connected with the extrusion device and used for heating the extrusion device to the preset temperature so as to trigger heat deformation of the metal opening pipe. According to the pipe pressing machine, the surface of the metal opening pipe is extruded by theextrusion device and subjected to heat transfer from the extrusion device, the expansion force exerted on the metal opening pipe is uniform, cracks are not likely to happen in the extrusion deformation process, accordingly, product attractiveness is not influenced, the production yield can be improved, the production cost can be reduced, and the resource is saved.

Owner:雅香丽化妆用品(深圳)有限公司

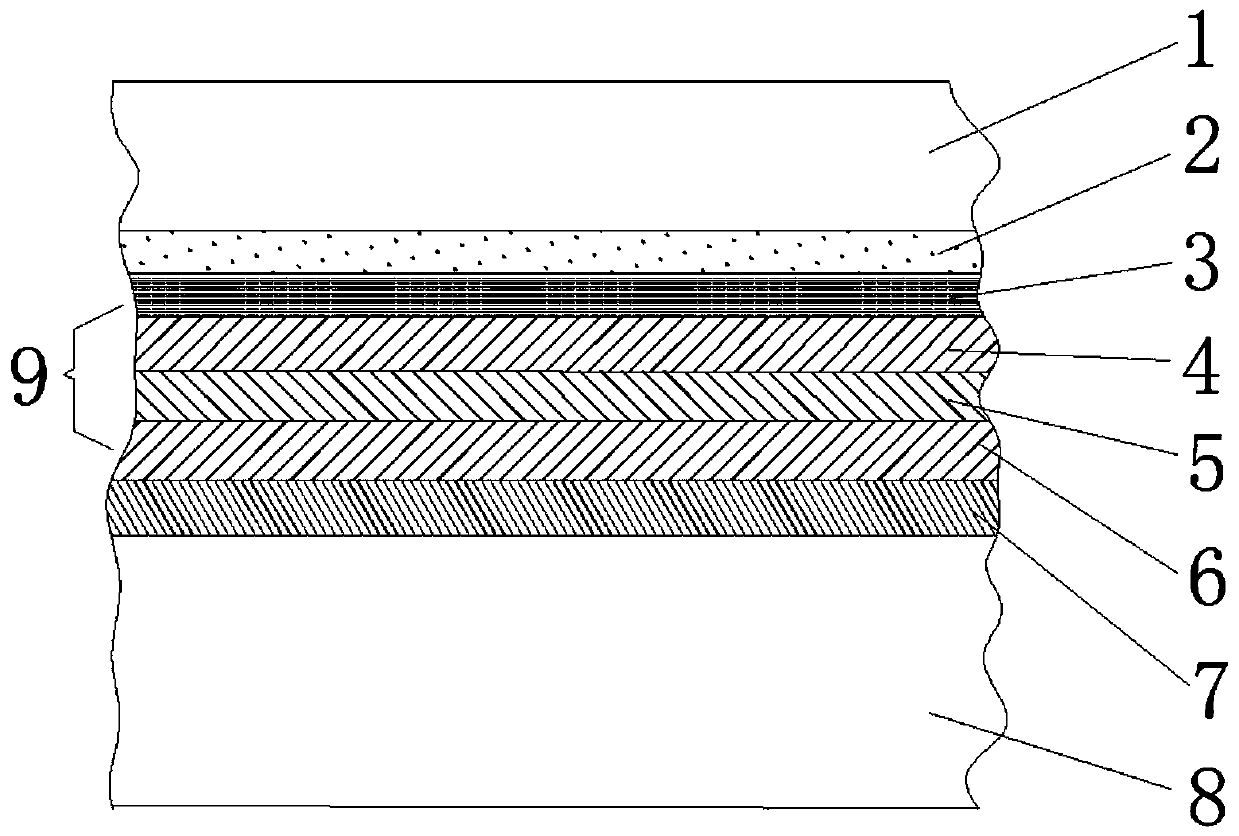

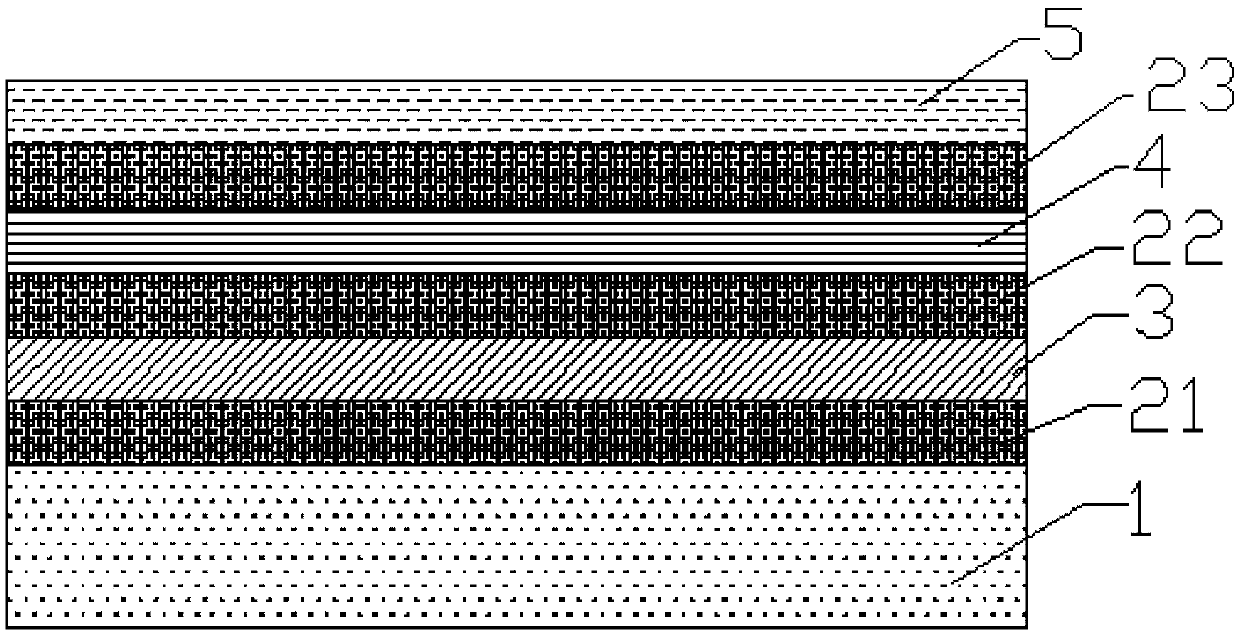

BOPET high-simulation metal wire drawing VCM film, use thereof, and VCM

ActiveCN103692725ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsBoPETCase hardening

The invention discloses a BOPET high-simulation metal wire drawing VCM film, a use thereof, and a VCM. The VCM film sequentially comprises a surface hardening coat, a transparent BOPET film with one surface subjected to surface wire drawing treatment, a fastness enhancing coat, a vacuum aluminum coat and an anti-oxidation protection coat; the surface hardening coat is an ultraviolet-curable polyurethane coating layer; the fastness enhancing coat is a polyurethane coating layer, and the above polyurethane coating is a primer with the model of SC-400 before aluminizing; and the anti-oxidation protection coat is a polyurethane coating layer, and the above polyurethane coating a top coating with the model of SC-500. The VCM film adopts single-layer BOPET as a film main material, so the consumption of a raw film is reduced, the production and making cost is saved, the life of a product is prolonged, and the tolerances of various bad conditions are improved. The VCM film has a best visual sense effect of a simulation metal wire drawing plate, and truly realizes the high simulation purpose of wire drawing metal plates of different materials.

Owner:SHANGHAI RADIX VACUUM METALIZING

Production process of plastic panel with effects of brushed metal and electroplating process

The invention discloses a production process of a plastic panel with effects of brushed metal and an electroplating process. The production process comprises the steps of producing a mould; carrying out wire drawing line treatment on the inner cavity of the mould; producing a panel according to the mould; and carrying out surface treatment on the mould, so that the surface of the mould has a surface layer with luster of electroplated metal. The plastic panel produced by the process not only has texture of brushed metal and luster of electroplated metal, but also has insulation and electrical resistance; besides, the plastic panel has the characteristics of low cost, high safety and good decorative effect.

Owner:朱德洪

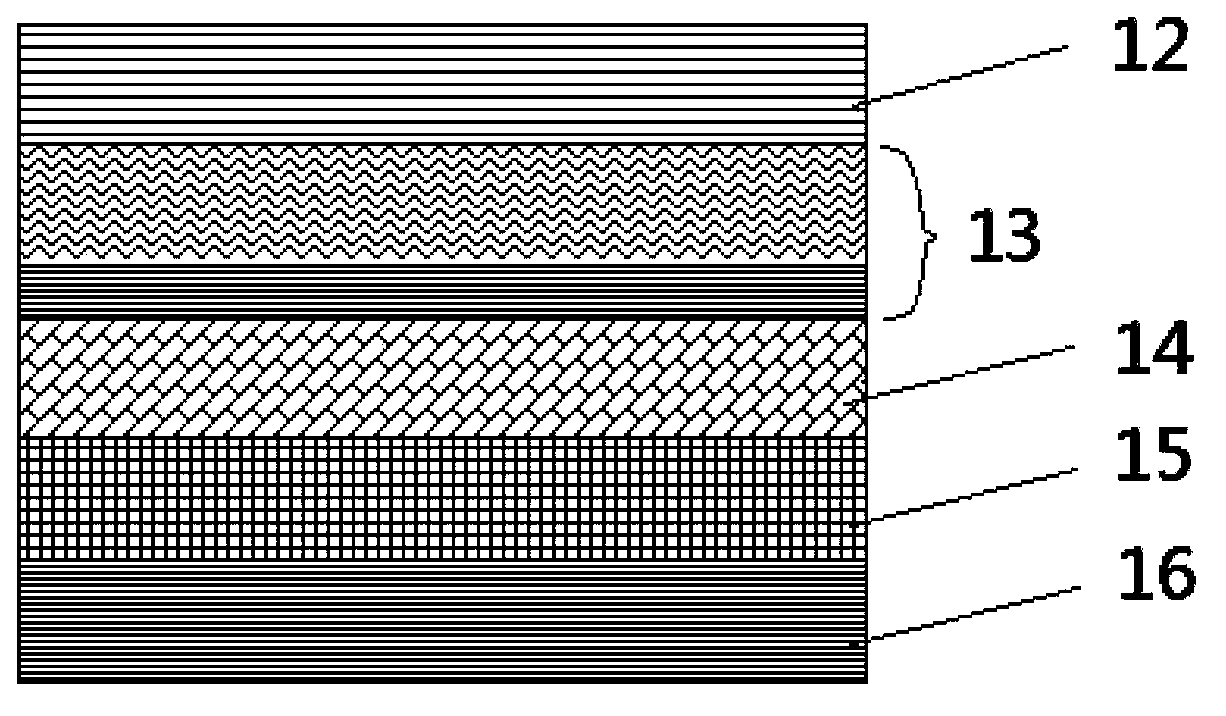

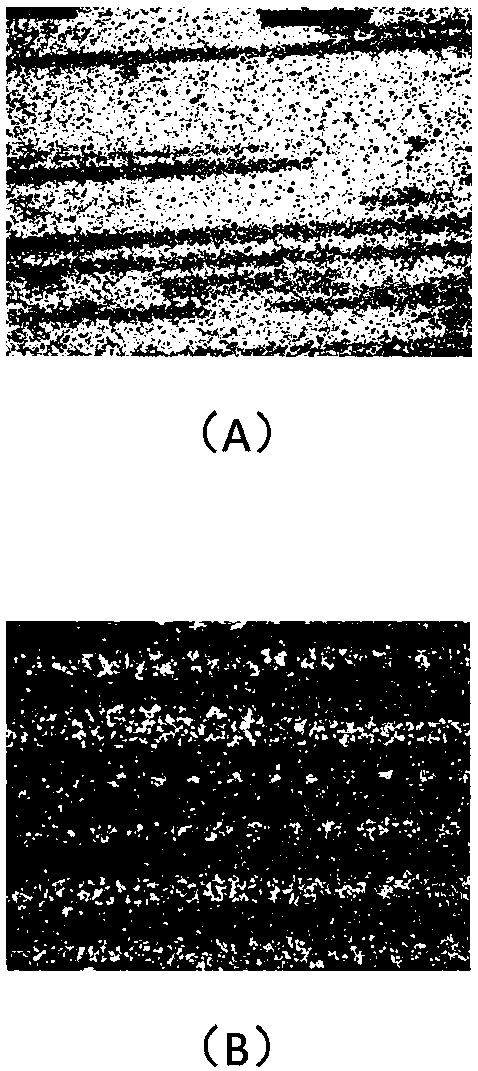

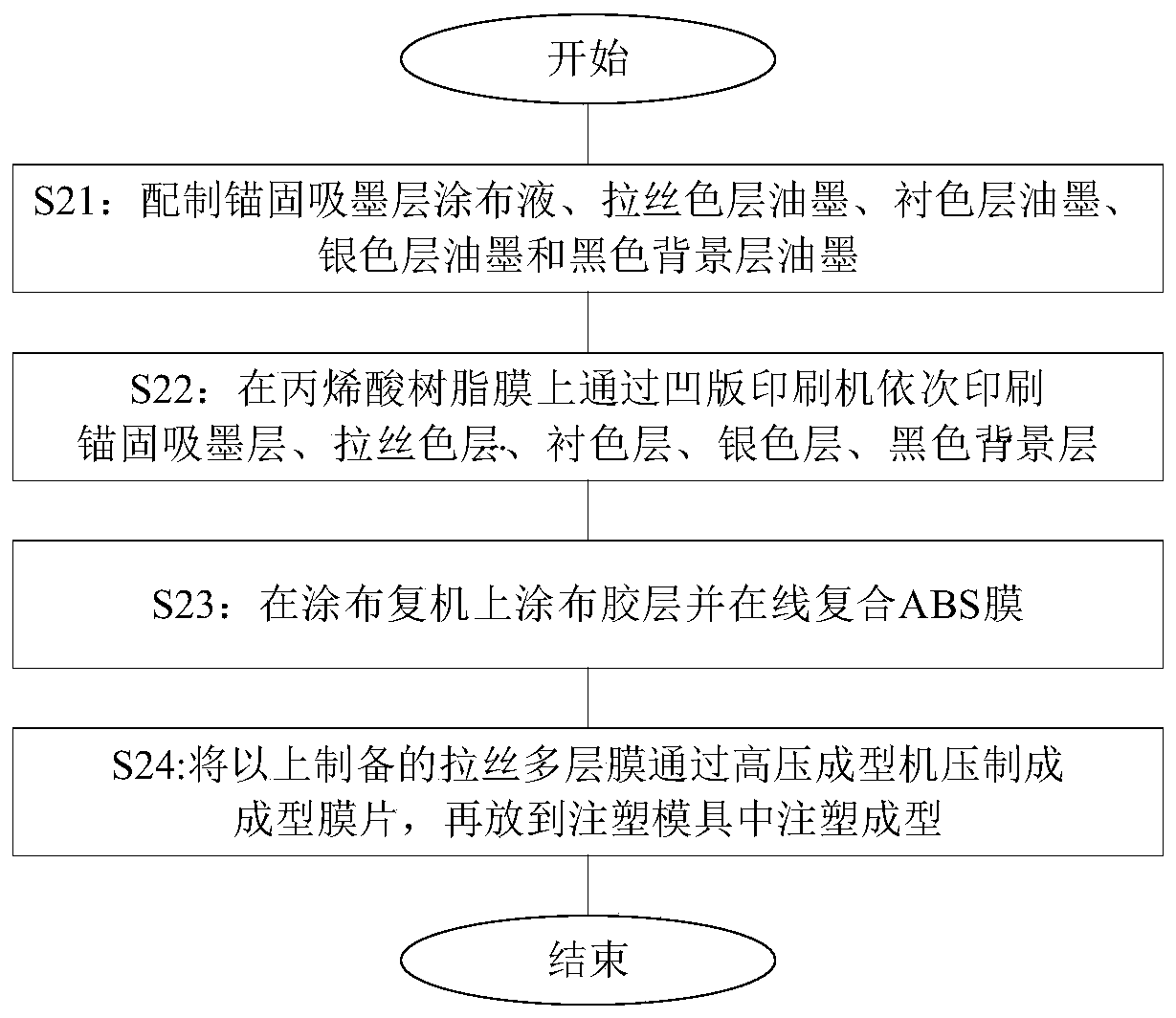

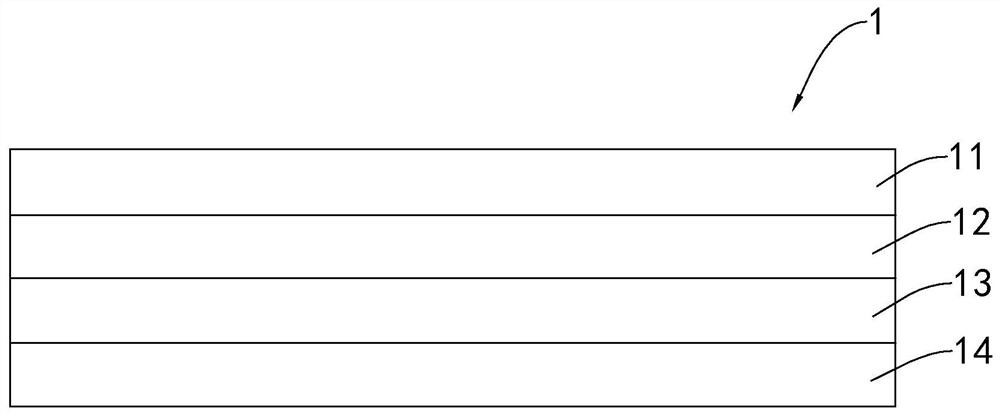

Multilayer film with brushed metal effect layer

ActiveCN110126409AImprove transfer abilityGuaranteed to be clear and beautifulLamination ancillary operationsSynthetic resin layered productsAcrylic resinHome appliance

The invention disclose a multilayer film. The multilayer film comprises an acrylic resin film, an anchoring and ink-absorbing layer, a brushed metal color layer, a contrast color layer, a silver layer, a black background layer, a rubber layer and an ABS film which are sequentially laminated together. The multilayer film has the brushed metal effect, has excellent resistance and moldability, and can be applied to the surface decoration of high-grade plastic parts such as automobile interiors, home appliances and 3C product casings.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

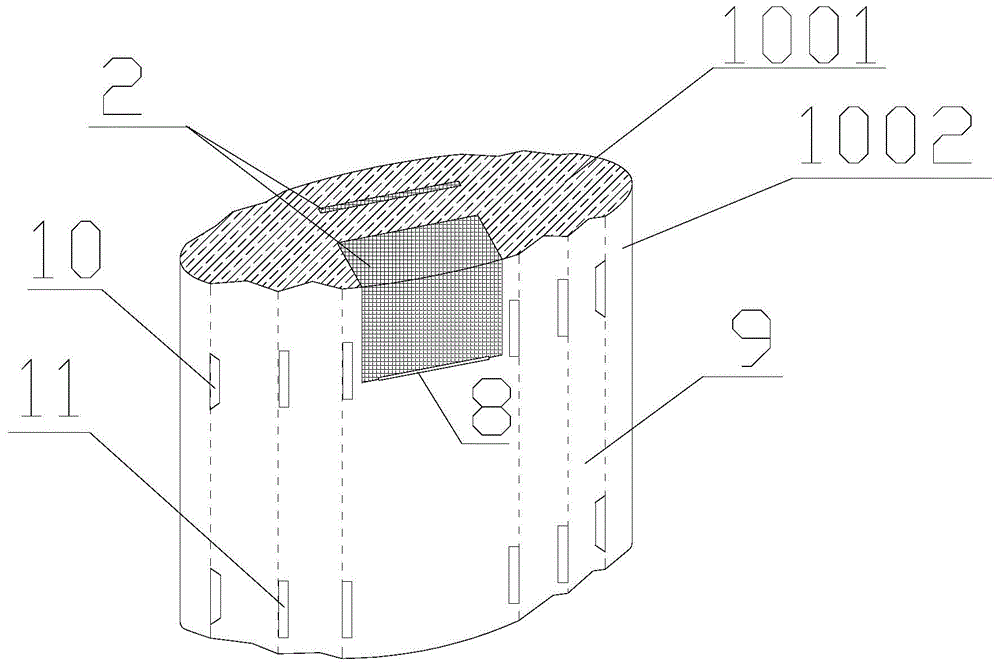

Foldable cigarette box with imitating brushed metal used for anti-counterfeiting

InactiveCN104528196AFlexibleEasy accessContainers for flexible articlesPackaging cigaretteEngineeringBrushed metal

The invention provides a foldable cigarette box with imitating brushed metal used for anti-counterfeiting. The foldable cigarette box comprises a box body cover, a box body wall, a flap cover, an anti-counterfeiting coating, an opening, a square hole, a rotating shaft, a plastic inner body, an imitating brushed metal layer. The box body cover is oval-shaped. The box body cover and the box body wall constitute a whole box body. The imitating brushed metal layer is arranged on the box body in a gluing mode. The square hole is formed in the box body cover. The opening is formed in the joint of the box body cover and the box body wall. The rotating shaft is arranged at the opening of the box body wall. The flap cover which is connected to the box body wall through the rotating shaft comprises a first bending part and a second bending part, and the anti-counterfeiting coating is arranged on the flap cover. A folding part is disposed on the box body wall and is longitudinally provided with a plurality of cutting lines. Insert cards and card slots which are mutually matched are disposed on the cutting lines. The plastic inner body is arranged in the box body in a gluing mode. The foldable cigarette box has the advantages of having the anti-counterfeiting function, being foldable, saving space, and being attractive, non-slip, and convenient to use because cigarettes are easy to take out.

Owner:天津渤海化学股份有限公司

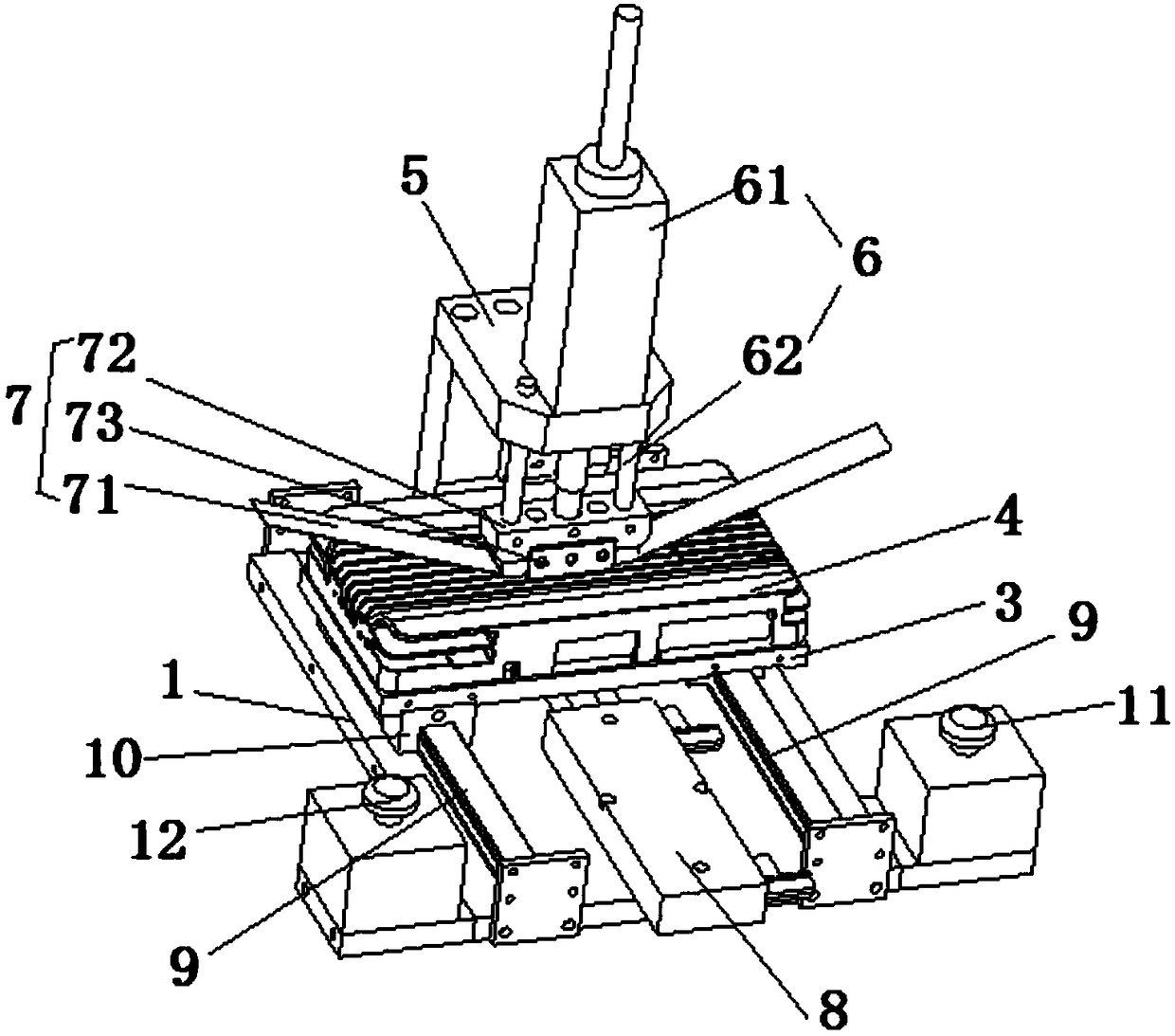

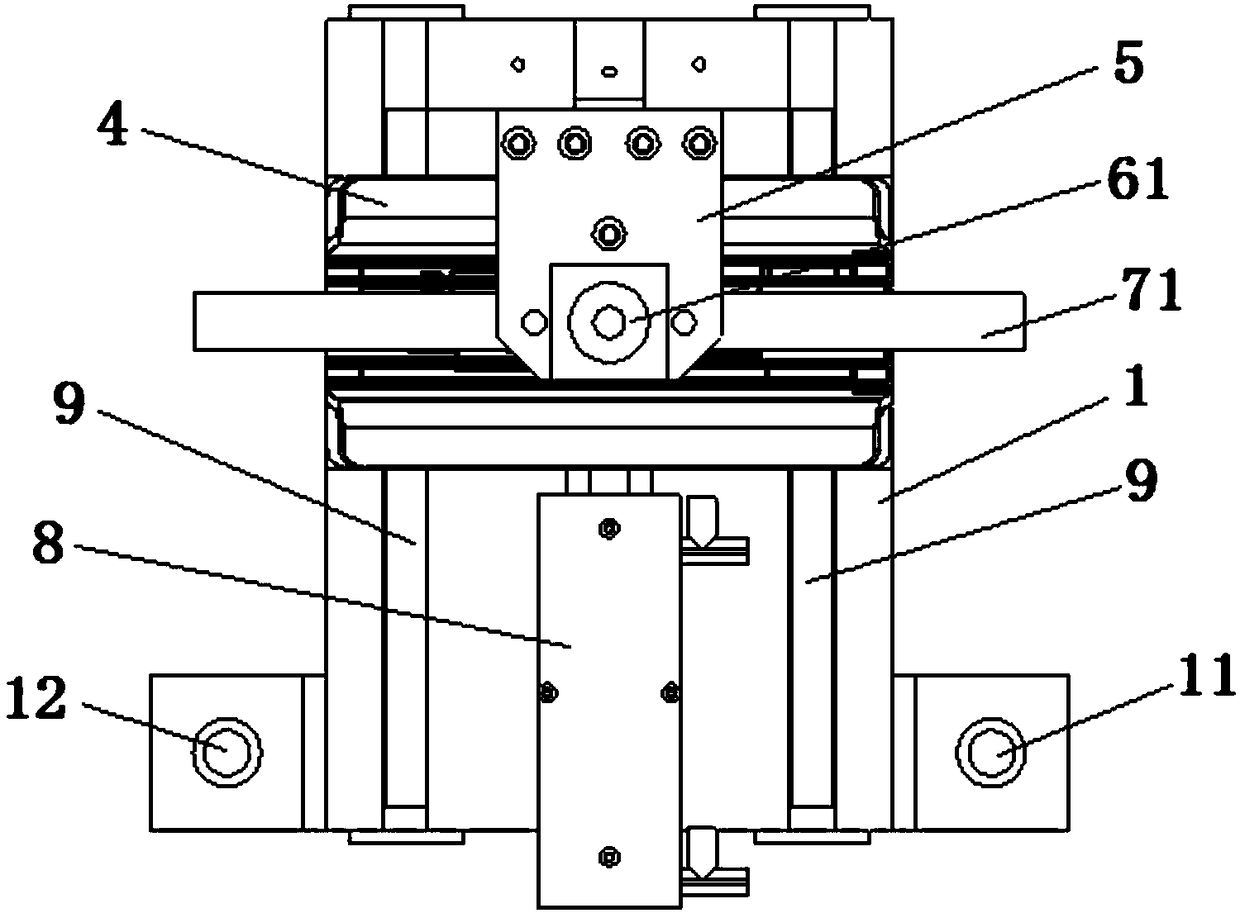

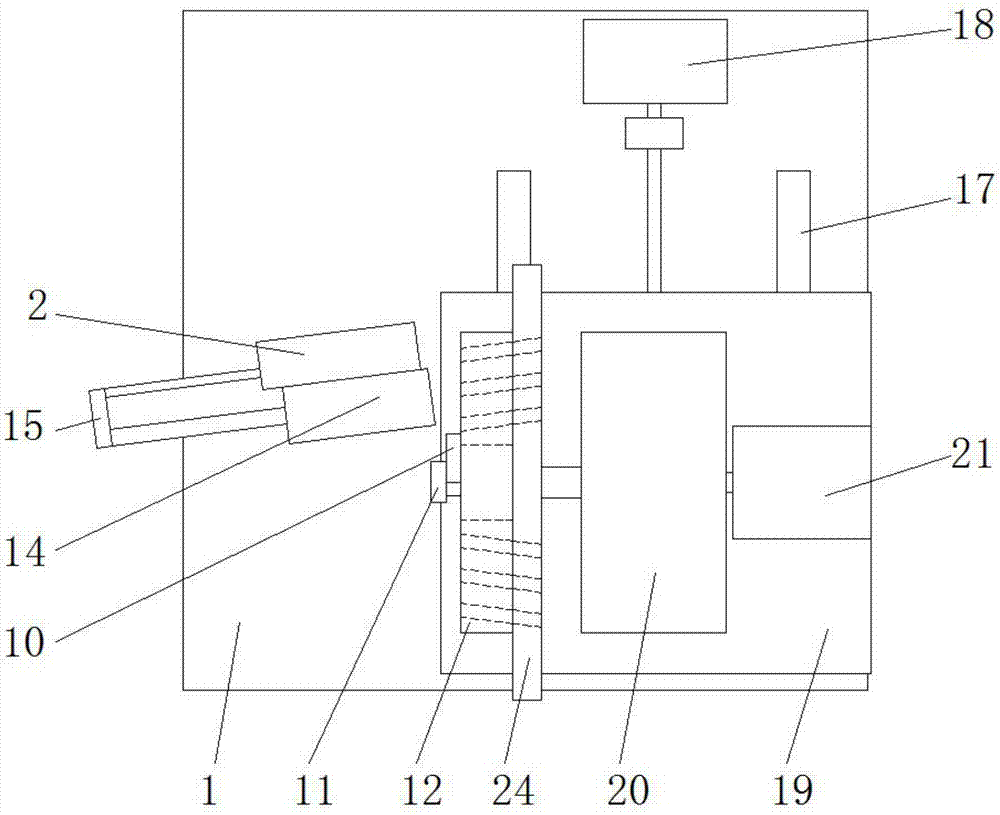

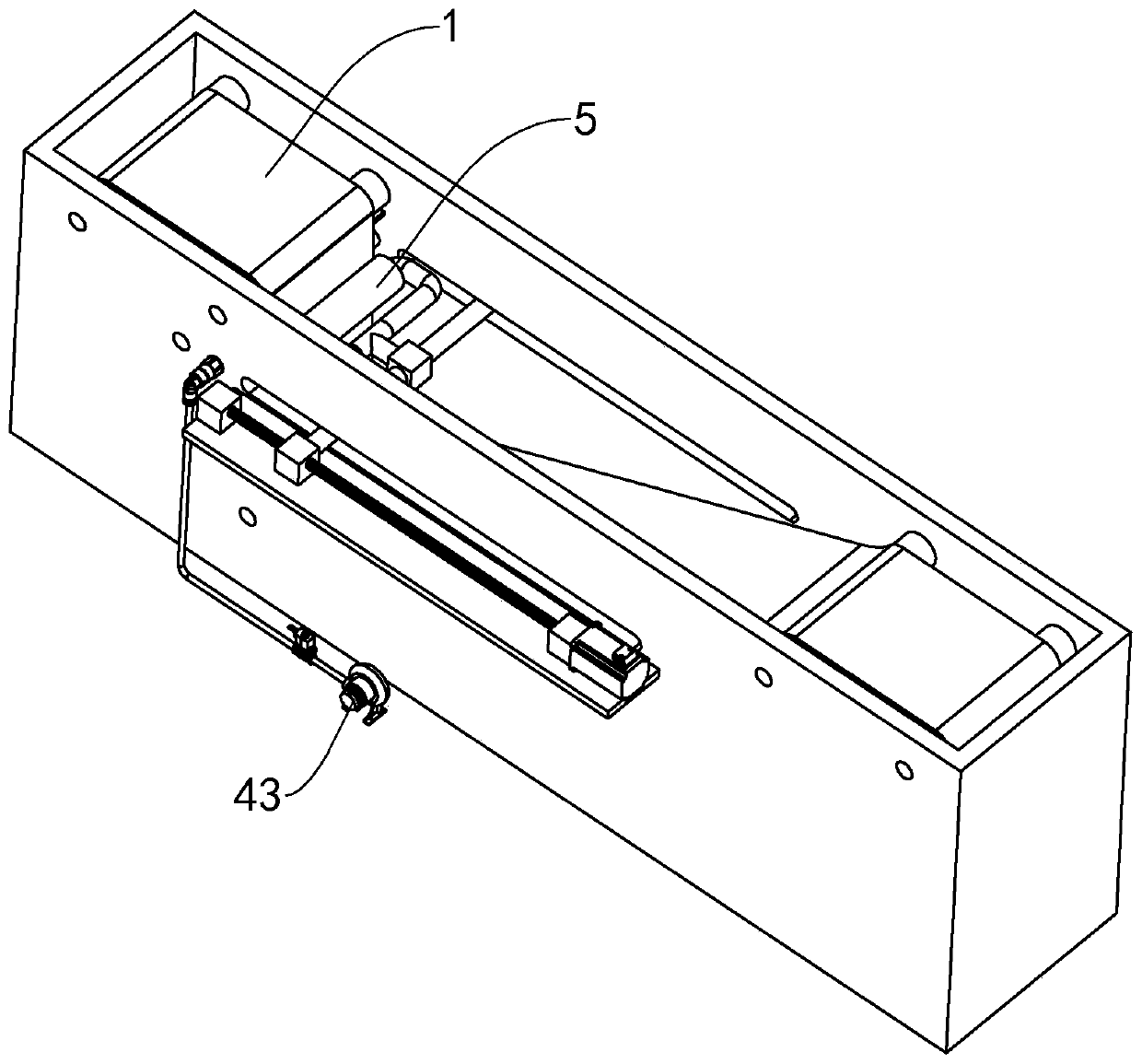

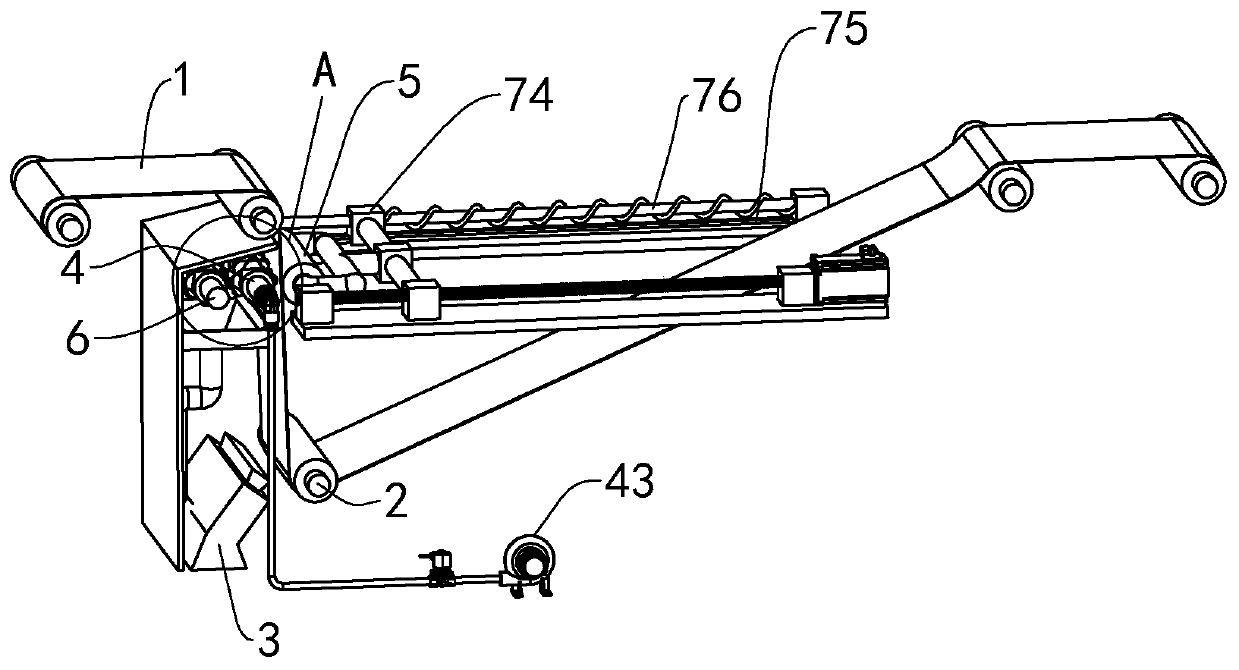

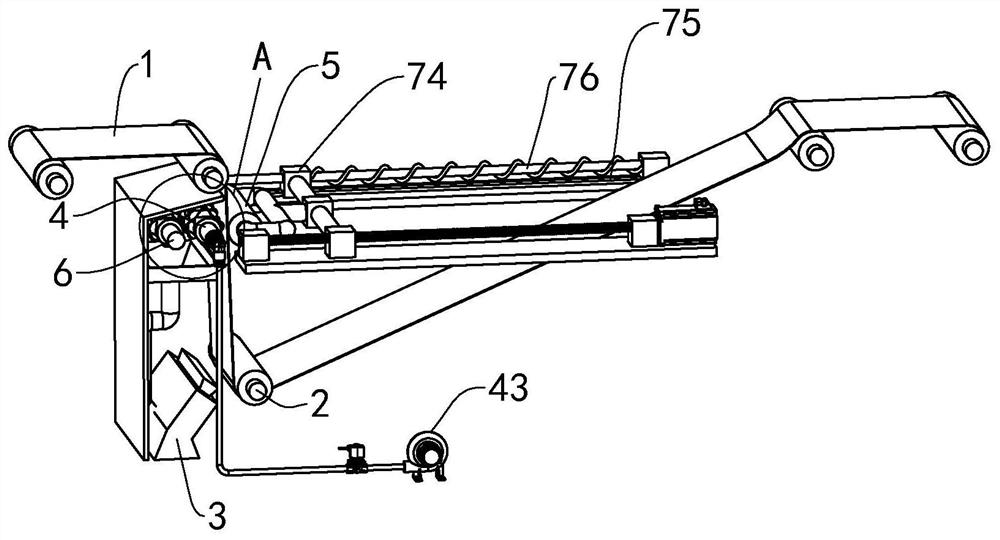

Automatic device achieving partial drawing of metal piece

PendingCN108161667ARealize partial drawingImprove work efficiencyBelt grinding machinesGrinding work supportsVertical planeEngineering

The invention discloses an automatic device achieving partial drawing of a metal piece. The automatic device achieving partial drawing of the metal piece comprises a base and a control device. The base is provided with a positioning platform face which can horizontally move. The positioning platform face is provided with a positioning mechanism which is matched with the metal piece to be subjectedto drawing. The base is vertically provided with a support. The top end of the support is provided with a lifting mechanism, and the lifting mechanism is connected with a drawing mechanism. The drawing mechanism comprises an abrasive belt which can rotate in a vertical plane. The polishing face of the abrasive belt is parallel to the drawn part of the metal piece to be subjected to drawing. The upper end face of the abrasive belt is provided with a drawing press block. The drawing press block is connected with a lifting mechanism, and the side face of the drawing press block is provided withan abrasive belt check block. The control device is electrically connected with the positioning platform face and the lifting mechanism. By means of the automatic device achieving partial drawing of the metal piece, partial drawing of a product can be automatically achieved, the working efficiency is high, the machining stability is good, the precision is high, the product percent of pass is high,and the application and popularization value is achieved.

Owner:SHANGHAI WUTENG METAL PROD CO LTD

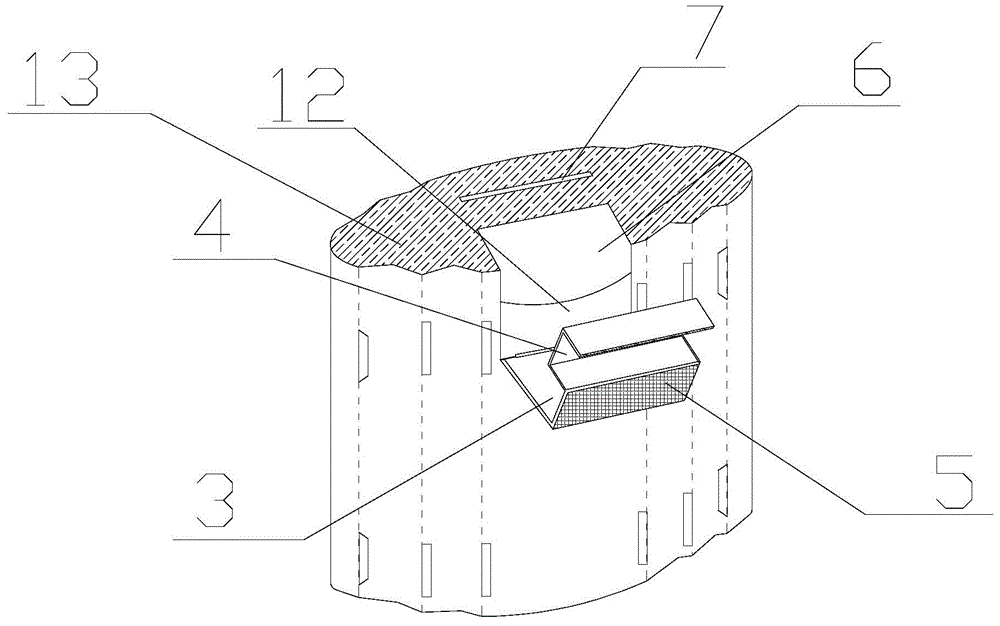

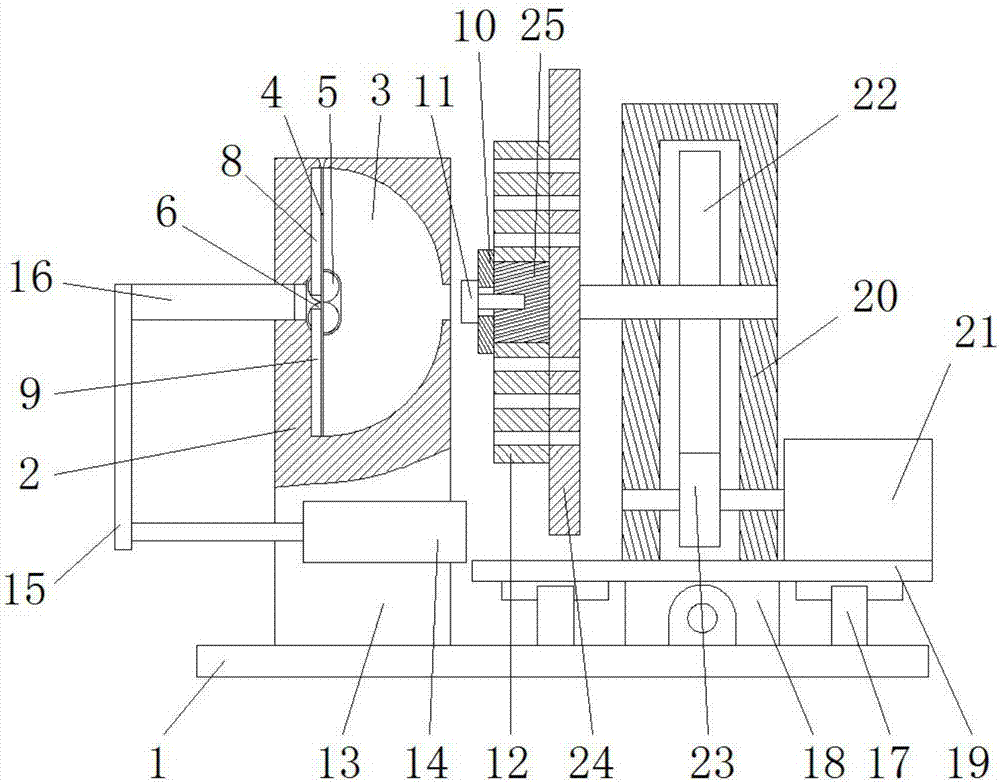

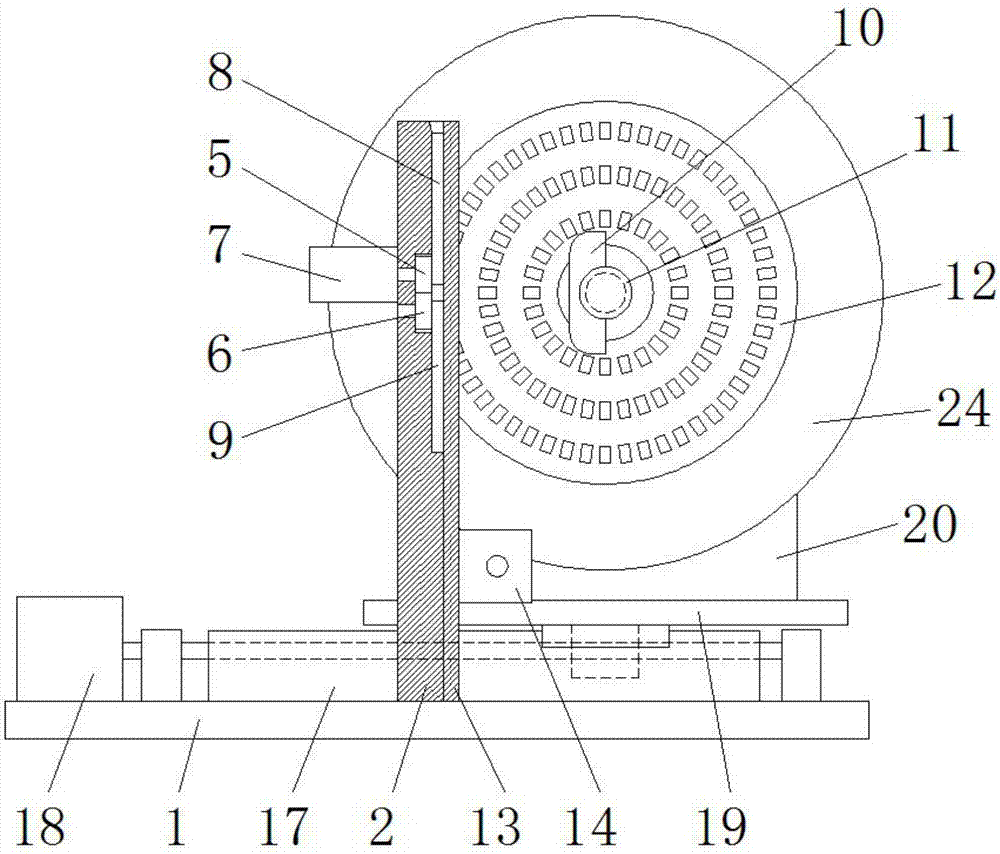

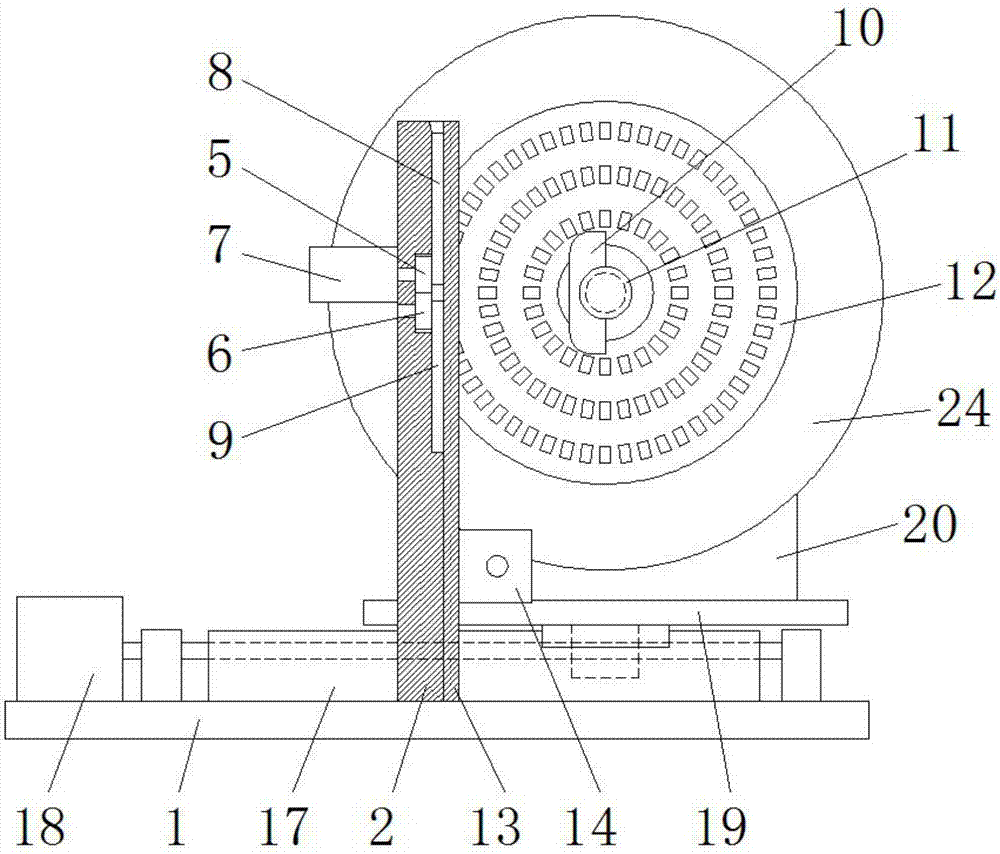

Straight hole disc brush metal brush wire cuttage device

The invention discloses a straight hole disc brush metal brush wire cuttage device. The device comprises a base, a bending device and a locating device, wherein the bending device comprises a supporting plate, a semi-circular bending arm groove is formed in the side surface of the supporting plate, a gear groove is formed in the center of the bending arm groove, the gear groove is internally provided with an upper bending gear and a lower bending gear, an upper bending arm and a lower bending arm are fixedly connected to the upper bending gear and the lower bending gear respectively, the locating device comprises a guide rail, a locating motor, and a mobile base plate, wherein the mobile base plate is fixedly provided with a support and a scale division motor, the support is internally provided with a scale division large gear and a scale division small gear, and a scale division disc is fixedly connected to the a rotary shaft of the scale division large gear. In the straight hole disc brush metal brush wire cuttage device, by using the bending device to automatically bend a metal brush wire, both the time and labor are saved, the working efficiency is high, when the metal brush wire is bended, the symmetry is good, through the adoption of an automatic cuttage mode, the labor cost is greatly saved, the specifications of the finished product are good in uniformity, and thus the straight hole disc brush metal brush wire cuttage device has high application and popularization value.

Owner:安徽长中刷业有限公司

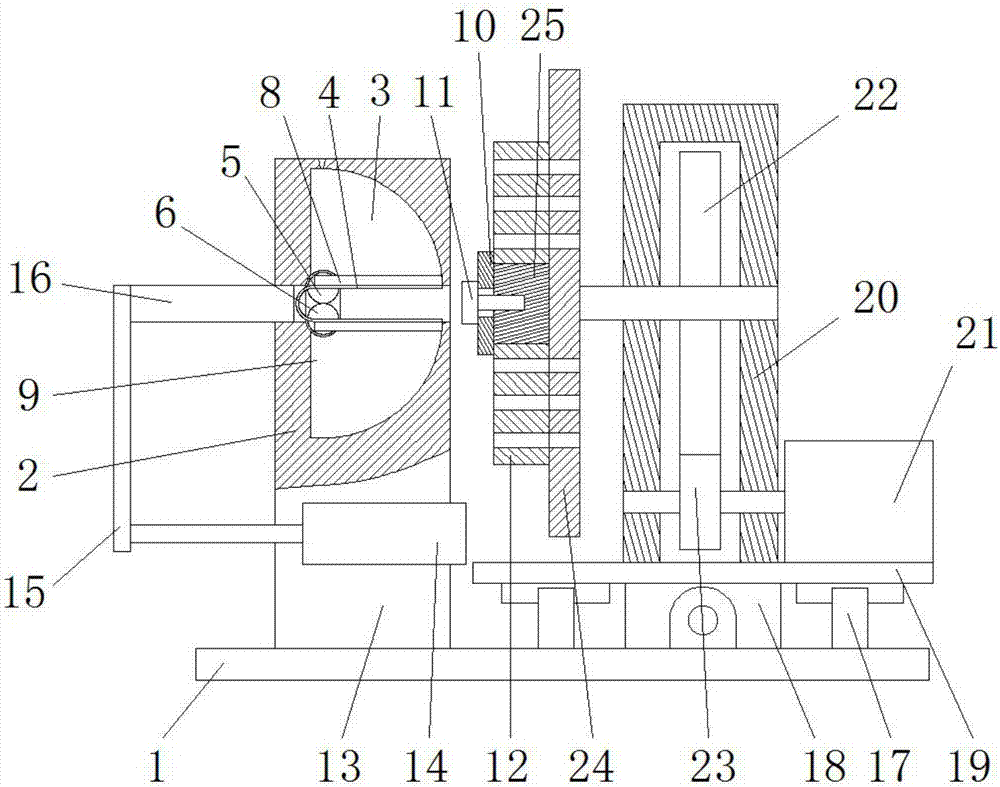

Inclined hole tray brush metal brush wire cutting device

The invention discloses an inclined hole tray brush metal brush wire cutting device. The device comprises a base, a bending device and a positioning device, wherein the bending device comprises a support plate, a semicircular bending arm groove is formed in the side face of the support plate, and a gear groove is formed in the center of the bending arm groove; an upper bending gear and a lower bending gear are arranged in the gear groove, an upper bending arm and a lower bending arm are fixedly connected to the upper bending gear and the lower bending gear respectively, and the positioning device comprises guide rails, a positioning motor and a movable baseplate; a support and an indexing motor are fixedly arranged on the movable baseplate, a large indexing gear and a small indexing gear are arranged in the support, and a rotation shaft of the large indexing gear is fixedly connected with an index plate. According to the inclined hole tray brush metal brush wire cutting device, metal brush wires are bent automatically by using the bending device, and the device saves time and effort, and is higher in working efficiency and better in symmetry of metal brush wire bending; by using an automatic cutting mode, the labor cost is greatly saved, the uniformity of the trimmed size is better, and the device has good application and popularization value.

Owner:安徽长中刷业有限公司

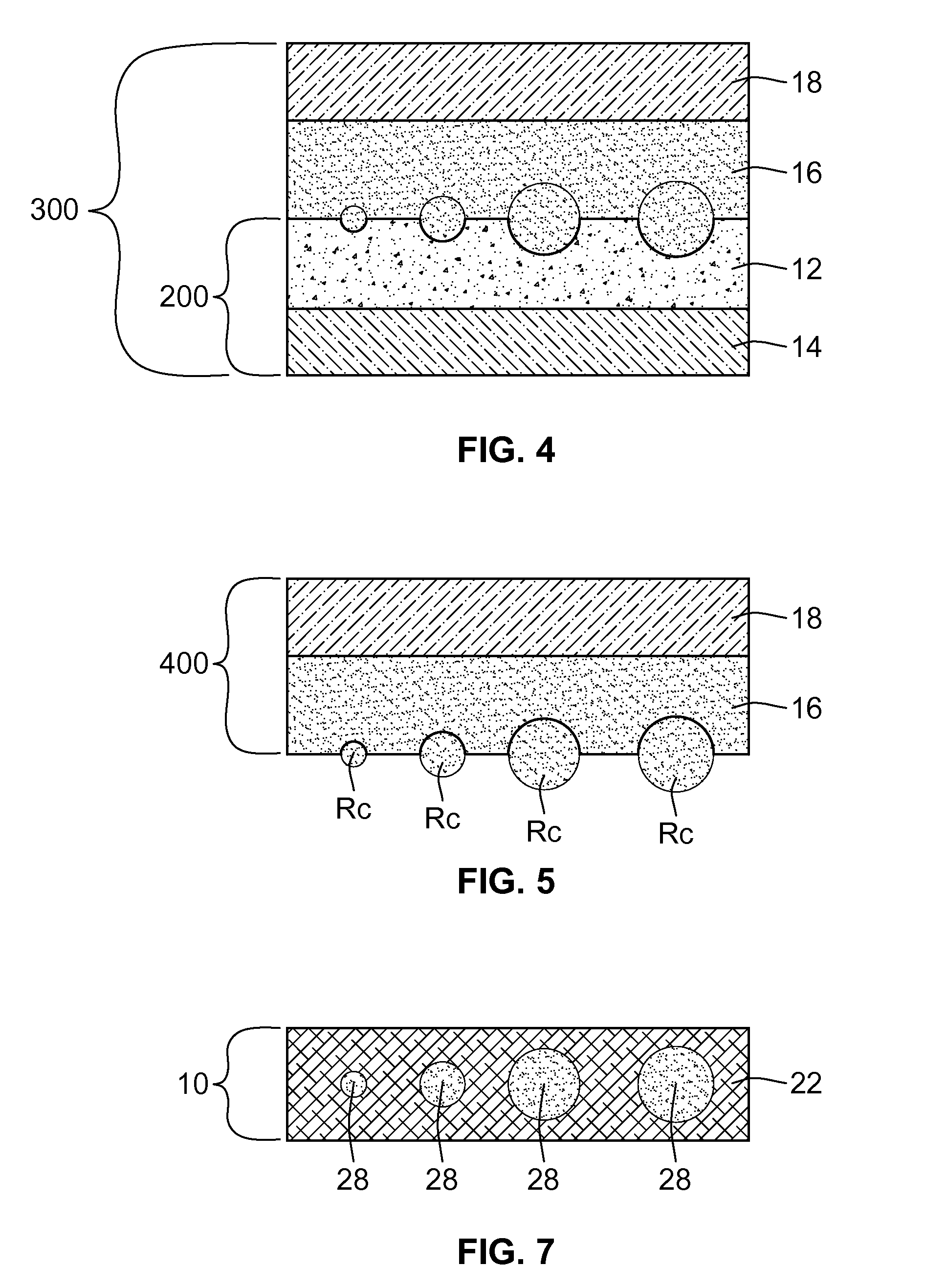

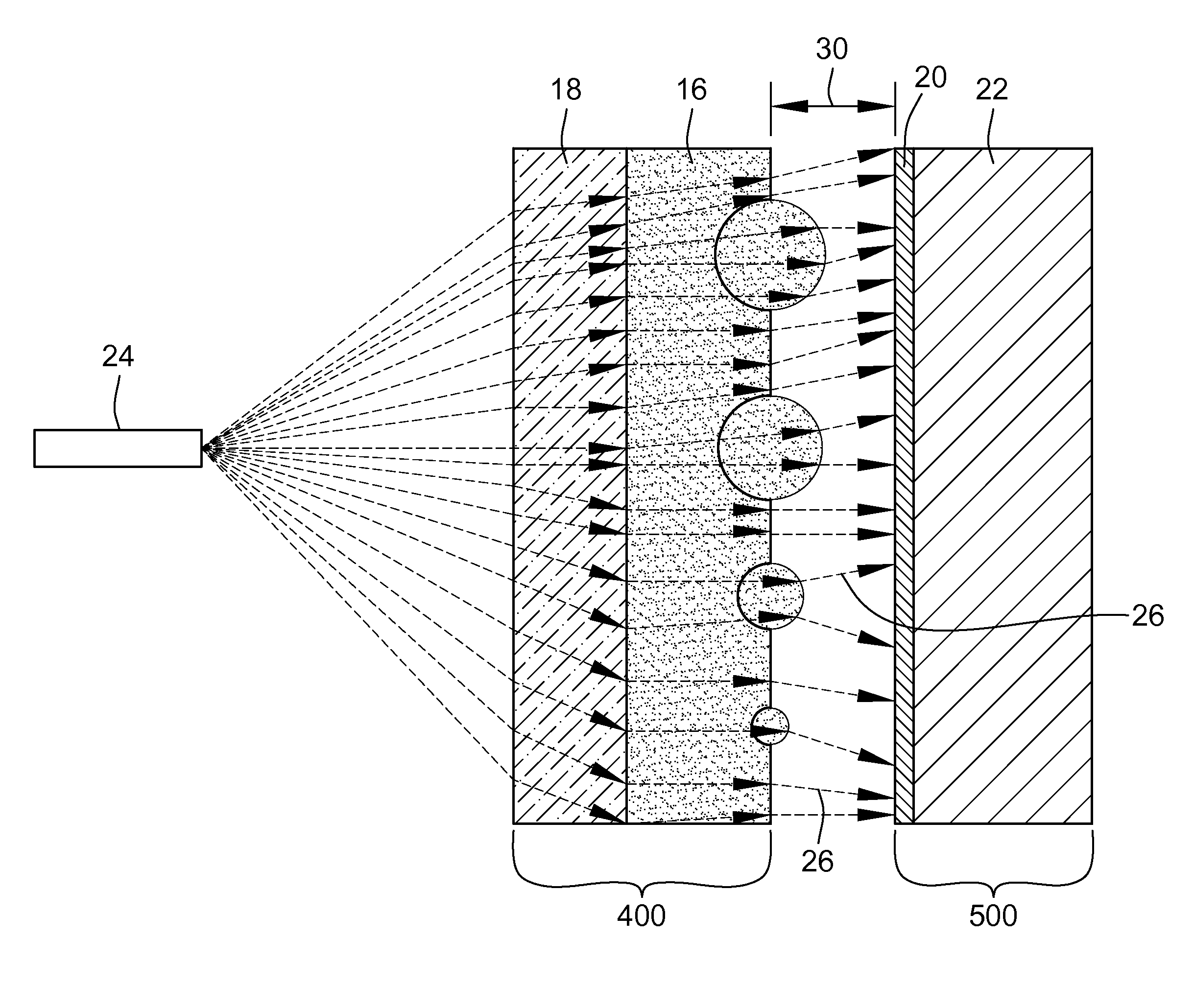

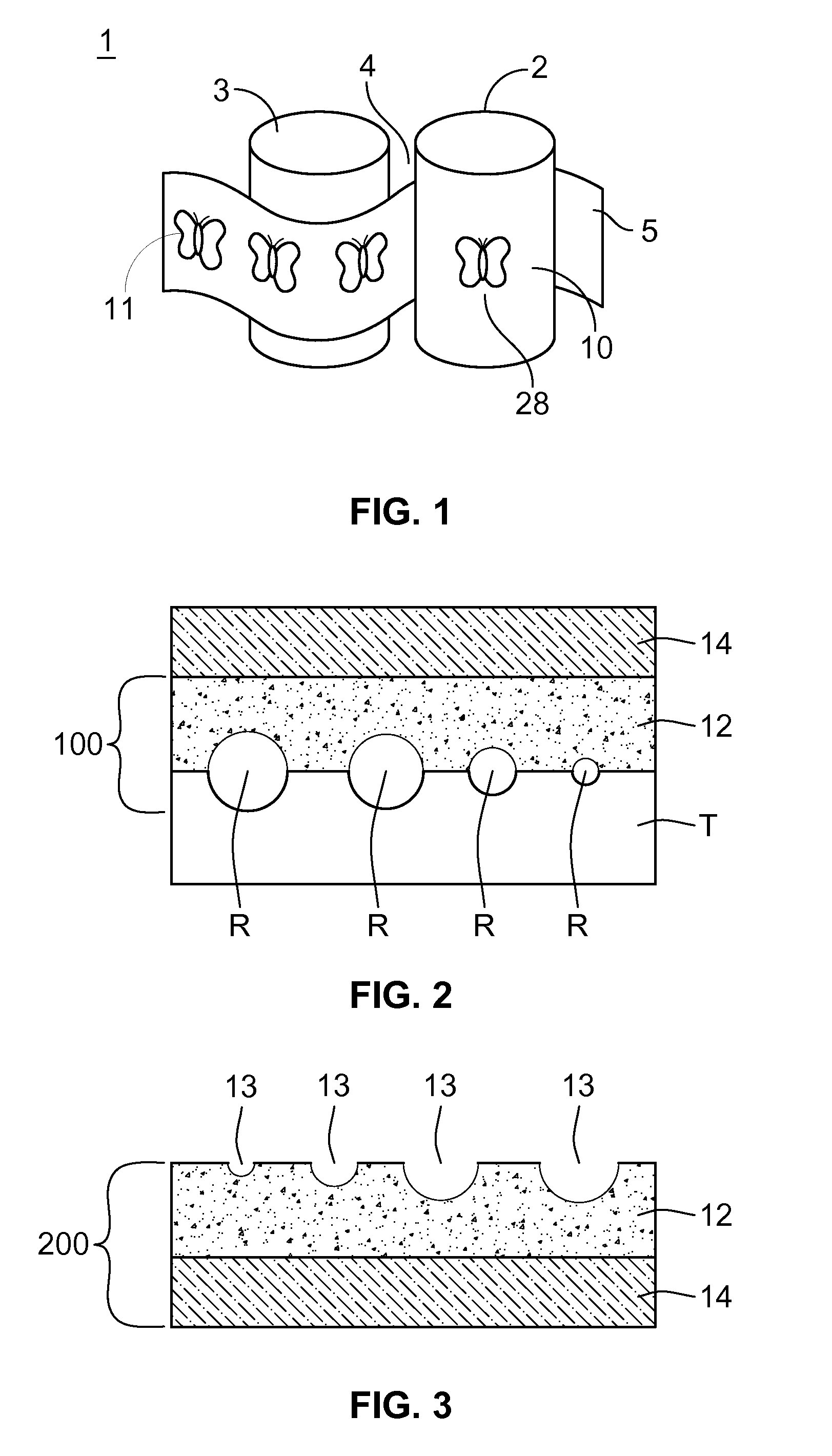

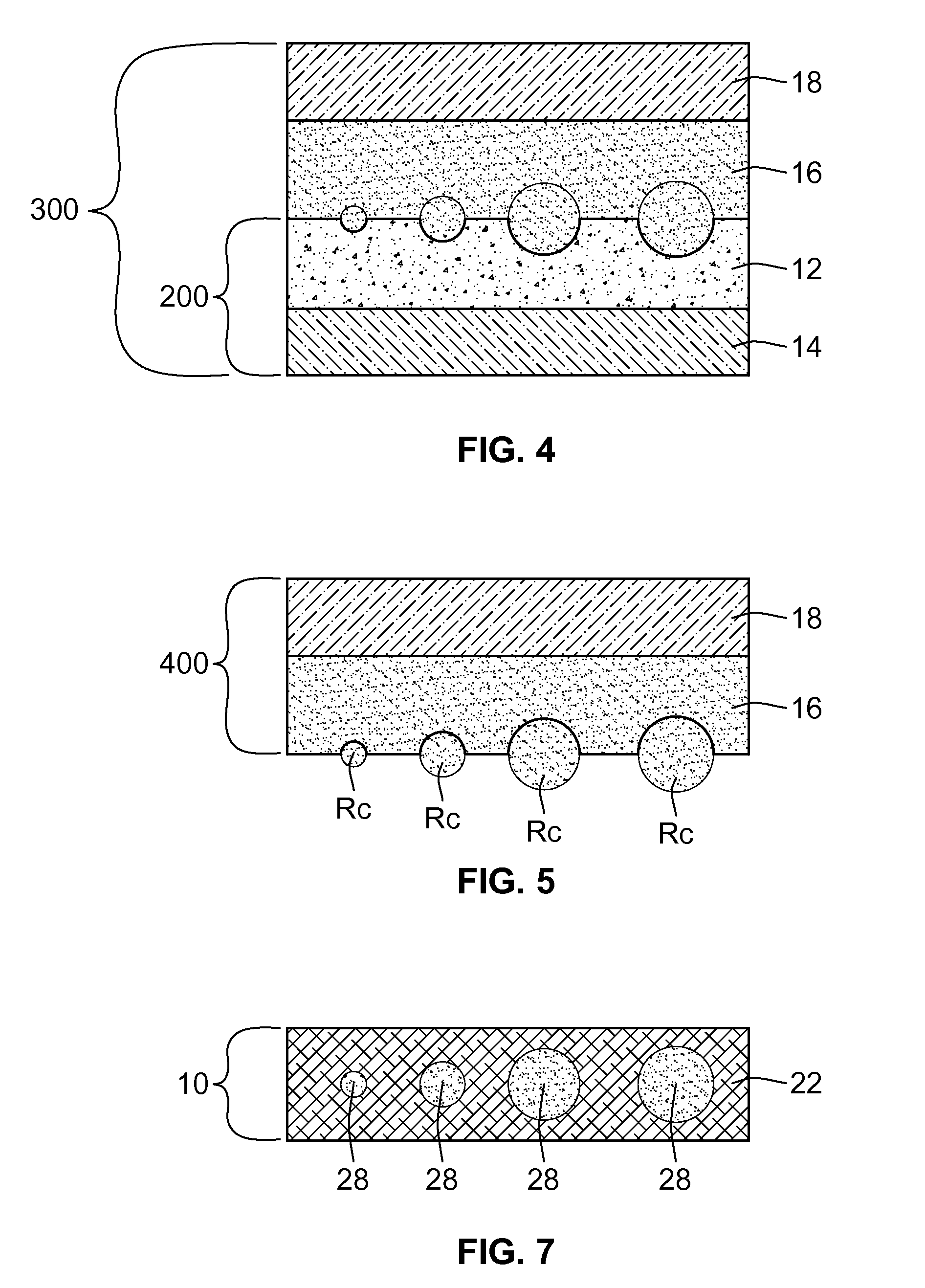

Imaging of deep structures of reliefs for shallow relief embossing

A variety of deep structured decorative patterns originate with mechanical relief or etching. The present method incorporates a deeply patterned or textured etching or relief into a thin film embossing shim to simulate the look of the deep pattern or texture when used to emboss thin film or material. A transparent mold of the relief surface (such as brushed metal, engine-turned patterns, and textured glass) is formed using UV curable liquid and a transparent substrate. The relief copy in the transparent mold or overlay is mapped onto a photoresist surface or plate by shining or expanding one or more laser lights or laser beams through the transparent mold. The different heights of the relief copy of the transparent mold will cause the light to diffract / refract to form a corresponding patterned etching in the photoresist plate. The resulting photoresist plate is then metalized and electroplated to form a thin film embossing shim. The thin film embossing shim is then used with conventional embossing equipment to form thin film embossings. The embossed thin films can then be metalized and laminated onto substrate to create a product that has shifting patterns that reflect at a variety of viewing angles when (observed under normal lighting conditions) exposed to white light.

Owner:ILLINOIS TOOL WORKS INC

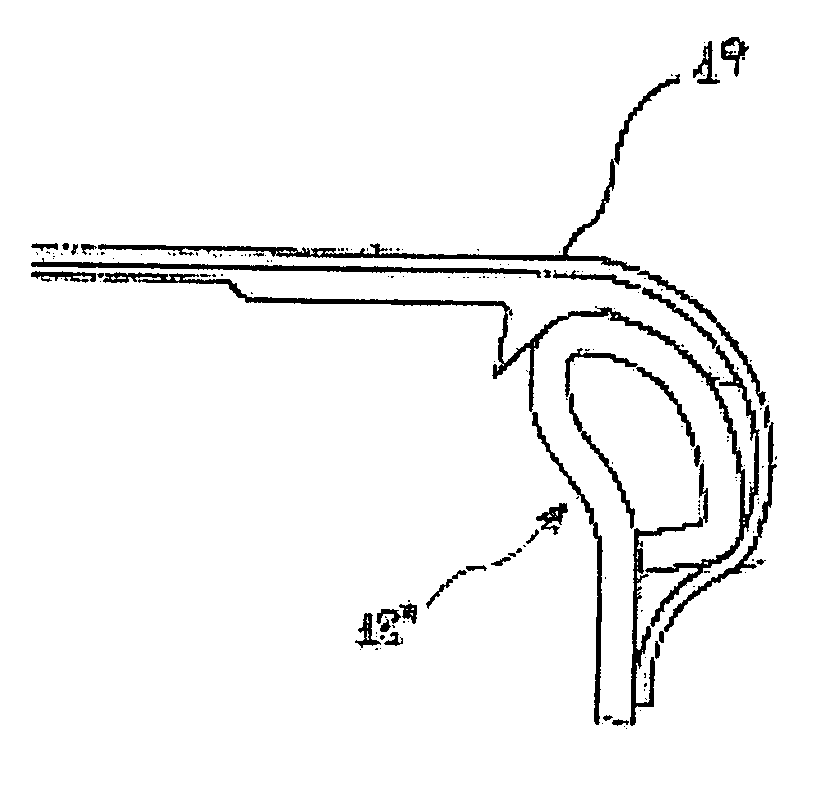

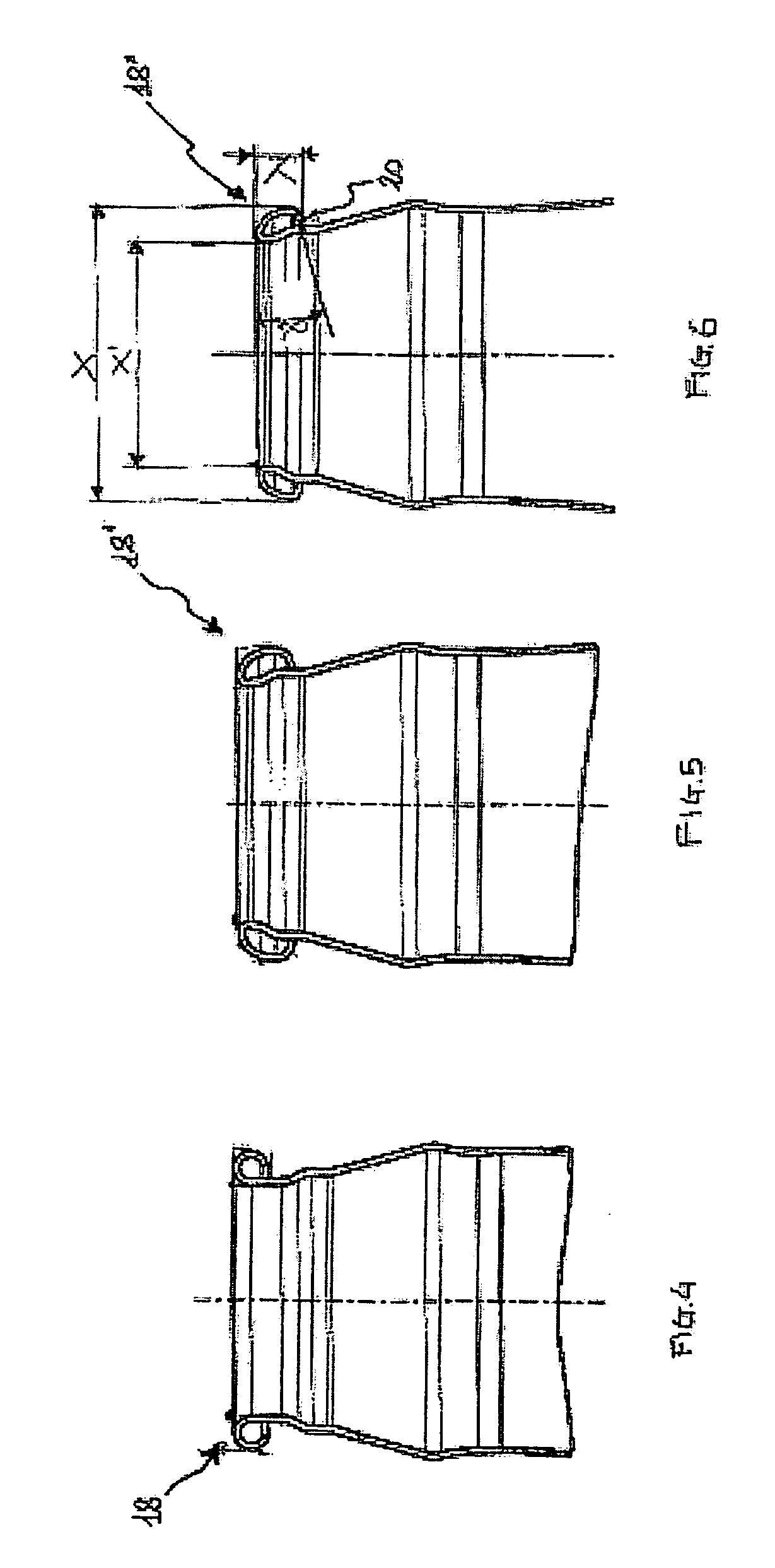

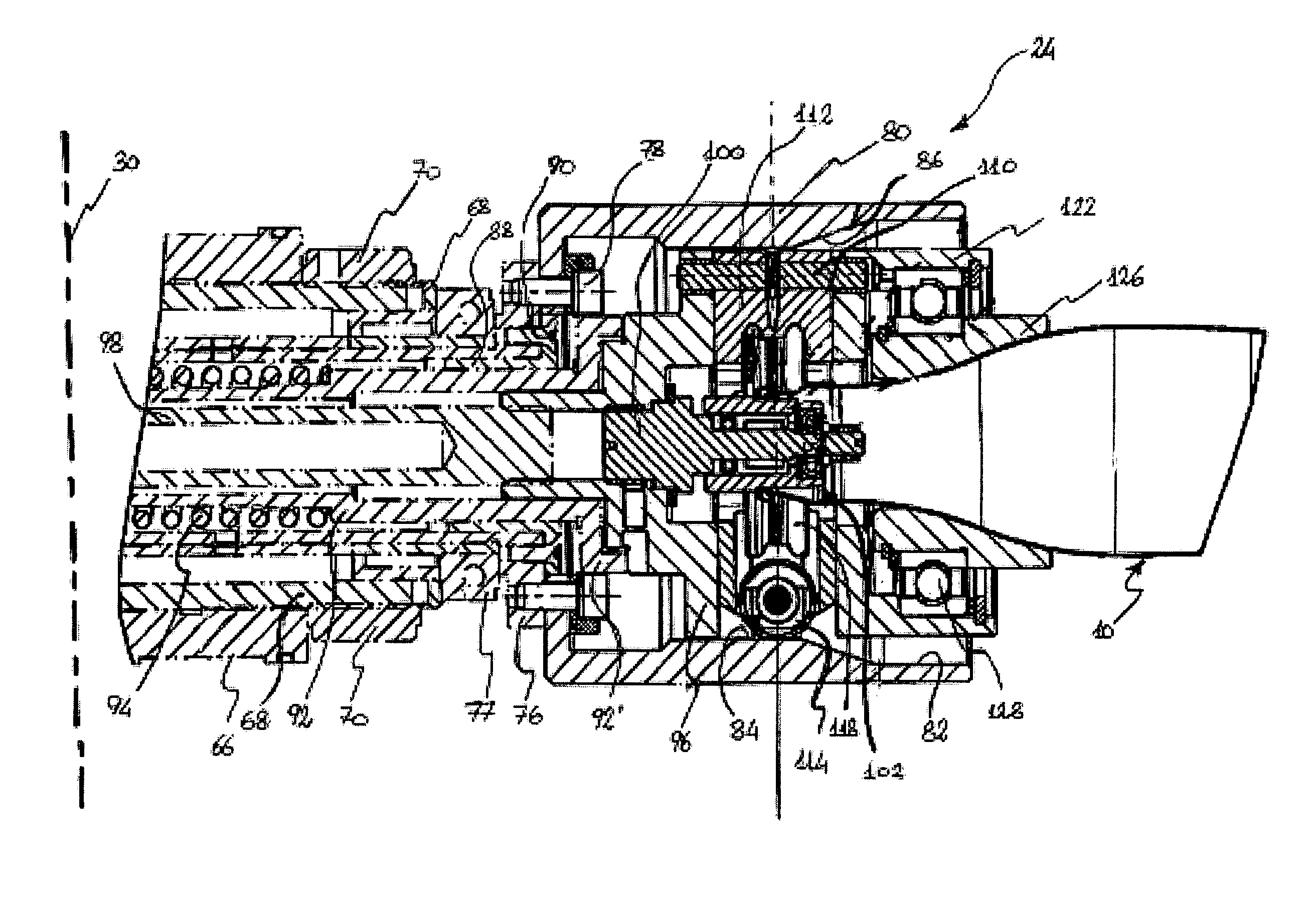

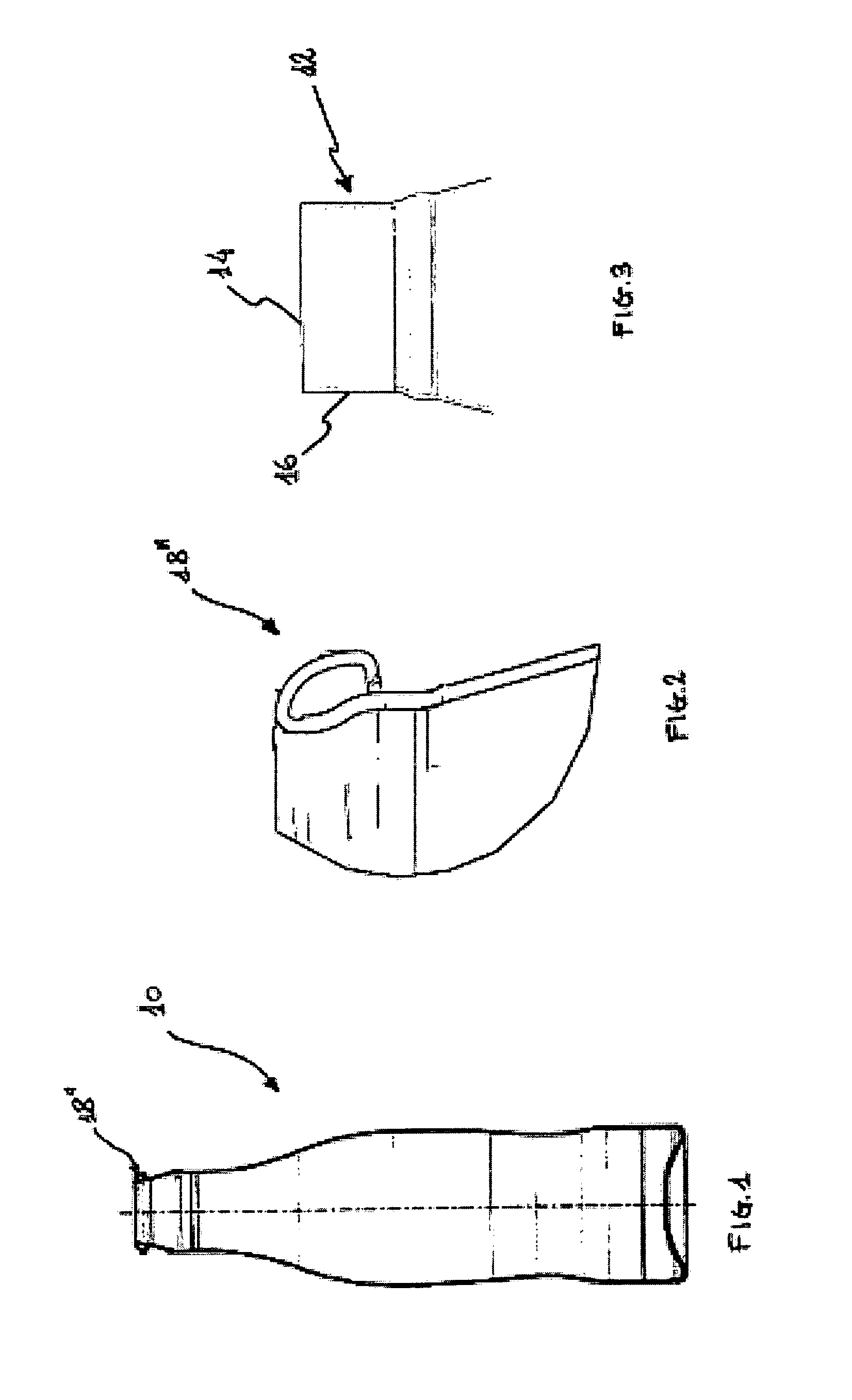

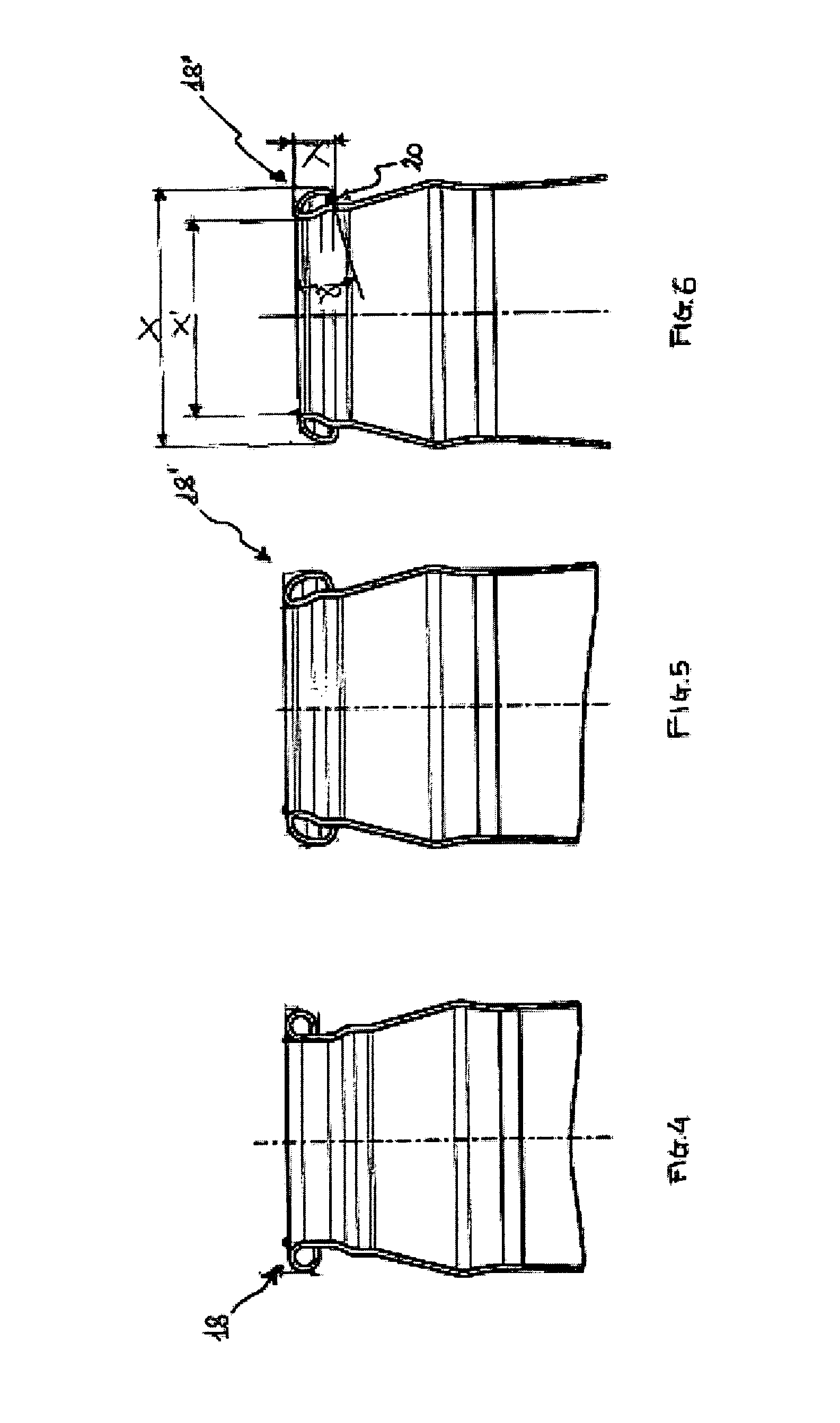

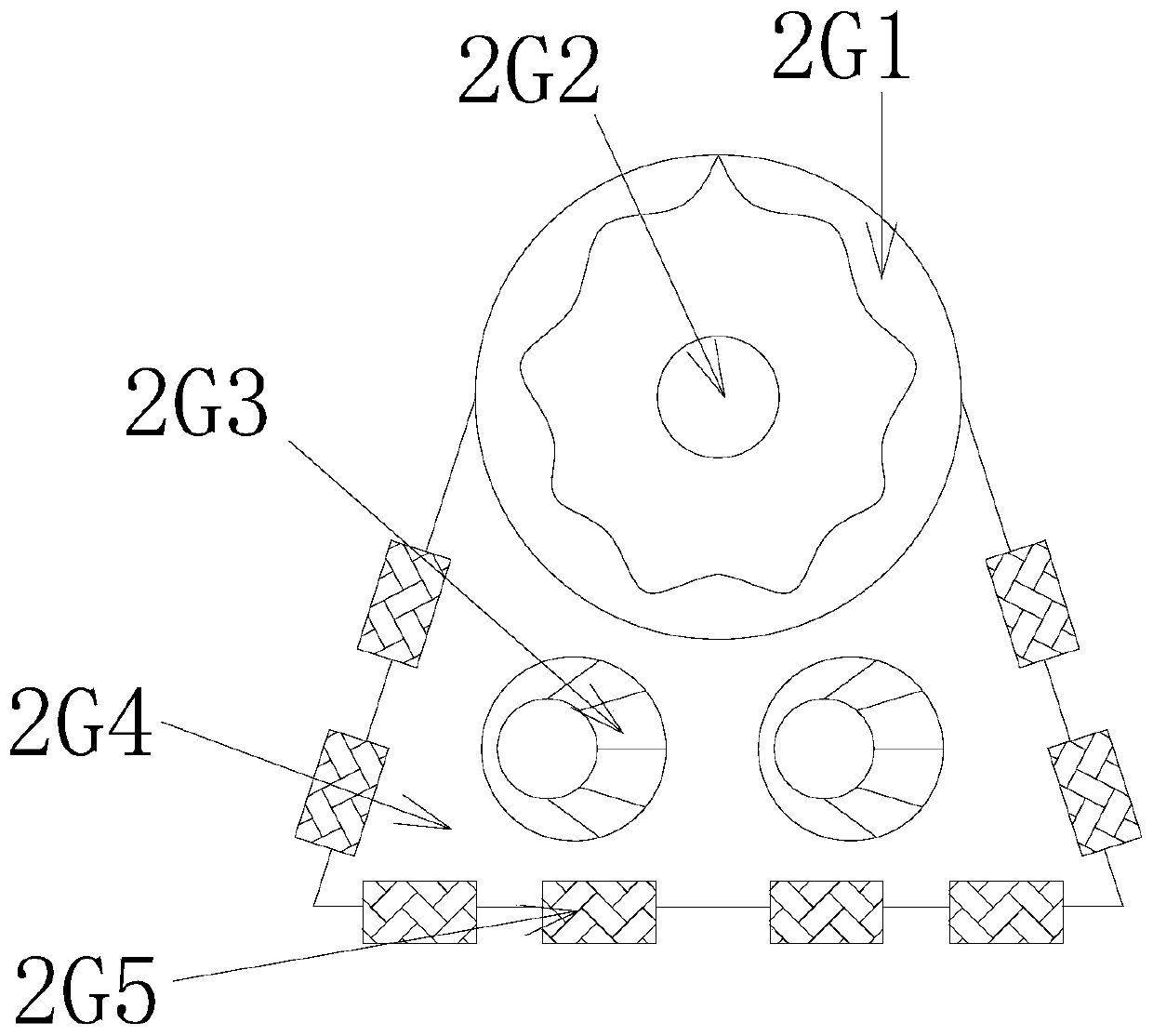

Process and Apparatus to Make an Edge or a Collar Featuring a Complex Structure on Metal Rough Pieces

ActiveUS20090165526A1High degreeQuality improvementMetal rolling arrangementsHollow articlesFood sectorEngineering

A process and apparatus to make an edge or a collar featuring a complex structure on extruded, deep-drawn and deep-drawn / wire-drawn metal rough pieces with which bottles for the beverage and food sector or for technical use are particularly obtained, suitable for the application of a closing cap and fit to use on a tapering machine. The process includes a starting operating stage to deform an upper end portion of a metal holder by turning it outwardly so as to obtain an edge or a collar with a basically circular section, one or more intermediate operating stages to deform the edge or collar by squeezing in the radial direction and stretching towards the bottom of the metal holder, a final operating deformation stage to obtain an edge or collar with a complex ovoidal profile for the application of at least two caps of different types.

Owner:MALL HERLAN

Imaging of deep structures of reliefs for shallow relief embossing

A variety of deep structured decorative patterns originate with mechanical relief or etching. The present method incorporates a deeply patterned or textured etching or relief into a thin film embossing shim to simulate the look of the deep pattern or texture when used to emboss thin film or material. A transparent mold of the relief surface (such as brushed metal, engine-turned patterns, and textured glass) is formed using UV curable liquid and a transparent substrate. The relief copy in the transparent mold or overlay is mapped onto a photoresist surface or plate by shining or expanding one or more laser lights or laser beams through the transparent mold. The different heights of the relief copy of the transparent mold will cause the light to diffract / refract to form a corresponding patterned etching in the photoresist plate. The resulting photoresist plate is then metalized and electroplated to form a thin film embossing shim. The thin film embossing shim is then used with conventional embossing equipment to form thin film embossings. The embossed thin films can then be metalized and laminated onto substrate to create a product that has shifting patterns that reflect at a variety of viewing angles when (observed under normal lighting conditions) exposed to white light.

Owner:ILLINOIS TOOL WORKS INC

Process and apparatus to make an edge or a collar featuring a complex structure on metal rough pieces

ActiveUS8286460B2High degreeQuality improvementMetal rolling arrangementsHollow articlesFood sectorEngineering

A process and apparatus to make an edge or a collar featuring a complex structure on extruded, deep-drawn and deep-drawn / wire-drawn metal rough pieces with which bottles for the beverage and food sector or for technical use are particularly obtained, suitable for the application of a closing cap and fit to use on a tapering machine. The process includes a starting operating stage to deform an upper end portion of a metal holder by turning it outwardly so as to obtain an edge or a collar with a basically circular section, one or more intermediate operating stages to deform the edge or collar by squeezing in the radial direction and stretching towards the bottom of the metal holder, a final operating deformation stage to obtain an edge or collar with a complex ovoidal profile for the application of at least two caps of different types.

Owner:MALL HERLAN

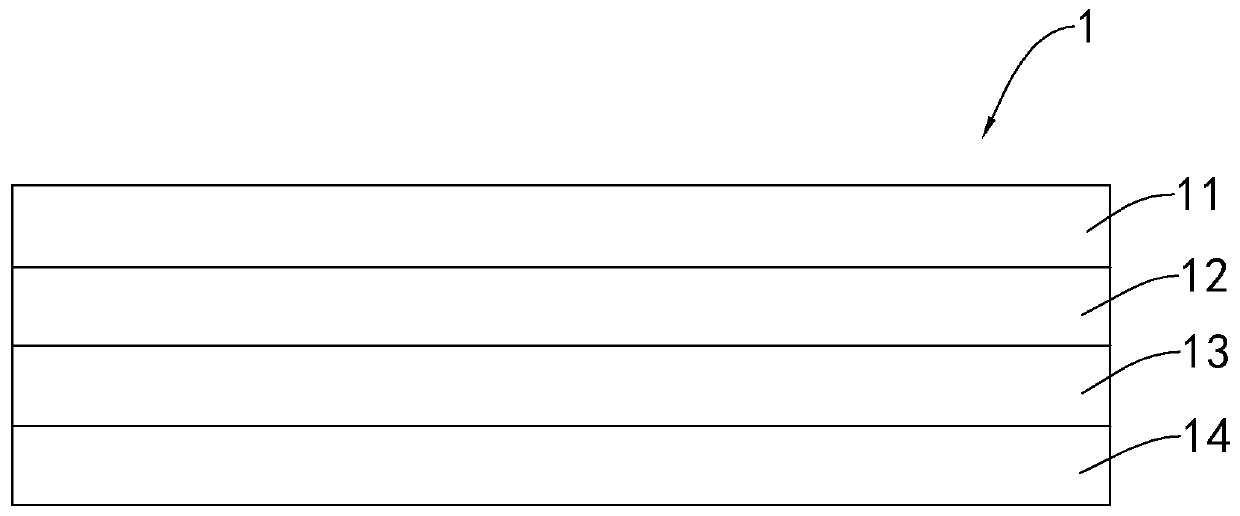

Brushed-metal composite board

InactiveCN109760392AReduce dosageLow costSynthetic resin layered productsMetal layered productsThermal insulationOptoelectronics

The invention relates to a brushed-metal composite board. The brushed-metal composite board comprises a plastic substrate layer, a bonding layer I, a thermal insulation layer, a bonding layer II, a brushed metal layer, a bonding layer III and a protective film layer which are connected sequentially, wherein the plastic substrate layer is a PP or PE layer; the thermal insulation layer is an aerogelfelt layer or a vacuum board layer; the brushed metal layer is of a composite structure of a brushed aluminum foil layer and an oxidation treated film layer; the protective film layer is a dried paint layer; the bonding layers I, II and III can be high-temperature-resistant double-faced adhesive tape layers. The brushed-metal composite board is attractive, durable and light in texture, has low cost and thermal insulation performance, and is particularly applicable to occasions needing thermal insulation.

Owner:丹阳市日晟工业设备有限公司

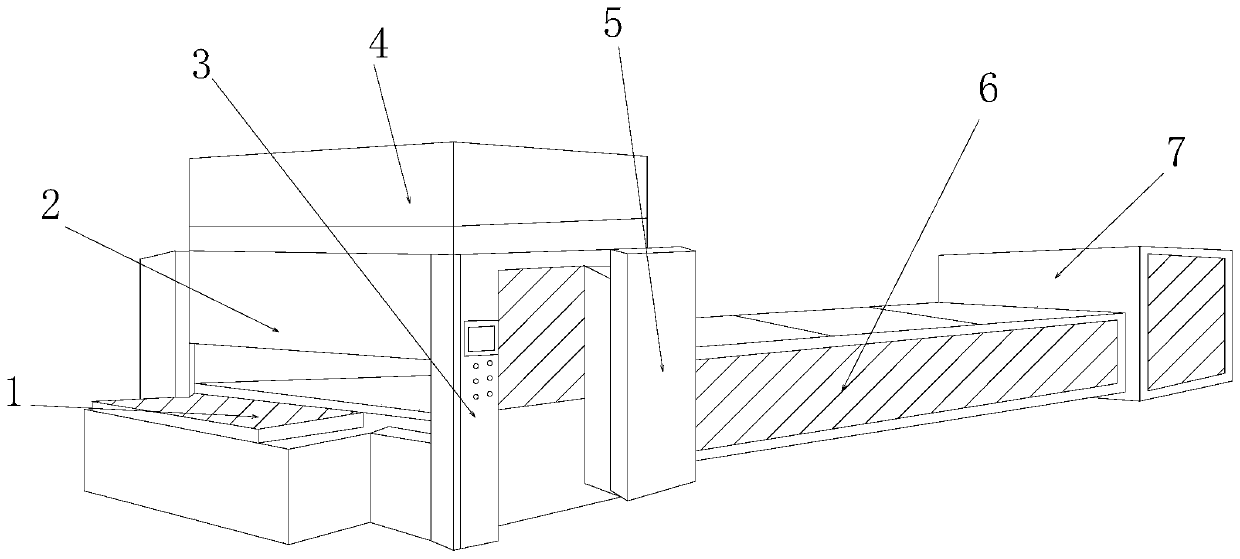

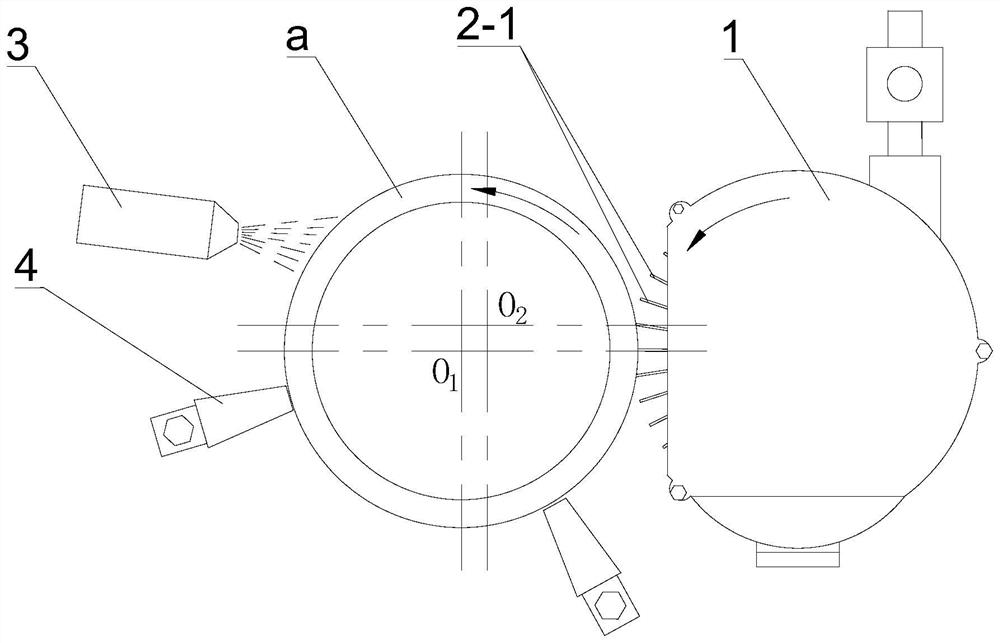

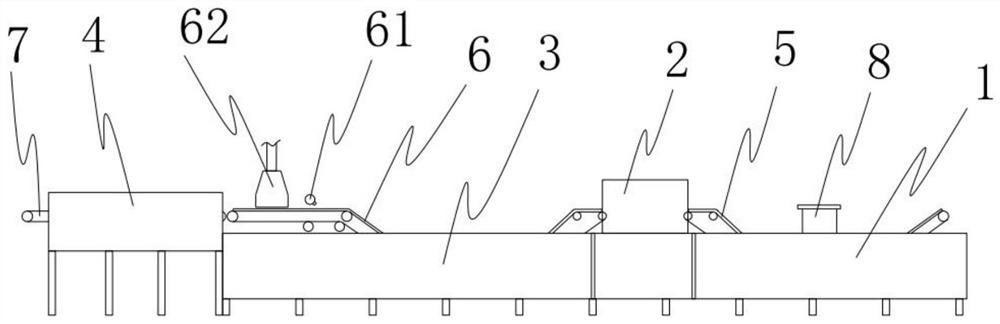

Automatic spraying assembly line based on metal covering protective layer and capable of transversely moving and rotatably swinging

InactiveCN111111969AGuaranteed DensityGuarantee the operation effect of the processSpraying apparatusProduction lineHuman–machine interface

The invention discloses an automatic spraying assembly line based on a metal covering protective layer and capable of transversely moving and rotatably swinging. The automatic spraying assembly line structurally comprises a feeding object stage, a transverse moving and rotatably swinging machine frame, a human machine interface board, an axle wheel top cover groove, a distribution motor box, a conveyor belt plate box and a finished storage cabinet. According to the automatic spraying assembly line, the cooperation of the transverse moving and rotatably swinging machine frame and the axle wheeltop cover groove is realized, the arc surface spraying operation is carried out through the bending rotary swinging of rotary brush plates in cooperation with a track, and thus the paint spraying ofthe metal covering protective layer carries out one-step in-place operation; and the spraying rotary brush plates and hoisting clamp seats are combined into a bidirectional clamping plate for sprayingthe sliding and brushing metal surface of the front end and the rear end of the bidirectional clamping plate, the vertical metal surface is transferred back along the arc surface to form a rotatableswinging sweeping effect, and residual paint liquid bonding the surface forms a sieve brush cleaning effect after a rotary propeller wind wheel band is convoluted, so that liquid drops are rapidly slipped off, the quality and key effect of the single-side protective layer at the later stage is facilitated, the super-thin homogeneous processing of the paint surface is also facilitated, and the production line spraying qualification rate is improved.

Owner:汪志辉

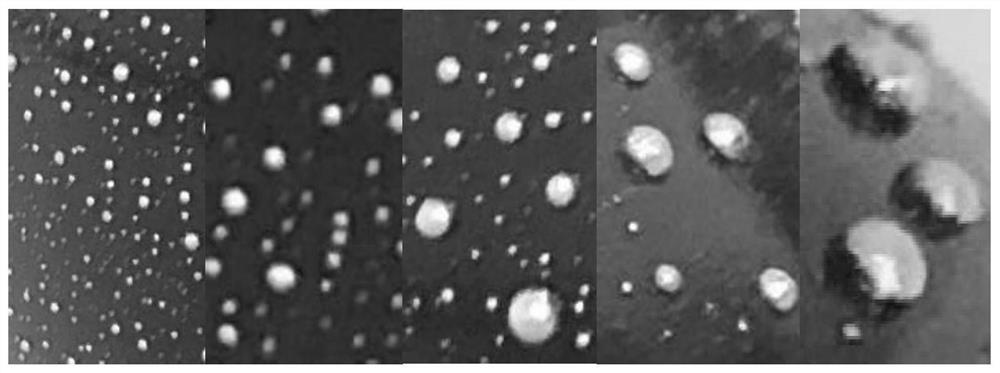

Brushed metal panel label, glue brushing device and production process of brushed metal panel label

ActiveCN110164291APaste effect is goodConsumption controlStampsSpraying apparatusCoated surfaceManufacturing technology

The invention discloses a brushed metal panel label, a glue brushing device and a production process of the brushed metal panel label, and belongs to the technical field of label production and manufacturing. The technical problem that the using amount of a glue solution is too large is solved. The brushed metal panel label is characterized in that a material belt is included; the material belt sequentially comprises a plastic surface layer, a printed surface layer, adhesive layers and a release layer from outside to inside; the printed surface layer comprises an ink surface layer and a mirrorsurface printing layer from outside to inside; the plastic surface layer is made of a transparent material; the ink surface layer comprises a non-coated surface and a coated surface; and the mirror surface printing layer makes contact with the plastic surface layer through the non-coated surface, the adhesive layers are discretely distributed on the printed surface layer, according to a discretedistribution form, a plurality of discrete points are formed on the surfaces of the adhesive layers, and the amount of the glue solution from the center to the outside of the discrete points is lowered step by step. The brushed metal panel label, the glue brushing device and the production process of the brushed metal panel label have the technical effects that the glue amount of all positions ofthe adhesive layers is unevenly distributed, the consumption of the glue solution is controlled, and the brushed metal panel label can still keep a good sticking effect.

Owner:GUANLIDA TRADEMARKS PROD SUZHOU CO LTD

Method for processing brushed effect on glass surface

The invention relates to glass processing, and discloses a method for processing a brushed effect on a glass surface. Trench type fine lines which are 0.1mu m-1mm are processed on the glass surface corroded by a corrosion solution. According to the method disclosed by the invention, the trench type fine lines which are 0.1mu m-1mm are processed on the corroded glass surface so that the metal line effect similar with brushed stainless steel is formed on the glass surface or a mirror surface, the brushed metal effects at different colors can be processed on the glass surfaces or the mirror surfaces at different colors, and a product is easily cleaned and cannot be oxidized.

Owner:SHENZHEN DICKSON IMPORT & EXPORT CO LTD

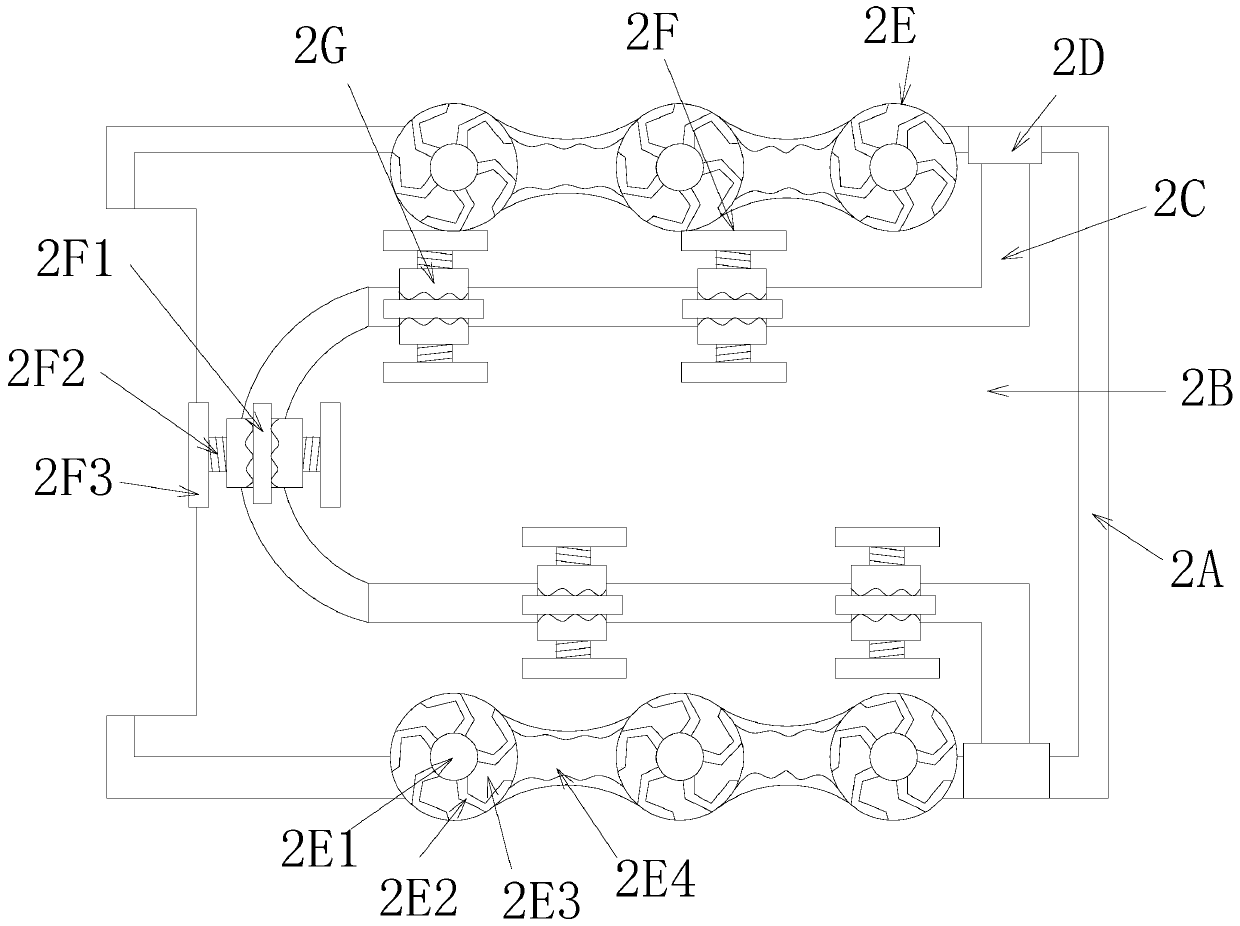

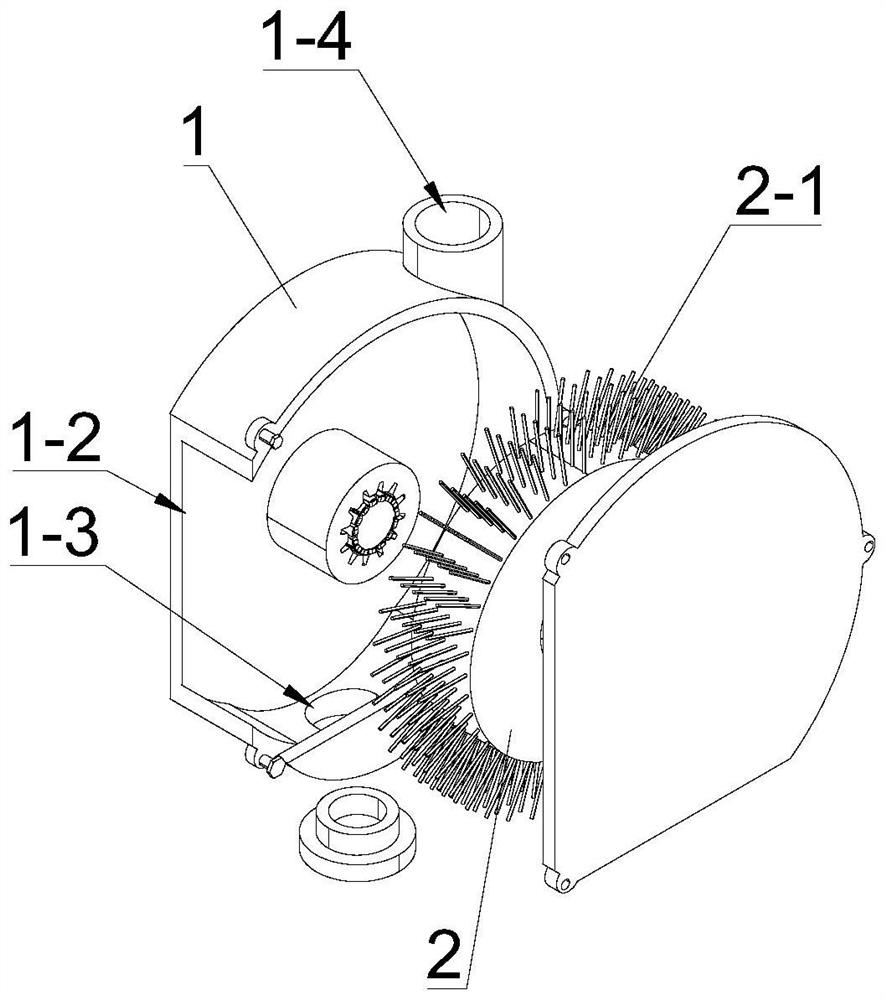

A kind of brush type metal workpiece surface strengthening grinding processing equipment and method

ActiveCN110653671BEvenly arrangedThe effect of uniform strengthening processingGrinding machine componentsRevolution surface grinding machinesBristleMachined surface

The invention discloses a brushing type metal workpiece surface intensive grinding processing equipment and method. The processing equipment includes a rotating clamping device, a mixing brushing device and a high-pressure spraying device. The mixing brushing device includes a mixing mechanism and a brushing mechanism. The brushing mechanism includes a brushing housing, a rotating wheel brush and a second rotating drive mechanism; the rotating wheel brush is rotatably connected in the brushing housing, and its outer surface is provided with bristles distributed along the circumference; The bottom of the inner cavity of the brush housing is provided with a material storage space, and the side wall of the inner cavity of the brushing housing is provided with an escape port for preventing the bristles from extending to the processing surface of the workpiece; the rotating wheel brush is located above the material storage space , the path through which the free ends of the bristles turn intersects with the storage space. The invention can not only ensure more uniform effect and better quality of the enhanced grinding process, but also prevent the pollution caused by the diffusion of abrasive materials in the working environment, and at the same time prevent the processed surface of the workpiece from being oxidized.

Owner:GUANGZHOU UNIVERSITY

A multi-functional disk brush metal brush wire cutting device

Owner:安徽长中刷业有限公司

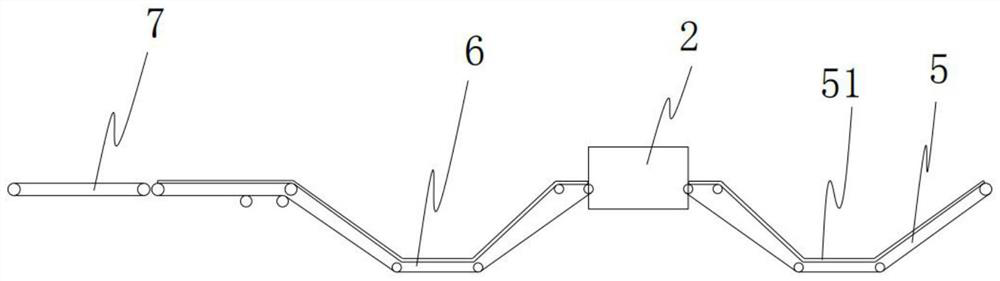

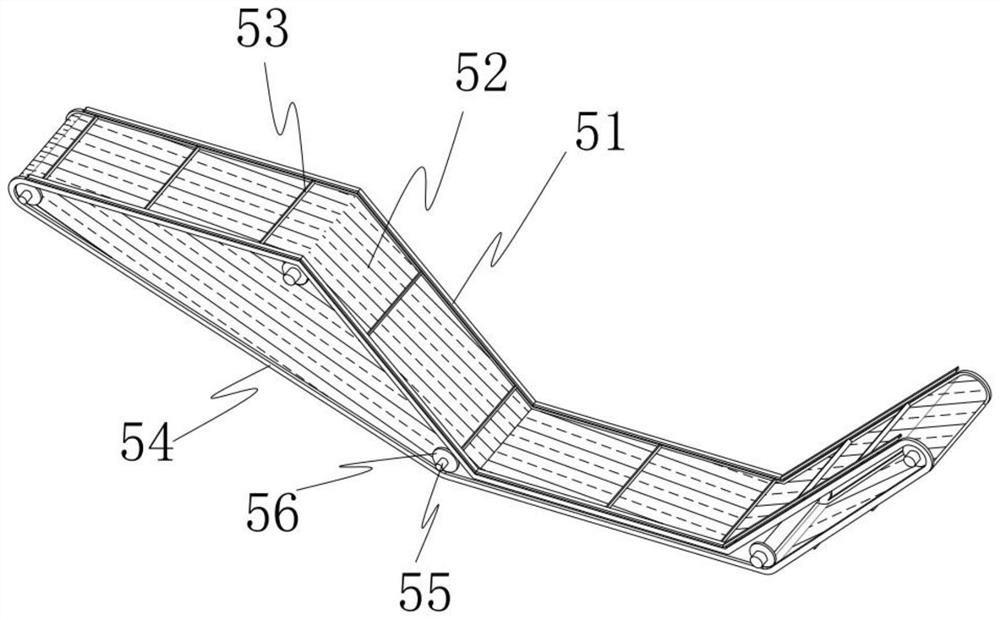

Automatic cleaning equipment for metal parts

ActiveCN112058794AReduce human inputImprove cleaning efficiencyDrying gas arrangementsDrying machines with progressive movementsProcess engineeringDry box

The invention relates to automatic cleaning equipment for metal parts. The automatic cleaning equipment comprises a clear water cleaning pool, a brushing mechanism, a purified water cleaning pool anda drying mechanism; a first conveying belt passing through the position below the liquid level of the clear water cleaning pool is arranged in the clear water cleaning pool, and the brushing mechanismis provided with brush wheels used for brushing the metal parts and a conveying component used for conveying the metal parts; a second conveying belt passing through the position below the liquid level of the purified water cleaning pool is arranged in the purified water cleaning pool, and the drying mechanism comprises a drying box and a third conveying belt; and the first conveying belt conveysthe metal parts cleaned by the clear water cleaning pool to the conveying component, the conveying component conveys the brushed metal parts to the second conveying belt, the second conveying belt conveys the metal parts cleaned by the pure water cleaning pool to the third conveying belt, and the third conveying belt outputs the metal parts after conveying the metal parts to be dried by the drying box. By the adoption of the automatic cleaning equipment for the metal parts, manpower input on a metal part cleaning line can be reduced, and cleaning efficiency is improved.

Owner:广州市万伟金属制品有限公司

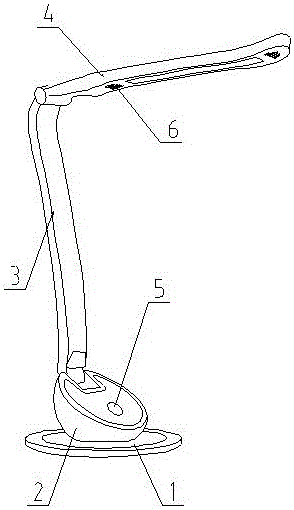

Wear-resisting commercial office table lamp with good heat dissipation

InactiveCN105937729AEasy to foldSmall footprintLighting support devicesElectric circuit arrangementsEngineeringTouch switch

The invention relates to a wear-resisting commercial office table lamp with good heat dissipation, and belongs to the technical field of household appliances. The lamp comprises an anti-skid bottom disc (1), an inclined semicircular base (2) is arranged on the anti-skid bottom disc (1), a lamp arm (3) is hinged to the upper end of the inclined semicircular base (2), a lamp holder (4) is hinged to the lamp arm (3), and a plurality of LED light sources are arranged on the back face of the lamp holder (4); a brushed metal protection film is arranged on the front face of the lamp holder (4), the front sides and the rear sides of the LED light sources are each provided with a plurality of heat dissipation holes (6), and a touch switch (5) is arranged on the front face of the inclined semicircular base (2); and the wear-resisting commercial office table lamp with good heat dissipation can be conveniently folded, is small in occupied space when not used and is convenient to store and carry.

Owner:WUXI BALAS LIGHTING ELECTRONICS

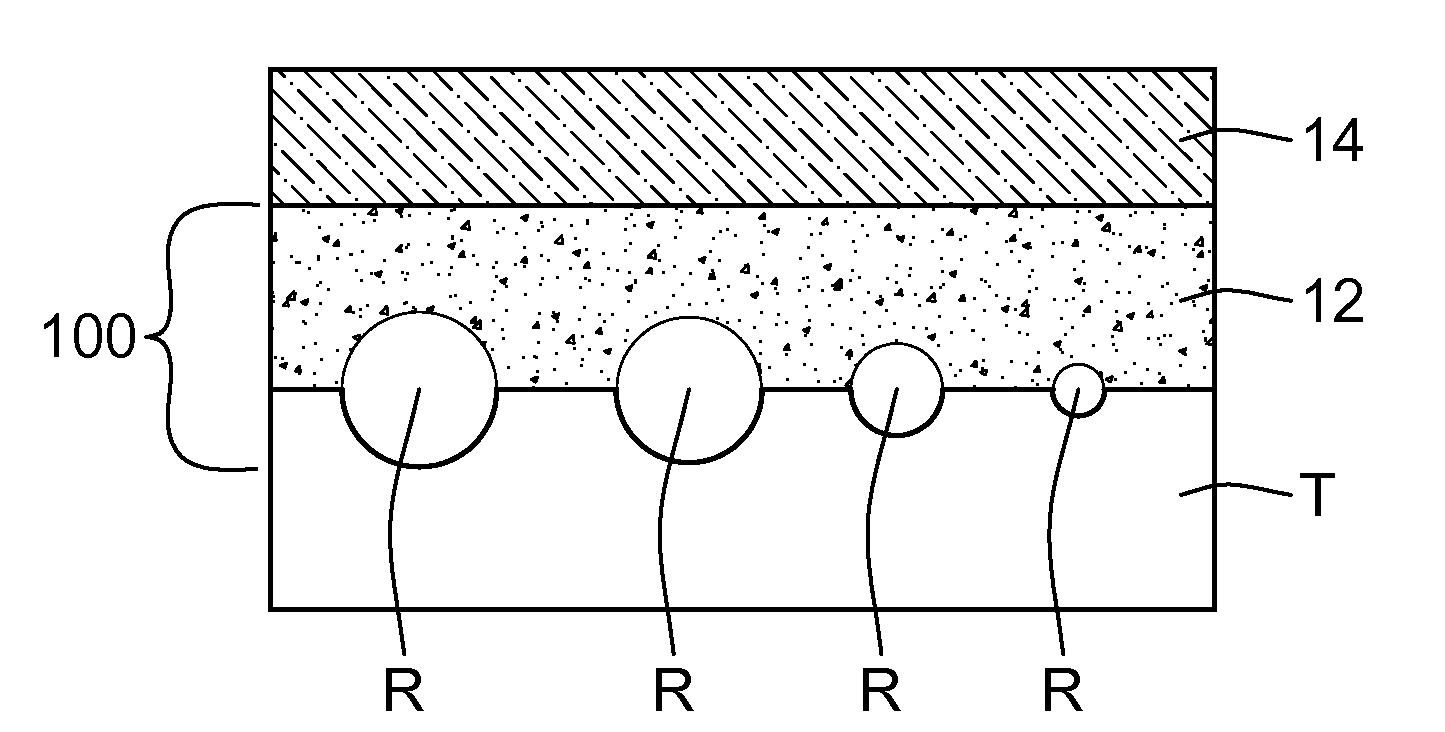

Method of texturing synthetic material extrusions

ActiveUS8574678B2Radiation applicationsDecorative surface effectsSynthetic materialsSurface roughness

A method of texturing a synthetic material, such as polyvinyl chloride (PVC), to resemble a natural material is provided. The method can include texturing a PVC profile after extrusion in order to achieve a surface roughness of about 70 to about 300 micro inches roughness average. The method can include producing a line pattern surface roughness to make the textured PVC resemble a wood finish, particularly when the method includes applying a paint or stain to the textured PVC. The method can include producing a radial pattern surface roughness to make the textured PVC resemble a brushed metal finish. The method of the present invention can be applied to existing PVC elements, such as extruded elements, either at the manufacturing level or at the consumer level. A kit can also be provided including a texturing means, a paint or stain, and instructions.

Owner:DALLAIRE INDS

A metal brush filament bending device for disc brush

The invention discloses a tray brush metallic brush wire bending device. The device comprises a base, a support plate and a half-pace are arranged on the base, an upper bending gear and a lower bending gear are arranged in the support plate, an upper bending arm and a lower bending arm which are symmetrically arranged are fixedly connected to the outer side faces of the upper bending gear and the lower bending gear respectively, a horizontal transverse through hole is formed inside the half-pace, a push air cylinder is arranged at the outer end of the horizontal transverse through hole, the inside of the half-pace is further provided with a horizontal longitudinal through hole, a blanking air cylinder is arranged at the outer end of the horizontal longitudinal through hole, a loading channel is formed in the lower portion of the horizontal transverse through hole, a loading air cylinder is arranged at the right end of the loading channel, a feeding through hole is formed in the lower portion of the left end of the loading channel, and a feeding air cylinder is arranged at the bottom of the feeding through hole. In the tray brush metallic brush wire bending device, a metallic brush wire is automatically bent by adopting the bending device, time is shortened, force is saved, the work efficiency is high, the symmetry of the bent metallic brush wire is good, the bent metallic brush wire is fixed through a rubber ring, which facilitates storage and transfer, and the device is reasonable in structure design and easy to operates and use.

Owner:安徽长中刷业有限公司

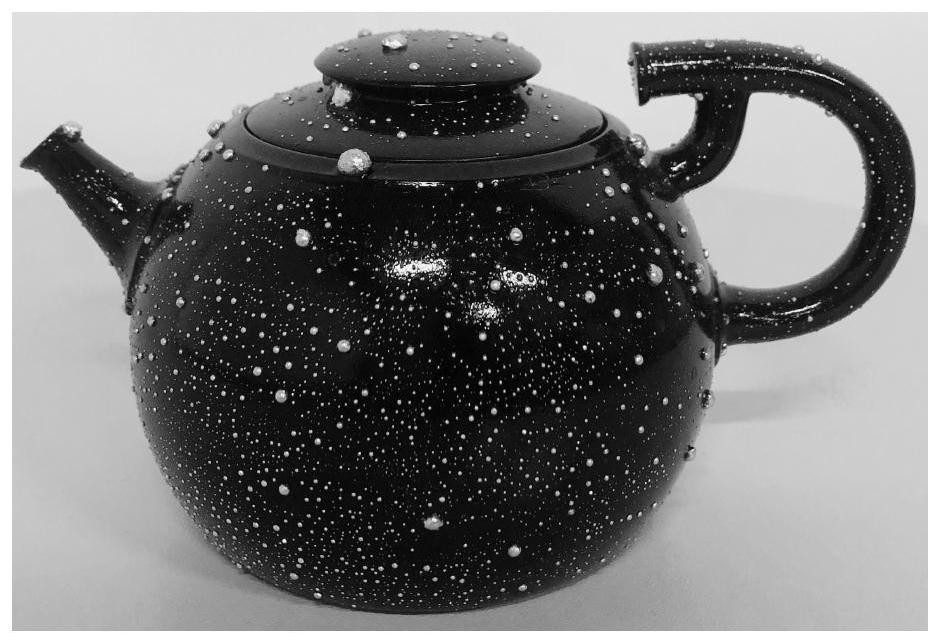

A combination of metal and ceramics

Owner:厦门文气艺术品有限公司

Metal drawing panel label, glue brushing device and production method thereof

ActiveCN110164291BPaste effect is goodConsumption controlStampsSpraying apparatusCoated surfacePolymer science

The invention discloses a brushed metal panel label, a glue brushing device and a production process of the brushed metal panel label, and belongs to the technical field of label production and manufacturing. The technical problem that the using amount of a glue solution is too large is solved. The brushed metal panel label is characterized in that a material belt is included; the material belt sequentially comprises a plastic surface layer, a printed surface layer, adhesive layers and a release layer from outside to inside; the printed surface layer comprises an ink surface layer and a mirrorsurface printing layer from outside to inside; the plastic surface layer is made of a transparent material; the ink surface layer comprises a non-coated surface and a coated surface; and the mirror surface printing layer makes contact with the plastic surface layer through the non-coated surface, the adhesive layers are discretely distributed on the printed surface layer, according to a discretedistribution form, a plurality of discrete points are formed on the surfaces of the adhesive layers, and the amount of the glue solution from the center to the outside of the discrete points is lowered step by step. The brushed metal panel label, the glue brushing device and the production process of the brushed metal panel label have the technical effects that the glue amount of all positions ofthe adhesive layers is unevenly distributed, the consumption of the glue solution is controlled, and the brushed metal panel label can still keep a good sticking effect.

Owner:GUANLIDA TRADEMARKS PROD SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com