Two-in-one automatic laminating machine for front frame of flat-panel TV

A flat-panel TV, two-in-one technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problem that the structure design of the TV front frame laminating machine is not reasonable enough, can not meet the needs of people, and increase resources and manpower. The waste of resources and manpower can be reduced, the paste effect is good, and the structure design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

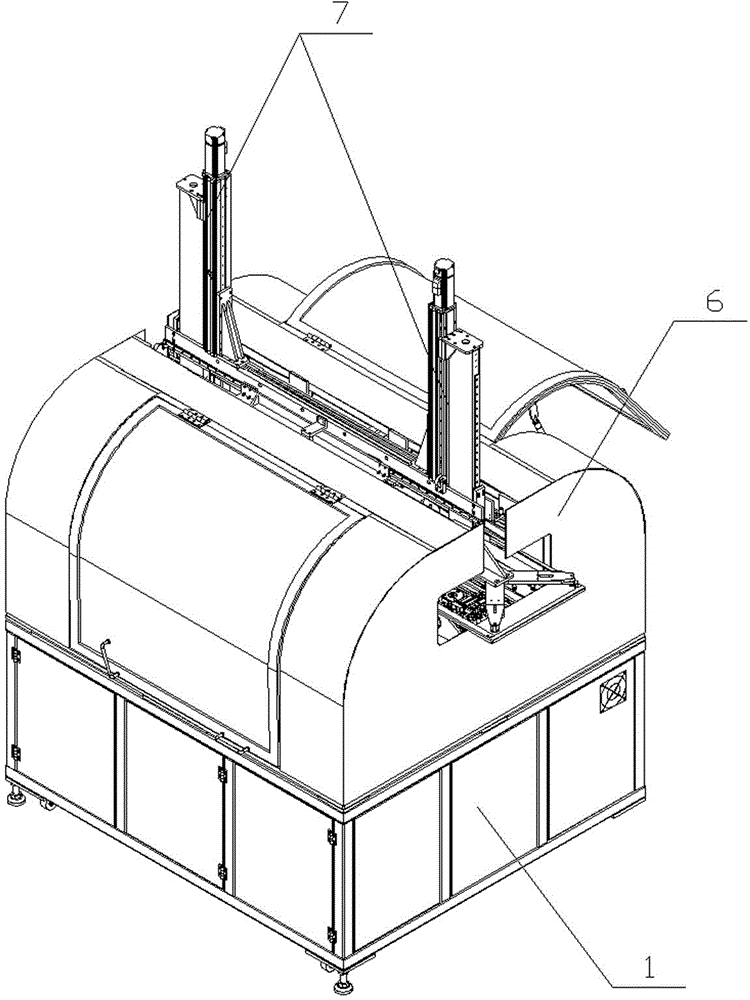

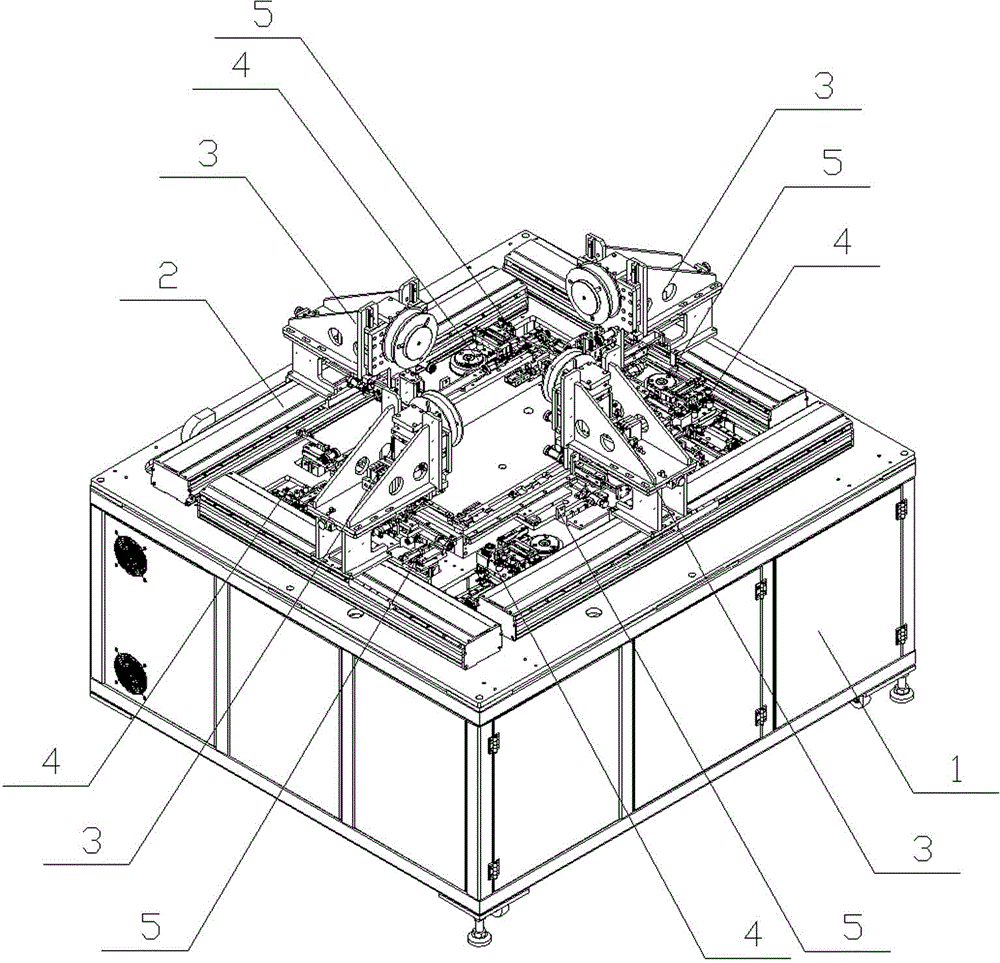

[0020] Such as figure 1 , figure 2 As shown, this specific embodiment adopts the following technical solutions: it includes a fuselage frame 1, a fixture frame 2, four film applicators 3, a glue applicator 4, a film covering device 5, an arc-shaped upper cover 6, and a telescopic manipulator for retrieving materials. 7 and the feeding telescopic manipulator 8, the fuselage frame 1 is provided with a jig frame 2, and the four sides of the jig frame 2 are respectively provided with four film sticking heads 3, and the inside of the jig frame 2 corresponds to four film sticking heads 3 Gluing head 4 and laminating device 5 are arranged at the lower position of each, arc-shaped upper cover 6 is arranged on the top of fuselage frame 1, and material taking and discharging device 7 is arranged on arc-shaped upper cover 6 .

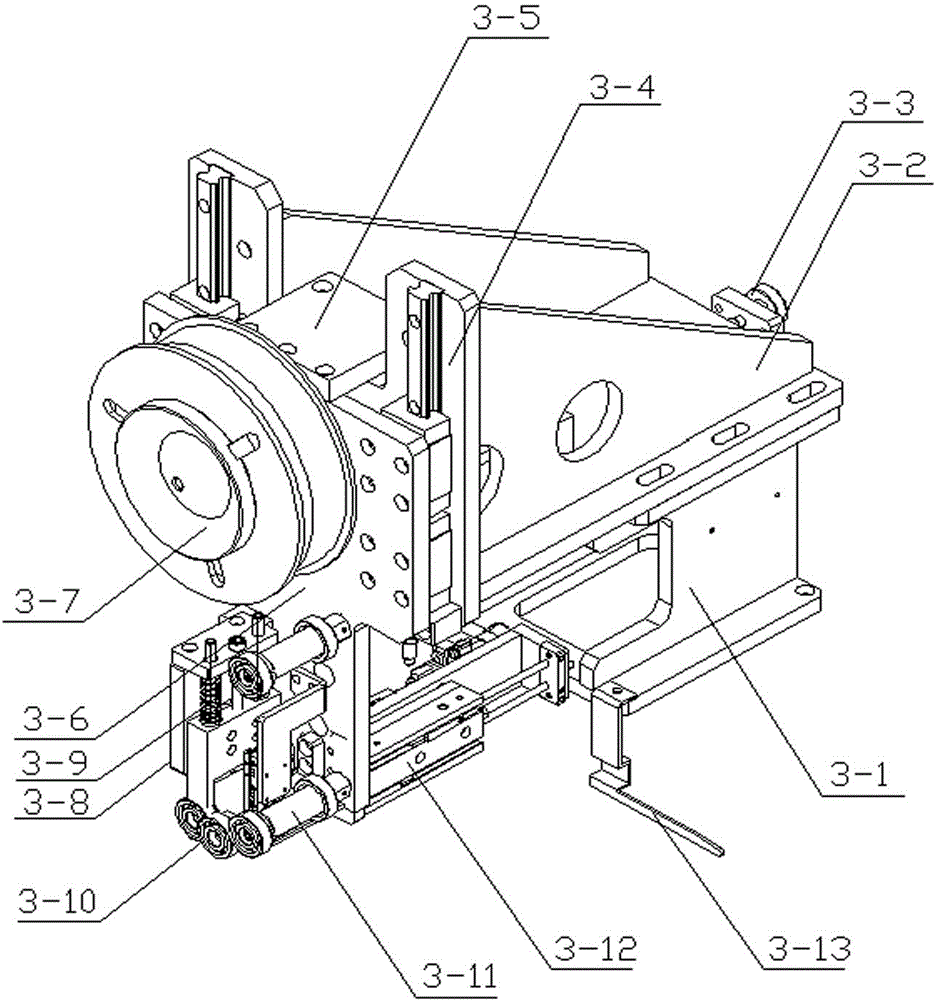

[0021] Such as image 3 As shown, the film sticking head 3 includes a film head fixing seat 3-1, a film head ribbed side plate 3-2, a film head front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com