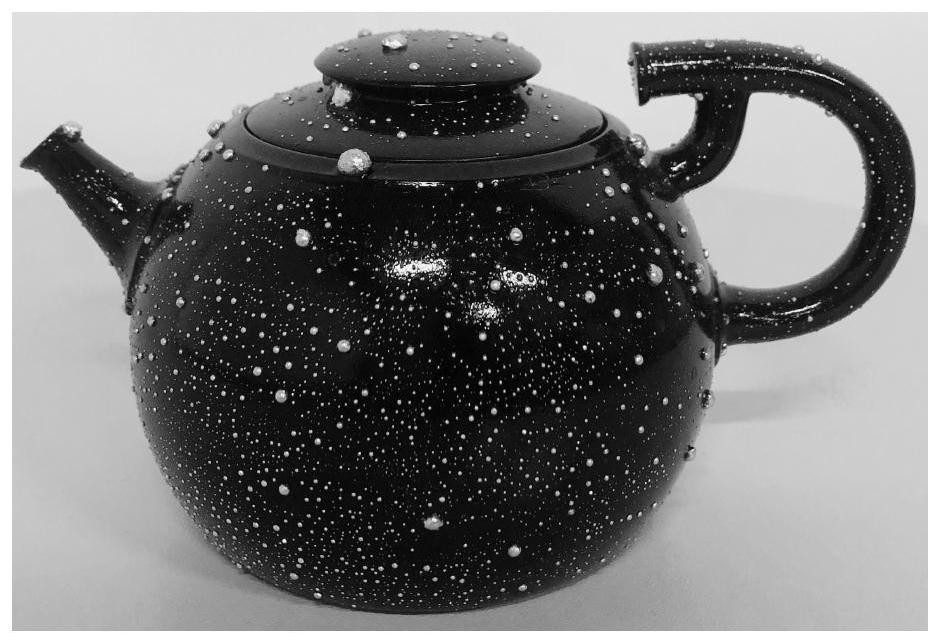

A combination of metal and ceramics

A ceramic and metal technology, applied in the field of metal and ceramic combination technology, can solve problems such as limiting the designer's thinking and imagination space, and achieve the effect of wide process and operation range, stable process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention discloses a combination process of metal and ceramics, comprising:

[0029] S1. Modulating metal slurry;

[0030] S2. Brush metal paste on the ceramic body or glazed parts to be decorated to form a metal layer;

[0031] S3. After the metal layer is dry, it is fired in a kiln, and the firing temperature meets the following conditions at the same time:

[0032] a. The firing temperature is higher than the melting point of the metal particles in the metal paste;

[0033] b. The firing temperature is between the initial melting temperature and the melting temperature of the body or glaze of the ceramic.

[0034] The metal paste is prepared from gold, silver or copper metal particles.

Embodiment 2

[0036] The ceramics are fired at a high temperature, and then glaze fired at 1140°C to obtain a low-temperature glossy black glaze.

[0037] S1, prepare silver paste;

[0038] S2. Brush silver paste on the glazed parts to be decorated to form a silver layer. The weight of silver in the silver layer is controlled at 20mg / cm 2 -40mg / cm 2 ;

[0039] S3, after drying, it is fired in a kiln at 1120°C.

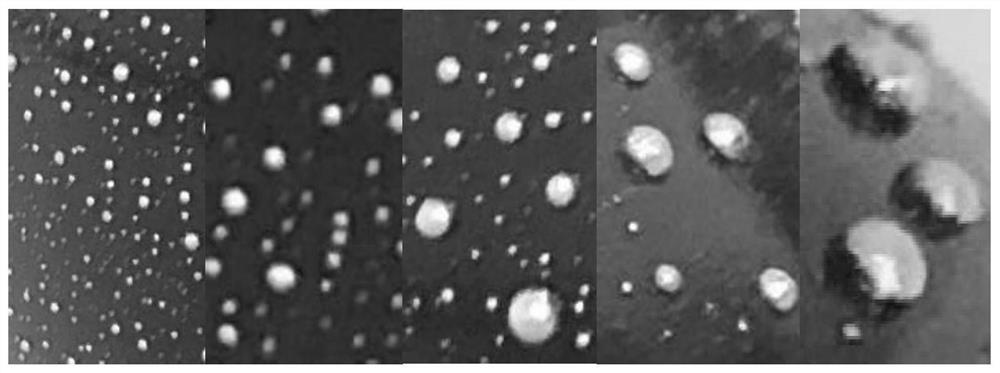

[0040] The silver balls obtained at this time are small in size (mostly 0.1-1mm), which belong to the dense decorative effect, the visual effect is average, and there are few raised balls.

Embodiment 3

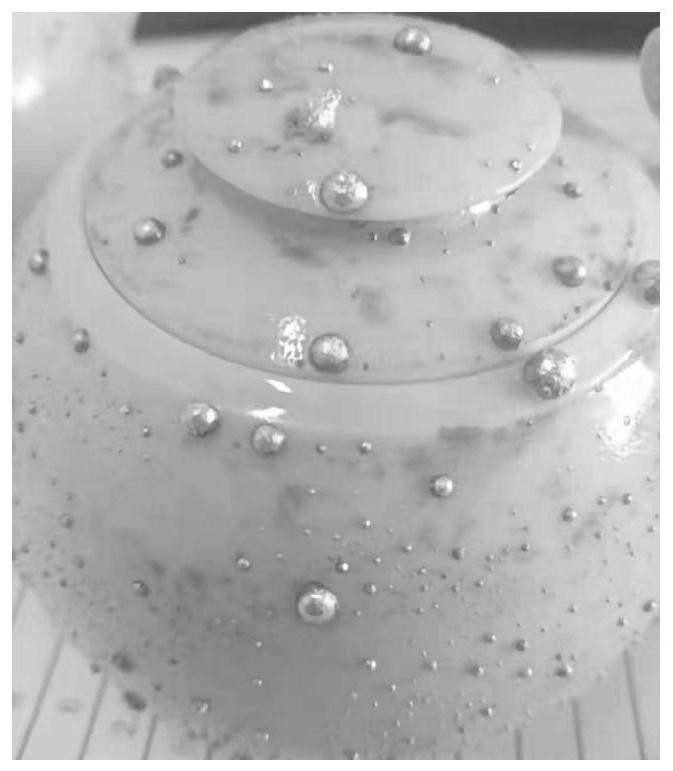

[0042] The ceramics are fired at a high temperature, and then glaze fired at 1140°C to obtain a low-temperature glossy black glaze.

[0043] S1, prepare silver paste;

[0044] S2. Brush silver paste on the glazed parts to be decorated to form a silver layer. The weight of silver in the silver layer is controlled at 40mg / cm 2 -50mg / cm 2 ;

[0045] S3, after drying, it is fired in a kiln at 1100°C.

[0046] The size of the silver balls obtained at this time is relatively small (mostly between 0.2-2mm), which belongs to a denser decorative effect, and the number of raised balls increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com