Brushed metal panel label, glue brushing device and production process of brushed metal panel label

A metal wire drawing and panel technology, which is applied to the device for coating liquid on the surface, the spray device, the identification device, etc., can solve the problem of excessive use of glue, and achieve the effect of good paste effect, simple operation, flexible structure and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

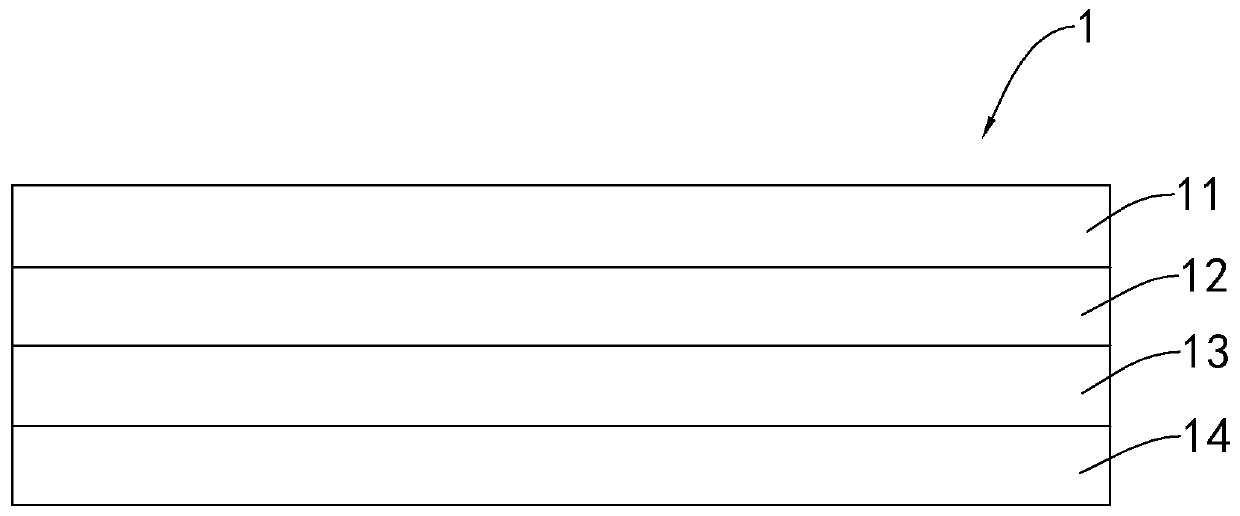

[0049] Embodiment 1: refer to figure 1 , is a metal wire drawing panel label disclosed by the present invention, comprising a strip 1, the strip 1 sequentially includes a plastic surface layer 11, a printing surface layer 12, an adhesive layer 13 and a release layer 14 from the outside to the inside, and the plastic surface layer 11 The outer surface of the surface is smooth, oil-resistant and waterproof, and the plastic surface layer 11 is a transparent material, and the inside characters can be seen through the plastic surface layer 11; the printing surface layer 12 includes an ink surface layer and a mirror printing layer from the outside to the inside; the ink surface The layer includes a non-coating surface and a coating surface, the non-coating surface and the coating surface are in the same layer, the mirror printing layer contacts the plastic surface layer 11 through the non-coating surface, and the adhesive layer 13 is discretely distributed on the printing surface lay...

Embodiment 2

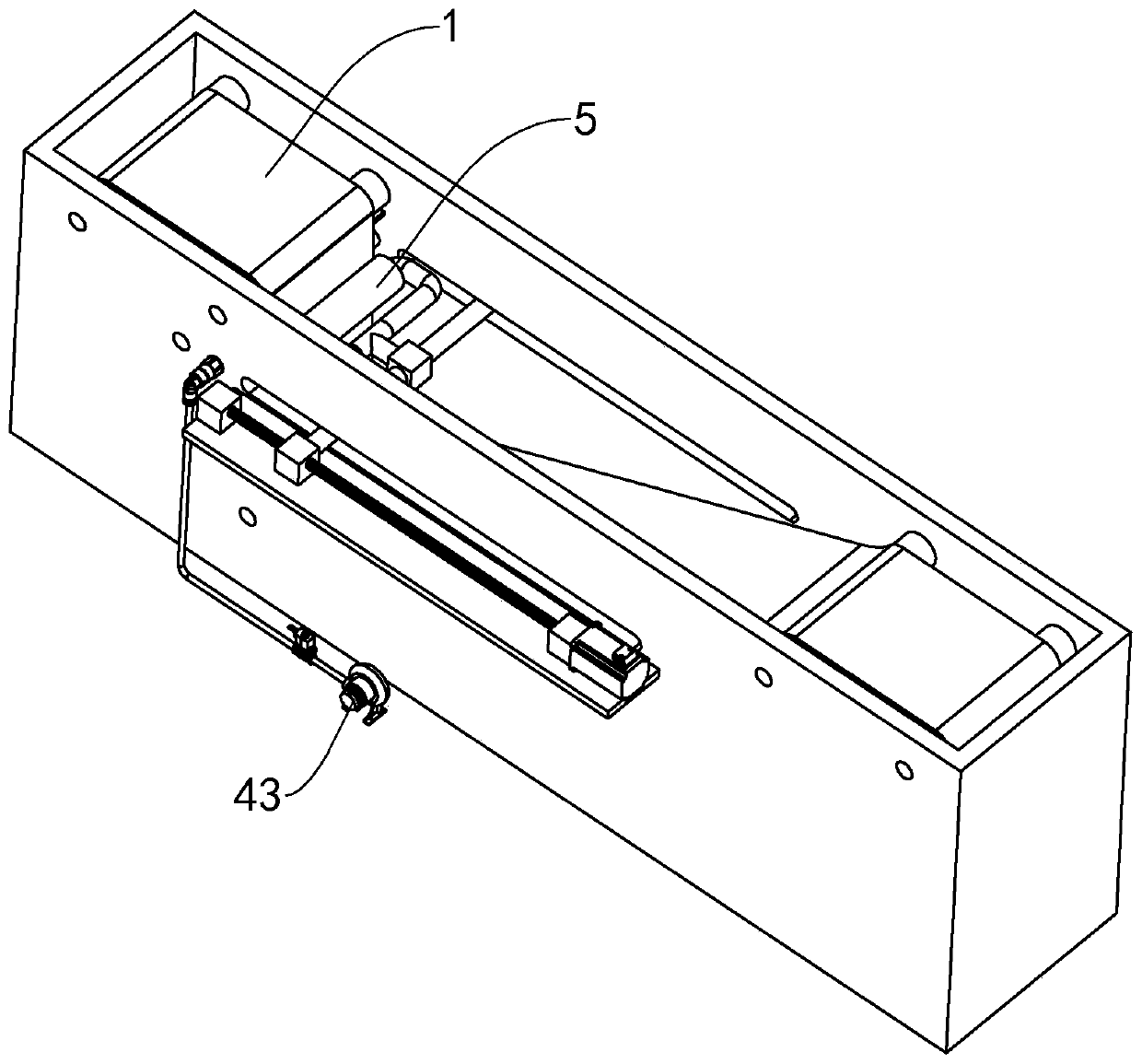

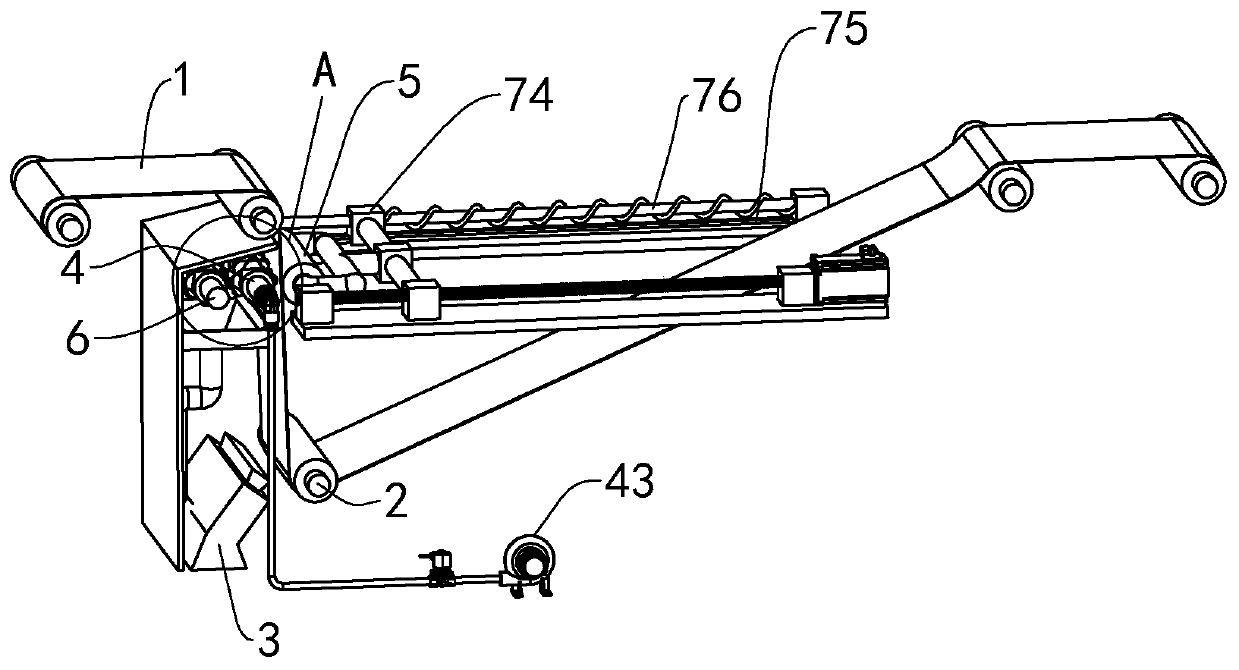

[0050] Example 2: Reference figure 2 and image 3 , a kind of glue brushing device of production embodiment 1, comprises frame, and frame inner side is provided with material passing roller 2, and material passing roller 2 feeds belt 1 to bypass, and the rotating shaft of passing material roller 2 connects lifting mechanism (not shown in the figure shown), the lifting mechanism can use a screw structure to lift or a hydraulic cylinder to lift; the material belt 1 is further extended upwards, one side of the material belt 1 is squeezed by the release roller 4, and the other side is squeezed by the extrusion roller 5 pressure. Due to the existence of extrusion force, the adhesive layer 13 on the material belt 1 will actually be in close contact with the release roller 4, thereby realizing the transfer of the glue solution.

[0051] refer to Figure 4 , the outside of the release roller 4 is coated with a flexible glue-absorbing layer, which can be made of materials such as s...

Embodiment 3

[0056] Embodiment 3: A kind of production process of metal wire drawing panel label, comprises using the glue brushing device of embodiment 2, comprises the following steps:

[0057] S1: wrap the material tape 1 between the material passing roller 2 and the release roller 4;

[0058] S2: adjust the angle of the glue spraying mechanism 3 so that the glue spraying mechanism 3 faces the material belt 1 on the material passing roller 2;

[0059] S3: adjust the extrusion roller 5, so that the extrusion roller 5 and the release roller 4 clamp the material belt 1;

[0060] S4: Check the electrical connection and mechanical connection of the glue spraying mechanism 3 and the glue extrusion mechanism, and start after confirming that there is no fault.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com